| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: HEDS-1500 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Features

∑ Focused Emitter and

Detector in a Single Package

∑ 655 nm Visible Emitter

∑ 0.178 mm (0.007) Resolution

∑ TO-5 Miniature Sealed

Package

∑ Photodiode Output

Description

The HEDS-1500 is a fully inte-

grated module designed for

applications requiring optical

reflective sensing. The module

contains a 655 nm visible LED

HEDS-1500

655 nm Precision Optical

Reflective Sensor

Technical Data

emitter and a matched I.C. photo-

detector. A bifurcated aspheric

lens is used to image the active

areas of the emitter and the

detector to a single spot 4.27 mm

(0.168 in.) in front of the pack-

age. The output signal is a current

generated by the photodiode.

Applications

Applications for the HEDS-1500

include bar code scanning,

pattern recognition and verifica-

tion, object sizing, optical limit

switching, tachometry, textile

thread counting and defect

detection, dimensional monitor-

ing, line locating, paper edge

detection, and any application

where precision optical reflective

sensing is desired.

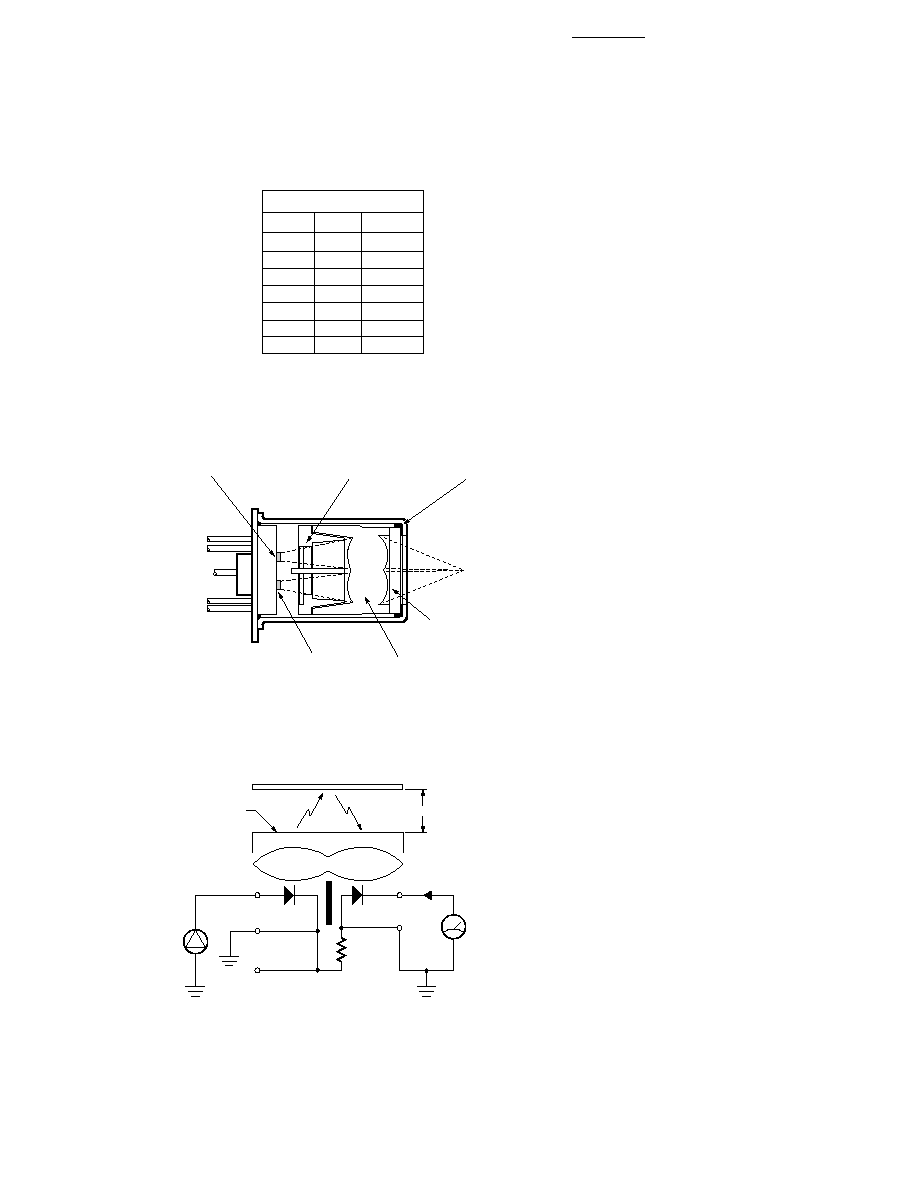

Mechanical

Considerations

The HEDS-1500 is packaged in a

high profile 8 pin TO-5 metal can

with a glass window. The emitter

and photodetector chips are

mounted on the header at the

base of the package. Positioned

above these active elements is a

CL

5.08

(0.200)

