| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: ADP1110 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

ADP1110

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700

World Wide Web Site: http://www.analog.com

Fax: 617/326-8703

© Analog Devices, Inc., 1996

Micropower, Step-Up/Step-Down Switching

Regulator; Adjustable and Fixed 3.3 V, 5 V, 12 V

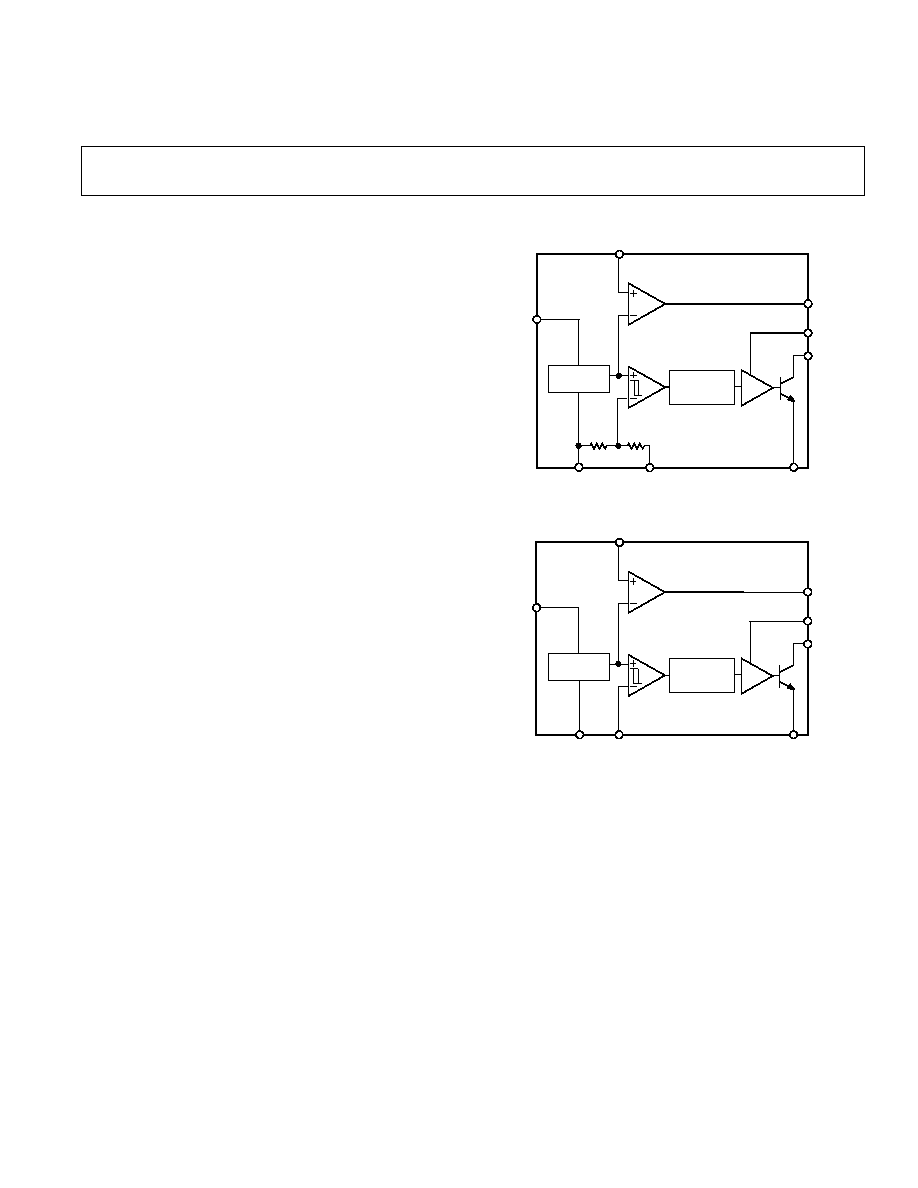

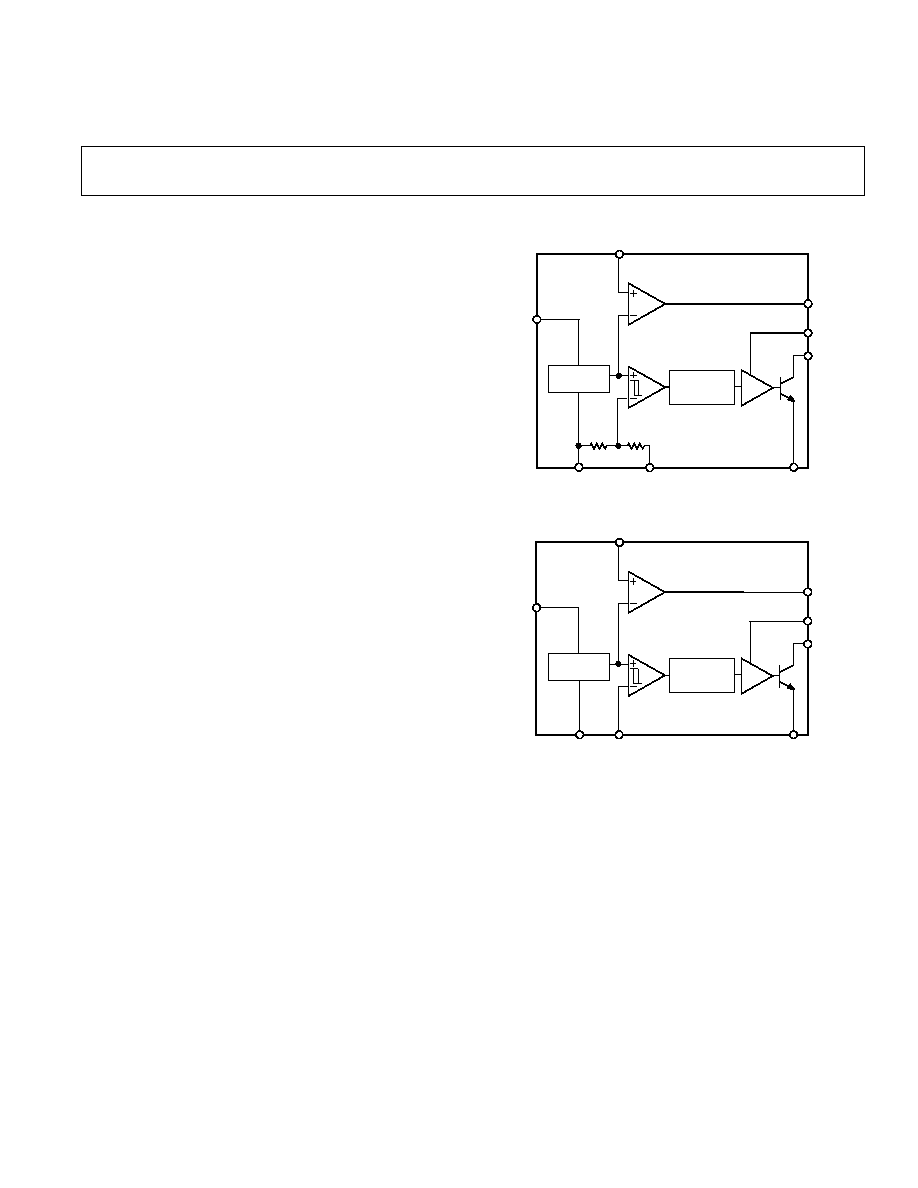

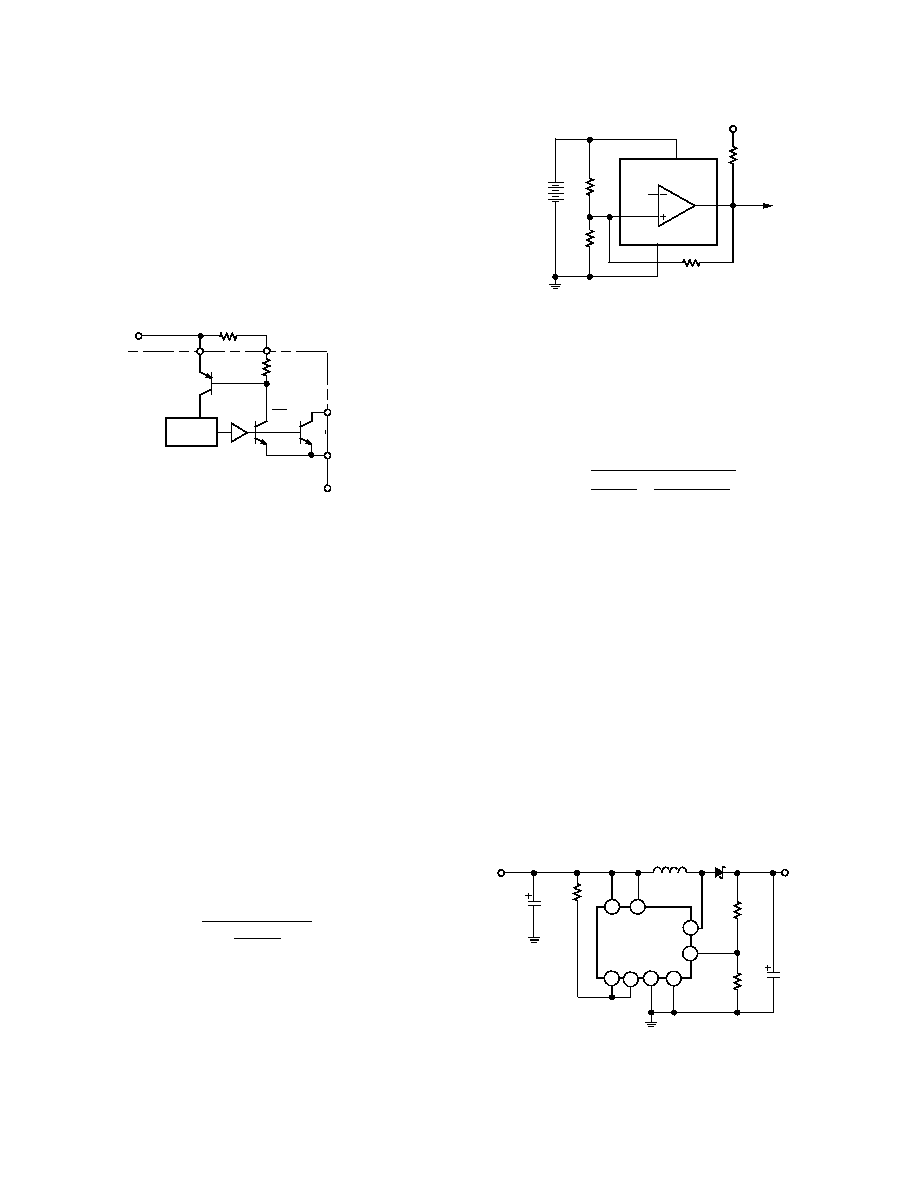

FUNCTIONAL BLOCK DIAGRAMS

SENSE

A0

DRIVER

I

LIM

SW1

SW2

V

IN

SET

220mV

REFERENCE

GAIN BLOCK/

ERROR AMP

A2

A1

Q1

OSCILLATOR

ADP1110

GND

COMPARATOR

R1

R2

300k

ADP1110 Block Diagram--Fixed Output Version

A0

DRIVER

I

LIM

SW1

SW2

V

IN

GND

SET

220mV

REFERENCE

GAIN BLOCK/

ERROR AMP

COMPARATOR

FB

A2

A1

Q1

OSCILLATOR

ADP1110

ADP1110 Block Diagram--Adjustable Output Version

FEATURES

Operates at Supply Voltages From 1.0 V to 30 V

Step-Up or Step-Down Mode

Minimal External Components Required

Low-Battery Detector

User-Adjustable Current Limiting

Fixed or Adjustable Output Voltage Versions

8-Pin DIP or SO-8 Package

APPLICATIONS

Cellular Telephones

Single-Cell to 5 V Converters

Laptop and Palmtop Computers

Pagers

Cameras

Battery Backup Supplies

Portable Instruments

Laser Diode Drivers

Hand-Held Inventory Computers

GENERAL DESCRIPTION

The ADP1110 is part of a family of step-up/step-down switch-

ing regulators that operate from an input voltage supply as little

as 1.0 V. This very low input voltage allows the ADP1110 to be

used in applications that use a single cell as the primary power

source.

