| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: EK01 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

APEX MICROTECHNOLOGY CORPORATION ∑ TELEPHONE (520) 690-8600 ∑ FAX (520) 888-3329 ∑ ORDERS (520) 690-8601 ∑ EMAIL prodlit@apexmicrotech.com

INTRODUCTION

This easy-to-use kit provides a platform for the evaluation of

PWM amplifiers using the SA01 pin-out configuration. It can be used

to analyze a multitude of standard or proprietary circuit configura-

tions, and is flexible enough to do most standard amplifier test

configurations. The board is designed for surface mounting all

components except the switching amplifier.

The schematic is shown in Figure 2. Note that all of the compo-

nents shown on the schematic will probably not be used for any

single circuit. Some components will simply be omitted, while others

require installation of a jumper to complete the signal path.

Only components unique to the EK01 are provided in this kit.

Hardware similar to that shown in figure 1 must be obtained locally.

The PC board and the foot print of the heatsink measure 3" by 5".

PARTS LIST

Part #

Description

Quantity

HS16

Heatsink

1

MS04

PC mount Cage Jacks

1 Bag/12 each

EK01PC

PC Board

1

60SPG00001

Spacer Grommets

4

ASSEMBLY

1. From the non-silk screen side, insert and solder cage jacks. Be

sure each one is fully seated.

2. From the non-silk screen side, push spacer grommets into PC

board until fully seated. Grommets will snug when screws are

inserted for heatsink mounting.

3. Apply TW10 thermal washer or a thin, even coat of thermal

grease to the bottom of the SA01. If grease is from a tube make

sure there is no sign separation of solids and liquids. If from a jar,

stir it prior to application.

4. Use #14 sleeving to insulate and align at least 2 opposite pins of

the amplifier.

5. Mount amplifier to heatsink using #6 screws and nuts. Do not

over torque.

6. Install components as needed. External connections may be

soldered directly or standard banana jacks may be soldered to

these pads.

7. Insert amplifier pins into cage jacks and fasten board to heatsink.

TW10

Thermal Washer

1 Box/10 each

BEFORE YOU GET STARTED

*

All Apex amplifiers should be handled using proper ESD precautions.

*

Always use the heatsink included in this kit with thermal grease.

*

Torque the part to the specified 8 to 10 in-lbs (.9 to 1.13 N*M)

*

Always use adequate power supply bypassing.

*

Do not change connections while the circuit is powered.

*

Initially set all power supplies to the minimum operating levels allowed in the device data sheet.

*

Check for oscillations.