REFERENCE PLANE

MAXIMUM SIGNAL POINT

4.27 ± 0.25

(0.168 ± 0.010)

5.08

(0.200)

9.40 (0.370)

8.51 (0.335)

0.86 (0.034)

0.73 (0.029)

1.14 (0.045)

0.73 (0.029)

15.24 (0.600)

12.70 (0.500)

11.50 (0.453)

11.22 (0.442)

8.33 (0.328)

7.79 (0.307)

12.0

(0.473)

S.P.

R.P.

NOTES:

1. ALL DIMENSIONS IN MILLIMETERS AND (INCHES).

2. ALL UNTOLERANCED DIMENSIONS ARE FOR REFERENCE ONLY.

3. THE REFERENCE PLANE (R.P.) IS THE TOP SURFACE OF THE PACKAGE.

4. NICKEL CAN AND GOLD PLATED LEADS.

5. S.P. = SEATING PLANE.

6. THE LEAD DIAMETER IS 0.45 mm (0.018 IN.) TYP.

4.11

(0.162)

Package Dimensions

2

bifurcated aspheric acrylic lens

that focuses them to the same

point.

The sensors can be rigidly se-

cured by commercially available

two piece TO-5 style heat sinks,

such as Thermalloy 2205, Aavid

Engineering 321527, or 8 pin

0.200 inch diameter pin circle

sockets. These fixtures provide a

stable reference platform for

affixing the HEDS-1500 to a

circuit board.

In applications requiring contact

scanning, protective focusing tips

are available. Focusing tips are

available in either metal or poly-

carbonate packages using a

sapphire ball as the contact

surface. The Agilent part numbers

are HEDS-3001, HBCS-2999,

HBCS-4999, HBCS-A998, and

HBCS-A999.