The ADP1110 can be configured to operate in either step-up or

step-down mode, but for input voltages greater than 3 V, the

ADP1111 would be a more effective solution.

An auxiliary gain amplifier can serve as a low battery detector or

as a linear regulator.

The quiescent current of 300

µ

A makes the ADP1110 useful in

remote or battery powered applications.

The 70 kHz frequency operation also allows for the use of

surface-mount external capacitors and inductors.

Battery protection circuitry limits the effect of reverse current to

safe levels at reverse voltages up to 1.6 V.

≠2≠

REV. 0

ADP1110≠SPECIFICATIONS

Parameter

Conditions

V

S

Min

Typ

Max

Units

QUIESCENT CURRENT

Switch Off

I

Q

300

µ

A

INPUT VOLTAGE

Step-Up Mode

V

IN

1.15

12.6

V

Step-Down Mode

30

V

COMPARATOR TRIP POINT VOLTAGE

ADP1110

1

210

220

230

mV

OUTPUT SENSE VOLTAGE

ADP1110-3.3

2

V

OUT

3.13

3.30

3.47

V

ADP1110-5

2

4.75

5.00

5.25

V

ADP1110-12

2

11.4

12.00

12.6

V

COMPARATOR HYSTERESIS

ADP1110

4

8

mV

OUTPUT HYSTERESIS

ADP1110-3.3

66

130

mV

ADP1110-5

90

180

mV

ADP1110-12

200

400

mV

OSCILLATOR FREQUENCY

f

OSC

52

70

90

kHz

DUTY CYCLE

Full Load (V

FB

< V

REF

)

DC

62

69

78

%

SWITCH ON TIME

t

ON

7.5

10

12.5

µ

s

FEEDBACK PIN BIAS CURRENT

ADP1110 V

FB

= 0 V

I

FB

150

240

nA

SET PIN BIAS CURRENT

V

SET

= V

REF

I

SET

300

500

nA

A0 OUTPUT LOW

I

AO

= 300

µ

A

V

AO

0.15

0.4

V

V

SET

= 150 mV

REFERENCE LINE REGULATION

1.0 V

V

IN

1.5 V

0.35

%/V

1.5 V

V

IN

12 V

0.05

0.1

%/V

SWITCH SATURATION VOLTAGE

V

IN

= 1.5 V, I

SW

= 400 mA, +25

∞

C

V

CESAT

300

500

mV

STEP-UP MODE

T

MIN

to T

MAX

600

mV

V

IN

= 1.5 V, I

SW

= 500 mA, +25

∞

C

400

650

mV

T

MIN

to T

MAX

750

mV

V

IN

= 5 V, I

SW

= 1 A, +25

∞

C

700

1000

mV

A2 ERROR AMP GAIN

R

L

= 100 k

3

A

V

1000

5000

V/V

REVERSE BATTERY CURRENT

T

A

= +25

∞

C

4

I

REV

750

mA

CURRENT LIMIT TEMPERATURE

V

IN,

T

A

= +25

∞

C

≠0.3

%/

∞

C

COEFFICIENT

SWITCH OFF LEAKAGE CURRENT

Measured at SW1 Pin,

I

LEAK

1

10

µ

A

T

A

= +25

∞

C

MAXIMUM EXCURSION BELOW GND

I

SW1

10

µ

A, Switch Off

V

SW2

≠400

≠350

mV

T

A

= +25

∞

C

NOTES

1

This specification guarantees that both the high and low trip point of the comparator fall within the 210 mV to 230 mV range.

2

This specification guarantees that the output voltage of the fixed versions will always fall within the specified range. The waveform at the sense pin will exhibit a saw-

tooth shape due to the comparator hysteresis.

3

100 k

resistor connected between a 5 V source and the AO pin.

4

The ADP1110 is guaranteed to withstand continuous application of +1.6 V applied to the GND and SW2 pins while V

IN

, I

LIM

, and SW1 pins are grounded.

5

All limits at temperature extremes are guaranteed via correlation using standard statistical quality control methods.

Specifications subject to change without notice.

(0 C to +70 C, V

IN

= 1.5 V unless otherwise noted)

ADP1110

≠3≠

REV. 0

PIN DESCRIPTION

Mnemonic

Function

I

LIM

For normal conditions this pin is connected to

V

IN

. When lower current is required, a resistor

should be connected between I

LIM

and V

IN

.

Limiting the switch current to 400 mA is

achieved by connecting a 220

resistor.

V

IN

Input Voltage.

SW1

Collector Node of Power Transistor. For step-

down configuration, connect to V

IN

. For step-

up configuration, connect to an inductor/diode.

SW2

Emitter Node of Power Transistor. For step-

down configuration, connect to inductor/diode.

For step-up configuration, connect to ground.

Do not allow this pin to go more than a diode

drop below ground.

GND

Ground.

AO

Auxiliary Gain (GB) Output. The open collec-

tor can sink 300

µ

A. It can be left open if unused.

SET

Gain Amplifier Input. The amplifier has posi-

tive input connected to SET pin and negative

input connected to 220 mV reference. It can be

left open if unused.

FB/SENSE

On the ADP1110 (adjustable) version this pin

is connected to the comparator input. On the

ADP1110-3.3, ADP1110-5 and ADP1110-12,

the pin goes directly to the internal application

resistor that set output voltage.

ABSOLUTE MAXIMUM RATINGS

Input Supply Voltage, Step-Up Mode . . . . . . . . . . . . . . . 15 V

Input Supply Voltage, Step-Down Mode . . . . . . . . . . . . . 36 V

SW1 Pin Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 V

SW2 Pin Voltage . . . . . . . . . . . . . . . . . . . . . . . . . ≠0.5 V to V

IN

Feedback Pin Voltage (ADP1110) . . . . . . . . . . . . . . . . . . 5.5 V

Switch Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 A

Maximum Power Dissipation . . . . . . . . . . . . . . . . . . 500 mW

Operating Temperature Range . . . . . . . . . . . . . 0

∞

C to +70

∞

C

Storage Temperature Range . . . . . . . . . . . . . ≠65

∞

C to 150

∞

C

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . . 300

∞

C

TYPICAL APPLICATION

1.5V

AA CELL*

I

LIM

V

IN

SW1

SW2

GND

ADP1110-5

47µH

5V

15µF

TANTALUM

SENSE

OPERATES WITH CELL VOLTAGE

1.0V

*ADD 10µF DECOUPLING CAPACITOR IF BATTERY IS

*

MORE THAN 2' AWAY FROM ADP1110.

1

2

3

4

5

8

Figure 1. 1.5 V to 5 V Converter

ORDERING GUIDE

Model

Output Voltage

Package

ADP1110AN

ADJ

N-8

ADP1110AR

ADJ

SO-8

ADP1110AN-3.3

3.3 V

N-8

ADP1110AR-3.3

3.3 V

SO-8

ADP1110AN-5

5 V

N-8

ADP1110AR-5

5 V

SO-8

ADP1110AN-12

12 V

N-8

ADP1110AR-12

12 V

SO-8

WARNING!

ESD SENSITIVE DEVICE

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADP1110 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

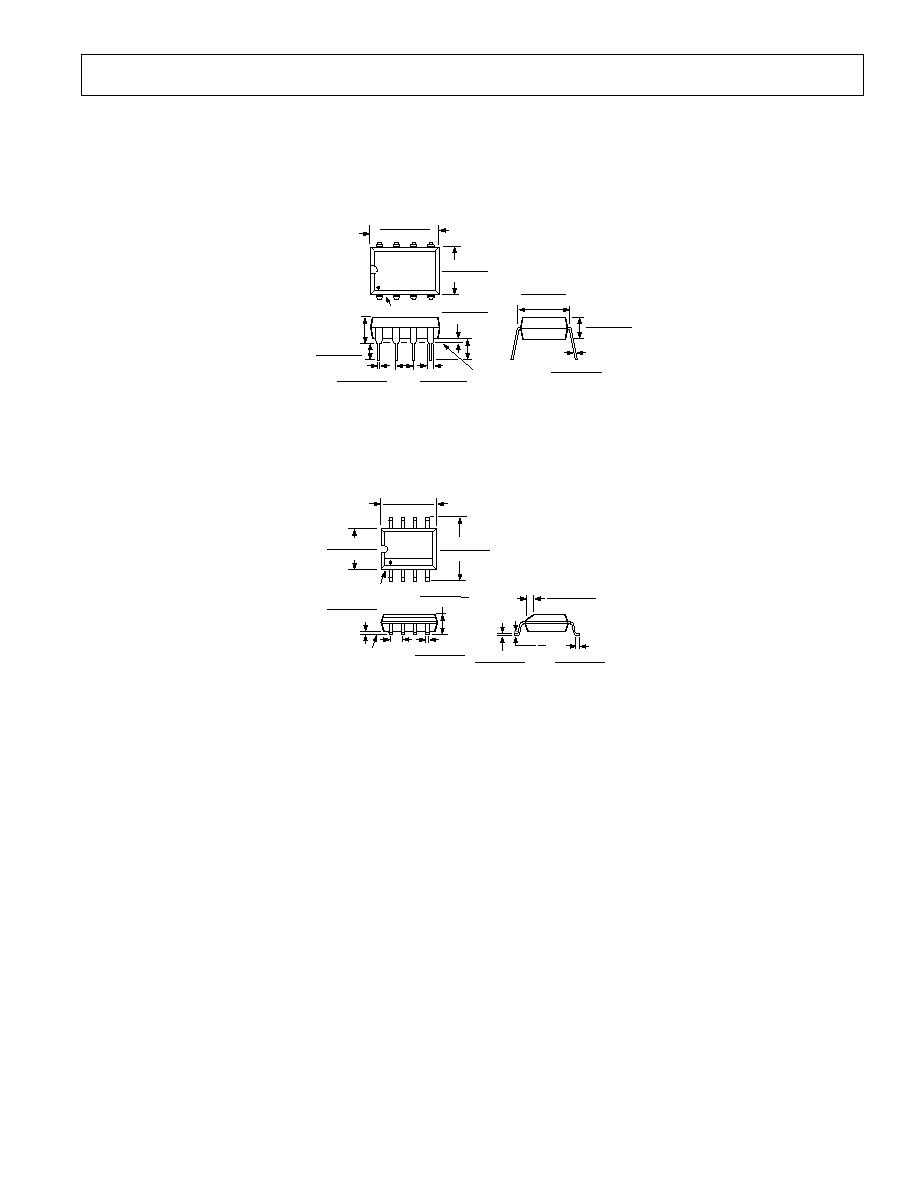

8-Lead SOIC

(SO-8)

A0

I

LIM

SW1

GND

V

IN

SW2

FB (SENSE)*

SET

1

2

3

4

8

7

6

5

TOP VIEW

(Not to Scale)

ADP1110

*FIXED VERSIONS

T

JMAX

= 90

o

,

JA

= 150

o

C/W

8-Lead Plastic DIP

(N-8)

A0

I

LIM

SW1

GND

V

IN

SW2

*FIXED VERSIONS

FB (SENSE)*

SET

1

2

3

4

8

7

6

5

ADP1110

TOP VIEW

(Not to Scale)

