ACS704ELC-005

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

AB SO LUTE MAX I MUM RAT INGS

Supply Voltage, V

CC

.......................................... 16 V

Reverse Supply Voltage, V

RCC

........................≠16 V

Output Voltage, V

OUT

........................................16 V

Reverse Output Voltage, V

ROUT

......................≠0.1 V

Output Current Source, I

OUT(Source)

................. 3 mA

Output Current Sink, I

OUT(Sink)

.......................10 mA

Operating Temperature,

Maximum

Junction,

T

J(max)

....................... 165∞C

Storage Temperature, T

S

......................≠65 to 170∞C

Features and Benefits

∑ Small footprint, low-profile SOIC8 package

∑ 1.5

m internal conductor resistance

∑ Excellent replacement for sense resistors

∑ 800

V

RMS

minimum isolation voltage beween pins 1-4 and 5-8

∑ 4.5 to 5.5 V, single supply operation

∑ 50 kHz bandwidth

∑ 133 mV/A output sensitivity and 15 A dynamic range

∑ Output voltage proportional to ac and dc currents

∑ Factory-trimmed for accuracy

∑ Extremely stable output offset voltage

∑ Near-zero magnetic hysteresis

∑ Ratiometric output from supply voltage

The Allegro ACS704 family of current sensors provides economical and

precise solutions for current sensing in industrial, automotive, commercial, and

communications systems. The device package allows for easy implementation

by the customer. Typical applications include motor control, load detection and

management, switched-mode power supplies, and overcurrent fault protection.

The device consists of a precision, low-offset linear Hall sensor circuit with

a copper conduction path located near the surface of the die. Applied current

flowing through this copper conduction path generates a magnetic field which is

sensed by the integrated Hall IC and converted into a proportional voltage. Device

accuracy is optimized through the close proximity of the magnetic signal to the

Hall transducer. A precise, proportional voltage is provided by the low-offset,

chopper-stabilized BiCMOS Hall IC, which is programmed for accuracy at the

factory.

The output of the device has a positive slope (>V

CC

/ 2) when an increasing current

flows through the primary copper conduction path (from pins 1 and 2, to pins 3

and 4), which is the path used for current sensing. The internal resistance of this

conductive path is typically 1.5 m, providing low power loss. The thickness

of the copper conductor allows survival of the device at up to 5◊ overcurrent

conditions. The terminals of the conductive path are electrically isolated from the

sensor leads (pins 5 through 8). This allows the ACS704 family of sensors to be

used in applications requiring electrical isolation without the use of opto-isolators

or other costly isolation techniques.

The ACS704 is provided in a small, surface mount SOIC8 package. The leadframe

is plated with 100% matte tin, which is compatible with standard lead (Pb) free

printed circuit board assembly processes. Internally, the flip-chip uses high-

temperature Pb-based solder balls, currently exempt from RoHS and WEEE. The

device is fully calibrated prior to shipment from the factory.

Package LC

Use the following complete part number when ordering:

Part Number

Package

ACS704ELC-005

SOIC8 surface mount

TÐV America

Certificate Number:

U8V 04 12 54214 005

5

4

3

2

1

6

7

8

*

100 total pulses, 250 ms duration each, applied at a rate of

1 pulse every 100 seconds.

Nominal Operating Temperature, T

A

Range

E............................................ ≠40 to 85∫C

Overcurrent Transient Tolerance*, I

P

................ 60 A

Fully Integrated, Hall Effect-Based Linear Current Sensor

with Voltage Isolation and a Low-Resistance Current Conductor

Pin 1: IP+

Pin 2: IP+

Pin 3: IP≠

Pin 4: IP≠

Pin 5: GND

Pin 6: VOUT

Pin 7: VOUT

Pin 8: VCC

2

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

Amp

Out

VCC

+5 V

Pin 8

Pin 7

VOUT

Pin 6

VOUT

GND

Pin 5

Filter

Dynamic Of

fset

Cancellation

IP+ IP+

0.1 F

Pin 1 Pin 2

IP≠

IP≠

Pin 3 Pin 4

Gain

Temperature

Coefficient

Offset

Voltage

Regulator

Trim Control

To all subcircuits

Functional Block Diagram

3

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

PERFORMANCE CHARACTERISTICS

, T

A

= ≠40∞C to 85∞C, V

CC

= 5 V unless otherwise specified

Propagation Time

t

PROP

I

P

=±5 A, T

A

= 25∞C

≠

4

≠

s

Response Time

t

RESPONSE

I

P

=±5 A, T

A

= 25∞C

≠

8

≠

s

Rise Time

t

r

I

P

=±5 A, T

A

= 25∞C

≠

9

≠

s

Frequency Bandwidth

f

≠3 dB, T

A

= 25∞C; I

P

is 10 A peak-to-

peak; no external filter

≠

50

≠

kHz

Sensitivity

Sens

Over full range of I

P

,

I

P

applied for 5 ms; T

A

= 25∞C

≠

133

≠

mV/A

Over full range of I

P

,

I

P

applied for 5 ms; T

A

= ≠40 to 85∞C

124

≠

142

mV/A

Noise

V

NOISE

Peak-to-peak, T

A

= 25∞C,

no external filter

≠

90

≠

mV

Root Mean Square, T

A

= 25∞C,

no external filter

≠

16

≠

mV

Linearity

E

LIN

Over full range of I

P

,

I

P

applied for 5 ms; T

A

= ≠40 to 85∞C

≠

±1

±4.7

%

Symmetry

E

SYM

Over full range of I

P

,

I

P

applied for 5 ms; T

A

= ≠40 to 85∞C

98

100

104.5

%

Zero Current Output Voltage

V

OUT(Q)

I

P

= 0 A, T

A

= 25∞C

≠

V

CC

/ 2

≠

V

Electrical Offset Voltage

V

OE

I

P

= 0 A, T

A

= 25∞C

≠15

≠

15

mV

I

P

= 0 A, T

A

= ≠40 to 85∞C

≠65

≠

65

mV

Magnetic Offset Error

I

ERROM

I

P

= 0 A, after excursion of 8.3 A;

T

A

= ≠40 to 85∞C

≠

±0.01

±0.05

A

Total Output Error

2

E

TOT

I

P

=±5 A

, I

P

applied for 5 ms;

T

A

= 25∞C

≠

±1.5

≠

%

I

P

= ±5 A

, I

P

applied for 5 ms;

T

A

= ≠40 to 85∞C

≠

≠

±12.5

%

1

Device may be operated at higher primary current, I

P

, and Ambient Temperature, T

A

, levels, provided that the Maximum Junction Temperature, T

J(max)

,

is not exceeded.