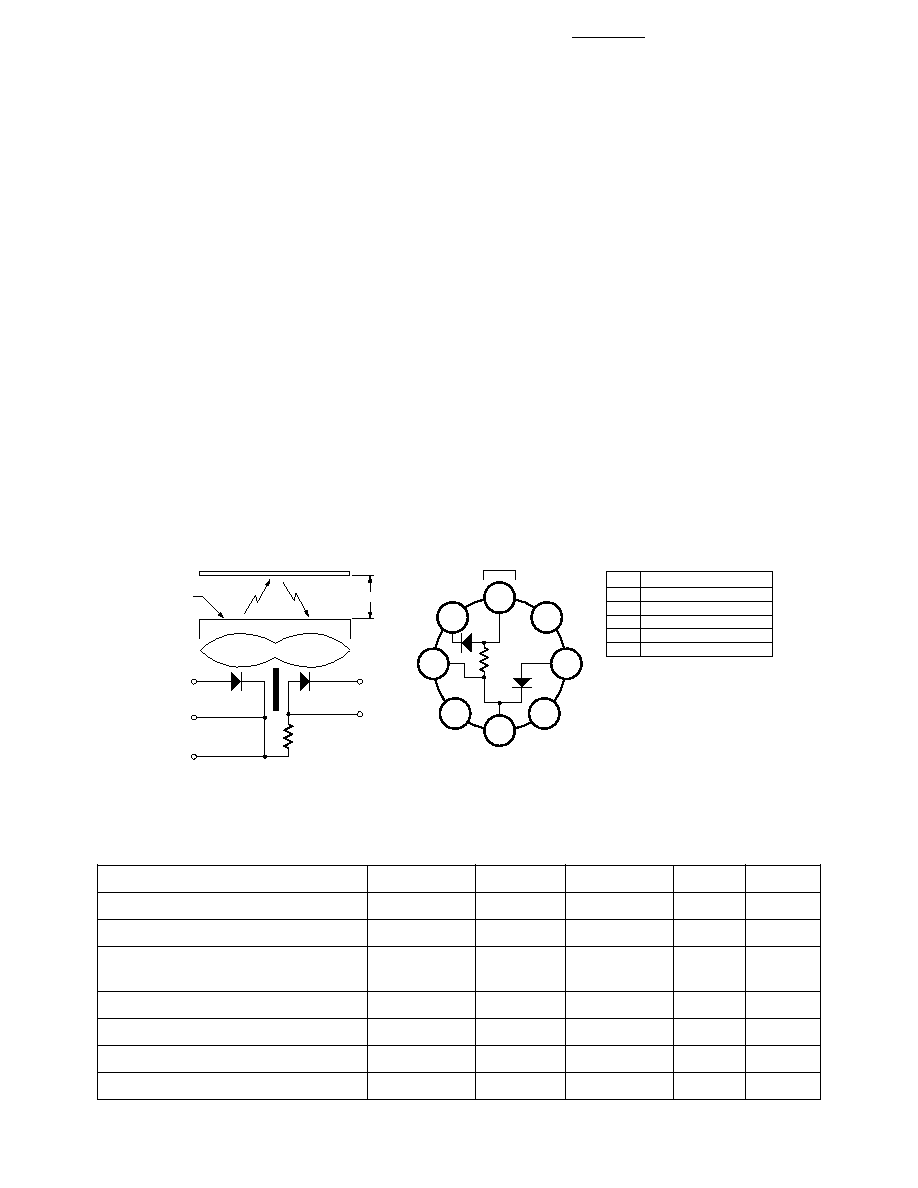

Electrical Operation

The detector of the sensor is a

single photodiode. Figure 7 shows

photocurrent being supplied from

the cathode of the photodiode to

an inverting input of the opera-

tional amplifier. The cathode of

the 655 nm emitter is physically

and electrically connected to the

case-substrate of the device.

Applications that require modula-

tion or switching of the LED

should be designed to have the

cathode connected to the electri-

cal ground of the system.

Applications where ambient light

is present will require a special

LED drive and recovery circuit to

achieve the full resolution of the

sensor. Application Note 1040

provides data and schematics to

support HEDS-1500 sensor oper-

ation in ambient light conditions.

A reliability data sheet is available

for the HEDS-1500 precision

optical reflective sensor.

Absolute Maximum Ratings @ T

A

= 25

∞

C

Parameter

Symbol

Min.

Max.

Units

Note

Operating Temperature

T

A

-20

70

∞

C

Storage Temperature

T

S

-40

75

∞

C

Lead Soldering Temperature

260

∞

C

1

for 10 sec.

Average LED Forward Current

I

f

50

mA

Peak LED Forward Current

I

fp

(data pending)

2

Reverse LED Input Voltage

V

r

5

V

Photodiode Bias (-V = forward bias)

V

d

-0.3

7

V

3

(See next page for Notes.)

