| –≠–Ľ–Ķ–ļ—ā—Ä–ĺ–Ĺ–Ĺ—č–Ļ –ļ–ĺ–ľ–Ņ–ĺ–Ĺ–Ķ–Ĺ—ā: MA7001 | –°–ļ–į—á–į—ā—Ć:  PDF PDF  ZIP ZIP |

MA7001

1/15

The MA7001 512 x 9 FIFO is manufactured using Dynex

Semiconductor's CMOS-SOS high performance, radiation

hard, 3

Ķ

m technology.

The Dynex Semiconductor Silicon-on-Sapphire process

provides significant advantages over bulk silicon substrate

technologies In addition to very good total dose hardness and

neutron hardness >10

15

n/cm

2

, the Dynex Semiconductor

technology provides very high transient gamma and single

event upset performance without compromising speed of

operation The Sapphire substrate also eliminates latch-up

giving greater flexibility of use in electrically severe

environments.

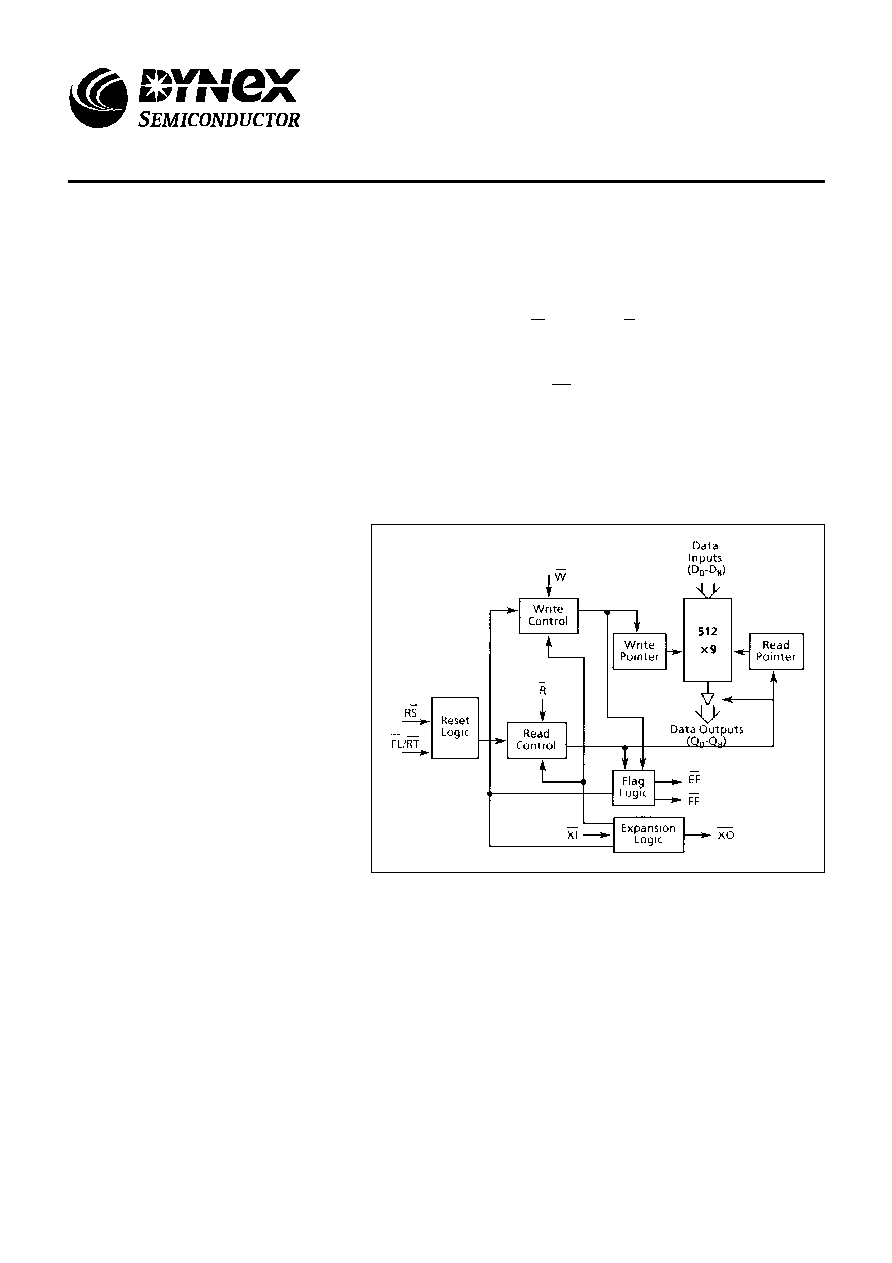

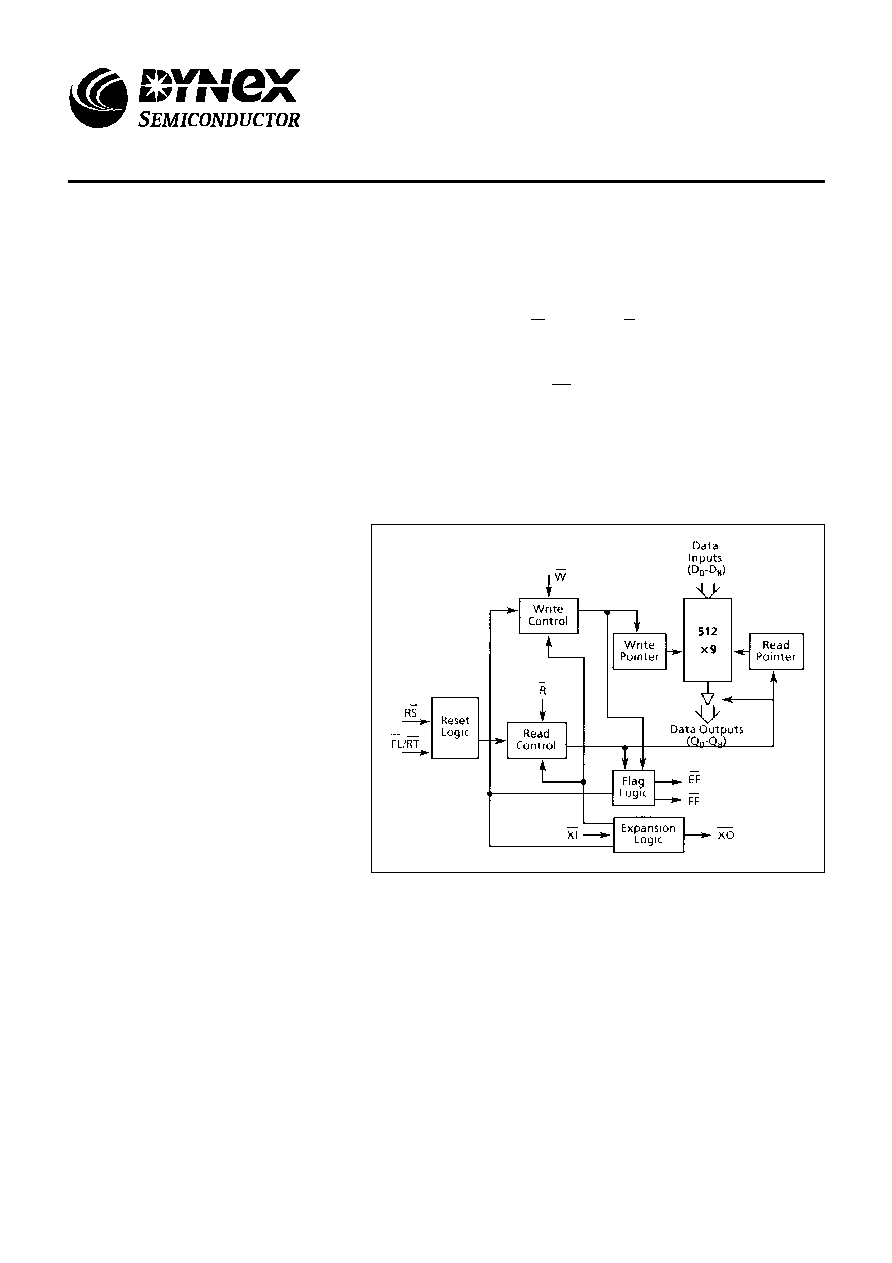

The MA7001 implements a First-ln First-Out algorithm that

reads and writes data on a first-in first-out basis. The dual-port

static RAM memory is organised as 512 words of 9 bits (8 bit

data and 1 bit for parity or control purposes).

Sequential read and write accesses are achieved using a

ring pointer architecture that requires no external addressing

information. Data is toggled in and out of the device by using

the WRITE (

W

) and READ (

R

) pins.

Full and Empty status flags prevent data overflow and

underflow. Expansion logic on the device allows for unlimited

expansion capability in both word size and depth. A

RETRANSMIT (

RT

) feature allows for reset of the read pointer

to its initial position to allow retransmission of data.

The device is designed for applications requiring

asynchronous and simultaneous read/write in multiprocessing

and rate buffering (sourcing and sinking data at different rates

eg. interfacing fast processors and slow peripherals).

FEATURES

s

Radiation Hard CMOS-SOS Technology

s

Fast Access Time 60ns Typical

s

Single 5V Supply

s

Inputs Fully TTL and CMOS Compatible

s

-55

į

C to +125

į

C Operation

Figure 1: Block Diagram

MA7001

Radiation Hard 512x9 Bit FIFO

Replaces June 1999 version, DS3519-4.0

DS3519-5.0 January 2000

MA7001

2/15

DC CHARACTERISTICS AND RATINGS

Symbol

Parameter

Min.

Max.

Units

V

DD

Supply Voltage

-0.5

7.0

V

V

IN

Input Voltage

-0.3

V

DD

+0.3

V

T

A

Operating Temperature

-55

125

į

C

T

S

Storage Temperature

-65

150

į

C

Stresses above those listed may cause permanent

damage to the device. This is a stress rating only and

functional operation of the device at these conditions, or at

any other condition above those indicated in the

operations section of this specification, is not Implied

Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

Figure 2: Absolute Maximum Ratings

The following D.C. and A.C. electrical characteristics apply to pre-radiation at T

A

= -55

į

C to +125

į

C, V

DD

= 5V

Ī

10% and post

100kRad(Si) total dose radiation at T

A

= 25

į

C, V

DD

= 5V

Ī

10%. GROUP A SUBGROUP 1, 2, 3.