T

JMAX

= 90

o

,

JA

= 130

o

C/W

PIN CONFIGURATIONS

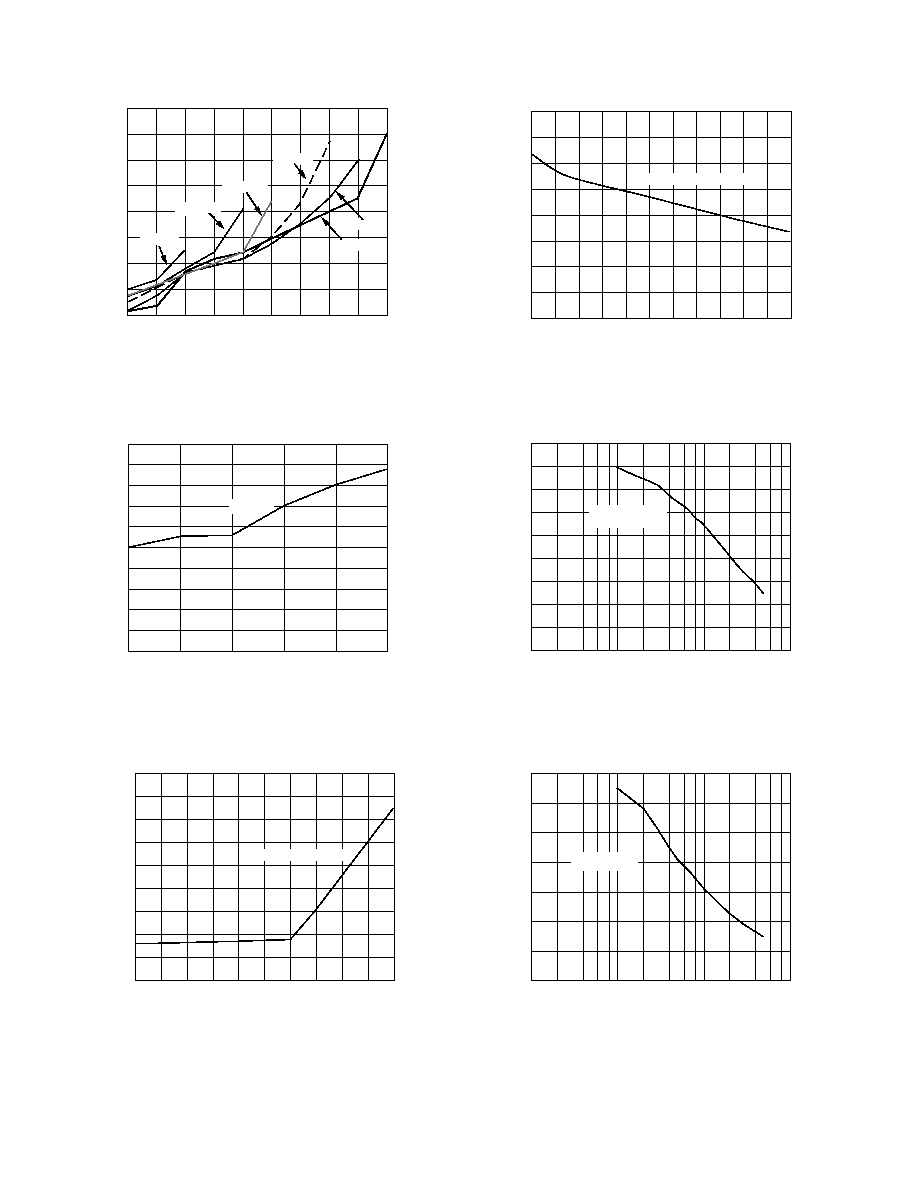

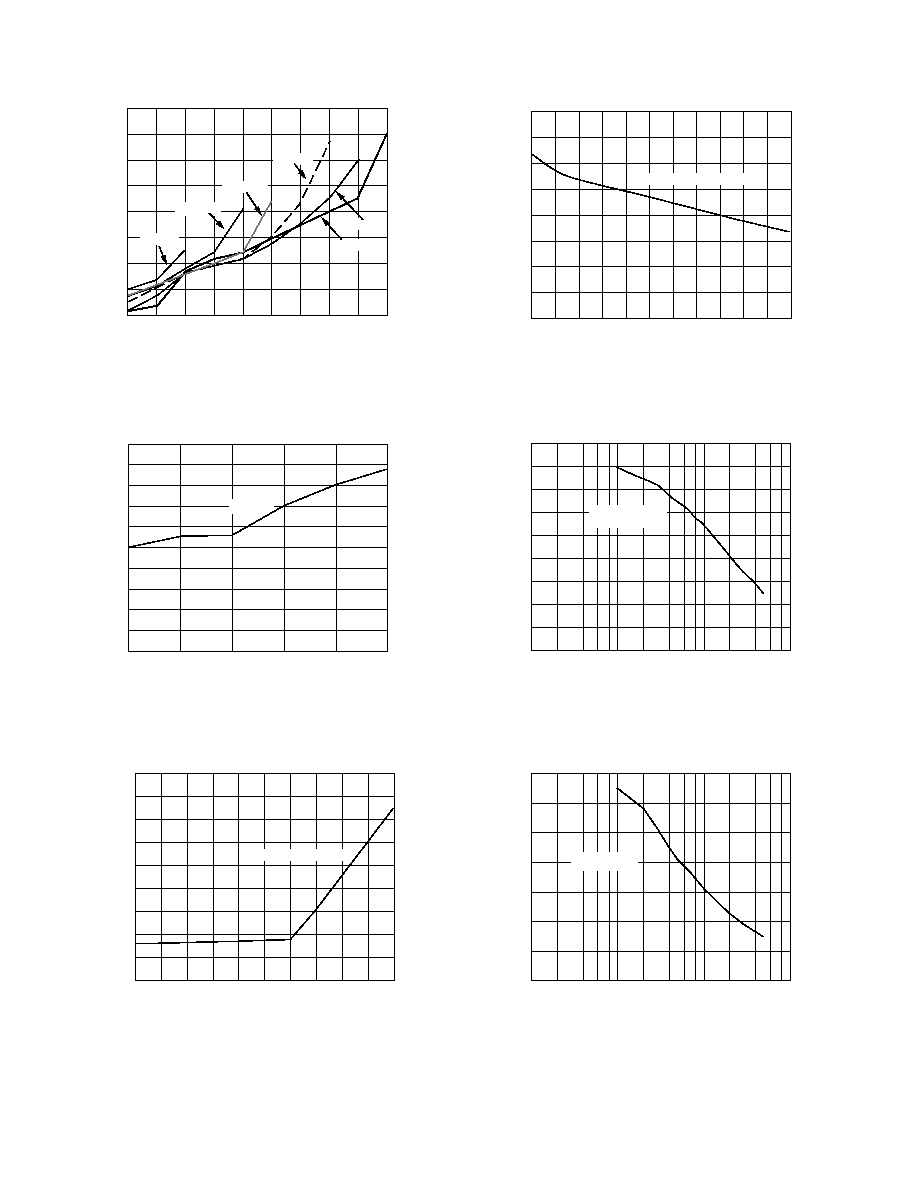

ADP1110-Typical Characteristics

≠4≠

REV. 0

I

SWITCH

CURRENT ≠ A

1.4

0

0.1

1.4

0.2

0.4

0.5

0.6

0.8

1

1.2

1.25

1.2

0.6

0.4

0.2

1

0.8

V

IN

= +1V

V

IN

= +1.2V

V

IN

= +1.5V

V

IN

= +2V

V

IN

= +3V

V

IN

= +5V

SATURATION VOLTAGE ≠ V

Figure 2. Saturation Voltage vs. I

SWITCH

Current in Step-Up

Mode

I

SWITCH

CURRENT ≠ A

2

1.8

0

0.1

0.9

0.2

0.4

0.6

0.8

1.2

0.6

0.4

0.2

1.6

1.4

0.8

1

V

IN

= +12V

ON VOLTAGE ≠ V

Figure 3. Switch ON Voltage vs. I

SWITCH

Current In Step-

Down Mode

INPUT VOLTAGE ≠ V

1

30

3

6

9

12

15

18

21

24

27

1800

0

1600

1400

1200

1000

800

600

400

200

QUIESCENT CURRENT

QUIESCENT CURRENT ≠ µA

Figure 4. Quiescent Current vs. Input Voltage

76

66

60

2

30

4

6

8

10

12

15

18

21

24

27

74

68

64

62

72

70

INPUT VOLTAGE ≠ V

OSCILLATOR FREQUENCY ≠ kHz

OSCILLATOR FREQUENCY

Figure 5. Oscillator Frequency vs. Input Voltage

R

LIM

≠

1.9

1.7

0.1

1

1000

10

100

1.5

1.3

0.5

1.1

0.9

0.7

0.3

SWITCH CURRENT ≠ A

STEP-DOWN WITH

V = +12V

Figure 6. Maximum Switch Current vs. R

LIM

R

LIM

≠

0.1

1

1000

10

100

1.5

1.3

0.5

1.1

0.9

0.7

0.3

STEP-UP MODE

WITH V

+5V

SWITCH CURRENT ≠ A

Figure 7. Maximum Switch Current vs. R

LIM

ADP1110

≠5≠

REV. 0

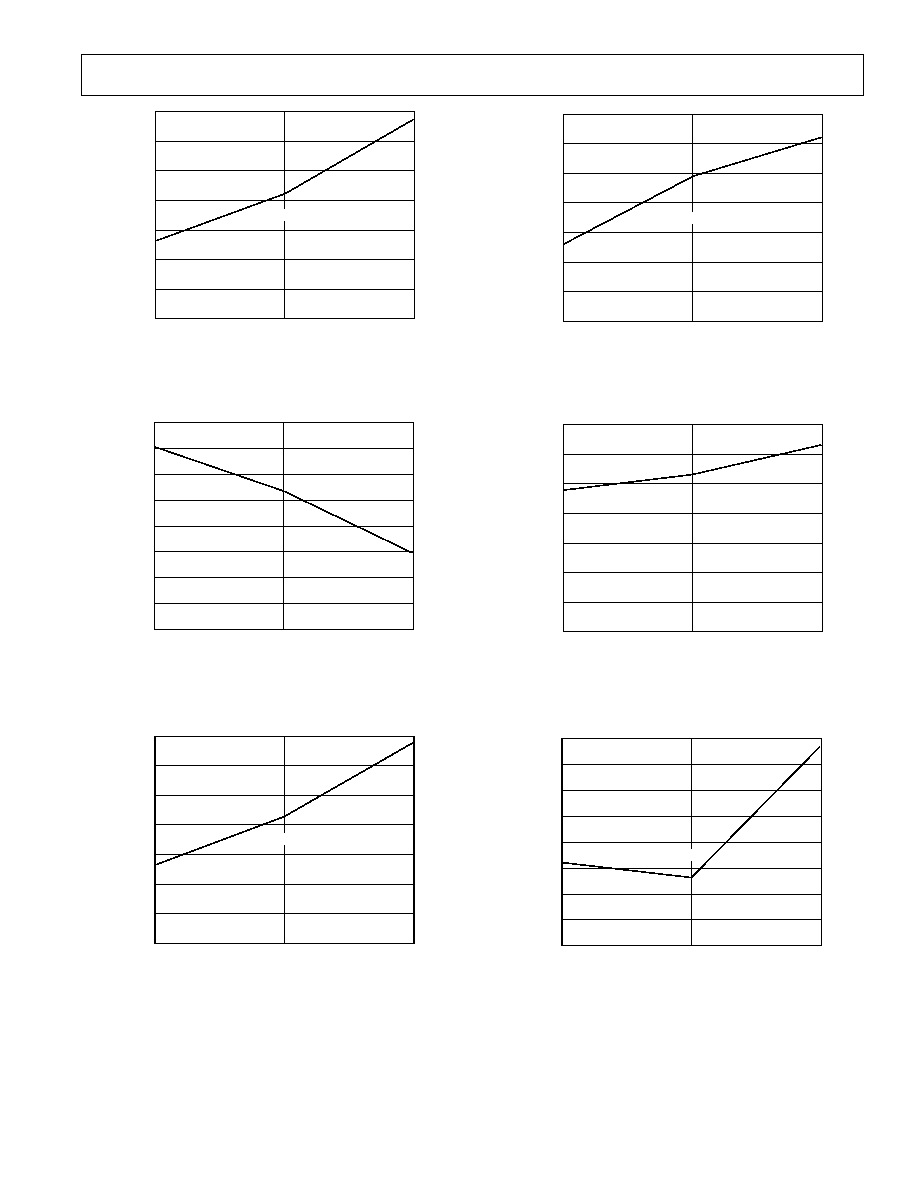

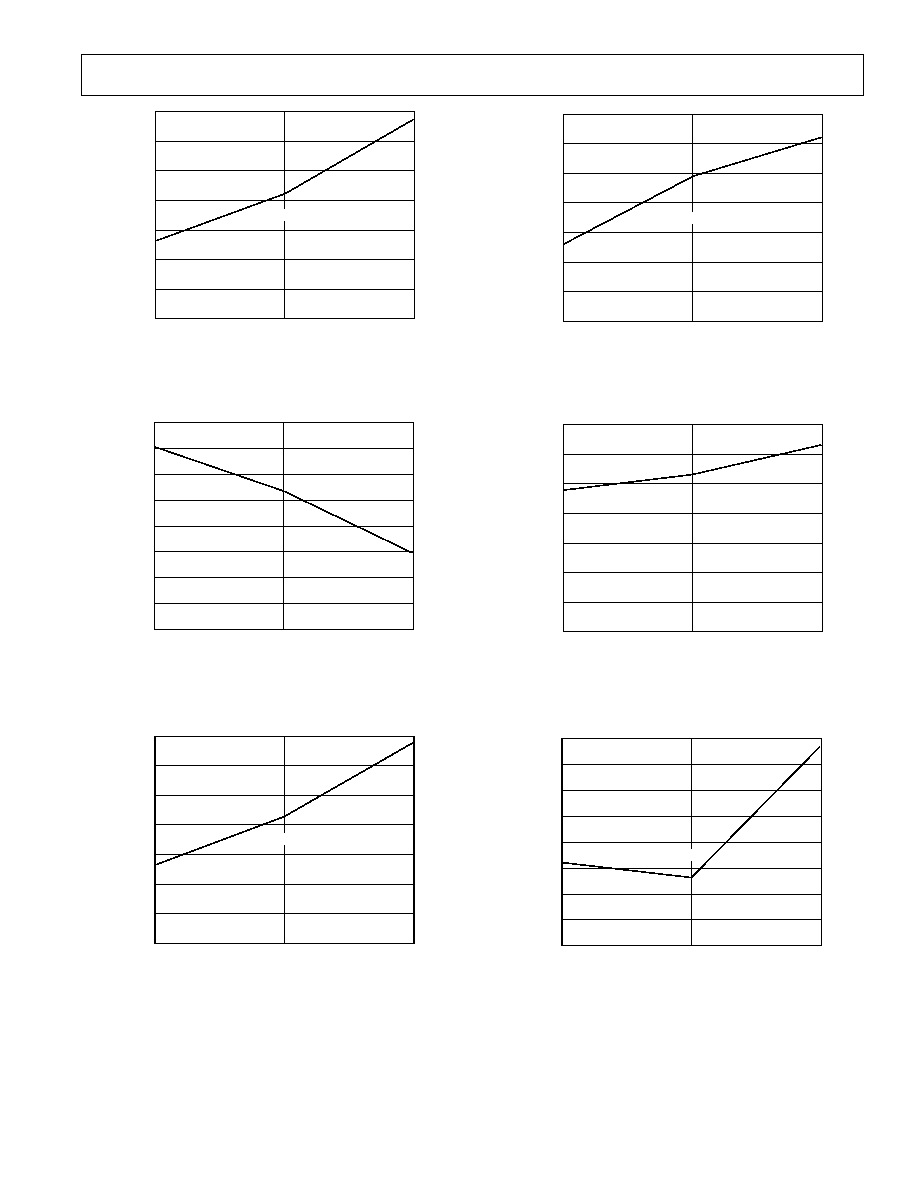

TEMPERATURE ≠ C

78

76

64

0

70

25

72

70

68

66

74

OSCILLATOR FREQUENCY

OSCILLATOR FREQUENCY ≠ kHz

Figure 8. Oscillator Frequency vs. Temperature

TEMPERATURE ≠ C

ON TIME ≠ µs

9.0

8.9

8.2

0

70

25

8.6

8.5

8.4

8.3

8.8

8.7

SWITCH ON TIME

Figure 9. Switch ON Time vs. Temperature

TEMPERATURE ≠ C

66

65

59

0

70

25

63

62

61

60

64

DUTY CYCLE

DUTY CYCLE ≠ %

Figure 10. Duty Cycle vs. Temperature

TEMPERATURE ≠ C

0.54

0.53

0.47

0

70

25

0.51

0.5

0.49

0.48

0.52

V

IN

= +1.5

@

I

SWITCH

= +0.5A

V

CE(SAT)

≠ V

Figure 11. Switch ON Voltage Step-Down vs. Temperature

TEMPERATURE ≠ C

350

300

0

0

70

25

200

150

100

50

250

QUIESCENT CURRENT

QUIESCENT CURRENT ≠ µA

Figure 12. Quiescent Current vs. Temperature

TEMPERATURE ≠ C

160

120

0

70

25

145

140

135

125

155

150

BIAS CURRENT

BIAS CURRENT ≠ nA

130

Figure 13. FB Pin Bias Current vs. Temperature

ADP1110

≠6≠

REV. 0

THEORY OF OPERATION

The ADP1110 is a flexible, low-power, switch-mode power

supply (SMPS) controller. The regulated output voltage can be

greater than the input voltage (boost or step-up mode) or less

than the input (buck or step-down mode). This device uses a

gated-oscillator technique to provide very high performance with

low quiescent current.

A functional block diagram of the ADP1110 is shown on the

first page. The internal 220 mV reference is connected to one

input of the comparator, while the other input is externally

connected (via the FB pin) to a feedback network connected to

the regulated output. When the voltage at the FB pin falls below

220 mV, the 70 kHz oscillator turns on. A driver amplifier provides

base drive to the internal power switch, and the switching action

raises the output voltage. When the voltage at the FB pin exceeds

220 mV, the oscillator is shut off. While the oscillator is off, the

ADP1110 quiescent current is only 300

µ

A. The comparator

includes a small amount of hysteresis, which ensures loop

stability without requiring external components for frequency

compensation.

The maximum current in the internal power switch can be set

by connecting a resistor between V

IN

and the I

LIM

pin. When the

maximum current is exceeded, the switch is turned OFF. The

current limit circuitry has a time delay of about 800 ns. If an

external resistor is not used, connect I

LIM

to V

IN

. Further informa-

tion on I

LIM

is included in the "Applications" section of this data

sheet.