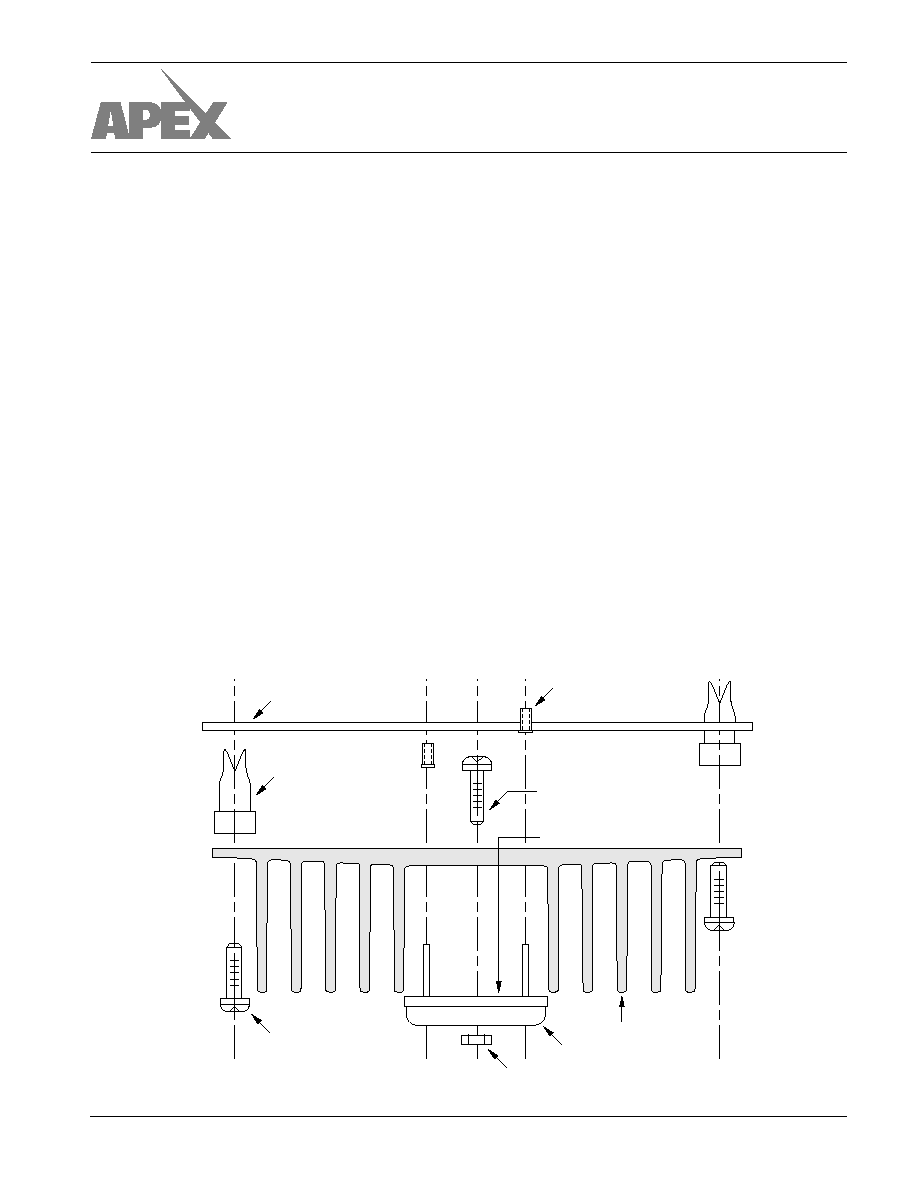

Heatsink

Switching Amplifier

Hex Nut 6-32 THD 1/4"

#8 or #10 Screw (1/2" - 3/4" LG)

Spacer Grommet

6-32 x 1/2 Lg. Screw

TW10 thermal washer or

thermal grease as required

PC Board (Silkscreen side)

FIGURE 1.

Cage Jack

Solder as required

H T T P : / / W W W . A P E X M I C R O T E C H . C O M ( 8 0 0 ) 5 4 6 - A P E X ( 8 0 0 ) 5 4 6 - 2 7 3 9

M I C R O T E C H N O L O G Y

EVALUATION KIT FOR SA01 PIN-OUT

EK01

APEX MICROTECHNOLOGY CORPORATION ∑ 5980 NORTH SHANNON ROAD ∑ TUCSON, ARIZONA 85741 ∑ USA ∑ APPLICATIONS HOTLINE: 1 (800) 546-2739