Symbol

Parameter

Conditions

Min.

Typ.

Max.

Unit

V

IH

Input logic '1' voltage

-

2.0

-

-

V

V

IL

Input logic '0' voltage

-

-

-

0.8

V

I

IL

Input leakage current (any input) (Note 4)

Note 1

-10

-

10

Ķ

A

I

OL

Output leakage current (Note 4)

Note 2

-50

-

50

Ķ

A

V

OH

Output logic '1' voltage

l

OUT

= -1mA

2.4

-

-

V

V

OL

Output loglc '0' voltage

l

OUT

= 2mA

-

-

0.4

V

I

DD1

Average V

DD

power supply current (Note 3)

Freq = 10MHz

-

70

100

mA

I

DD2

Average standby current (Note 3)

R = W = RS = FL/RT

= V

DD

/2

-

8

15

mA

I

DD3(L)

Powerdown current (Note 3)

All Inputs = V

DD

-0.2V

-

-

3.0

mA

NOTES:

1. Measurements with V

SS

V

IN

V

DD

2.

R

> V

IH

, V

SS

V

OUT

V

DD

3. I

DD

measurements are made wlth outputs open, V

DD

= 5.5V

4. Guaranteed but not measured at -55

į

C

Figure 3a: DC Electrical Characteristics

MA7001

3/15

AC CHARACTERISTICS

Characteristics apply to pre-radiation at T

A

= -55

į

C to +125

į

C, V

DD

= 5V

Ī

10% and post

100kRad(Si) total dose radiation at T

A

= 25

į

C, V

DD

= 5V

Ī

10%. GROUP A SUBGROUP 9, 10, 11.

Symbol

Parameter

Min.

Max.

Units

t

RC

Read Cycle Time

110

-

ns

t

A

Access Time

-

100

ns

t

RR

Read Recovery Time

25

-

ns

t

RPW

Read Pulse Width (Note 2)

85

-

ns

t

RLZ

Read Pulse Low to Data Bus at Low Z (Note 3)

10

-

ns

t

DV

Data Valid from Read Pulse High

20

-

ns

t

RHZ

Read Pulse High to Data Bus at High Z (Note 3)

-

30

ns

t

WC

Write Cycle Time

100

-

ns

t

WPW

Write Pulse Width (Note 2)

80

-

ns

t

WR

Write Recovery Time

20

-

ns

t

DS

Data Setup Time

40

-

ns

t

DH

Data Hold Time

10

-

ns

t

RSC

Reset Cycle Time (Note 3)

100

-

ns

t

RS

Reset Pulse Width (Note 2)

80

-

ns

t

RSR

Reset Recovery Time (Note 3)

20

-

ns

t

RTC

Retransmit Cycle Time (Note 3)

100

-

ns

t

RT

Retransmit Pulse Width (Note 2)

80

-

ns

t

RTR

Retransmit Recovery Time (Note 3)

20

-

ns

t

EFL

Reset to Empty Flag Low

-

100

ns

t

REF

Read Low to Empty Flag Low

-

90

ns

t

RFF

Read High to Full Flag High

-

70

ns

t

WEF

Write High to Empty Flag High

-

70

ns

t

WFF

Write Low to Full Flag Low

-

90

ns

t

EFR

EF High to Valid Read (Note 3)

10

-

ns

t

RPI

Read Protect Indeterminant (Note 3)

-

35

ns

t

FFW

FF High to Valid Wrlte (Note 3)

10

-

ns

t

WPI

Write Protect Indeterminant (Note 3)

-

35

ns

Notes:

1. Timings referenced as in A.C. Test Conditions, figure 5

2. Pulse wldths less than minimum values are not allowed

3. Values guaranteed by deslgn, not currently tested

Figure 3b: AC Characteristics

MA7001

4/15

Symbol

Parameter

Conditions

FT

Functionality

V

DD

= 3-6V, FREQ = 100kHz - 9MHz

V

IL

= V

SS

, V

IH

= V

DD

, V

OL

1.5V, V

OH

1.5V

TEMP = -55 to +125

į

C, RADIATION 1MRAD TOTAL DOSE

GROUP A SUBGROUPS 7, 8A, 8B

Figure 3b: Functionality

Subgroup

Definition

1

Static characteristics specified in Table 3a at +25

į

C

2

Static characteristics specified in Table 3a at +125

į

C

3

Static characteristics specified in Table 3a at -55

į

C

7

Functional characteristics specified in Table 3c at +25

į

C

8A

Functional characteristics specified in Table 3c at +125

į

C

8B

Functional characteristics specified in Table 3c at -55

į

C

9

Switching characteristics specified in Table 3b at +25

į

C

10

Switching characteristics specified in Table 3b at +125

į

C

11

Switching characteristics specified in Table 3b at -55

į

C

Figure 4: Definition of Subgroups

MA7001

5/15

Input Pulse Levels

GND to 3.0V

Input Rise and Fall Times

5ns

Input Timing Reference Levels

1.5V

Output Reference Levels

1.5V

Output Load

See Figure 7

Figure 5: AC Test Conditions

Symbol

Parameter

Conditions

Max.

Unit

C

IN

Input Capacltance (Note 1)

V

IN

= 0V

7

pF

C

OUT

Output Capacitance (Notes 1 and 2)

V

OUT

= 0V

12

pF

NOTES:

1. Characterized values, not currently tested.

2. With output deselected.

Figure 6: Capacitance

TRUTH TABLES

Input

Output

Pointer

Operation

R

W

RS

RT

Xl

EF

FF

Data

Read

Write

Reset

1

1

0

x

0

0

1

Z

Zero

Zero

Retransmit*

1

1

1

0

0

1

1

Z

Zero

N/C

Read

1

0

x

1

1

0

1

1

valid

Increment

N/C

Read

x

x

1

1

0

0

1

Z

N/C

N/C

Write

x

1

0

1

1

0

x

1

x

N/C

Increment

Write

x

x

1

1

0

1

0

x

N/C

N/C

* Only available if less than 512 writes since last reset.

Figure 8: Single Device or Width Expansion: Read, Write, Reset and Retransmit

Input

Output

Pointer

Operation

R

W

RS

FL

Xl

EF

FF

Data

Read

Write

Reset First

1

1

0

0

1

0

1

Z

Zero

Zero

Reset Rest

1

1

0

1

1

0

1

Z

Zero

Zero

NOTES:

1. See Modes of Operation for connections of

Xl

and

XO

in depth expansion mode.

2.

XI

is connected to

XO

of previous device (Figure 12).

Figure 9: Depth Expansion: Reset and First Load

Output

under test

Test Point

LOAD 1

50pF*

Figure 7: Output Load

* Includes jig

and scope

capacitances

MA7001

6/15

SIGNAL DESCRIPTIONS

Reset (RS)

Reset occurs when

RS

is in a low state, setting both read and

write pointers to the first location in memory. Reset is required

prior to the first write. Both READ (

R

) and WRITE (

W

) signals

must be in high states during reset.

Read Enable (

R

):

Providing the EMPTY FLAG (

EF

) is not set, i.e. there is still

data to be read, a read cycle commences on the falling edge of

R, (see Figure 16). Data is read in a First-ln First-Out manner

independent of write operations. When reads are disabled

data outputs (Q0 - Q8) are in a high impedance state. Reading

the last available memory location sets the EMPTY FLAG

(

EF

), which is cleared following a write cycle.

Write Enable (

W

):

Providing the FULL FLAG (

FF

) is not set, i.e. there exists at

least one memory location for writing, a write cycle

commences on the falling edge of (

W

), (see Figure 17). Data is

written into consecutive memory locations independent of read

operations on the rising edge of W. Data set up and hold times

are with respect to the rising edge of

W

.

Expansion In (

Xl

):

There are two possible modes of operation for the FIFO. One

with

Xl

grounded in which the device is in singledevice mode,

the other is a depth expension mode or daisy chain

configuration. In the latter mode

Xl

inputs come from

EXPANSION OUT (

XO

) outputs of the device preceding it in

the chain.

Expansion Out (

XO

):

In depth expansion mode

XO

from one device signals the next

device in the chain that the last location in its memory has been

accessed.

Full Flag (

FF

):

FF

becomes active when the last available memory location

has been written to, (see Figure 18). In general, this occurs

whenever the write pointer coincides with the read pointer

following a write cycle. Writes are inhibited while

FF

is active,

and may only proceed after a read cycle has occured.

FF

will go high t

RFF

after completion of a valid READ operation.

FF

will go low t

WFF

from the beginning of a subsequent WRITE

operation, provided that a second READ has not been

completed. Writes beginning t

FFW

after

FF

goes high, are valid.

Writes beginning after

FF

goes low and ending more than t

WPI

before FF goes high, are invalid (ignored). Writes beginning

less than twpl before

FF

goes high and less than t

FFW

later,

may or may not occur (be valid) depending on the internal flag

status (see Figure 19).

If a Write to the last but one physical location completes while

the last location (511th) is being Read, the

FF

will not be

activated. The next Read should start after the last Write has

completed.

As a WRITE operation is being performed to the last physical

memory location (511th) whilst the READ pointer is waiting at

the 510th physical location the FULL flag is activated for a

duration less than 20ns.

Note: The last physical location (511th) is accessed after 511

WRITE or READ operations after RESET.

Empty Flag (

EF

):

Following an initial RESET

EF

is active, becoming inactive

after the first write cycle, (see Figure 20).

EF

becomes active

once the read and write pointers are coincident following a

read cycle. Reading will not take place whilst

EF

is active, and

may only proceed once a write cycle has occured.

EF

will go high t

WEF

after completion of a valid WRITE

operation.

EF

will again go low t

REF

from the beginning of a

subsequent READ operation, provided that a second WRITE

has not been completed. Reads beginning t

EFR

after

EF

goes

high, are valid. Reads begun after

EF

goes low and ending

more than t

RPI

before

EF

goes high, are invalid (ignored).