The ADP1110 internal oscillator provides 10

µ

s ON and 5

µ

s

OFF times, which is ideal for applications where the ratio between

V

IN

and V

OUT

is roughly a factor of three (such as generating +5 V

from a single 1.5 V cell). Wider range conversions, as well as

step-down converters, can also be accomplished with a slight

loss in the maximum output power that can be obtained.

An uncommitted gain block on the ADP1110 can be connected

as a low≠battery detector. The inverting input of the gain block

is internally connected to the 220 mV reference. The noninverting

input is available at the SET pin. A resistor divider, connected

between V

IN

and GND with the junction connected to the SET

pin, causes the AO output to go LOW when the low battery set

point is exceeded. The AO output is an open collector NPN

transistor that can sink 300

µ

A.

The ADP1110 provides external connections for both the

collector and emitter of its internal power switch, which permits

both step-up and step-down modes of operation. For the step-

up mode, the emitter (Pin SW2) is connected to GND and the

collector (Pin SW1) drives the inductor. For step-down mode,

the emitter drives the inductor while the collector is connected

to V

IN

.

The output voltage of the ADP1110 is set with two external

resistors. Three fixed-voltage models are also available:

ADP1110≠3.3 (+3.3 V), ADP1110≠5 (+5 V) and ADP1110-12

(+12 V). The fixed-voltage models are identical to the

ADP1110 except that laser-trimmed voltage-setting resistors are

included on the chip. Only three external components are

required to form a +3.3 V, +5 V or +12 V converter. On the

fixed-voltage models of the ADP1110, simply connect the

SENSE pin (Pin 8) directly to the output voltage.

COMPONENT SELECTION

General Notes on Inductor Selection

When the ADP1110 internal power switch turns on, current

begins to flow in the inductor. Energy is stored in the inductor

core while the switch is on, and this stored energy is then

transferred to the load when the switch turns off. Because both

the collector and the emitter of the switch transistor are

accessible on the ADP1110, the output voltage can be higher,

lower, or of opposite polarity than the input voltage.

To specify an inductor for the ADP1110, the proper values of

inductance, saturation current, and DC resistance must be

determined. This process is not difficult, and specific equations

for each circuit configuration are provided in this data sheet. In

general terms, however, the inductance value must be low

enough to store the required amount of energy (when both

input voltage and switch ON time are at a minimum) but high

enough that the inductor will not saturate when both V

IN

and

switch ON time are at their maximum values. The inductor

must also store enough energy to supply the load without

saturating. Finally, the dc resistance of the inductor should be

low so that excessive power will not be wasted by heating the

windings. For most ADP1110 applications, an inductor of

15

µ

H to 100

µ

H with a saturation current rating of 300 mA to

1A and dc resistance <0.4

is suitable. Ferrite-core inductors

that meet these specifications are available in small, surface-

mount packages.

To minimize Electro-Magnetic Interference (EMI), a toroid or

pot-core type inductor is recommended. Rod-core inductors are

a lower-cost alternative if EMI is not a problem.

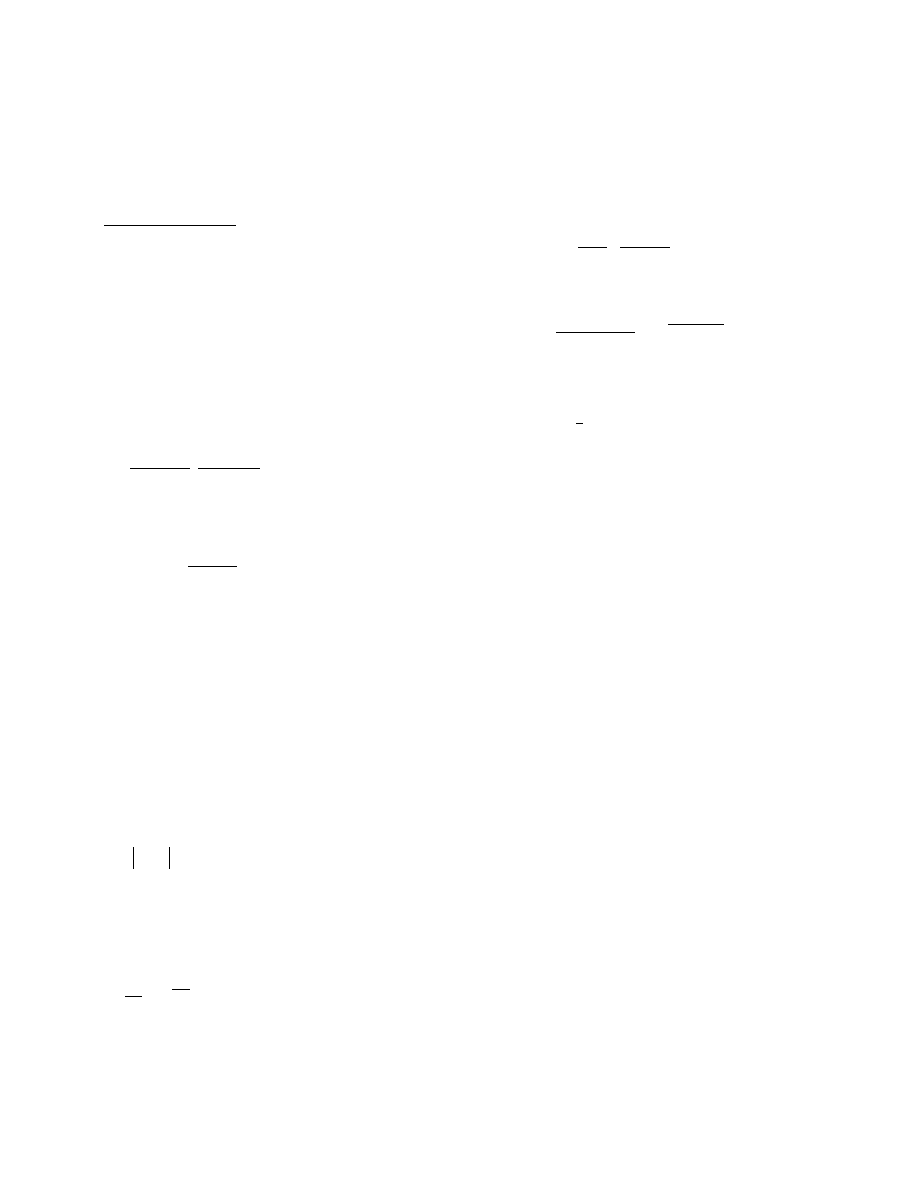

TEMPERATURE ≠ C

400

0

0

70

25

250

200

150

50

350

300

BIAS CURRENT

BIAS CURRENT ≠ nA

100

Figure 14. Set Pin Bias Current vs. Temperature

V

REF

≠ mV

TEMPERATURE ≠ C

220

219

211

0

70

25

215

214

213

212

217

216

218

REFERENCE VOLTAGE

Figure 15. Reference Voltage vs. Temperature

ADP1110

≠7≠

REV. 0

CALCULATING THE INDUCTOR VALUE

Selecting the proper inductor value is a simple three-step

process:

1. Define the operating parameters: minimum input voltage,

maximum input voltage, output voltage and output current.