2

Percentage of I

P

, with I

P

= 5 A; Output filtered. Up to a 2.0% shift in E

TOT

may be observed at end-of-life for this device.

ELECTRICAL CHARACTERISTICS,

over operating ambient temperature range unless otherwise stated

Characteristic

Symbol

Test Conditions

Min.

Typ.

Max.

Units

Primary Sensed Current

1

I

P

≠5

≠

5

A

Supply Voltage

V

CC

4.5

5.0

5.5

V

Supply Current

I

CC

V

CC

= 5.0 V, output open

5

8

10

mA

Output Resistance

R

OUT

I

OUT

= 1.2 mA

≠

1

2

Output Capacitance Load

C

LOAD

VOUT to GND

≠

≠

10

nF

Output Resistive Load

R

LOAD

VOUT to GND

4.7

≠

≠

k

Primary Conductor Resistance

R

PRIMARY

T

A

= 25∞C

≠

1.5

≠

m

Isolation Voltage

V

ISO

Pins 1-4 and 5-8; 60 Hz, 1 minute

800

1200

≠

V

4

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

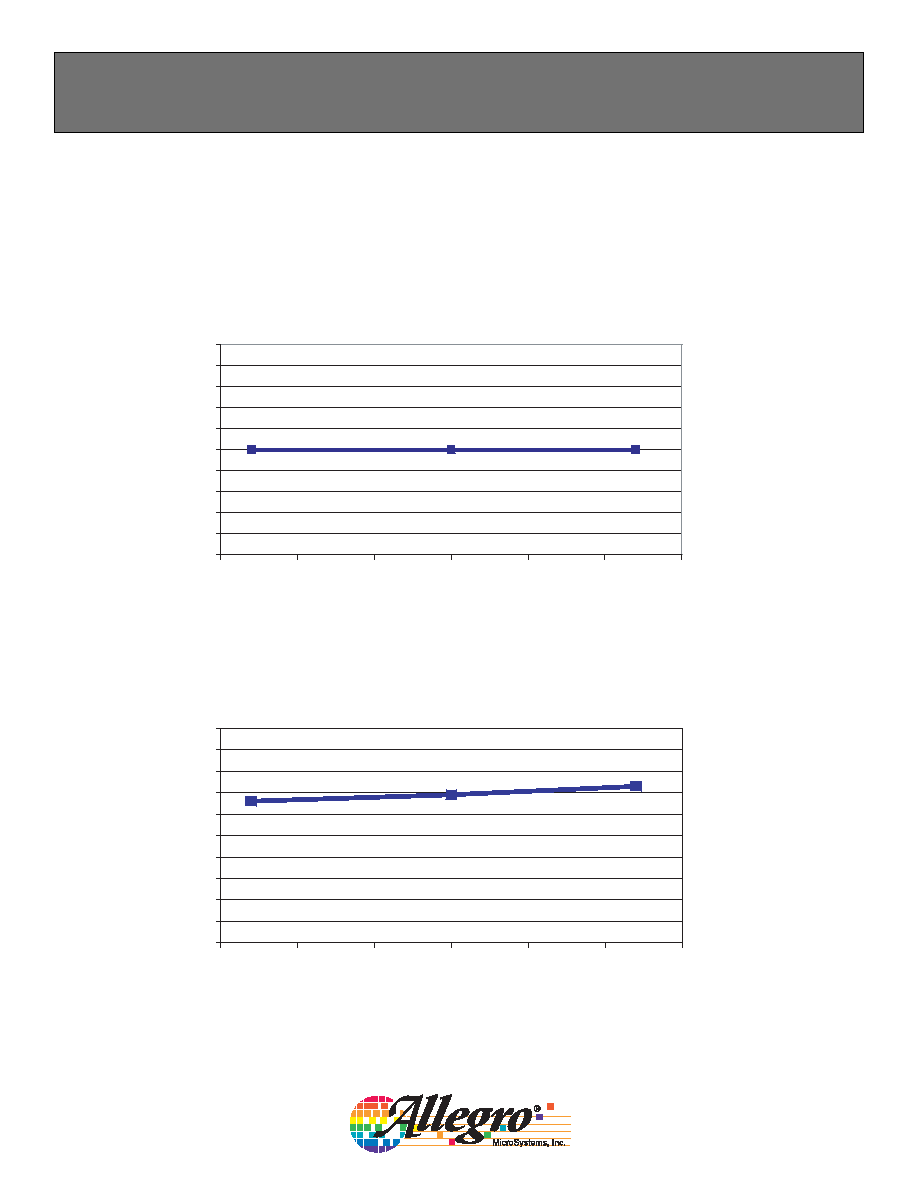

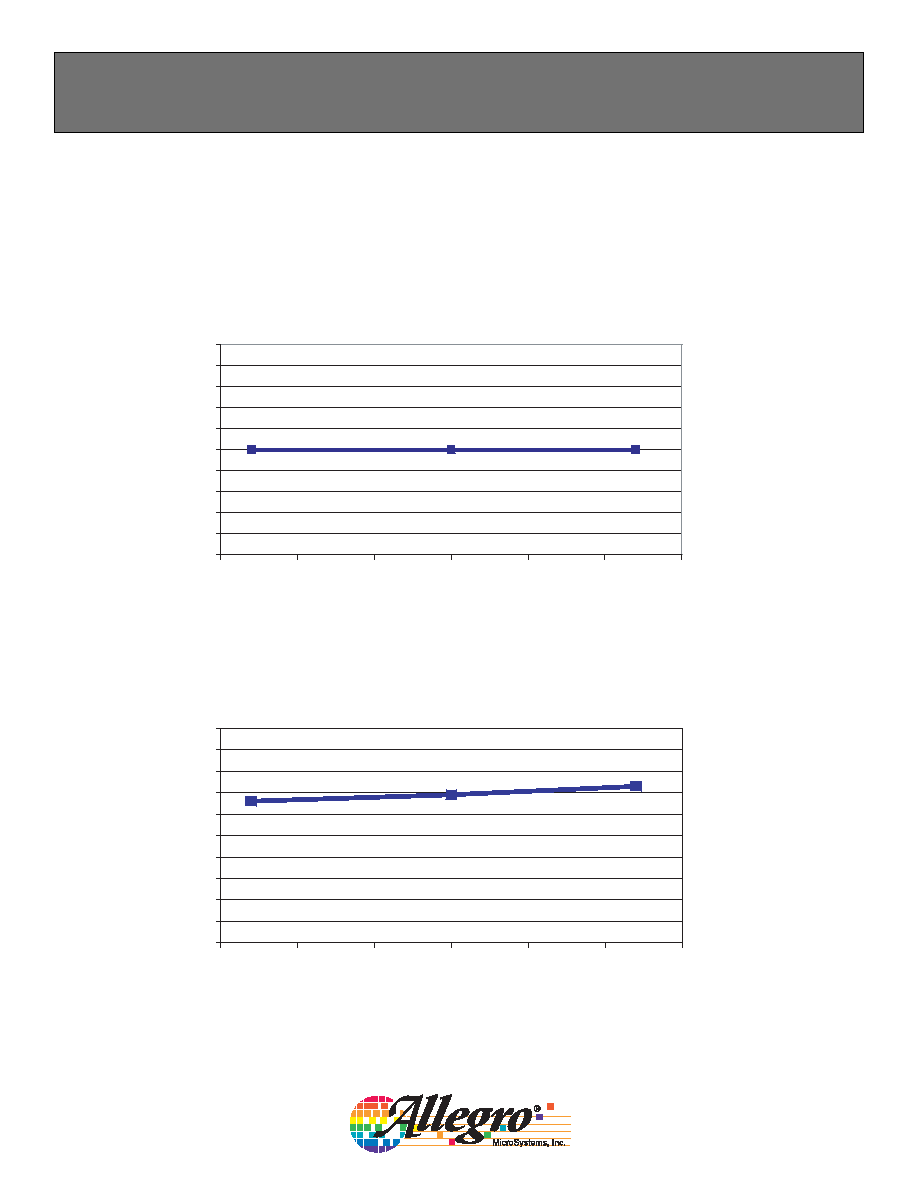

Typical Performance Characteristics

-50

-25

0

25

50

75

100

125

150

Supply Current versus Ambient Temperature

V

CC

= 5 V

T

A

(∞C)

I

CC

(mA

)

6.0

6.4

6.8

7.2

7.6

8.0

8.4

8.8

9.2

9.6

10.0

4.5

4.6

4.7

4.8

4.9

5

5.1

5.2

5.3

5.4

5.5

Supply Current versus Applied V

CC

V

CC

(V)

I

CC

(mA

)