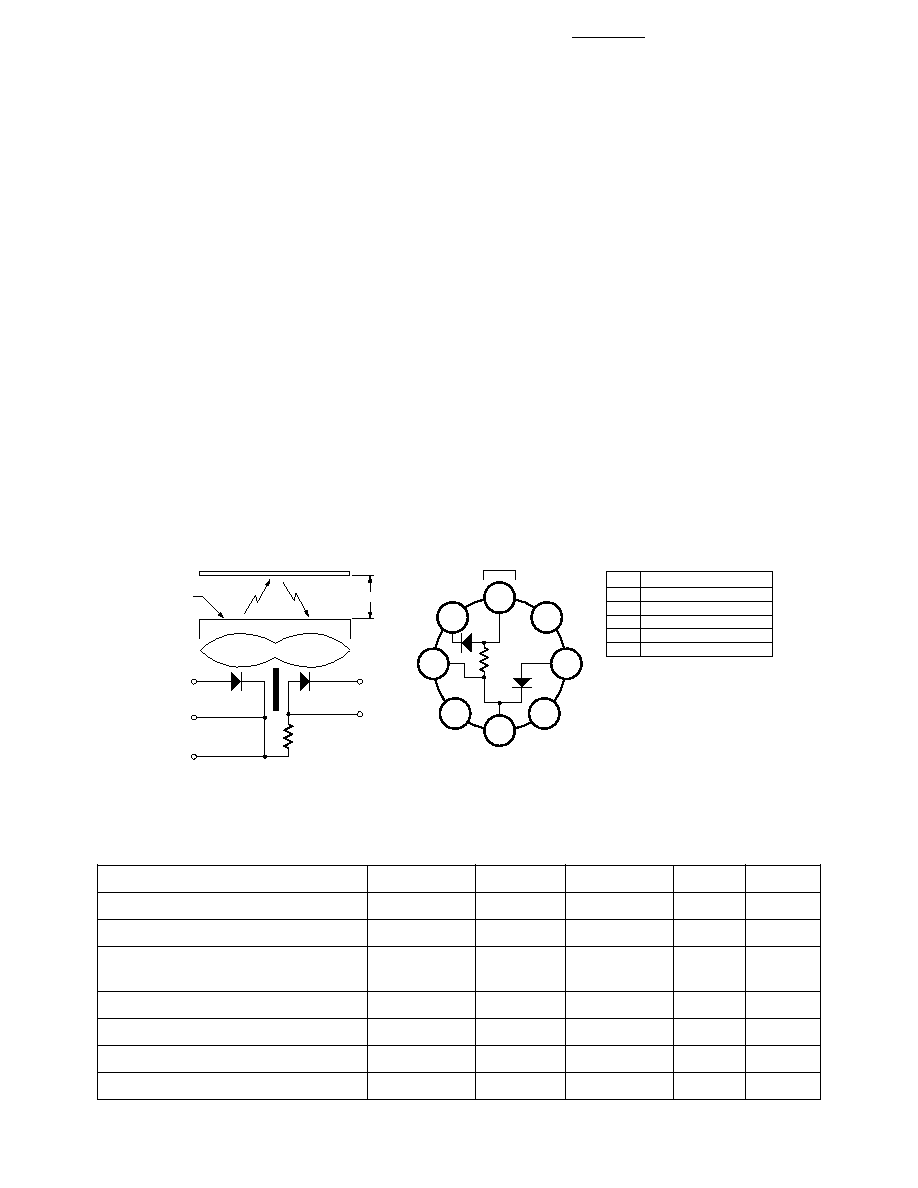

7

3

5

2

6

4

TOP VIEW

PIN #

FUNCTION

1

2

4

6

8

PHOTODIODE CATHODE

HEADER GROUND

**

LED ANODE

PHOTODIODE ANODE

**CUSTOMER SHOULD NOT CONNECT

GROUND TO PIN 4.

INTERNAL CONNECTION TO PIN 4

WILL BE DELETED IN THE FUTURE.

DPS

LED

SCHEMATIC DIAGRAM

CONNECTION DIAGRAM

1

8

REFERENCE

PLANE

REFLECTOR

6

CASE, SUBSTRATE

RS

DPS

1

8

LED

Z

2

4

RS ≠ CHARACTERISTIC NOT DEFINED

RS

3

Electrical/Optical Characteristics at T

A

= 25

∞

C

Parameter

Symbol

Min.

Typ.

Max.

Units

Conditions

Note

Figure

Reflected Photocurrent

I

pr

80

125

≠

nA

I

f

= 35 mA

4, 5, 11

1, 2, 4, 7

Quality Factor

<Q>

0.82

0.95

1.0

≠

I

f

= 35 mA

4, 6

Maximum Signal Point (MSP)

Z

4.01

4.27

4.52

mm

4, 7

4

(0.158) (0.168) (0.178)

(inch)

LED Forward Voltage

V

f

≠

1.72

1.86

V

I

f

= 35 mA

3

LED Reverse Breakdown Voltage

BVR

5.0

≠

≠

V

I

r

= 100

µ

A

Photodiode Dark Current

I

d

≠

50

1000

pA

V

d

= 5 V, I

f

= 0

8

LED Peak Wavelength

lambda

655

670

nm

I

f

= 35 mA

5

I

pr

Temperature Coefficient

K

e

-0.006

1/

∞

C

9

System Optical Step

d

0.154

mm

≠

10

8

Response Size (OSR)

(0.006)

(inch)

Notes:

1. CAUTION: The thermal constraints of the acrylic lens will not permit conventional wave soldering procedures. The typical preheat

and post-soldering cleaning procedures and dwell times can subject the lens to thermal stresses beyond the absolute maximum

ratings and can cause it to defocus.