2. Select the appropriate conversion topology (step-up, step-

down, or inverting).

3. Calculate the inductor value, using the equations in the

following sections.

INDUCTOR SELECTION≠STEP-UP CONVERTER

In a step-up or boost converter (Figure 19), the inductor must

store enough power to make up the difference between the input

voltage and the output voltage. The power that must be stored

is calculated from the equation:

P

L

=

V

OUT

+

V

D

-

V

IN MIN

(

)

(

)

∑

I

OUT

(

)

(Equation 1)

where V

D

is the diode forward voltage (

0.5 V for a 1N5818

Schottky). Because energy is only stored in the inductor while

the ADP1110 switch is ON, the energy stored in the inductor

on each switching cycle must be must be equal to or greater

than:

P

f

L

OSC

(Equation 2)

in order for the ADP1110 to regulate the output voltage.

When the internal power switch turns ON, current flow in the

inductor increases at the rate of:

I

L

(t)

=

V

IN

R'

1

-

e

≠R't

L

(Equation 3)

where L is in Henrys and R' is the sum of the switch equivalent

resistance (typically 0.8

at +25

∞

C) and the dc resistance of

the inductor. If the voltage drop across the switch is small

compared to V

IN

, a simpler equation can be used:

I

L

(t)

=

V

IN

L

t

(Equation 4)

Replacing `t' in the above equation with the ON time of the

ADP1110 (10

µ

s, typical) will define the peak current for a

given inductor value and input voltage. At this point, the

inductor energy can be calculated as follows:

E

L

=

1

2

L

∑

I

2

PEAK

(Equation 5)

As previously mentioned, E

L

must be greater than P

L

/f

OSC

so

that the ADP1110 can deliver the necessary power to the load.

For best efficiency, peak current should be limited to 1 A or

less. Higher switch currents will reduce efficiency because of

increased saturation voltage in the switch. High peak current also

increases output ripple. As a general rule, keep peak current as low

as possible to minimize losses in the switch, inductor and diode.

In practice, the inductor value is easily selected using the equations

above. For example, consider a supply that will generate 12 V at

120 mA from a 4.5 V to 8 V source. The inductor power required

is from Equation 1:

P

L

=

12 V

+

0.5 V

-

4.5 V

(

)

∑

120 mA

=

960 mW

On each switching cycle, the inductor must supply:

P

L

f

OSC

=

960 mW

70 kHz

=

13.7

µ

J

Assuming a peak current of 1 A as a starting point, (Equation 4)

can be rearranged to recommend an inductor value:

L

=

V

IN

I

L(MAX )

t

=

4.5V

1 A

10

µ

s

=

45

µ

H

Substituting a standard inductor value of 47

µ

H with 0.2

dc

resistance will produce a peak switch current of:

I

PEAK

=

4.5V

1.0

1

-

e

≠1.0

∑

10

µ

s

47

µ

H

=

862 mA

Once the peak current is known, the inductor energy can be

calculated from Equation 5:

E

L

=

1

2

47

µ

H

(

)

∑

862 mA

(

)

2

=

17.5

µ

J

Since the inductor energy of 17.5

µ

J is greater than the P

L

/f

OSC

requirement of 13.7

µ

J, the 47

µ

H inductor will work in this

application. By substituting other inductor values into the same

equations, the optimum inductor value can be determined.

When selecting an inductor, the peak current must not exceed

the maximum switch current of 1.5 A.

The peak current must be evaluated for both minimum and

maximum values of input voltage. If the switch current is high

when V

IN

is at its minimum, the 1.5 A limit may be exceeded at the

maximum value of V

IN

. In this case, the ADP1110's current limit

feature can be used to limit switch current. Simply select a resistor

(using Figure 7) that will limit the maximum switch current to the

I

PEAK

value calculated for the minimum value of V

IN

. This will

improve efficiency by producing a constant I

PEAK

as V

IN

increases.

See the "Limiting the Switch Current" section of this data sheet for

more information.

Note that the switch current limit feature does not protect the

circuit if the output is shorted to ground. In this case, current is

only limited by the dc resistance of the inductor and the forward

voltage of the diode.

INDUCTOR SELECTION≠STEP-DOWN CONVERTER

The step-down mode of operation is shown in Figure 20.

Unlike the step-up mode, the ADP1110's power switch does not

saturate when operating in the step-down mode; therefore,

switch current should be limited to 800 mA in this mode. If the

input voltage will vary over a wide range, the I

LIM

pin can be

used to limit the maximum switch current. Higher switch

current is possible by adding an external switching transistor as

shown in Figure 22.

The first step in selecting the step-down inductor is to calculate

the peak switch current as follows:

I

PEAK

=

2 I

OUT

DC

V

OUT

+

V

D

V

IN

≠V

SW

+

V

D

(Equation 6)

where: DC = duty cycle (0.69 for the ADP1110)

V

SW

= voltage drop across the switch

V

D

= diode drop (0.5 V for a 1N5818)

I

OUT

= output current

V

OUT

= the output voltage

V

IN

= the minimum input voltage

ADP1110

≠8≠

REV. 0

As previously mentioned, the switch voltage is higher in step-

down mode than in step-up mode. V

SW

is a function of switch

current and is therefore a function of V

IN

, L, time and V

OUT

.

For most applications, a V

SW

value of 1.5 V is recommended.

The inductor value can now be calculated:

L

=

V

IN(MIN )

≠V

SW

≠V

OUT

I

PEAK

∑

t

ON

(Equation 7)

where: t

ON

= Switch ON time (10

µ

s)

If the input voltage will vary (such as an application that must

operate from a 9 V, 12 V or 15 V source), an R

LIM

resistor

should be selected from Figure 6. The R

LIM

resistor will keep

switch current constant as the input voltage rises. Note that

there are separate R

LIM

values for step-up and step-down modes

of operation.

For example, assume that +5 V at 250 mA is required from a

+9 V to +18 V source. Deriving the peak current from Equation

6 yields:

I

PEAK

=

2

∑

250 mA

0.69

5

+

0.5

9

-

1.5

+

0.5

=

498 mA

Then, the peak current can be inserted into Equation 7 to

calculate the inductor value:

L

=

9 ≠1.5 ≠ 5

498 mA

∑

10

µ

s

=

50

µ

s

Since 50

µ

H is not a standard value, the next lower standard

value of 47

µ

H would be specified.

To avoid exceeding the maximum switch current when the

input voltage is at +18 V, an R

LIM

resistor should be specified.

Using the step-down curve of Figure 6, a value of 560

will

limit the switch current to 500 mA.

INDUCTOR SELECTION--POSITIVE-TO-NEGATIVE

CONVERTER

The configuration for a positive-to-negative converter using the

ADP1110 is shown in Figure 23. As with the step-up converter,

all of the output power for the inverting circuit must be supplied

by the inductor. The required inductor power is derived from

the formula:

P =

I

L

OUT

V

V

OUT

D

+

(

)

∑

(

)

(Equation 8)

The ADP1110 power switch does not saturate in positive-to-

negative mode. The voltage drop across the switch can be

modeled as a 0.75 V base-emitter diode in series with a 0.65

resistor. When the switch turns on, inductor current will rise at

a rate determined by:

I

L

(t)

=

V

L

R'

1

-

e

≠R't

L

(Equation 9)

where: R' = 0.65

+ R

L(DC)

V

L

= V

IN

≠ 0.75 V

For example, assume that a ≠5 V output at 75 mA is to be

generated from a +4.5 V to +5.5 V source. The power in the

inductor is calculated from Equation 8:

P

L

=

|≠ 5V|

+

0.5V

(

)

∑

75 mA

(

)

=

413 mW

During each switching cycle, the inductor must supply the

following energy:

P

L

f

OSC

=

413 mW

70 kHz

=

5.9

µ

J

Using a standard inductor value of 56

µ

H with 0.2

dc

resistance will produce a peak switch current of:

I

PEAK

=

4.5V ≠ 0.75V

0.65

+

0.2

1

-

e

≠0.85

∑

10

µ

s

56

µ

H

=

621 mA

Once the peak current is known, the inductor energy can be

calculated from Equation 9:

E

L

=

1

2

56

µ

H

(

)

∑

621 mA

(

)

2

=

10.8

µ

J

Since the inductor energy of 10.8

µ

J is greater than the P

L

/f

OSC

requirement of 5.9

µ

J, the 56

µ

H inductor will work in this

application.

The input voltage only varies between 4.5 V and 5.5 V in this

example. Therefore, the peak current will not change enough to

require an R

LIM

resistor and the I

LIM

pin can be connected

directly to V

IN

. Care should be taken, of course, to ensure that

the peak current does not exceed 800 mA.

CAPACITOR SELECTION

For optimum performance, the ADP1110's output capacitor

must be selected carefully. Choosing an inappropriate capacitor

can result in low efficiency and/or high output ripple.

Ordinary aluminum electrolytic capacitors are inexpensive but

often have poor Equivalent Series Resistance (ESR) and

Equivalent Series Inductance (ESL). Low ESR aluminum

capacitors, specifically designed for switch mode converter

applications, are also available, and these are a better choice

than general purpose devices. Even better performance can be

achieved with tantalum capacitors, although their cost is higher.

Very low values of ESR can be achieved by using OS-CON

capacitors (Sanyo Corporation, San Diego, CA). These devices

are fairly small, available with tape-and-reel packaging and have

very low ESR.