8.44

8.46

8.48

8.50

8.52

8.54

8.56

8.58

8.60

8.62

8.64

8.66

5

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

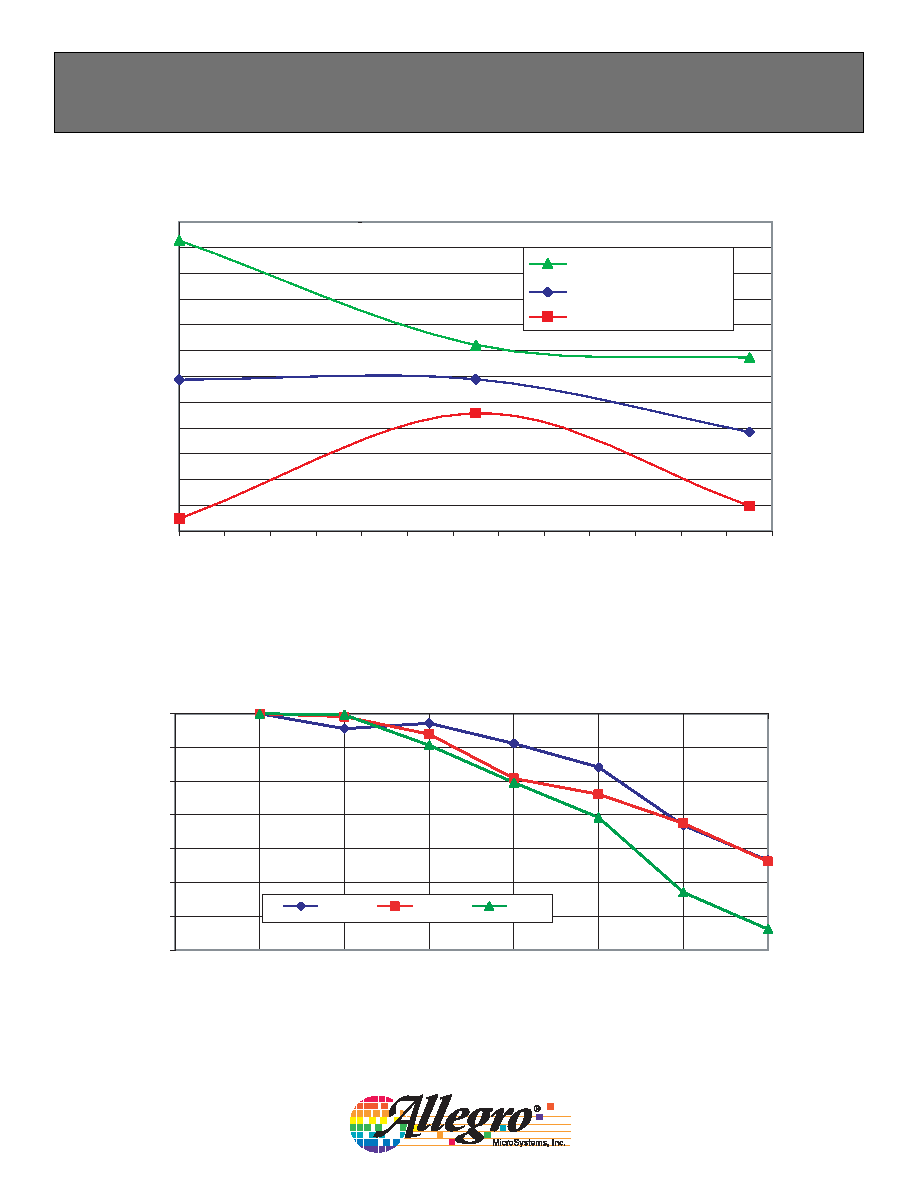

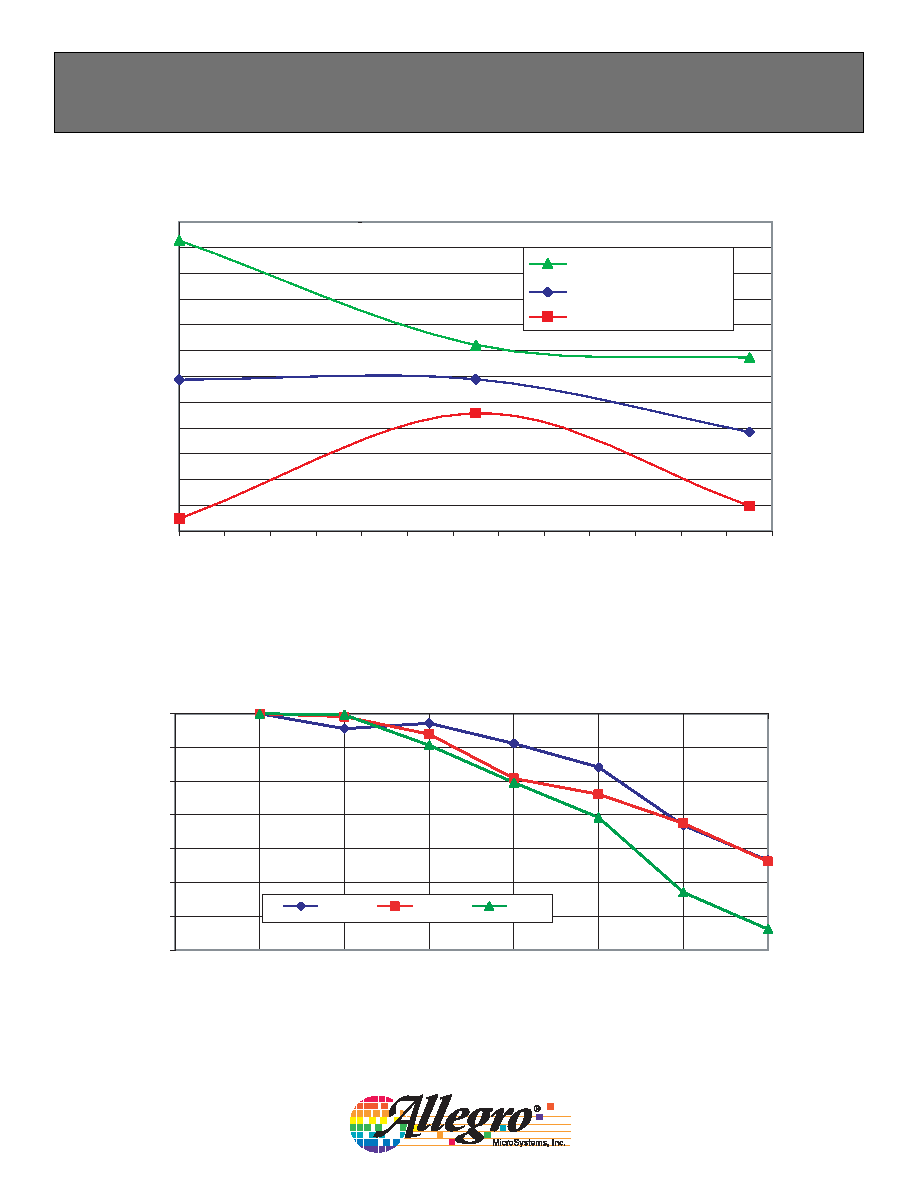

1.0

1.3

1.6

1.9

2.2

2.5

2.8

3.1

3.4

3.7

4.0

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

2

3

4

5

6

7

8

9

V

OUT

(V

)

-40

25

85

∞C

Output Voltage versus Primary Current

V

CC

= 5 V

I

P

(A)

110

115

120

125

130

135

140

145

150

-10 -9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

2

3

4

5

6

7

8

9

10

Sens (mV/A)

-40

25

85

∞C

Sensitivity versus Primary Current

V

CC

= 5 V

I

P

(A)

6

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

-50

-25

0

25

50

75

100

125

150

V

OUT(Q)

(V

)

2.480

2.484

2.488

2.492

2.496

2.500

2.504

2.508

2.512

2.516

2.520

Zero Current Output Voltage vs. Ambient Temperature

T

A

(∞C)

I

P

= 0 A

-50

-25

0

25

50

75

100

125

150

Zero Current Output Currrent versus Ambient Temperature

(Data in above chart converted to amperes)

T

A

(∞C)

I

P

= 0 A

I

VOUT(Q)

(A)

-0.20

-0.16

-0.12

-0.08

-0.04