Reads beginning less than t

RIP

before

EF

goes high and less

than t

EFR

later, may or may not occur (be valid) depending on

the internal flag status (See Figure 21). If a Read to the last but

one physical location completes while the last location (511th)

is being written, the

EF

will not be activated. The next Read

should be activated after the last Write has completed.

First Load/Retransmit (

FL

/

RT

):

This is a dual purpose input depending on the mode of

operation of the device. In single device mode

Xl

= 0 data may

be retransmitted, i.e. it may be re-read. In depth expansion

mode

FL

signifies the first device in the chain. When

RT

is

pulsed low the read pointer is set to the first memory location.

The write pointer is unaffected. This feature is disabled in

depth expansion mode, and can only be applied when

R

and

W

are inactive (See Figure 22).

Data Inputs (D0 - D8): Data inputs, 9 bit word, for write

operations.

Data Outputs (Q0 - Q8):

Data outputs, 9 bit word, for read operations. When

R

is

inactive these outputs are in a high impedance state.

MA7001

7/15

MODES OF OPERATION

Single Device Mode:

The single device mode is used with

Xl

grounded. (See Figure

10). In this mode the retransmit facility may be used to re-read

the data when less than 512 have been performed between

resets.

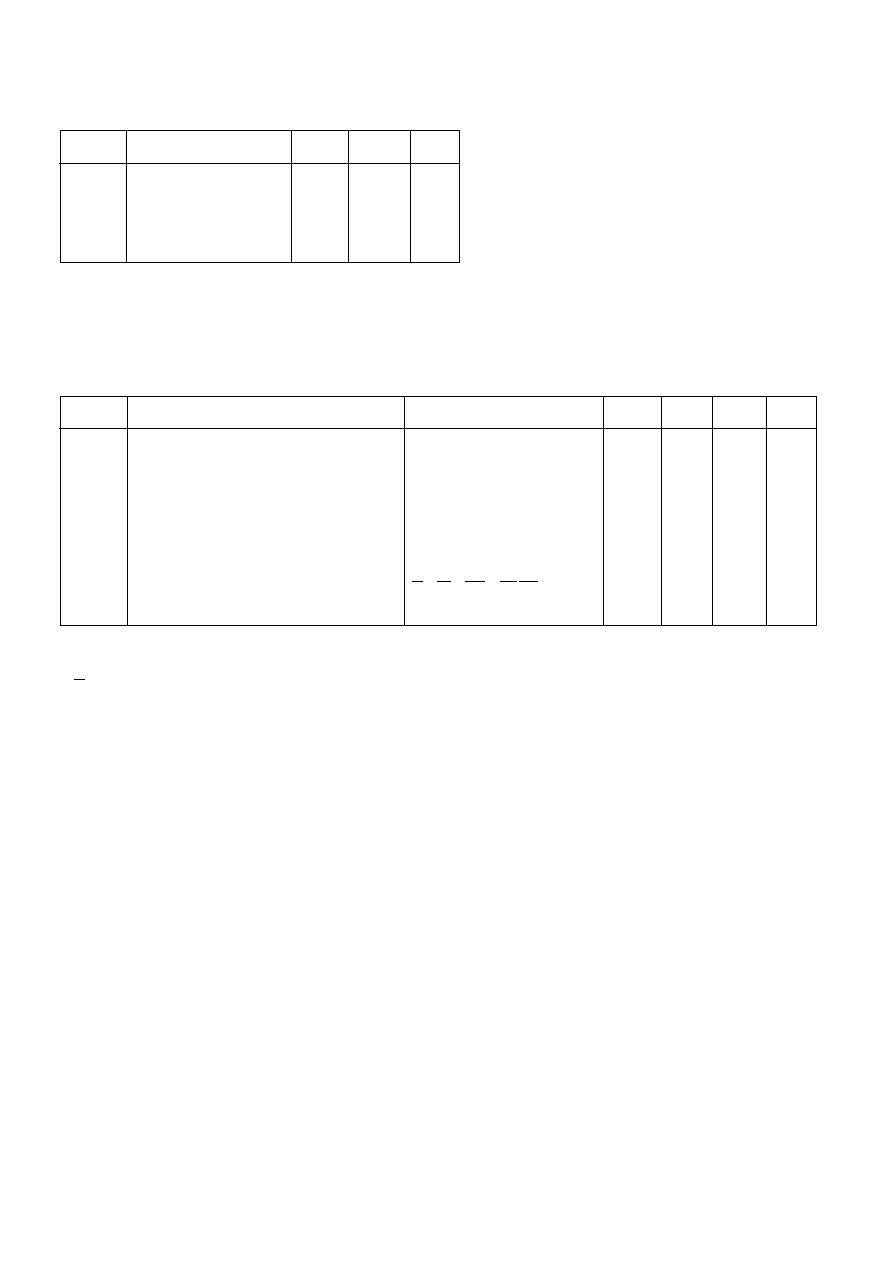

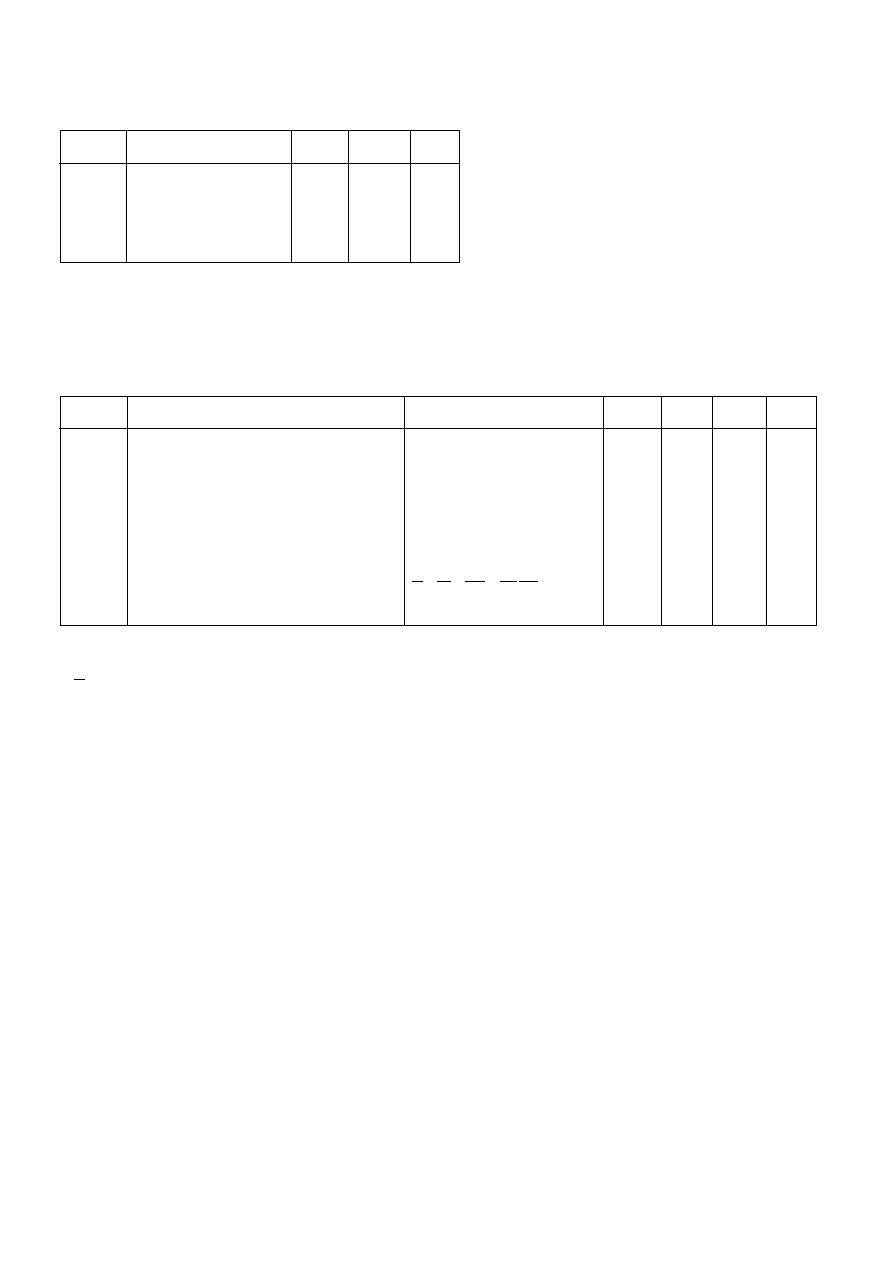

Width Expansion Mode:

In this mode two or more devices are used, depending on the

word length required, with the same control inputs applied to

each. The same operations are applied to all devices, thus

warning flags

EF

and

FF

are available from any or all of the

devices. Output Signals from devices in this mode should not

be merged. Figure 11 illustrates two devices configured in

width expansion mode to give an 18 bitword, (512 x 18).