EVALUATION KIT

FOR SA01 PIN-OUT

EK01

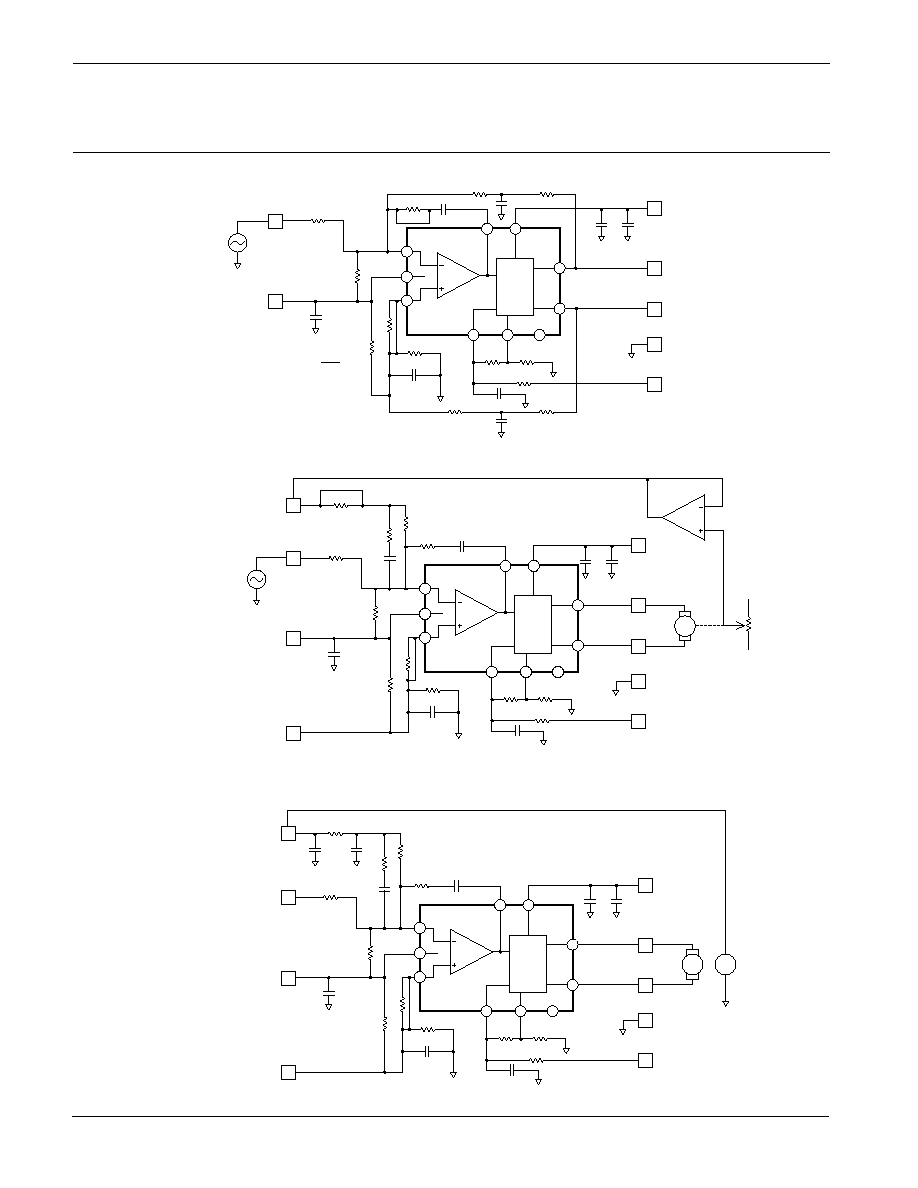

TYPICAL COMPONENT FUNCTIONS

R1 Provides -IN bias from the Reference voltage.

R2 Sets DC scaling for external feedback such as tachometers, position sensors or current sensors.

R3 With R4 sets DC operating point of +IN, with R13 and R15 sets gain of voltage feedback circuit.

R4 With R3 sets DC operating point of +IN.

R5 Input scaling of the control signal.

R6 With C6 sets the corner frequency of the integrator.

R7 With C3 & C4 forms a low pass filter for the external feedback loop. Often used with tachometers.

R8 With C2 forms a low pass filter for the current limit circuit.

R9 Current sense. Often is a piece of resistance wire.

R10 With R8 divides shutdown signal voltage feeding SHDN/FILTER pin.

R11 With C5 sets corner frequency for external feedback loop.

R12, 13, 15, 16 Provides voltage feedback for a voltage controlled output.

R14 Helps set gain or scale input voltage levels.

R17 With C12 provides low pass filtering of +IN signal.

C1 Power supply bypass.

C2 With R8 form a low pass filter for the current limit circuit, also filters the SHDN signal.

C3, 4 With R7 forms a low pass filter for the external feed back loop. Often used with tachometers.