0

0.04

0.08

0.12

0.16

0.20

7

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

-50

-25

0

25

50

75

100

V

OM

(A

)

Magnetic Offset Error versus Ambient Temperature

V

CC

= 5 V; I

P

= 0 A, after excursion to 8.33 A

T

A

(∞C)

-1.0

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

E

LIN

(%)

-50

-25

0

25

50

75

100

Nonlinearity versus Ambient Temperature

V

CC

= 5 V

I

P

= 5 A

T

A

(∞C)

8

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

Measurements taken at TA = ≠40, 25, and 85 degrees C

-5

-4

-3

-2

-1

0

1

2

3

4

5

6

7

T

A

(∞C)

E

TOT

(

%

o

f5A

)

Mean + 3 Sigma

Mean ≠ 3 Sigma

Mean

-40

-20

0

20

40

60

80

Typical Percentage Error versus Ambient Temperature

-7.0

-6.0

-5.0

-4.0

-3.0

-2.0

-1.0

0

0

10

20

30

40

50

60

70

3 A

5 A

10 A

dB Change fr

o

m

5 kHz Response

AC Current Frequency (kHz)

Attenuation of ACS704 Output versus AC Sinusoidal Current Frequency

9

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

Typical Peak-to-Peak Noise of ACS704ELC-005 at T

A

=25∞C

Step Response of ACS704ELC-005 at T

A

=25∞C

ACS704 Output (mV)