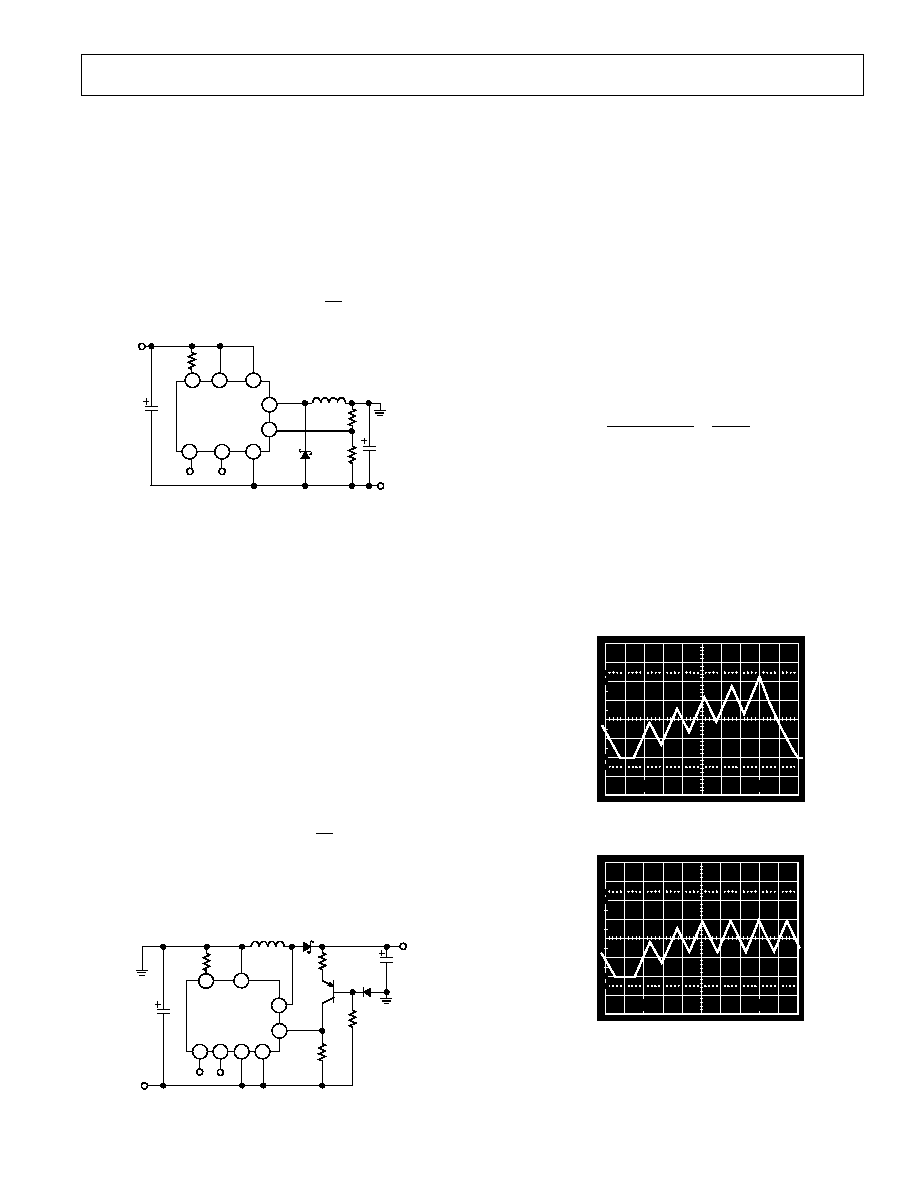

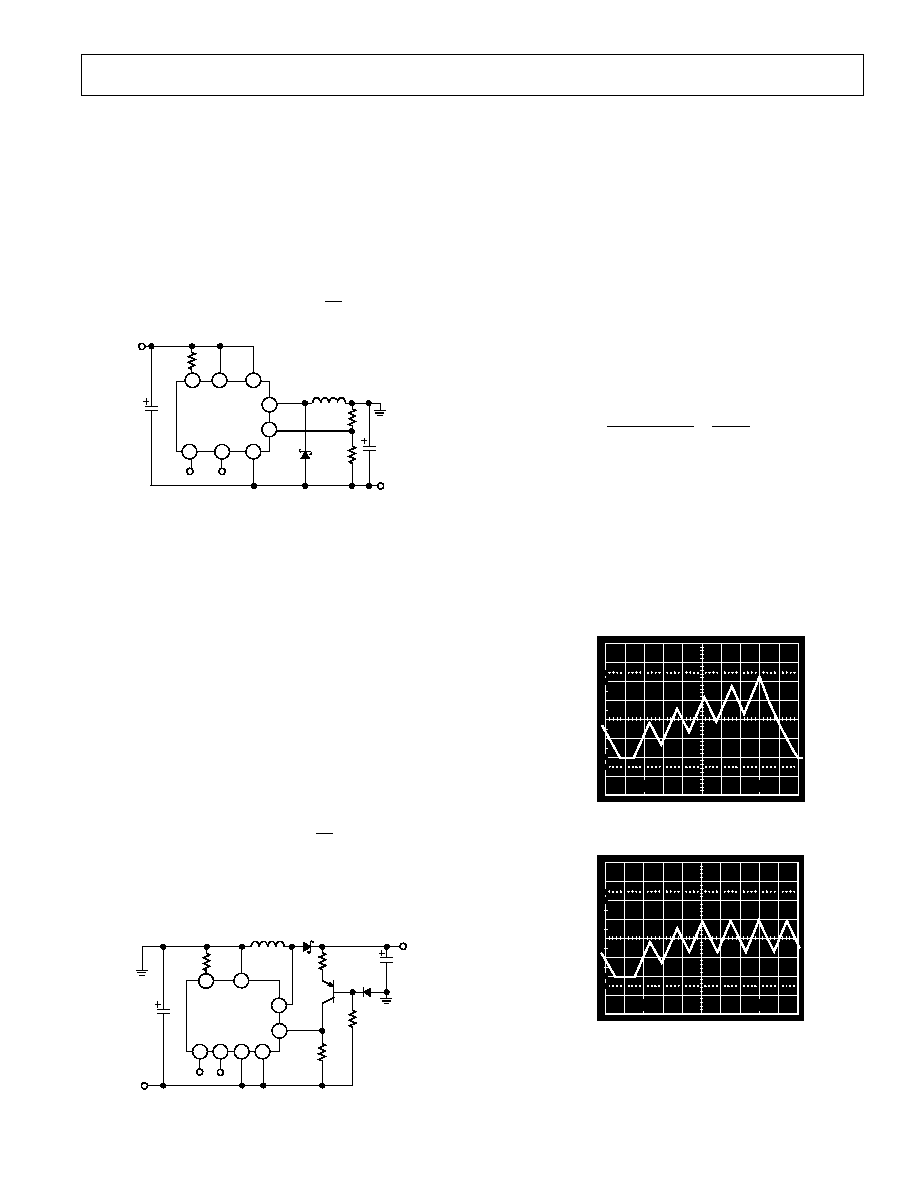

The effects of capacitor selection on output ripple are demon-

strated in Figures 16, 17 and 18. These figures show the output

of the same ADP1110 converter, that was evaluated with three

different output capacitors. In each case, the peak switch

current is 500 mA, and the capacitor value is 100

µ

F. Figure 16

shows a Panasonic HF-series 16-volt radial cap. When the

switch turns off, the output voltage jumps by about 90 mV and

then decays as the inductor discharges into the capacitor. The

rise in voltage indicates an ESR of about 0.18

. In Figure 17,

the aluminum electrolytic has been replaced by a Sprague 293D

series, a 6 V tantalum device. In this case the output jumps

ADP1110

≠9≠

REV. 0

about 30 mV, which indicates an ESR of 0.06

. Figure 18

shows an OS-CON 16≠volt capacitor in the same circuit, and

ESR is only 0.02

.

10

0%

100

90

1µs

50mV

Figure 16. Aluminum Electrolytic

10

0%

100

90

1µs

50mV

Figure 17. Tantalum Electrolytic

10

0%

100

90

1µs

50mV

Figure 18. OS-CON Capacitor

If low output ripple is important, the user should consider the

ADP3000. Because this device switches at 400 kHz, lower peak

current can be used. Also, the higher switching frequency

simplifies the design of the output filter. Consult the ADP3000

data sheet for additional details.

DIODE SELECTION

In specifying a diode, consideration must be given to speed,

forward voltage drop and reverse leakage current. When the

ADP1110 switch turns off, the diode must turn on rapidly if

high efficiency is to be maintained. Shottky rectifiers, as well as

fast signal diodes such as the 1N4148, are appropriate. The

forward voltage of the diode represents power that is not

delivered to the load, so V

F

must also be minimized. Again,

Schottky diodes are recommended. Leakage current is especially

important in low-current applications, where the leakage can be

a significant percentage of the total quiescent current.

For most circuits, the 1N5818 is a suitable companion to the

ADP1110. This diode has a V

F

of 0.5 V at 1 A, 4

µ

A to 10

µ

A

leakage, and fast turn-on and turn-off times. A surface mount

version, the MBRS130LT3, is also available.

For switch currents of 100 mA or less, a Shottky diode such as

the BAT85 provides a V

F

of 0.8 V at 100 mA and leakage less

than 1

µ

A. A similar device, the BAT54, is available in a SOT23

package. Even lower leakage, in the 1 nA to 5 nA range, can be

obtained with a 1N4148 signal diode.

General purpose rectifiers, such as the 1N4001, are not suitable

for ADP1110 circuits. These devices, which have turn-on times

of 10

µ

s or more, are too slow for switching power supply

applications. Using such a diode "just to get started" will result

in wasted time and effort. Even if an ADP1110 circuit appears

to function with a 1N4001, the resulting performance will not

be indicative of the circuit performance when the correct diode

is used.

CIRCUIT OPERATION, STEP-UP (BOOST) MODE

In boost mode, the ADP1110 produces an output voltage that is

higher than the input voltage. For example, +5 V can be derived

from one alkaline cell (+1.5 V), or +12 V can be generated from

a +5 V logic power supply.

Figure 19 shows an ADP1110 configured for step-up operation.

The collector of the internal power switch is connected to the

output side of the inductor, while the emitter is connected to

GND. When the switch turns on, pin SW1 is pulled near

ground. This action forces a voltage across L1 equal to V

IN

≠

V

CE(SAT),

and current begins to flow through L1. This current

reaches a final value (ignoring second-order effects) of:

I

PEAK

V

IN

≠V

CE(SAT )

L

∑

10

µ

s

where 10

µ

s is the ADP1110 switch's "on" time.

I

LIM

V

IN

SW1

SW2

FB

GND

ADP1110

L1

C

1

R1

R2

D1

8

1

2

3

4

5

V

IN

V

OUT

R3*

*OPTIONAL

Figure 19. Step-Up Mode Operation

When the switch turns off, the magnetic field collapses. The

polarity across the inductor changes, current begins to flow

through D1 into the load, and the output voltage is driven above

the input voltage.

The output voltage is fed back to the ADP1110 via resistors R1

and R2. When the voltage at pin FB falls below 220 mV, SW1

ADP1110

≠10≠

REV. 0

turns "on" again, and the cycle repeats. The output voltage is

therefore set by the formula:

V

OUT

=

220 mV

∑

1

+

R1

R2

The circuit of Figure 19 shows a direct current path from V

IN

to

V

OUT

, via the inductor and D1. Therefore, the boost converter

is not protected if the output is short circuited to ground.

CIRCUIT OPERATION, STEP-DOWN (BUCK) MODE

The ADP1110's step-down mode is used to produce an output

voltage that is lower than the input voltage. For example, the

output of four NiCd cells (+4.8 V) can be converted to a +3 V

logic supply.

A typical configuration for step-down operation of the ADP1110 is

shown in Figure 20. In this case, the collector of the internal

power switch is connected to V

IN

and the emitter drives the

inductor. When the switch turns on, SW2 is pulled up towards

V

IN

. This forces a voltage across L1 equal to V

IN

≠ V

CE

≠ V

OUT

and causes current to flow in L1. This current reaches a final

value of:

I

PEAK

V

IN

-

V

CE

-

V

OUT

L

∑

10

µ

s

where 10

µ

s is the ADP1110 switch's "on" time.

I

LIM

V

IN

SW1

SW2

GND

SET

AO

ADP1110

NC

NC

L1

C

1

R1

R2

D1

1N5818

V

OUT

C

2

V

IN

2

R

LIM

100

FB

1

3

6

7

5

4

8

Figure 20. Step-Down Mode Operation

When the switch turns off, the magnetic field collapses. The

polarity across the inductor changes, and the switch side of the

inductor is driven below ground. Schottky diode D1 then turns

on, and current flows into the load. Notice that the Absolute

Maximum Rating for the ADP1110's SW2 pin is 0.5 V below

ground. To avoid exceeding this limit, D1 must be a Schottky

diode. Using a silicon diode in this application will generate

forward voltages above 0.5 V that will cause potentially

damaging power dissipation within the ADP1110.

The output voltage of the buck regulator is fed back to the

ADP1110's FB pin by resistors R1 and R2. When the voltage at

pin FB falls below 220 mV, the internal power switch turns

"on" again and the cycle repeats. The output voltage is set by

the formula:

V

OUT

=

220 mV

∑

1

+

R1

R2

When operating the ADP1110 in step-down mode, the output

voltage is impressed across the internal power switch's emitter-

base junction when the switch is off. To protect the switch, the

output voltage should be limited to 6.2 V or less. If a higher

output voltage is required, a Schottky diode should be placed in

series with SW2, as shown in Figure 21.