C5 With R11 sets corner frequency for external feedback loop.

C6 With R6 sets the corner frequency of the integrator.

C7 Power supply bypass, must have very low ESR in MHz range.

C8 Filters reference or feedback voltage at +IN.

C9 Bypass for the reference voltage.

C10, 11 With R15 and R16 provides low pass filtering of voltage feedback.

C12 With R17 provides low pass filtering of +IN signal.

C13 Provides AC coupling of +IN signal.

D1 ≠ D4 Optional flyback diodes.

D5 ≠ D7 Input protection zener diodes.

FIGURE 2. PCB SCHEMATIC.

EA

PWM

+V

S

EA

OUT

≠IN

7.5V

REF

+IN

GND

SHDN/

FILTER

I

SENSE

A

OUT

B

OUT

SA01

1

5

2

3

7

6

9

4

8

10

+V

S

A

OUT

B

OUT

GND

C2

R13

R15

R16

C8

R4

R17

C9

C13

R14

R1

R5

C3

R7

C4

R11

C5

R2

R6

C6

C1

D4

C7

R12

R3

R8

R9

SHDN

SIG

TACH/

FEEDBACK

SIG

≠IN

REF

OUT

GND

+IN

R10

C10

C11

C12

D1

D5

D2

D6

D3

11V

D7

11V

11V

APEX MICROTECHNOLOGY CORPORATION ∑ TELEPHONE (520) 690-8600 ∑ FAX (520) 888-3329 ∑ ORDERS (520) 690-8601 ∑ EMAIL prodlit@apexmicrotech.com