5 A Excitation Signal

10

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

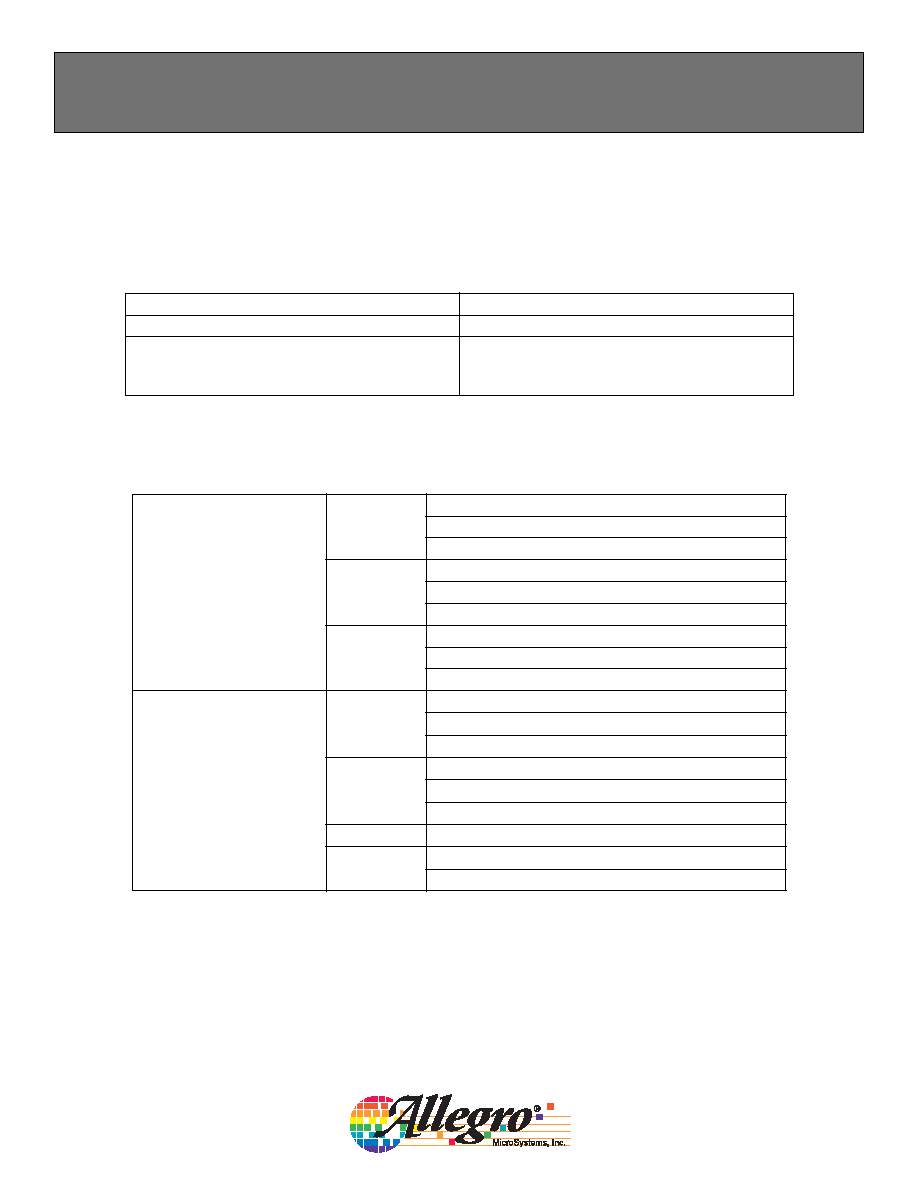

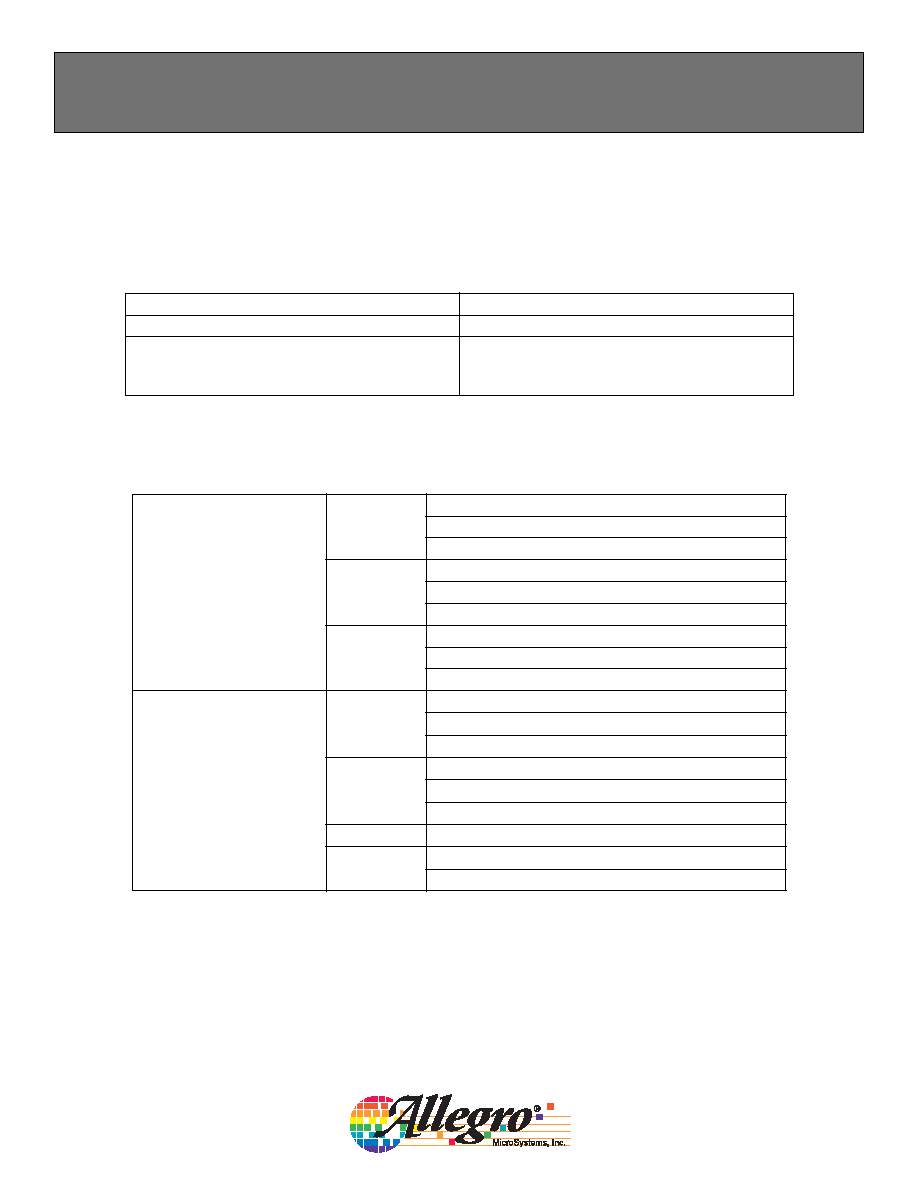

Break Frequency

of Filter on Output

(k Hz)

Nominal

Programmed

Sensitivity

(mV/A)

Unfiltered

Peak-to-Peak

Noise

(mV)

Filtered Peak-

to-Peak Noise

(mV)

Resolution

with Filtering

(A)

Measured Rise

Time for 5 A Step,

filtered

(s)

Unfiltered

133

90

90

0.67

8

40

47

0.35

12.5

10

25

0.20

35

7.0

22

0.17

46

3.9

12

0.10

90

ACS704ELC-005 Noise Filtering and Frequency Response Performance

11

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

Definitions of Accuracy Characteristics

Sensitivity (Sens). The change in sensor output in response to a 1 A change through the primary conductor. The sensitivity is the prod-

uct of the magnetic circuit sensitivity (G / A) and the linear IC amplifier gain (mV/G). The linear IC amplifier gain is programmed at the

factory to optimize the sensitivity (mV/A) for the full-scale current of the device.

Noise (V

NOISE

). The product of the linear IC amplifier gain (mV/G) and the noise floor for the Allegro Hall effect linear IC (1 G).

The noise floor is derived from the thermal and shot noise observed in Hall elements. Dividing the noise (mV) by the sensitivity

(mV/A) provides the smallest current that the device is able to resolve.