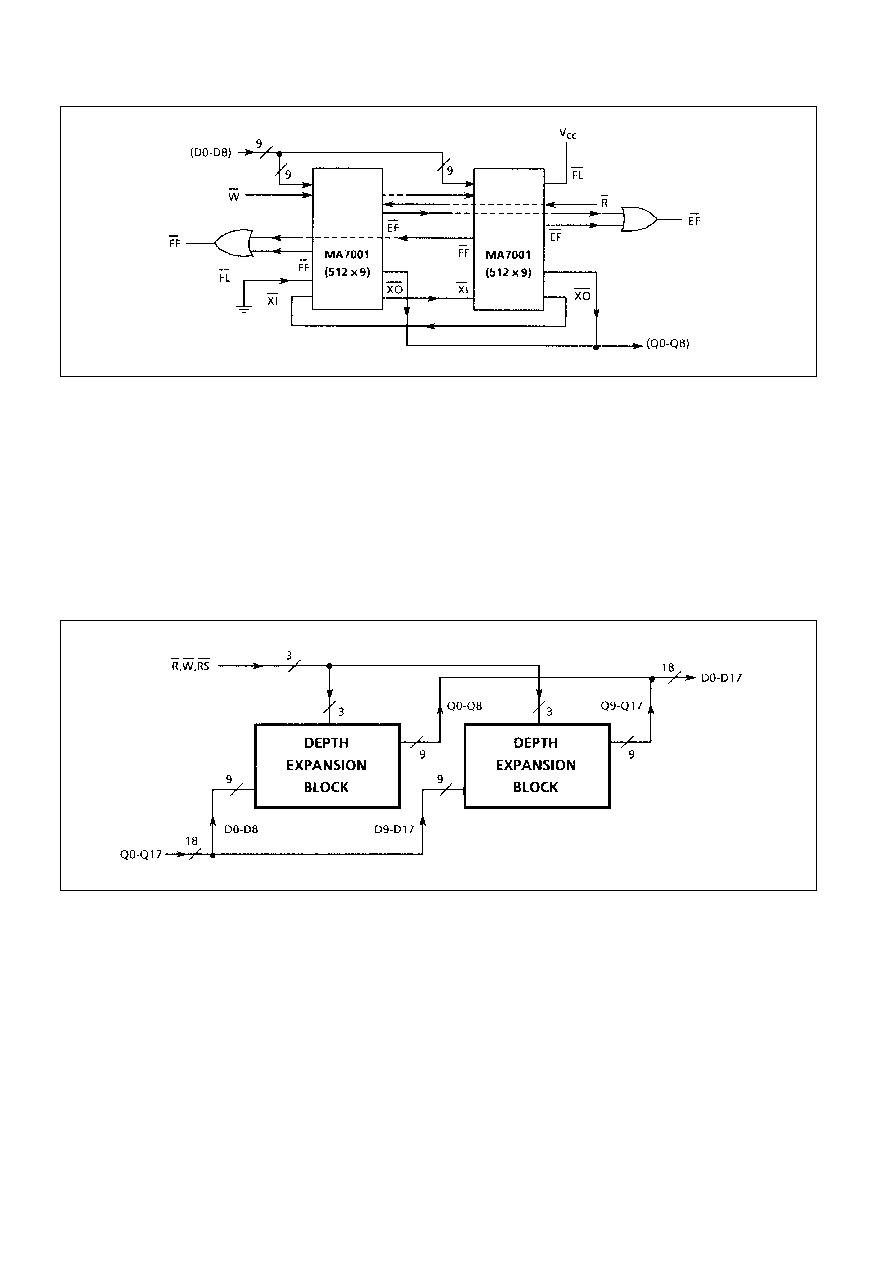

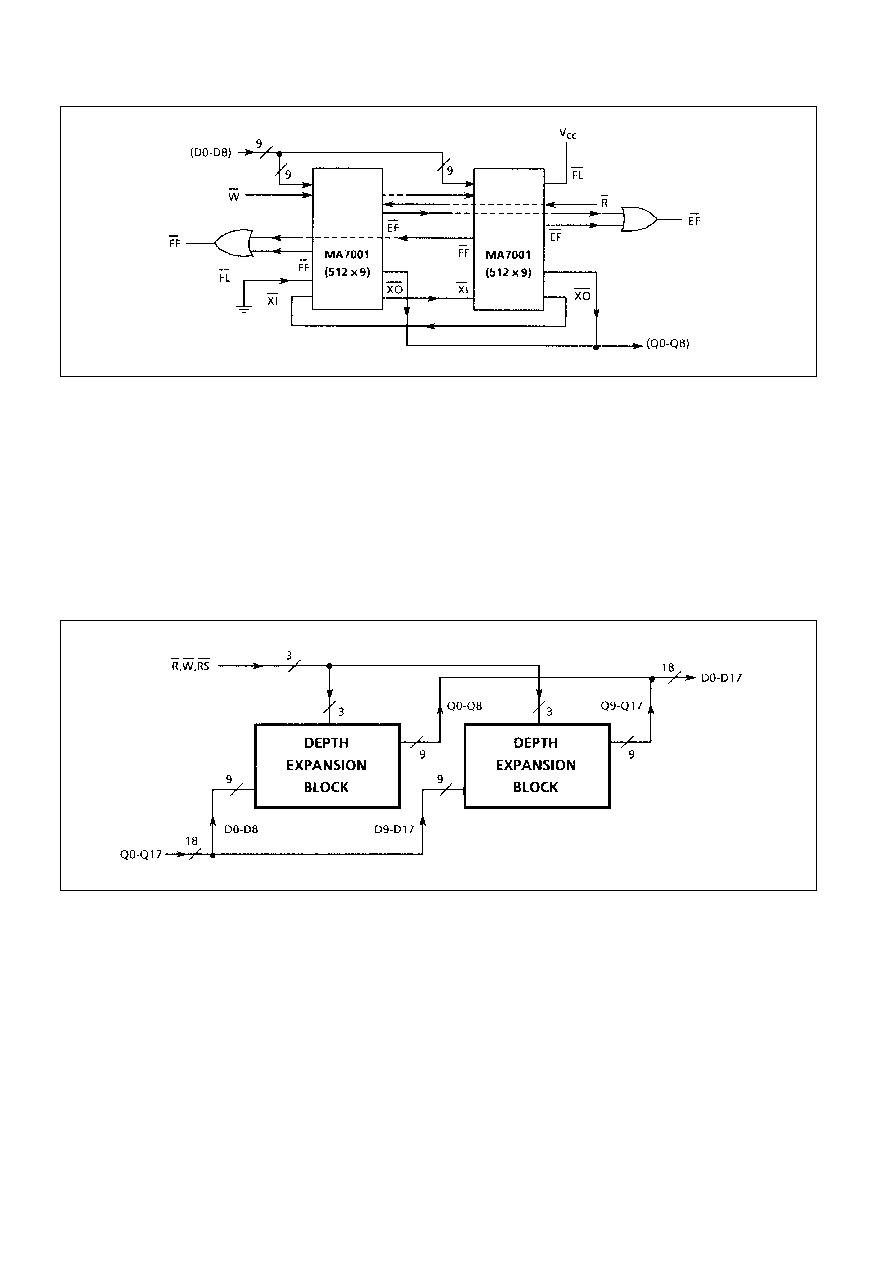

Depth Expansion Mode:

This has applications where more than 512 words are

required. The RETRANSMIT facility is not available in this

mode.

Two or more devices are organised in a daisy chain. The first

device in the chain has

FL

grounded, all others have

FL

in high

states.

XO

of each device is connected to

XI

of the next device

in the chain.

The same read, write and reset signals are applied to each

device. External logic is required to form new empty and full

flags, i.e. all

EF

's are ORed together and all

FF

's are ORed

together to form new empty and full flags respectively.

Figure 12 illustrates depth expansion of 2 devices (1024 x 9).

Figure 10: Single Device Mode (512 x 9 bits)

Figure 11: Width Expansion Mode (512 x 18 bits)

MA7001

8/15

Figure 12: Depth Expansion Mode (1024 x 9 bits)

Compound Expansion Mode:

Both width and depth expansion can be implemented into the

same expansion block. Note that no control signals are in

conflict in either of the two expansion modes, i.e. width or

depth expansion modes. Utilising compound expansion large

FIFO arrays are possible. Figure 13 illustrates the use of

compound expansion.

Bidirectional Mode:

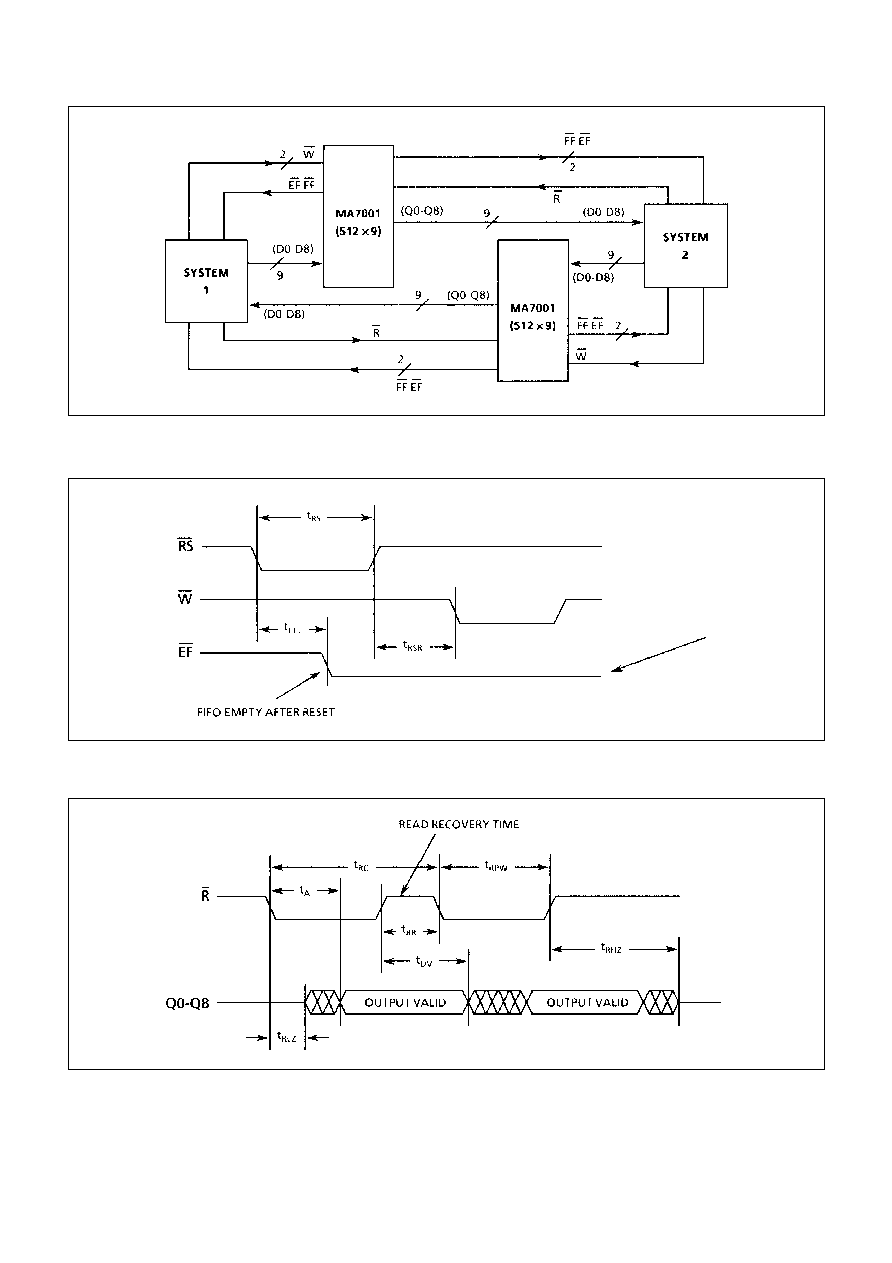

The FIFO is a unidirectional device, i.e. one system reads,

another writes. In cases where full communication is required

between two or more systems, two or more groups of devices

can be used. These groups can utilise any or all of the

expansion modes already mentioned. Figure 14 illustrates 2

systems connected so that each can transmit data to and

recieve data from each other, (see Modes of Operation for

connection of control and data signals).