I

LIM

V

IN

SW1

SW2

FB

GND

SET

AO

ADP1110

NC

NC

L1

C

L

R1

R2

D1

1N5818

OUTPUT

C

INPUT

INPUT

6

7

8

1

2

3

4

5

R

LIM

Figure 21. Step-Down Mode, V

OUT

> 6.2 V

If the input voltage to the ADP1110 varies over a wide range, a

current limiting resistor at Pin 1 may be required. If a particular

circuit requires high peak inductor current with minimum input

supply voltage, the peak current may exceed the switch maxi-

mum rating and/or saturate the inductor when the supply

voltage is at the maximum value. See the "Limiting the Switch

Current" section of this data sheet for specific recommendations.

INCREASING OUTPUT CURRENT IN THE STEP-DOWN

REGULATOR

Unlike the boost configuration, the ADP1110's internal power

switch is not saturated when operating in step-down mode. A

conservative value for the voltage across the switch in step-down

mode is 1.5 V. This results in high power dissipation within the

ADP1110 when high peak current is required. To increase the

output current, an external PNP switch can be added (Figure

22). In this circuit, the ADP1110 provides base drive to Q1

through R3, while R4 ensures that Q1 turns off rapidly. Because

the ADP1110's internal current limiting function will not work

in this circuit, R5 is provided for this purpose. With the value

shown, R5 limits current to 2 A. In addition to reducing power

dissipation on the ADP1110, this circuit also reduces the switch

voltage. When selecting an inductor value for the circuit of

Figure 22, the switch voltage can be calculated from the

formula:

V

SW

=

V

R5

+

V

Q1(SAT )

0.6V

+

0.4V

1V

I

LIM

V

IN

SW1

SW2

FB

GND

SET

AO

ADP1110

NC

NC

L1

C

L

R1

R2

D1

1N5821

OUTPUT

C

INPUT

R

LIM

INPUT

6

7

8

1

2

4

5

3

R4

220

R3

330

MJE210

0.3

R5

Figure 22. High Current Step-Down Operation

ADP1110

≠11≠

REV. 0

POSITIVE-TO-NEGATIVE CONVERSION

The ADP1110 can convert a positive input voltage to a negative

output voltage as shown in Figure 23. This circuit is essentially

identical to the step-down application of Figure 19, except that

the "output" side of the inductor is connected to power ground.

When the ADP1110's internal power switch turns off, current

flowing in the inductor forces the output (≠V

OUT

) to a negative

potential. The ADP1110 will continue to turn the switch on

until its FB pin is 220 mV above its GND pin, so the output

voltage is determined by the formula:

V

OUT

=

220 mV

∑

1

+

R1

R2

ILIM

VIN

SW1

SW2

FB

GND

SET

AO

ADP1110

NC

NC

L1

C

L

R1

R2

D1

1N5818

OUTPUT

C

INPUT

R

LIM

INPUT

6

7

8

1

2

4

5

3

NEGATIVE

OUTPUT

Figure 23. A Positive-to-Negative Converter

The design criteria for the step-down application also apply to

the positive-to-negative converter. The output voltage should be

limited to |6.2 V| unless a diode is inserted in series with the

SW2 pin (see Figure 21.) Also, D1 must again be a Schottky

diode to prevent excessive power dissipation in the ADP1110.

NEGATIVE-TO-POSITIVE CONVERSION

The circuit of Figure 24 converts a negative input voltage to a

positive output voltage. Operation of this circuit configuration is

similar to the step-up topology of Figure 19, except the current

through feedback resistor R1 is level-shifted below ground by a

PNP transistor. The voltage across R1 is V

OUT

≠ V

BEQ1

. However,

diode D2 level-shifts the base of Q1 about 0.6 V below ground

thereby cancelling the V

BE

of Q1. The addition of D2 also reduces

the circuit's output voltage sensitivity to temperature, which other-

wise would be dominated by the ≠2 mV V

BE

contribution of Q1.

The output voltage for this circuit is determined by the formula:

V

OUT

=

220 mV

∑

R1

R2

Unlike the positive step-up converter, the negative-to-positive

converter's output voltage can be either higher or lower than the

input voltage.

I

LIM

V

IN

SW1

SW2

FB

GND

SET

AO

ADP1110

NC

NC

L1

C

L

R2

D1

C

INPUT

R

LIM

6

7

8

1

2

4

5

3

POSITIVE

OUTPUT

10K

NEGATIVE

INPUT

Q1

2N3906

D2

1N4148

R1

Figure 24. A Negative-to-Positive Converter

LIMITING THE SWITCH CURRENT

The ADP1110's R

LIM

pin permits the switch current to be

limited with a single resistor. This current limiting action occurs

on a pulse by pulse basis. This feature allows the input voltage

to vary over a wide range without saturating the inductor or

exceeding the maximum switch rating. For example, a particular

design may require peak switch current of 800 mA with a 2.0 V

input. If V

IN

rises to 4 V, however, the switch current will

exceed 1.6 A. The ADP1110 limits switch current to 1.5 A and

thereby protects the switch, but the output ripple will increase.

Selecting the proper resistor will limit the switch current to

800 mA, even if V

IN

increases. The relationship between R

LIM

and maximum switch current is shown in Figure 6.

The I

LIM

feature is also valuable for controlling inductor current

when the ADP1110 goes into continuous-conduction mode.

This occurs in the step-up mode when the following condition is

met:

V

OUT

+

V

D IODE

V

IN

≠ V

SW

<

1

1≠ DC

where DC is the ADP1110's duty cycle. When this relationship

exists, the inductor current does not go all the way to zero

during the time that the switch is OFF. When the switch turns

on for the next cycle, the inductor current begins to ramp up

from the residual level. If the switch ON time remains constant,

the inductor current will increase to a high level (see Figure 25).

This increases output ripple and can require a larger inductor

and capacitor. By controlling switch current with the I

LIM

resistor, output ripple current can be maintained at the design

values. Figure 26 illustrates the action of the I

LIM

circuit.

10

0%

100

90

10µs

10mV

200mA/div.

Figure 25. I

LIM

Operation--I

L

Characteristic

10

0%

100

90

10µs

10mV

200mA/div.

Figure 26. I

LIM

Operation--I

L

Characteristic

ADP1110

≠12≠

REV. 0

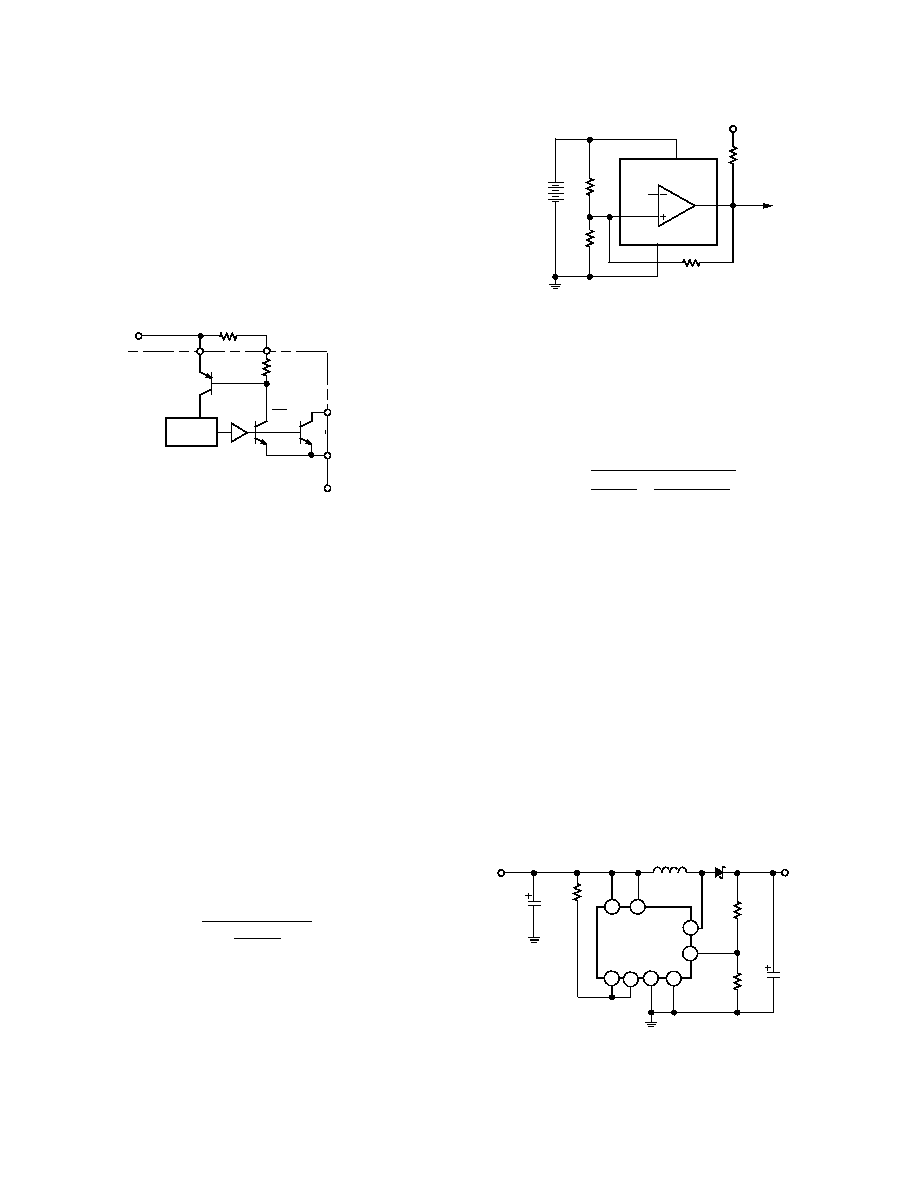

The internal structure of the I

LIM

circuit is shown in Figure 27.

Q1 is the ADP1110's internal power switch, that is paralleled by

sense transistor Q2. The relative sizes of Q1 and Q2 are scaled

so that I

Q2

is 0.5% of I

Q1

. Current flows to Q2 through an

internal 80

resistor and through the R

LIM

resistor. These two

resistors parallel the base-emitter junction of the oscillator-

disable transistor, Q3. When the voltage across R1 and R

LIM

exceeds 0.6 V, Q3 turns on and terminates the output pulse. If

only the 80

internal resistor is used (i.e., the I

LIM

pin is

connected directly to V

IN

), the maximum switch current will be

1.5 A. Figure 6 gives R

LIM

values for lower current-limit values.

72kHz

OSC

V

IN

POWER

SWITCH

SW2

SW1

R

LIM

DRIVER

80

(INTERNAL)

I

LIM

IQ1

V

IN

200

(EXTERNAL)

Q2

ADP1110

R1

Q3

Q1

Figure 27. ADP1110 Current Limit Operation

The delay through the current limiting circuit is approximately

800 ns. If the switch ON time is reduced to less than 3

µ

s,

accuracy of the current trip-point is reduced. Attempting to

program a switch ON time of 800 ns or less will produce

spurious responses in the switch ON time; however, the

ADP1110 will still provide a properly-regulated output voltage.

PROGRAMMING THE GAIN BLOCK

The gain block of the ADP1110 can be used as a low-battery

detector, error amplifier or linear post regulator. The gain block

consists of an op amp with PNP inputs and an open-collector

NPN output. The inverting input is internally connected to the

ADP1110's 220 mV reference, while the noninverting input is

available at the SET pin. The NPN output transistor will sink

about 300

µ

A.

Figure 28 shows the gain block configured as a low-battery

monitor. Resistors R1 and R2 should be set to high values to

reduce quiescent current, but not so high that bias current in

the SET input causes large errors. A value of 33 k

for R2 is a

good compromise. The value for R1 is then calculated from the

formula:

R1

=

V

LOBATT

≠ 220 mV

220 mV

R2

where V

LOBATT

is the desired low battery trip point. Since the

gain block output is an open-collector NPN, a pull-up resistor

should be connected to the positive logic power supply.

ADP1110

GND

AO

R

L

R1

V

BAT

SET

R2

33k

220V

V

REF

R

HYS

V

LOGIC

Figure 28. Setting the Low Battery Detector Trip Point

The circuit of Figure 28 may produce multiple pulses when

approaching the trip point due to noise coupled into the SET

input. To prevent multiple interrupts to the digital logic,

hysteresis can be added to the circuit. Resistor R

HYS

, with a

value of 1 M

to 10 M

, provides the hysteresis. The addition

of R

HYS

will change the trip point slightly, so the new value for

R1 will be:

R1

=

V

LOBATT

≠ 220 mV

220 mV

R2

≠

V

L

≠ 220 mV

R

L

+

R

HYS

where V

L

is the logic power supply voltage, R

L

is the pull-up

resistor, and R

HYS

creates the hysteresis.