2. (Reliability tests are proceeding--data not yet available.)

3. I

d

(max) = 100

µ

A. Recommended operation: V

d

(min) = 0 V V

d

(max) = 5 V Exceeding maximum conditions may cause permanent

damage to photodiode or to chip metallization.

4. Measured from a reflector coated with 99% diffuse reflective white paint (Kodak 6080) positioned 4.27 mm (0.168 in.) from the

reference plane. (See "Photocurrent Test Circuit" for test connection.) Measured physically is the total photocurrent, I

pt

, which

consists of a signal (reflected from target) component, I

pr

, and a component induced by reflection internal to the sensor (stray), I

ps

.

I

pt

= I

pr

+ I

ps

Specified is the reflected signal component, I

pr

.

5. See Bin Table.

6. <Q> = I

pr

/I

pt

.

7. Measured from the reference plane (R.P.) of the sensor.

8. Leakage current of photodiode measured in the dark.

9. Photocurrent variation with temperature varies with LED output which follows a natural exponential law:

I

p

(T) = I

p

(T

o

)*exp[K

e

(T-T

o

)].

10. OSR size is defined as the distance for a 10%-90% "step" response of I

pr

as the sensor moves over an abrupt step from opaque white

to black, or from opaque white to free space (no reflection).

11. Sensor contains no ambient light filtering--see Figure 6 for relative response of detector. In bright ambient light conditions, LED

signal may be a small portion of total signal. AC coupling and additional signal processing may be necessary. Reference Application

Note 1040.