Figure 13: Compound Expansion

MA7001

9/15

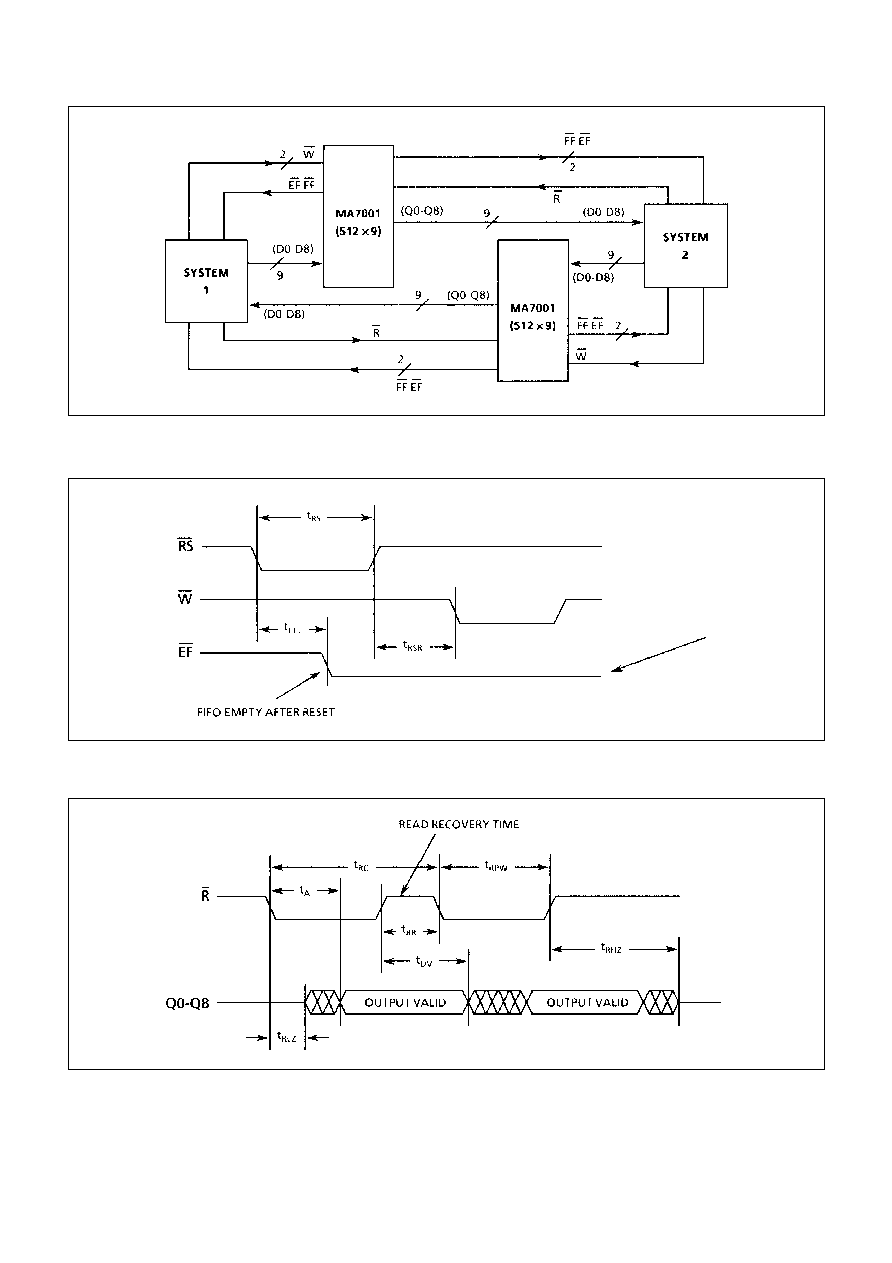

Figure 14: Bidirectional Mode (512 x 9 bits each way)