The gain block can also be used as a control element to reduce

output ripple. The ADP3000 is normally recommended for low-

ripple applications, but its minimum input voltage is 2 V. The

gain-block technique using the ADP1110 can be useful for step-

up converters operating down to 1 V.

A step-up converter using this technique is shown in Figure 29.

This configuration uses the gain block to sense the output

voltage and control the comparator. The result is that the

comparator hysteresis is reduced by the open loop gain of the

gain block. Output ripple can be reduced to only a few millivolts

with this technique, versus a typical value of 90 mV for a +5 V

converter using just the comparator. For best results, a large

output capacitor (1000

µ

F or more) should be specified. This

technique can also be used for step-down or inverting applica-

tions, but the ADP3000 is usually a more appropriate choice.

See the ADP3000 data sheet for further details.

I

LIM

V

IN

SW1

SW2

FB GND

SET

AO

ADP1110

L1

C

L

R1

R2

OUTPUT

C

INPUT

INPUT

6

7

8

1

2

4

5

3

1000µF

300k

13.8k

270k

10µF

D1

CTX15-4

1N5818

15µH

Figure 29. Using the Gain Block to Reduce Output Ripple

ADP1110

≠13≠

REV. 0

APPLICATION CIRCUITS

All-Surface-Mount, Single-Cell to 5 V Converter

This is a very simple, compact, low-part-count circuit that takes

a single alkaline 1.5 V cell input and produces a 5 V output.

The output current should be kept to 10 mA or less to conserve

battery life.

I

LIM

V

IN

SW1

SW2

SENSE

GND

SET

AO

ADP1110-5

NC

NC

L1

D1

1N5817

6

7

8

1

2

4

5

3

50µH

+5V

10mA

15µF

C

L

ONE

ALKALINE

CELL

CTX50-4

1.5V

Figure 30. All-Surface-Mount, Single-Cell to 5 V Converter

All-Surface-Mount, 3 V to 5 V Step-Up Converter

Similar to the previous circuit, this circuit takes a 3-volt input

and provides a 5 V output at 40 mA. As in the single-cell version,

the circuit is compact and uses only four external components.

I

LIM

V

IN

SW1

SW2

SENSE

GND

SET

AO

ADP1110-5

NC

NC

L1

6

7

8

1

2

4

5

3

220

3V

50µH

+5V

40mA

10µF

C

L

TWO

ALKALINE

CELLS

D1

1N5817

CTX50-4

Figure 31. All-Surface-Mount, 3 V to 5 V Step-Up

Converter

All-Surface-Mount, 9 V to 5 V Step-Down Converter

Featuring the same low parts count of the step-up design, this

circuit is the complement to the preceding one. The 220

resistor programs the current limit to around 600 mA.

I

LIM

V

IN

SW1

SW2

SENSE

GND

SET

AO

ADP1110-5

NC

NC

L1

D1

6

8

1

2

4

5

3

220

50µH

1N5817

+5V

40mA

10µF

C

L

9V

BATTERY

7

R

LIM

CTX50-4

Figure 32. All-Surface-Mount, 9 V to 5 V Step-Down

Converter

1.5 V to 5 V Dual-Output Step-Up Converter

This circuit works from a single 1.5 V cell and provides simulta-

neous outputs of +5 V and ≠5 V. The accuracy of the negative

output suffers slightly because of the extra diode drop of around

0.4 V.

I

LIM

V

IN

SW1

SW2

SENSE

GND

SET

AO

ADP1110-5

NC

NC

6

7

8

1

2

4

5

3

1.5V

L16

8µH

4.7µF

ONE

ALKALINE

CELL

4.7µF

+5V

3mA

NOTE: ALL DIODES 1N5818

≠5V

3mA

4.7µF

CTX68-4

Figure 33. 1.5 V to

±

5 V Dual-Output Step-Up

Converter

All-Surface-Mount Flash Memory VPP Generator

Figure 34 shows a circuit that can generate the programming

voltage, VPP to program flash memory. The key components

are the MOSFET and the bipolar transistor. These two devices

form a switch that, when ON, allows the ADP1110 to power-up

and function as a step-up converter. The output is +12 V at 120

mA. When the MOSFET switch is OFF, the output of the

circuit drops to just under +5 V thereby disabling the program-

ming capability.

Care should be taken so there is no short-circuit-current limiting

in the circuit in either operating mode.

I

LIM

V

IN

SW1

SW2

SENSE

GND

SET

AO

ADP1110-12

NC

NC

6

7

8

1

2

4

5

3

L1

50µH

10µF

C

L

LOGIC1 = PROGRAM

LOGIC0 = SHUTDOWN

D1

1N5818

CTX50-4

MMBT4403

1k

MMBF170

V

PP

+12V

120mA

+5V

10k

Figure 34. All Surface-Mount Flash Memory VPP Generator

ADP1110

≠14≠

REV. 0

1.5 V to +5 V, +10 V Dual Output Step-Up Converter

The circuit of Figure 35 illustrates a way to get outputs of

+10 V and +5 V from the same converter. The main 5 V output

is derived from the feedback provided by the 487 k

and 11 k

resistors. Capacitor C1 should be a multilayer ceramic variety

for best performance, but a good quality tantalum capacitor will

also give good performance at lower cost.

I

LIM

V

IN

SW1

SW2

FB

GND

SET

AO

ADP1110

NC

NC

6

7

8

1

2

4

5

3

1.5V

L1

50µH

4.7µF

ONE

ALKALINE

CELL

4.7µF

NOTE: ALL DIODES 1N5818

CTX50-4

+5V

3mA

11k

487k

+10V

3mA

D1

D2

D3

220

Figure 35. 1.5 V to +5 V, +10 V Dual Output Step-Up

Converter

1.5 V-Powered Laser Diode Driver

Figure 36 shows a circuit suitable for driving many laser diodes

that incorporate a photodiode to monitor the laser diode

current, this circuit makes use of the gain block and current-

limit functions to provide a feedback system based on the

average laser diode current. This current must be controlled

very closely or permanent damage to the laser diode is likely to

be the result.

To ensure that the laser is operating at the proper power level,

the actual optical power from the laser should be monitored

with a calibrated photodiode or optical power meter. In

addition, the actual diode current should also be monitored, and

R1 can be adjusted to give the correct output power.

NOTES

1. All inductors referenced are Coiltronics CTX-series except

where noted.

2. If the source of power is more than an inch or so from the

converter, the input to the converter should be bypassed with

approximately 10

µ

F of capacitance. This capacitor should be

a good quality tantalum or aluminum electrolytic.

I

LIM

V

IN

SW1

SW2

FB

GND

SET

AO

ADP1110

6

7

8

1

2

4

5

3

10

1N4148

220

1.5V

5.1k

0.022µF

1k

2.2µH

1µF

2

1N5818

MJE210

TOSHIBA

TOLD-9321

100µF

OS-Con

2N3906

1k

Figure 36. 1.5 V-Powered Laser Diode Driver

ADP1110

≠15≠

REV. 0

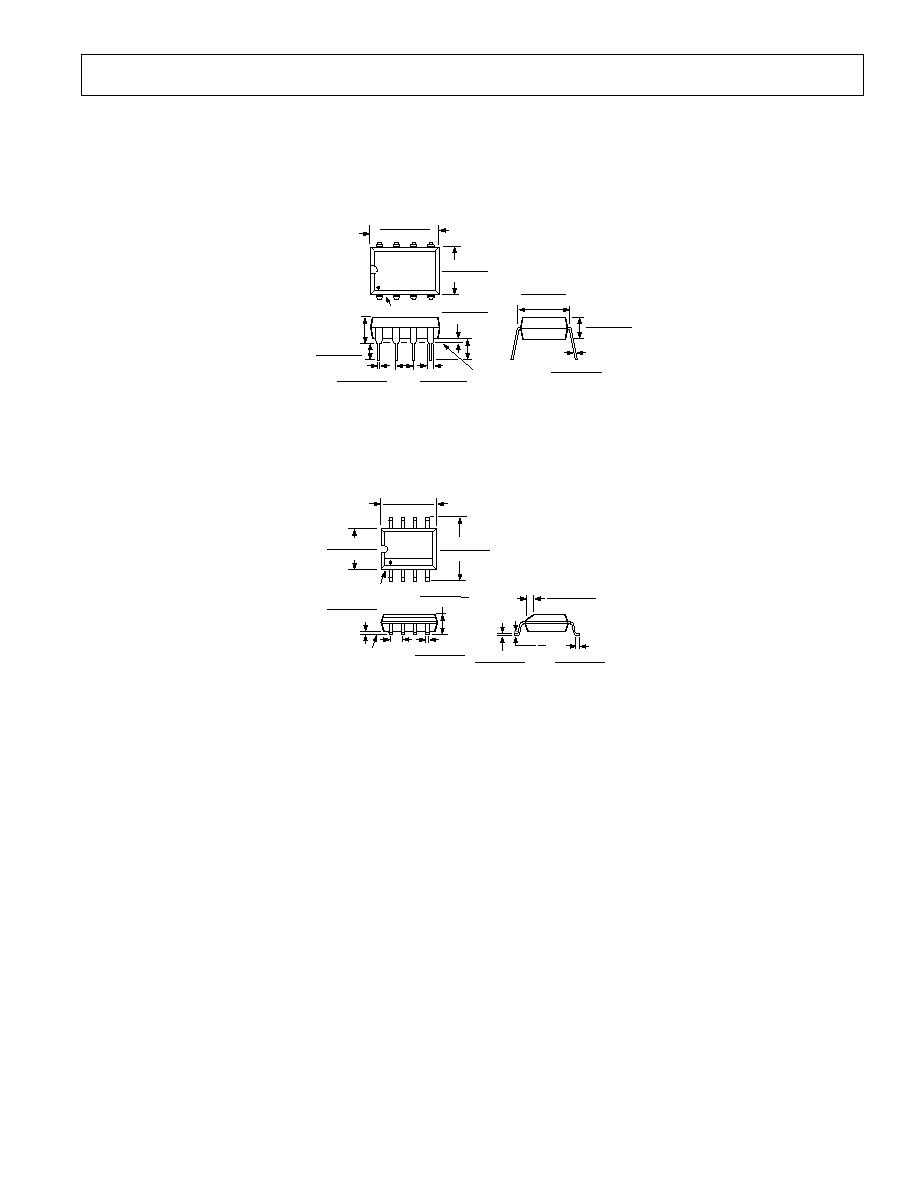

8-Lead Plastic DIP

(N-8)

8

1

4

5

0.430 (10.92)

0.348 (8.84)

0.280 (7.11)

0.240 (6.10)

PIN 1

SEATING

PLANE

0.022 (0.558)

0.014 (0.356)

0.060 (1.52)

0.015 (0.38)

0.210 (5.33)

MAX

0.130

(3.30)

MIN

0.070 (1.77)

0.045 (1.15)

0.100

(2.54)

BSC

0.160 (4.06)

0.115 (2.93)

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.195 (4.95)

0.115 (2.93)

8-Lead SOIC

(SO-8)

0.1968 (5.00)

0.1890 (4.80)

8

5

4

1

0.2440 (6.20)

0.2284 (5.80)

PIN 1

0.1574 (4.00)

0.1497 (3.80)

0.0688 (1.75)

0.0532 (1.35)

SEATING

PLANE

0.0098 (0.25)

0.0040 (0.10)

0.0192 (0.49)

0.0138 (0.35)

0.0500

(1.27)

BSC

0.0098 (0.25)

0.0075 (0.19)

0.0500 (1.27)

0.0160 (0.41)

8

∞

0

∞

0.0196 (0.50)

0.0099 (0.25)

x 45

∞

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

≠16≠

C2212≠12≠10/96

PRINTED IN U.S.A.