Linearity (E

LIN

): The degree to which the voltage output from the sensor varies in direct proportion to the primary current through its

full-scale amplitude. Nonlinearity in the output can be attributed to the saturation of the flux concentrator approaching the full-scale

current. The following equation is used to derive the linearity:

Definitions of Accuracy Characteristics

100 1≠

[{

[ {

Vout_full-scale amperes ≠ V

OUT(Q)

(

)

2 (Vout_half-scale amperes ≠ V

OUT(Q)

)

100

Vout_+full-scale amperes ≠ V

OUT(Q)

V

OUT(Q)

≠Vout_≠full-scale amperes

where V

out_full-scale amperes

= the output voltage (V) when the sensed current approximates full-scale ±I

P

.

Symmetry (E

SYM

). The degree to which the absolute voltage output from the sensor varies in proportion to either a positive or nega-

tive full-scale primary current. The following formula is used to derive symmetry:

Quiescent output voltage (V

OUT(Q)

). The output of the sensor when the primary current is zero. For a unipolar supply voltage, it

nominally remains at V

CC

/ 2. Thus, V

CC

= 5 V translates into V

OUT(Q)

= 2.5 V. Variation in V

OUT(Q)

can be attributed to the resolution

of the Allegro linear IC quiescent voltage trim and thermal drift.

Electrical offset voltage (V

OE

). The deviation of the device output from its ideal quiescent value of V

CC

/ 2 due to nonmagnetic causes.

To convert this voltage to amperes, divide by the device sensitivity, Sens.

Accuracy (E

TOT

). The accuracy represents the maximum deviation of the actual output from its ideal value. This is also known as the

total ouput error. The accuracy is illustrated graphically in the Output Voltage versus Current chart on the following page.

Accuracy is divided into four areas:

∑ 0 A at 25∞C. Accuracy of sensing zero current flow at 25∞C, without the effects of temperature.

∑ 0 A over temperature. Accuracy of sensing zero current flow including temperature effects.

∑ Full-scale current at 25∞C. Accuracy of sensing the full-scale current at 25∞C, without the effects of temperature.

∑ Full-scale current over temperature. Accuracy of sensing full-scale current flow including temperature effects.

Ratiometry. The ratiometric feature means that its 0 A output, V

OUT(Q)

, (nominally equal to V

CC

/2) and sensitivity, Sens, are propor-

tional to its supply voltage, V

CC

. The following formula is used to derive the ratiometric change in 0 A output voltage,

V

OUT(Q)RAT

(%):

The ratiometric change in sensitivity,

Sens

RAT

(%), is defined as:

100

V

OUT(Q)VCC

/ V

OUT(Q)5V

V

CC

/ 5 V

100

Sens

VCC

/ Sens

5V

V

CC

/ 5 V

12

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

Increasing V

OUT

(V)

+I

P

(A)

Accuracy

Accuracy

Accuracy

25∞C Only

Accuracy

25∞C Only

Accuracy

25∞C Only

Accuracy

0 A

v r

O e Temperature

Average

V

OUT

≠I

P

(A)

v r

O e Temperature

v r

O e Temperature

Decreasing V

OUT

(V)

≠5 A

5 A

Full Scale

Output voltage vs. current, illustrating sensor accuracy at 0 A and at full-scale current

13

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

Definitions of Dynamic Response Characteristics

Propagation delay (t

PROP

): The time required for the sensor output to reflect a change in the primary cur-

rent signal. Propagation delay is attributed to inductive loading within the linear IC package, as well as in the

inductive loop formed by the primary conductor geometry. Propagation delay can be considered as a fixed time

offset and may be compensated.

Response time (t

RESPONSE

): The time interval between a) when the primary current signal reaches 90% of its

final value, and b) when the sensor reaches 90% of its output corresponding to the applied current.

Rise time (t

r

): The time interval between a) when the sensor reaches 10% of its full scale value, and b) when

it reaches 90% of its full scale value. The rise time to a step response is used to derive the bandwidth of the

current sensor, in which (≠3 dB) = 0.35 / t

r

. Both t

r

and t

RESPONSE

are detrimentally affected by eddy current

losses observed in the conductive IC ground plane.

Primary Current

Transducer Output

90

0

I (%)

Propagation Time, t

PROP

t

Primary Current

Transducer Output

90

0

I (%)

Response Time, t

RESPONSE

t

Primary Current

Transducer Output

90

10

0

I (%)

Rise Time, t

r

t

14

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

Standards and Physical Specifications

Parameter

Specification

Flammability (package molding compound)

UL recognized to UL 94V-0

Fire and Electric Shock

UL60950-1:2003

EN60950-1:2001

CAN/CSA C22.2 No. 60950-1:2003

Device Branding Key (Two alternative styles are used)

ACS704T

ELC005

YYWWA

ACS

Allegro Current Sensor

704

Device family number

T

Indicator of 100% matte tin leadframe plating

E

Operating ambient temperature range code

LC

Package type designator

005

Primary sensed current

YY

Manufacturing date code: Calendar year (last two digits)

WW

Manufacturing date code: Calendar week

A

Manufacturing date code: Shift code

ACS704T

ELC005

L...L

YYWW

ACS

Allegro Current Sensor

704

Device family number

T

Indicator of 100% matte tin leadframe plating

E

Operating ambient temperature range code

LC

Package type designator

005

Primary sensed current

L...L

Manufacturing lot code

YY

Manufacturing date code: Calendar year (last two digits)

WW

Manufacturing date code: Calendar week

15

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

Amp

Regulator

Clock/Logic

Hall Element

Sa

mp

le

an

d

Ho

ld

Low-Pass

Filter

Chopper Stabilization Technique

Chopper Stabilization is an innovative circuit technique that is used to minimize the offset voltage of a Hall

element and an associated on-chip amplifier. Allegro patented a Chopper Stabilization technique that nearly

eliminates Hall IC output drift induced by temperature or package stress effects. This offset reduction technique

is based on a signal modulation-demodulation process. Modulation is used to separate the undesired dc offset

signal from the magnetically induced signal in the frequency domain. Then, using a low-pass filter, the modu-

lated dc offset is suppressed while the magnetically induced signal passes through the filter. As a result of this

chopper stabilization approach, the output voltage from the Hall IC is desensitized to the effects of temperature

and mechanical stress. This technique produces devices that have an extremely stable Electrical Offset Voltage,

are immune to thermal stress, and have precise recoverability after temperature cycling.

This technique is made possible through the use of a BiCMOS process that allows the use of low-offset and

low-noise amplifiers in combination with high-density logic integration and sample and hold circuits.