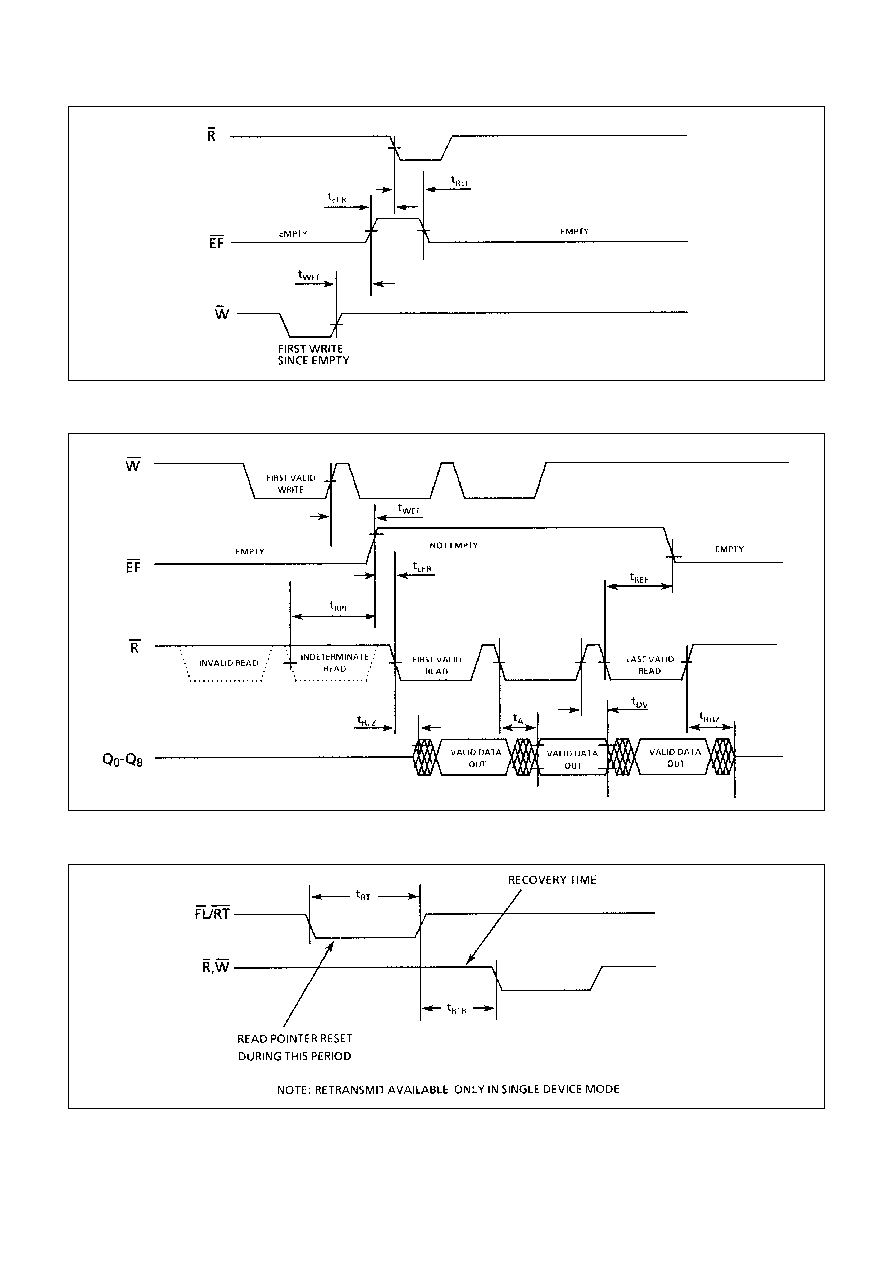

Figure 15: Reset

Figure 16: Asynchronous Read

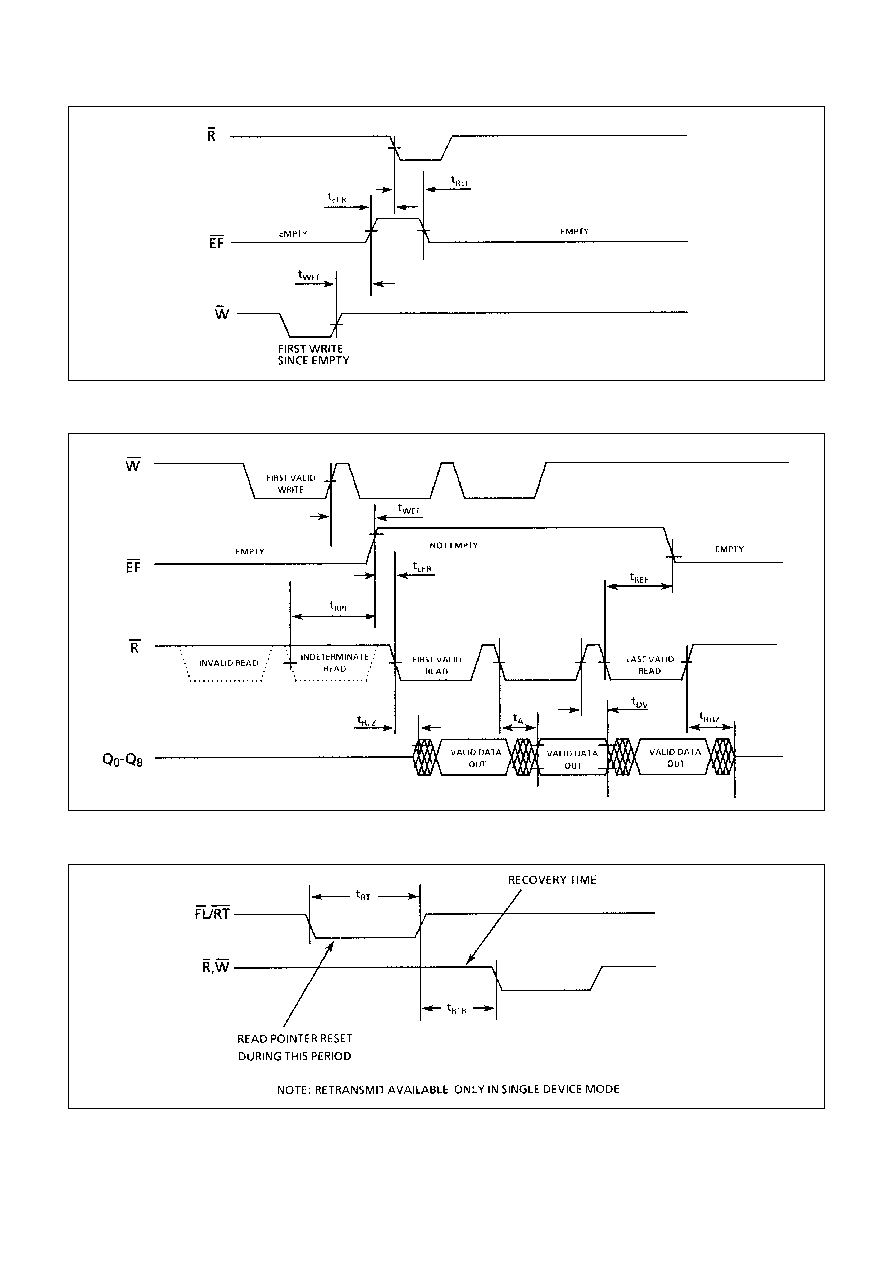

EMPTY FLAG

GOES 'HIGH'

AFTER WRITE

(See Figure 20)