EK01

EVALUATION KIT

FOR SA01 PIN-OUT

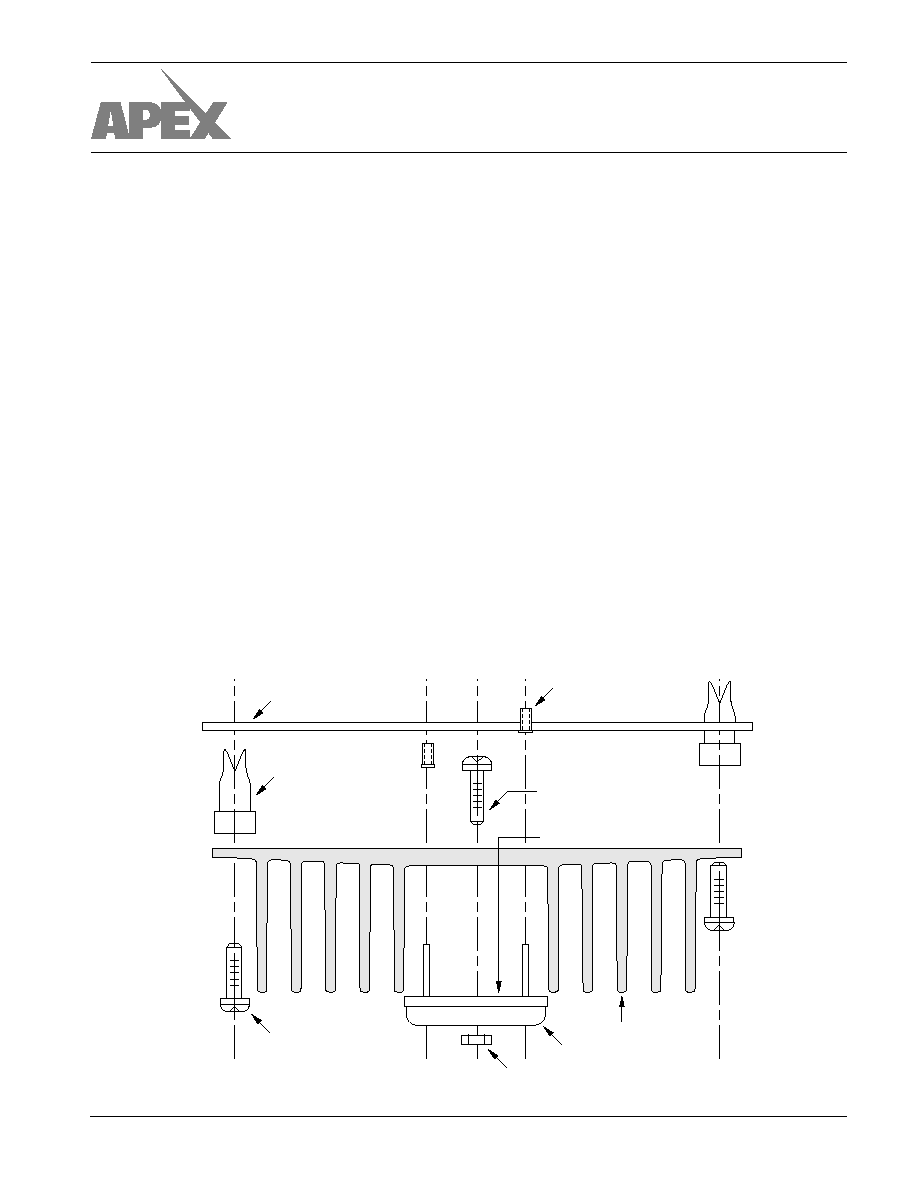

FIGURE 3. PCB FRONT.