Concept of Chopper Stabilization Technique

16

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

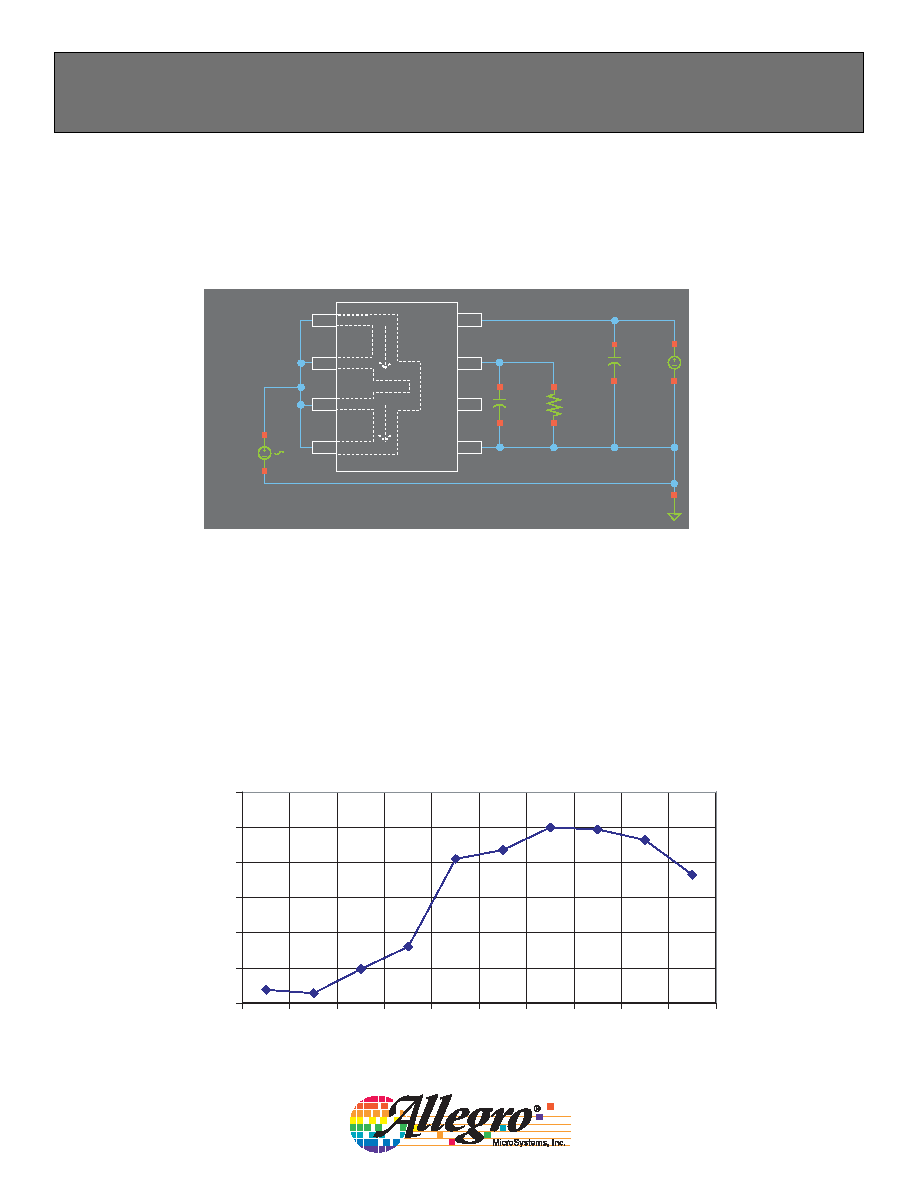

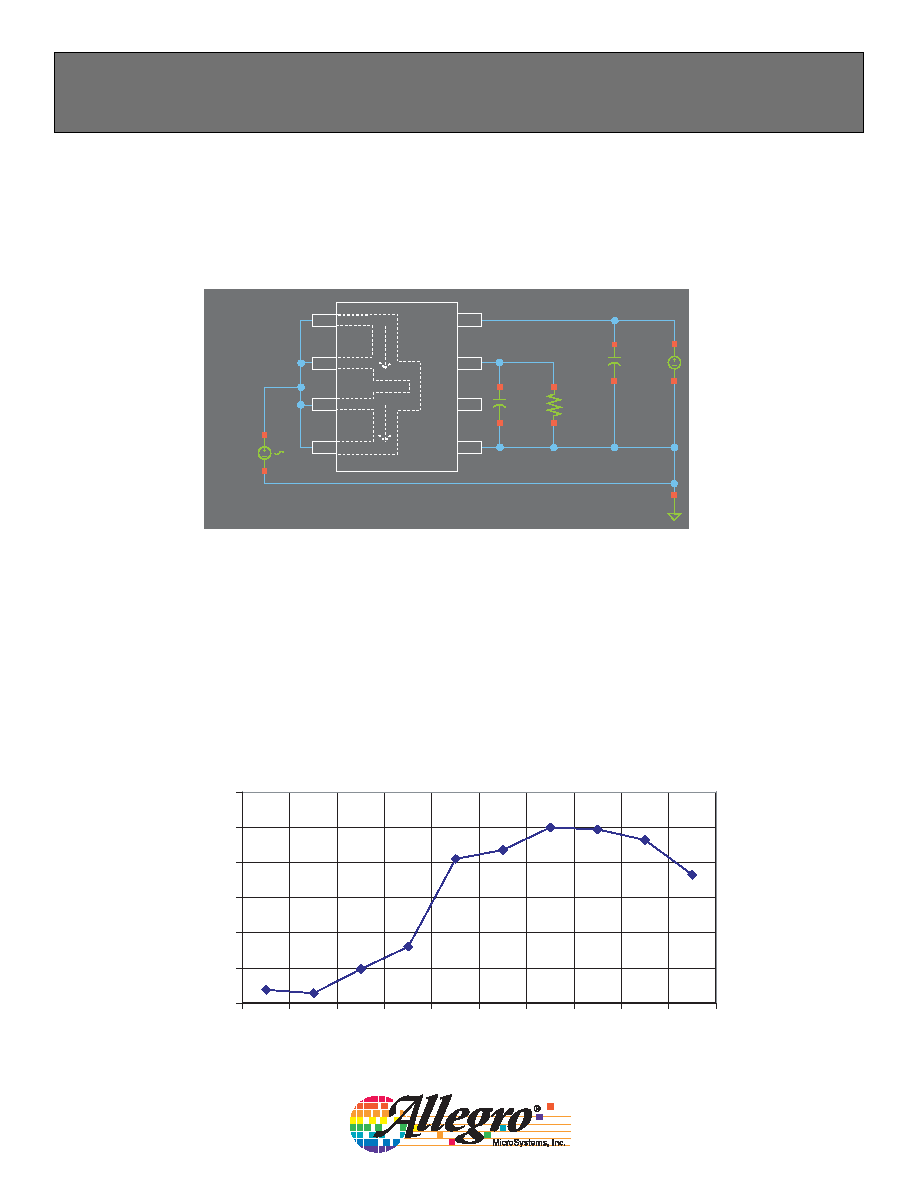

Applications Information

In order to quantify transient common-mode voltage rejection for the ACS704, a device was soldered onto a printed

circuit board. A 0.1 F bypass capacitor and a 5 V dc power supply were connected between VCC and GND (pins 8 and

5) for this device. A 10 k load resistor and a 0.01 F capacitor were connected in parallel between the VOUT pin and

the GND pin of the device (pins 7 and 5).