MA7001

10/15

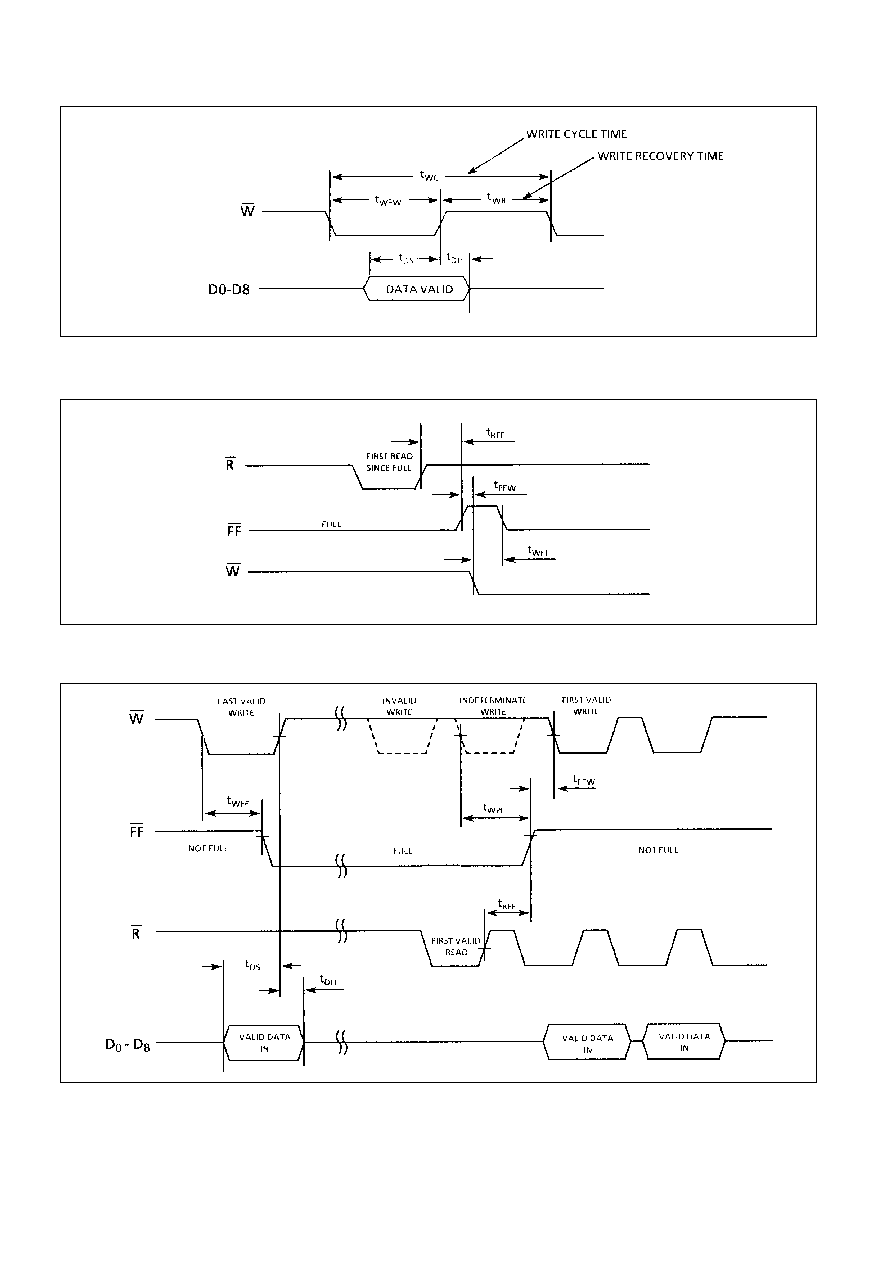

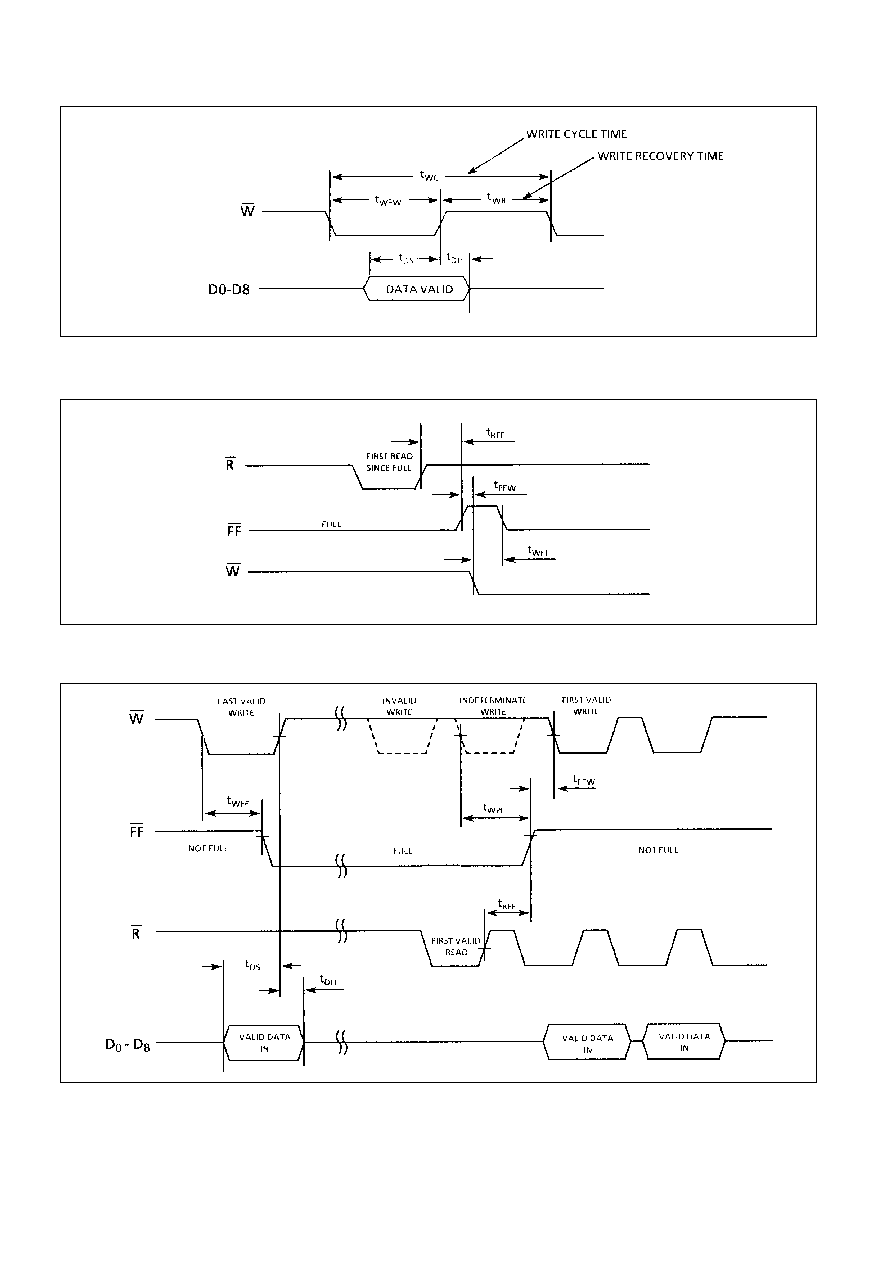

Figure 17: Asynchronous Write

Figure 18: Read/Write to Full Flag

Figure 19: Write and Full Flag

MA7001

11/15

Figure 20: Write/Read to Empty Flag

Figure 21: Read and Empty Flag

Figure 22: Retransmit Timing

MA7001

12/15

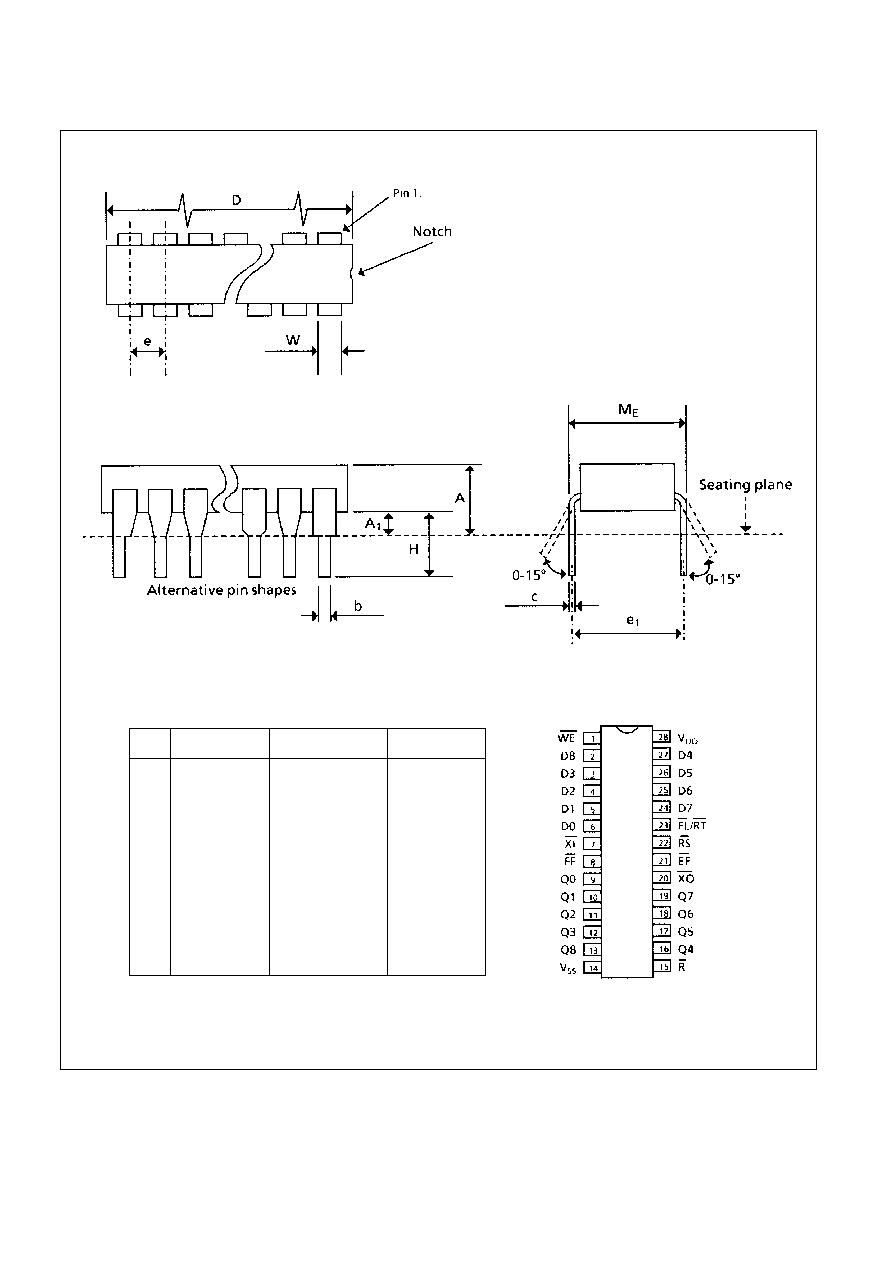

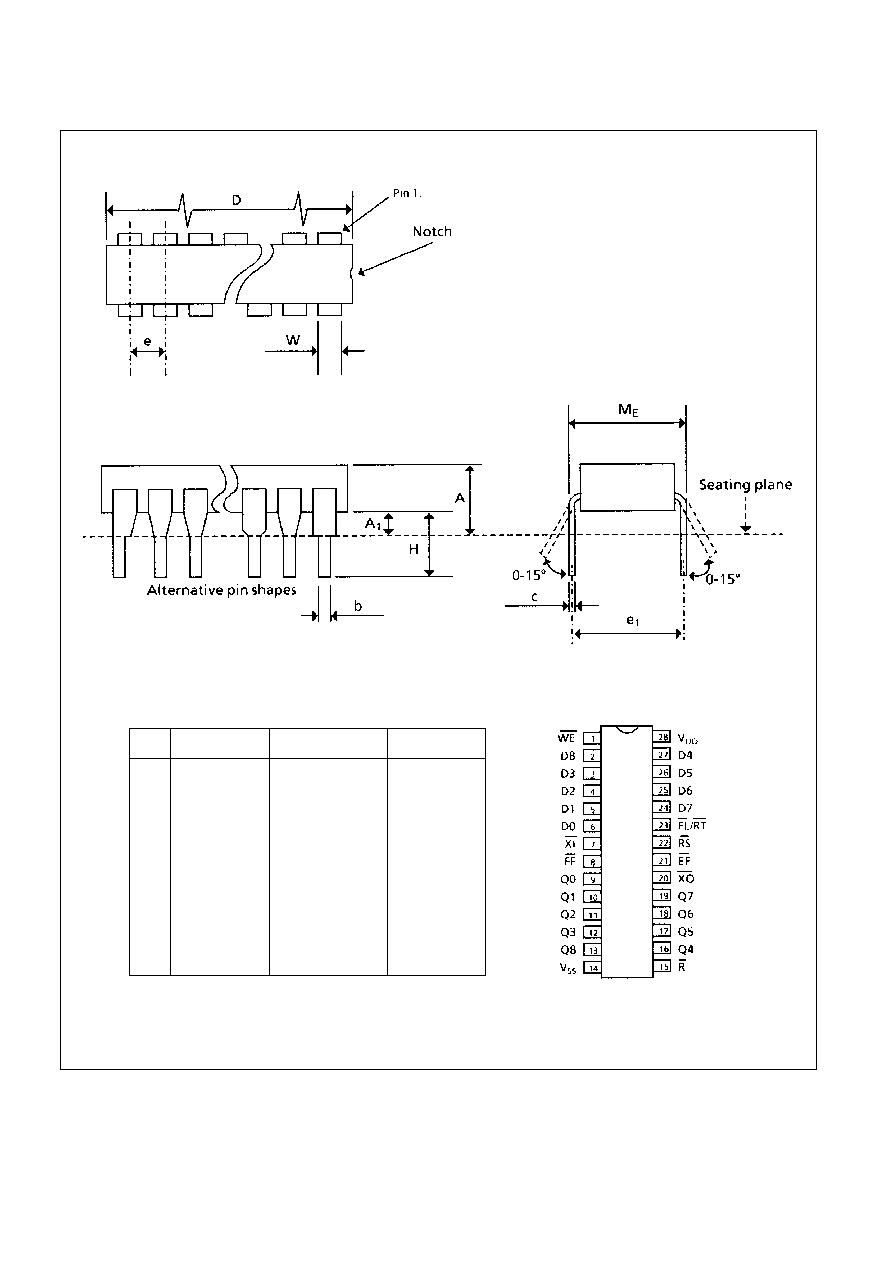

OUTLINES AND PIN ASSIGNMENTS

Figure 23: 28 Lead Ceramic DIL (Solder Seal) - Package Style C

Ref.

Min.

Nom.

Max.

A

-

-

5.71 (0.225)

A

1

0.38 (0.015)

-

1.53 (0.060)

b

0.35 (0.014)

-

0.59 (0.023)

c

0.20 (0.008)

-

0.36 (0.014)

D

-

-

36.02 (1.418)

e

-

2.54 (0.100) typ.

-

e

1

-

15.24 (0.600) typ.

-

H

4.71 (0.185)

-

5.38 (0.212)

M

E

-

-

15.90 (0.626)

W

-

-

1.53 (0.060)

Dimensions in mm (inches)

MA7001

13/15

Figure 24: 28 Lead Ceramic Flatpack (Solder Seal) - Package Style F

Ref.

Min.

Nom.

Max.

A

-

-

2.97 (0.117)

A

1

(0.026)

-

-

b

(0.015)

-

0.48 (0.019)

c

0.10 (0.003)

-

0.15 (0.006)

D

18.08 (0.712)

-

18.49 (0.728)

e

-

1.27 (0.050) typ.

-

L

(0.315)

-

(0.365)

M

12.50 (0.492)

-

12.09 (0.508)

M1

(0.372)

-

(0.388)

Dimensions in mm (inches)

MA7001

14/15

RADIATION TOLERANCE

Total Dose Radiation Testing

For product procured to guaranteed total dose radiation

levels, each wafer lot will be approved when all sample

devices from each lot pass the total dose radiation test.

The sample devices will be subjected to the total dose

radiation level (Cobalt-60 Source), defined by the ordering

code, and must continue to meet the electrical parameters

specified in the data sheet. Electrical tests, pre and post

irradiation, will be read and recorded.

GEC Plessey Semiconductors can provide radiation

testing compliant with MIL-STD-883 test method 1019,

Ionizing Radiation (Total Dose).