4

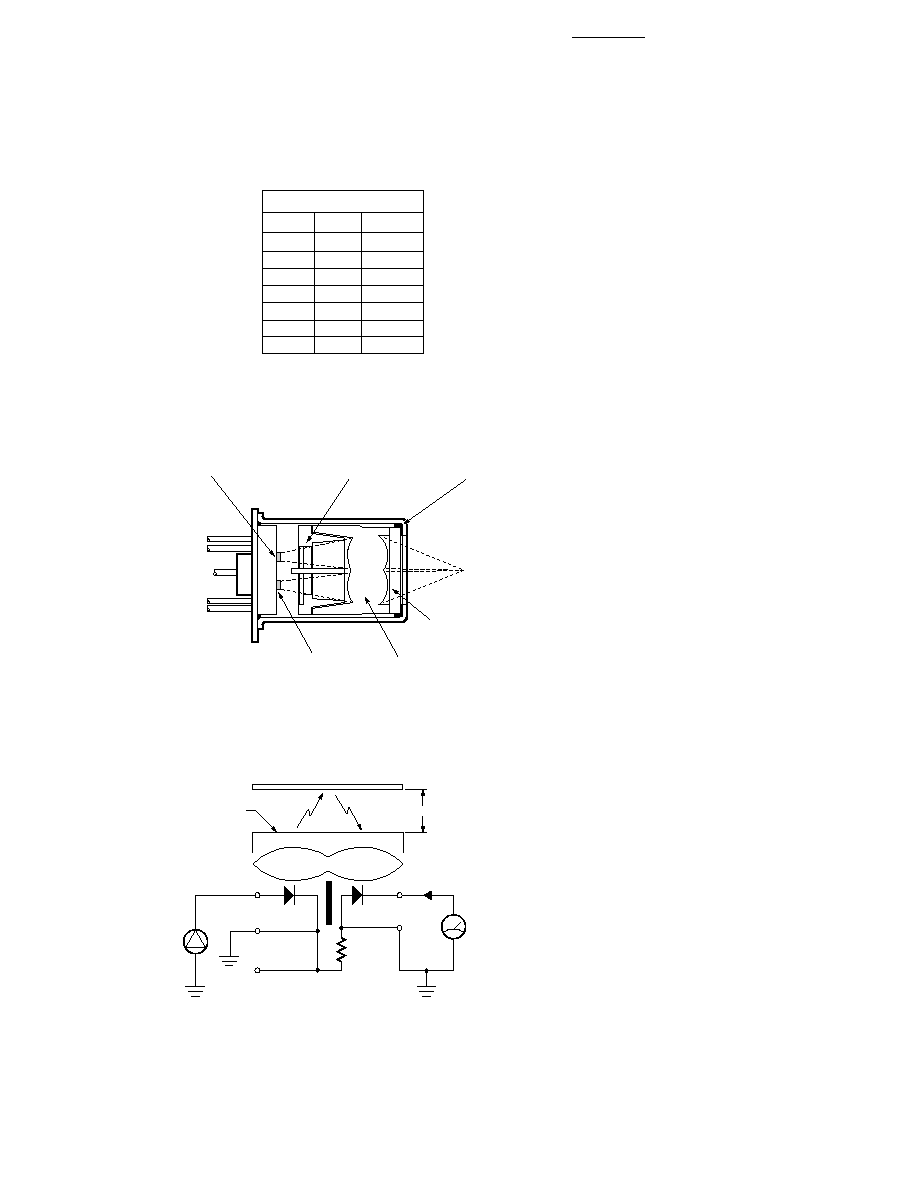

IPT

nA-METER

REFERENCE

PLANE

REFLECTOR

6

CASE, SUBSTRATE

RS

DPS

1

8

LED

Z

2

4

If

+Vf

BIN #

MIN.

1

2

3

4

5

6

7

I

pr

LIMITS

MAX.

80

105

125

150

180

215

270

110 nA

135

155

190

220

275

320

BIN TABLE

DETECTOR

0.406 mm SQUARE

BAFFLE

SENSING

AREA

EMITTER

0.185 mm DIA. JUNCTION

ACRYLIC

SEAL

LENS

GLASS

Figure 1. Photocurrent Test Circuit.

OPTICAL SYSTEM

Product Marking

The photocurrent binning of the

sensor is incorporated as part of

the date code format, assigned at

time of test--"CTYYWWan",

where:

C = letter identifying country of

assembly--S = Singapore

If blank = USA

T = tester code designation letter

(single letter)

YY = last two digits of year

WW = week number in year

a = single lot code letter (A - Z),

sequential assignment during

week

n = bin number

See Figure 7 for suggestion in the

application of photocurrent bins.

Test algorithm bins units to the

lowest bin number if a unit is in

the overlap region. Such units can

cross bin boundaries as tempera-

ture changes. (Ambient tempera-

ture affects LED efficiency

slightly and may cause several

percent change in I

pr

). Bin

numbers are for "reference only"

and do not constitute an absolute

guarantee.

The output of all LEDs degrade

with time, depending on drive

conditions and temperature.

The entire available distribution

of parts, appropriately marked,

will be shipped. Single bin orders

cannot be supplied.

5

PHOTOCURRENT NORMALIZED

AT I

F

= 35 mA, 25 ∞C

3.0

IF ≠ FORWARD CURRENT ≠ mA

30

0

0

100

10

50

70 80

0.5

1.5

2.0

2.5

20

40

60

90

1.0

V

F

≠ FORWARD VOLTAGE ≠ V

2.0

IF ≠ FORWARD CURRENT

1.5

1.0

1 µA

100 mA

1.7

1.1

10 mA

1.2

1.9

10 µA 100 µA 1 mA

1.4

1.6

1.8

1.3

PHOTOCURRENT NORMALIZED

TO PEAK @ MSP

1.0

DISTANCE FROM REFERENCE PLANE

OF SENSOR ≠ mm

0

3.0

5.0

0.2

3.5

4.0

4.5

0.4

0.6

0.8

5.5

6.0

MSP = 4.01 mm

SENSOR

MSP RANGE

MSP = 4.52 mm

LED LIGHT OUTPUT

(NORMALIZED TO 25 ∞C VALUE)

1.75

WAVELENGTH ≠ nm

0

595

715

655

0.25

615

635

0.75

1.25

1.50

675

695

1.00

0.50

-20 ∞C

NORMALIZED

0 ∞C

NORMALIZED

25 ∞C

NORMALIZED

70 ∞C

NORMALIZED

RESPONSE NORMALIZED TO PEAK

1.0

WAVELENGTH ≠ nm

0

550

900

0.2

650

0.4

0.6

0.8

800

600

700

750

850

Figure 2. Relative Reflected Photocurrent.

Figure 3. LED Forward Voltage vs. Forward Current.

Figure 4. Photocurrent Variation with Distance.

Figure 5. 655 nm Emitter Typical Spectral Distribution.

Figure 6. Relative Spectral Response of Sensor.