A function generator was connected between the primary current conductor (pins 1 thru 4) and the GND pin of

the device (pin 5). This function generator was configured to generate a 10 V peak (20 V peak-to-peak) sine

wave between pins 1-4 and pin 5. Note that the sinusoidal stimulus was applied such that no electrical current

would flow through the copper conductor composed of pins 1-4 of this device.

The frequency of this sine wave was varied from 60 Hz to 5 MHz in discrete steps. At each frequency, the

statistics feature of an oscilloscope was used to measure the voltage variations (noise) on the ACS704 output

in mV (peak to peak). The noise was measured both before and after the application of the stimulus. Transient

common-mode voltage rejection as a function of frequency is shown in the following figure.

ACS704 Schematic Diagram of the Circuit used to Measure Transient Rejection

Transient Common-Mode Voltage Rejection in the ACS704

Output

Vcc

Ground

8

7

6

5

1

2

3

4

IP

V1

V

OUT

=0V

V

OUT

=20VPP

freq=variable

C3

C0

V0

GND

R0

C=0.01µF

C=0.1µF

VDC=5V

R=10k

(kHz)

0.06

1

10

100

300

600

800

1000 3000 5000

Frequency of 20 V Peak-to-Peak Stimulus

≠60

≠55

≠50

≠45

≠40

≠35

≠30

Tr

ansi

en

t

R

e

j

e

ct

i

o

n

(

d

B

)

17

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

The Effect of PCB Layout on ACS704 Electrical Performance

Eight different PC boards were fabricated to characterize the effect of PCB design on the operating junction temperature of the

Hall-effect IC inside of the ACS704. These PC boards are shown in the figure below.

2 oz. Cu on one side of board

2 oz. Cu on both sides of board

An ACS704 device was soldered onto each PC board before beginning the thermal testing. Thermal management tests

were conducted with the following test conditions:

Tests were conducted at ambient temperature, T

a

= 20

∞C. All tests were conducted in still air.

14 gauge wires were used to connect a power supply to a single PC board. These wires carry the 15 A dc primary current during

the tests.

A 15 A dc primary current was applied to a single PC board containing an ACS704 device. This current flowed from pins 1 and 2

to pins 3 and 4 of the ACS704 package.

A 1 mA current was forced from the GND pin to the VCC pin by a Fluke 179 True RMS Multimeter. This was the only power

applied to pins 5-8 of the ACS704 package during testing.

The voltage required to force the 1 mA current from the GND pin to the VCC pin was measured after applying the 15 A primary

current for approximately 25 minutes. A graph similar to the graph below was used to determine the junction temperature of the

ACS704.

Voltage vs. Temperature Curve used to Determine Die Junction Temperature

18

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

The results of the testing are shown in the following table.

Improved PC Board Designs

The eight PC boards in the figure above do not represent an ideal PC board for use with the ACS704. The ACS704 evaluation

boards, for sale at the Allegro Web site On-Line Store, represent a more optimal PC board design (see photo below). On the

evaluation boards, the current to be sensed flows through very wide traces that were fabricated using 2 layers of 2 oz. copper.

Thermal management tests were conducted on the Allegro evaluation boards and all tests were performed using the same test

conditions described in the bulleted list above. The results for these thermal tests are shown in the table below. When using

the Allegro evaluation boards we see that even at an applied current of 20 A the junction temperature of the ACS704 is only

~30 degrees above ambient temperature.

ACS704 Thermal Performance on the Allegro Eval PC Boards

Applied Current (A)

T

a

= 20

∞C, Still Air

Temp Rise Above Ambient

(

∞C)

15

22

20

31

Effect of PCB Layout on ACS704 Thermal Performance

Tested at 15A, T

A

= 20∞C, still air, 2 oz. copper traces

PC Boards

Sides with Traces

Trace Width (mm)

Trace Length (mm)

Temperature Rise

Above Ambient (∞C)

1

4

50

90

1.5

50

Overheated

4

10

48

1.5

10

110

2

4

50

53

1.5

50

106

4

10

38

1.5

10

54

19

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ACS704ELC005-DS, Rev. 5

ACS704ELC-005

Package LC, 8-pin SOIC

The products described herein are manufactured under one or more of the following U.S. patents: 5,045,920; 5,264,783; 5,442,283; 5,389,889;

5,581,179; 5,517,112; 5,619,137; 5,621,319; 5,650,719; 5,686,894; 5,694,038; 5,729,130; 5,917,320; and other patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to time, such de par tures from the detail spec i fi ca tions as may be required to

permit improvements in the per for mance, reliability, or manufacturability of its products. Before placing an order, the user is cautioned to verify that

the information being relied upon is current.

Allegro products are not authorized for use as critical components in life-support devices or sys tems without express written approval.

The in for ma tion in clud ed herein is believed to be ac cu rate and reliable. How ev er, Allegro MicroSystems, Inc. assumes no re spon si bil i ty for its

use; nor for any in fringe ment of patents or other rights of third parties which may result from its use.

Copyright©2005, Allegro MicroSystems, Inc.

0.25

0.10

.010

.004

1.75

1.35

.069

.053

0.51

0.31

.020

.012

4.00

3.80

.157

.150

0.25

0.17

.010

.007

8∫

0∫

1.27

0.40

.050

.016

5.00

4.80

.197

.189

C

SEATING

PLANE

A

B

8X

0.25 [.010] M C

A

B

6.20

5.80

.244

.228

C

0.10 [.004]

8X

0.25 [.010] M B M

1.27 .050

0.25 .010

2

1

8

GAUGE PLANE

SEATING PLANE

Preliminary dimensions, for reference only

Dimensions in millimeters

U.S. Customary dimensions (in.) in brackets, for reference only

(reference JEDEC MS-012 AA)

Dimensions exclusive of mold flash, gate burrs, and dambar protrusions

Exact case and lead configuration at supplier discretion within limits shown

A Terminal #1 mark area

A