Total Dose (Function to specification)*

1x10

5

Rad(Si)

Transient Upset (Stored data loss)

5x10

10

Rad(Si)/sec

Transient Upset (Survivability)

>1x10

12

Rad(Si)/sec

Neutron Hardness (Function to specification)

>1x10

15

n/cm

2

Single Event Upset**

3.4x10

-9

Errors/bit day

Latch Up

Not possible

* Other total dose radiation levels available on request

** Worst case galactic cosmic ray upset - interplanetary/high altitude orbit

Figure 25: Radiation Hardness Parameters

MA7001

15/15

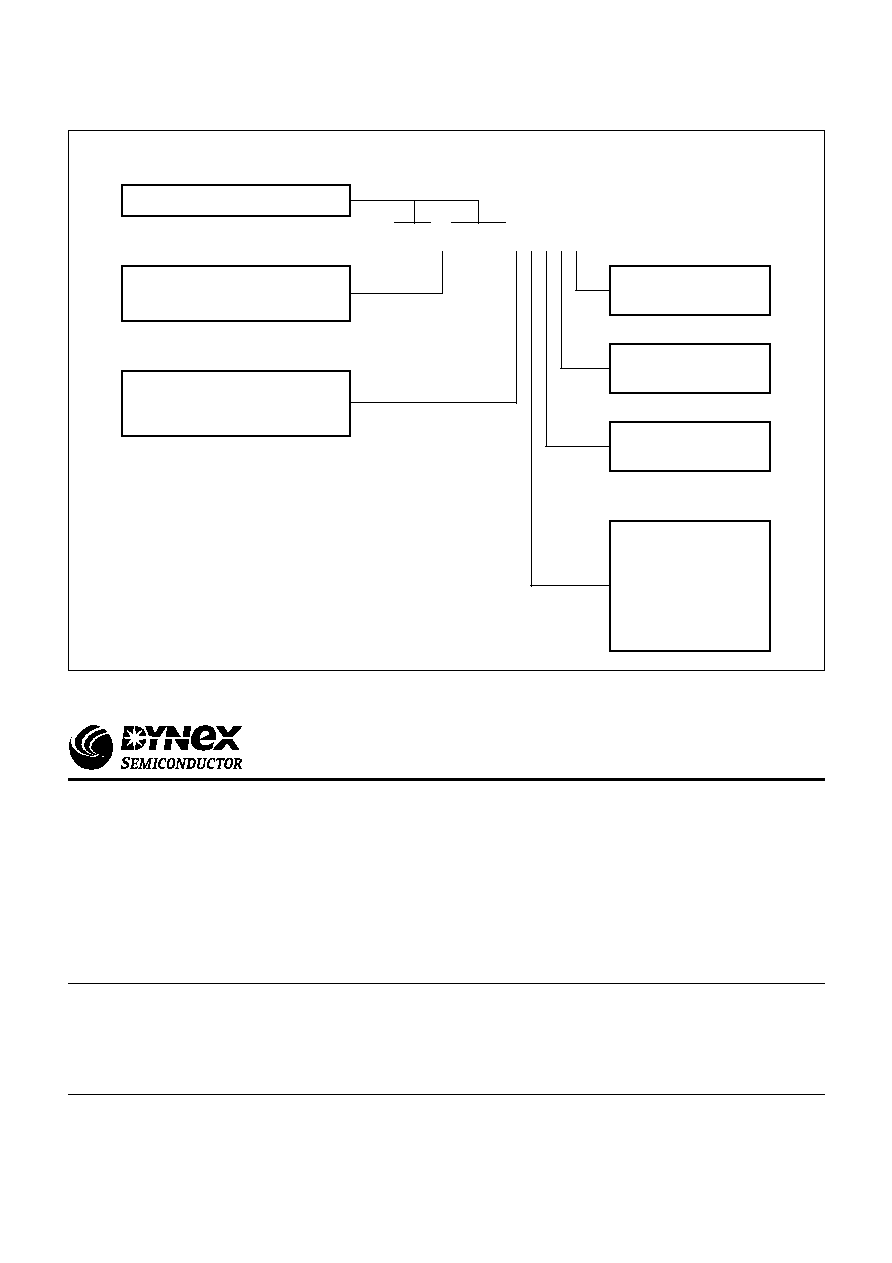

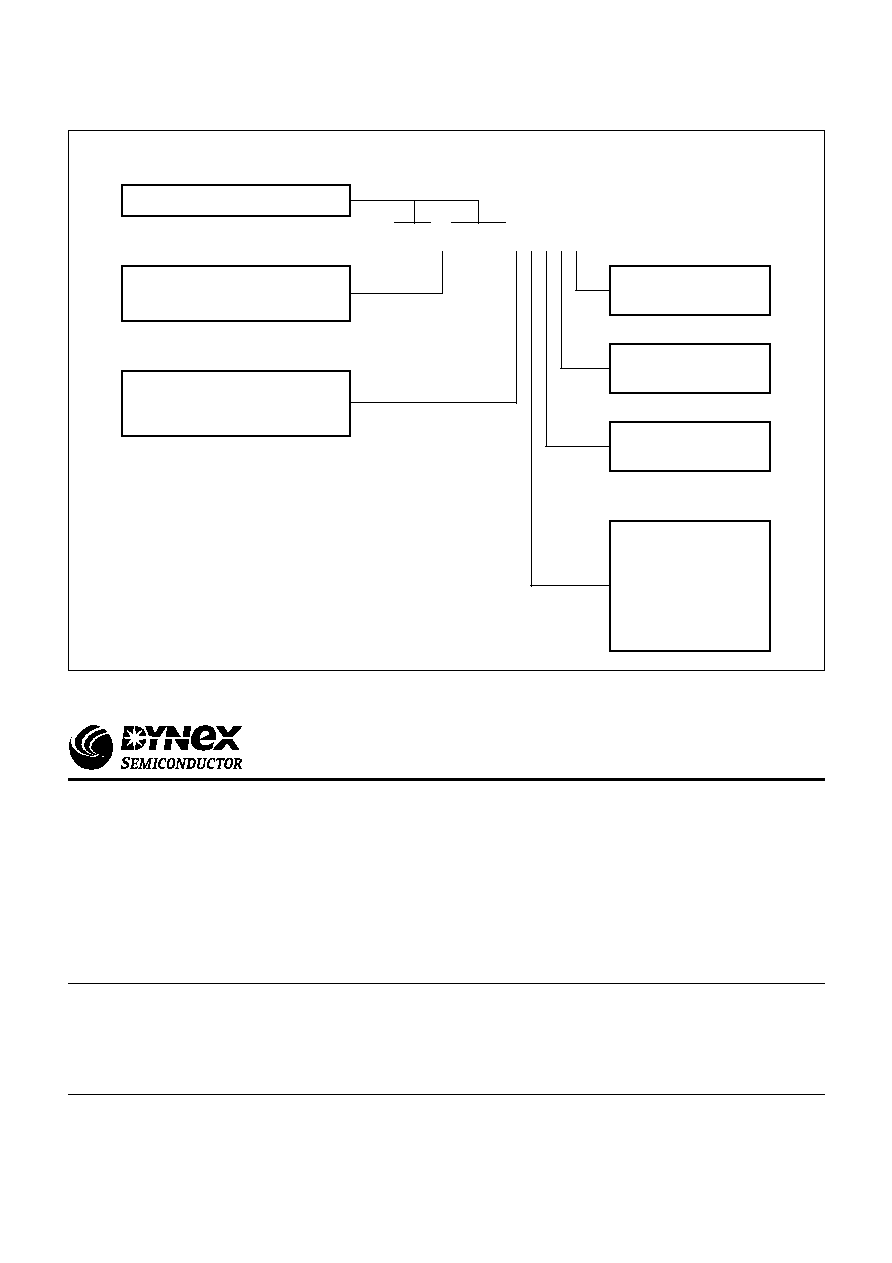

ORDERING INFORMATION

For details of reliability, QA/QC, test and assembly

options, see `Manufacturing Capability and Quality

Assurance Standards' Section 9.

Unique Circuit Designator

S

R

Radiation Hard Processing

100 kRads (Si) Guaranteed

Radiation Tolerance

C

F

N

Ceramic DIL (Solder Seal)

Flatpack (Solder Seal)

Naked Die

Package Type

QA/QCI Process

(See Section 9 Part 4)

Test Process

(See Section 9 Part 3)

Assembly Process

(See Section 9 Part 2)

L

C

D

E

B

S

Rel 0

Rel 1

Rel 2

Rel 3/4/5/STACK

Class B

Class S

Reliability Level

MAx7001xxxxx

CUSTOMER SERVICE CENTRES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

North America Tel: 011-800-5554-5554. Fax: 011-800-5444-5444

UK, Germany, Scandinavia & Rest Of World Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

SALES OFFICES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

Germany Tel: 07351 827723

North America Tel: (613) 723-7035. Fax: (613) 723-1518. Toll Free: 1.888.33.DYNEX (39639) /

Tel: (831) 440-1988. Fax: (831) 440-1989 / Tel: (949) 733-3005. Fax: (949) 733-2986.

UK, Germany, Scandinavia & Rest Of World Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

These offices are supported by Representatives and Distributors in many countries world-wide.

© Dynex Semiconductor 2000 Publication No. DS3518-5 Issue No. 5.0 January 2000

TECHNICAL DOCUMENTATION ≠ NOT FOR RESALE. PRINTED IN UNITED KINGDOM

HEADQUARTERS OPERATIONS

DYNEX SEMICONDUCTOR LTD

Doddington Road, Lincoln.

Lincolnshire. LN6 3LF. United Kingdom.

Tel: 00-44-(0)1522-500500

Fax: 00-44-(0)1522-500550

DYNEX POWER INC.

Unit 7 - 58 Antares Drive,

Nepean, Ontario, Canada K2E 7W6.

Tel: 613.723.7035

Fax: 613.723.1518

Toll Free: 1.888.33.DYNEX (39639)

This publication is issued to provide information only which (unless agreed by the Company in writing) may not be used, applied or reproduced for any purpose nor form part of any order or contract nor to be regarded

as a representation relating to the products or services concerned. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or service. The Company

reserves the right to alter without prior notice the specification, design or price of any product or service. Information concerning possible methods of use is provided as a guide only and does not constitute any

guarantee that such methods of use will be satisfactory in a specific piece of equipment. It is the user's responsibility to fully determine the performance and suitability of any equipment using such information and

to ensure that any publication or data used is up to date and has not been superseded. These products are not suitable for use in any medical products whose failure to perform may result in significant injury

or death to the user. All products and materials are sold and services provided subject to the Company's conditions of sale, which are available on request.

All brand names and product names used in this publication are trademarks, registered trademarks or trade names of their respective owners.

http://www.dynexsemi.com

e-mail: power_solutions@dynexsemi.com

Datasheet Annotations:

Dynex Semiconductor annotate datasheets in the top right hard corner of the front page, to indicate product status. The annotations are as follows:-

Target Information: This is the most tentative form of information and represents a very preliminary specification. No actual design work on the product has been started.

Preliminary Information: The product is in design and development. The datasheet represents the product as it is understood but details may change.

Advance Information: The product design is complete and final characterisation for volume production is well in hand.

No Annotation: The product parameters are fixed and the product is available to datasheet specification.