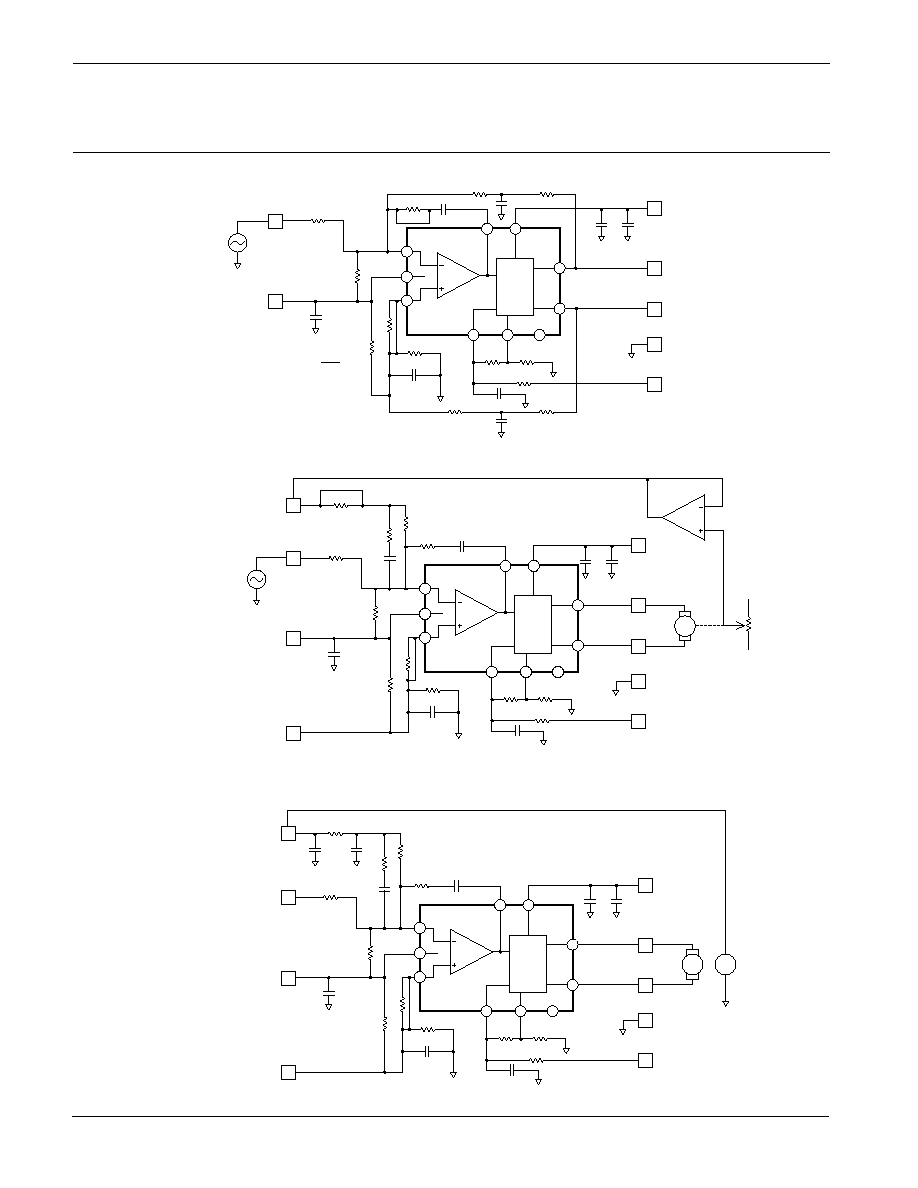

OPEN LOOP OPERATION

EA

PWM

+V

S

EA

OUT

≠IN

7.5V

REF

+IN

GND

SHDN/

FILTER

I

SENSE

A

OUT

B

OUT

SA01

1

5

2

3

7

6

9

4

8

10

+V

S

A

OUT

≠IN

+2.5/+7.5

B

OUT

GND

C2

R10

C9

R17

C12

C1

C6

R6

C7

R8

R9

SHDN

SIG

REF

OUT

V

IN

Duty Cycle @ A

OUT

2.5V 0%

5V 50%

7.5V 100%

V

IN

≠ 5

2.5

(A ≠ B) =

* V

S ≠

I

O

*

R

DSON

APEX MICROTECHNOLOGY CORPORATION ∑ 5980 NORTH SHANNON ROAD ∑ TUCSON, ARIZONA 85741 ∑ USA ∑ APPLICATIONS HOTLINE: 1 (800) 546-2739

EK01

COMMON

CONFIGURATIONS

EA

PWM

+V

S

EA

OUT

≠IN

7.5V

REF

+IN

GND

SHDN/

FILTER

I

SENSE

A

OUT

B

OUT

SA01

1

5

2

3

7

6

9

4

8

10

+V

S

A

OUT

B

OUT

GND

C2

R10

C8

R4

C9

R1

R17

R5

C3

R7

C4

R11

C5

R2

R6

C6

C1

C7

R3

R8

R9

SHDN

SIG

TACH/

FEEDBACK

SIG

REF

OUT

+IN

M

T

EA

PWM

+V

S

EA

OUT

≠IN

7.5V

REF

+IN

GND

SHDN/

FILTER

I

SENSE

A

OUT

B

OUT

SA01

1

5

2

3

7

6

9

4

8

10

+V

S

A

OUT

B

OUT

GND

C2

R10

C8

R4

C9

R1

R5

R7

R11

R17

C5

R2

R6

C6

C1

C7

R3

R8

R9

SHDN

SIG

TACH/

FEEDBACK

SIG

REF

OUT

+IN

+REF

≠REF

M

POSITION CONTROL

VOLTAGE CONTROL

SPEED CONTROL

EA

PWM

+V

S

EA

OUT

≠IN

7.5V

REF

+IN

GND

SHDN/

FILTER

I

SENSE

A

OUT

B

OUT

SA01

1

5

2

3

7

6

9

4

8

10

+V

S

A

OUT

B

OUT

GND

C2

R10

R13

C8

R4

C9

R1

R

O

R

O

R

I

R

F

R

F

R5

R17

R6

C6

C1

C7

R12

R3

R8

R9

SHDN

SIG

SIG

REF

OUT

R

F

R

I

(A ≠ B) = V

IN

*

R15

R16

C10

C11

This data sheet has been carefully checked and is believed to be reliable, however, no responsibility is assumed for possible inaccuracies or omissions. All specifications are subject to change without notice.

EK01U REV. C JANUARY 1998

© 1998 Apex Microtechnology Corp.