| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: G768B | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Ver 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

1

G768B

Global Mixed-mode Technology Inc.

Remote/Local Temperature Sensor, 2 Fan Controllers

with SMBus Serial Interface and System Reset Circuit

Features

Measures Two Remote and One Local

Temperatures

No Calibration Required

SMBus 2-Wire Serial Interface

Programmable Under/Over-temperature

Alarms

Supports SMBus Alert Response

Accuracy: ±5∞C (-40∞C to + 125∞C, remote)

±3∞C (+60∞C to + 100∞C, remote)

+4.5V to +5.5V Supply Range

Constant Fan Speed Control

Built-in MOSFET switch

Internal short-circuit protection

PWM control for stable operation

Watchdog for fan control

Precision Monitoring of 5V Power-Supply

Voltage

140ms Min Power-On Reset Pulse Width

RESET Output

Guaranteed RESET Valid to V

CC

=1V

Power Supply Transient Immunity

No External Components needed for reset

function

Small, 16-Pin SSOP Package

Applications

Desktop and Notebook

Central Office Computers

Telecom Equipment

Smart Battery Packs

Test and Measurement

LAN Servers

Multi-Chip Modules

Industrial Controls

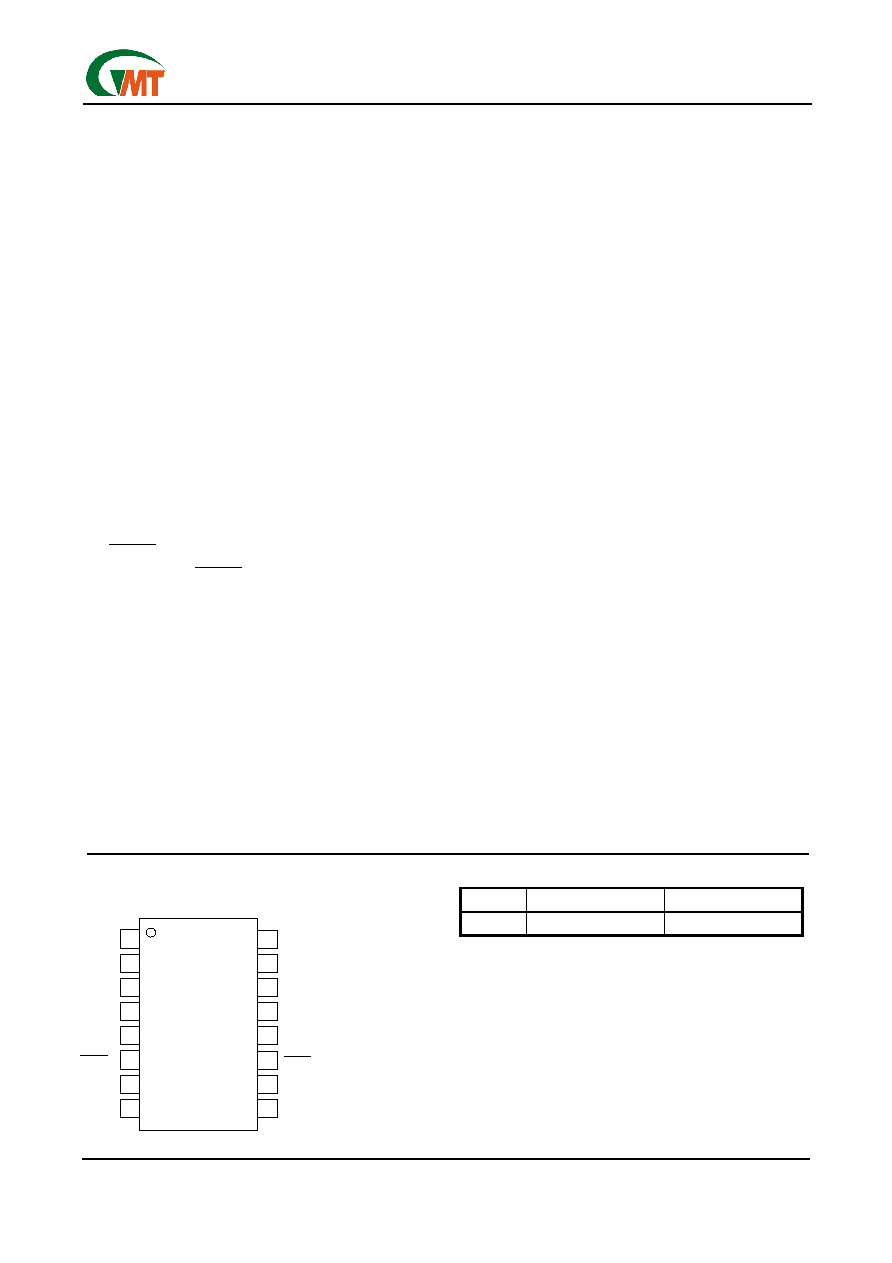

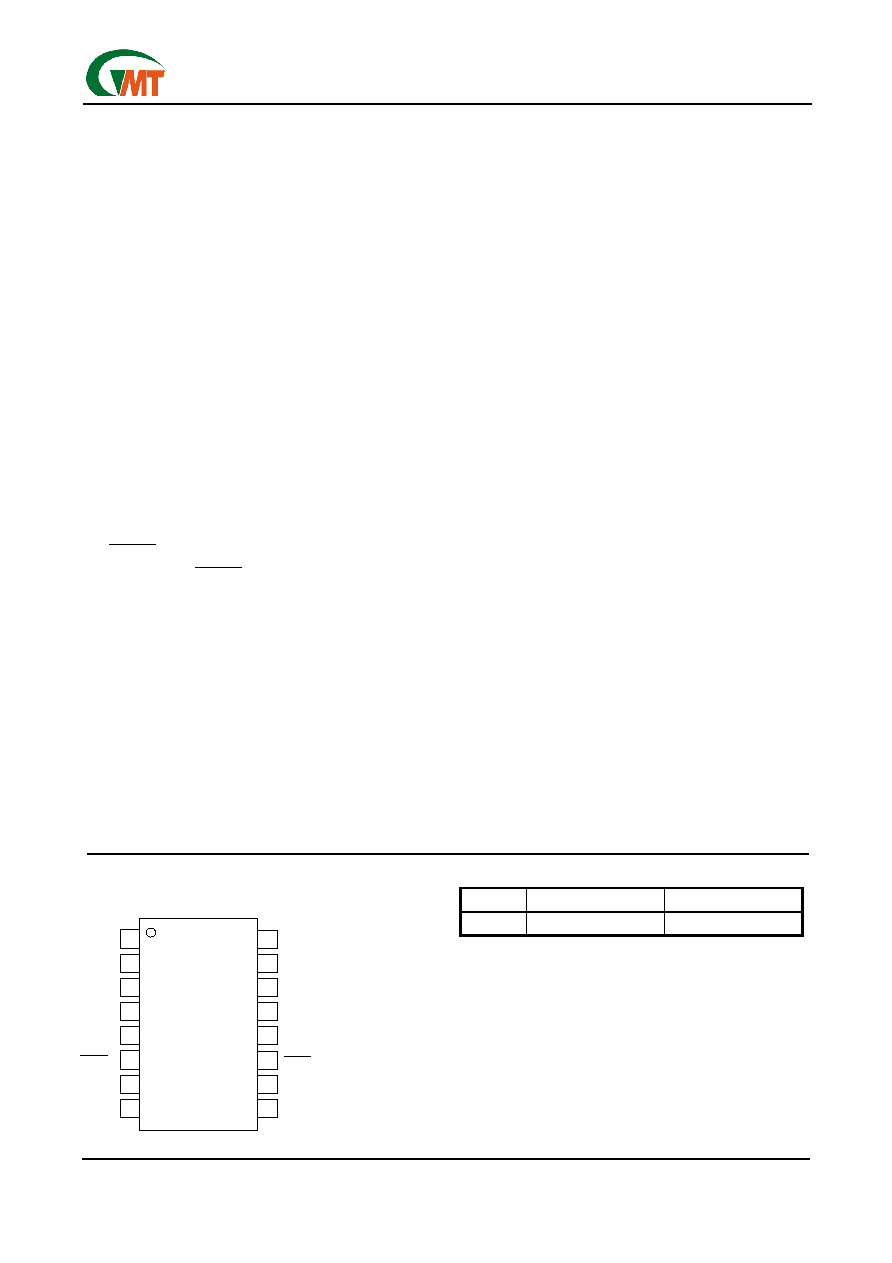

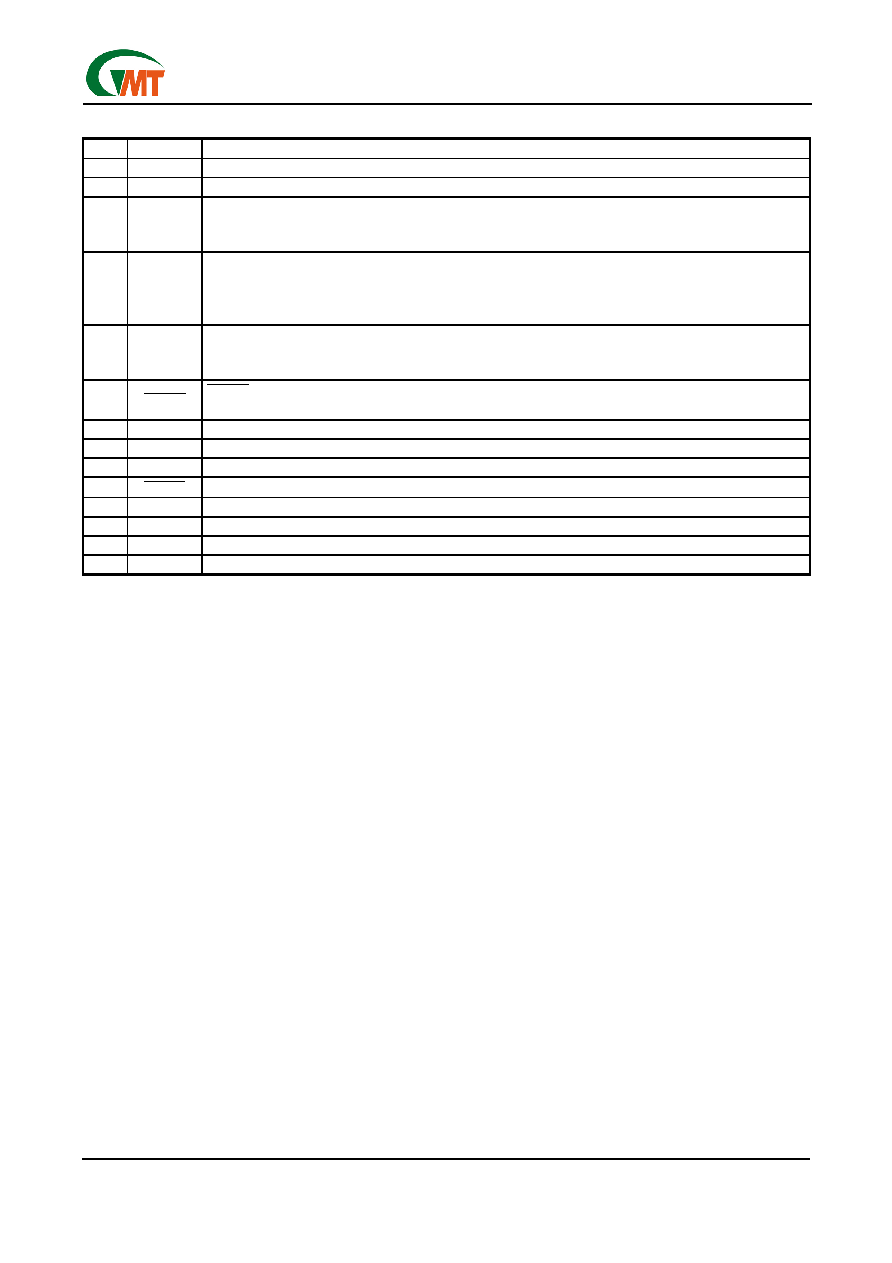

Pin Configuration

General Description

The G768B contains a precise digital thermometer, 2

fan controllers, and a system-reset circuit.

The G768B is backward compatible with G768, Except

that there is an additional watchdog function. This

function prevents fan from being out of control when

system fails.

The thermometer reports the temperature of 2 remote

sensors and its own package. The remote sensors are

diode-connected transistors typically a low-cost, easily

mounted 2N3904 NPN type that replace conventional

thermistors or thermocouples. Remote accuracy is ±5∞C

for multiple transistor manufacturers, with no calibration

needed. The remote channel can also measure the die

temperature of other ICs, such as microprocessors, that

contain an on-chip, diode-connected transistor.

The 2-wire serial interface accepts standard System

Management Bus (SMBus

TM

) Write Byte, Read Byte,

Send Byte, and Receive Byte commands to program

the alarm thresholds and to read temperature data.

The data format is 7 bits plus sign, with each bit cor-

responding to 1∞C, in two's-complement format.

Measurements can be done automatically and

autonomously, with the conversion rate programmed

by the user or programmed to operate in a single-shot

mode. The adjustable rate allows the user to control

the supply-current drain.

G768B also contains a 2-channel fan speed controller.

It connects directly to the fans and performs

closed-loop control of the fan speed independently.

The only external component required is a 10µF ca-

pacitor per channel. It determines the current fan

speed based on the fan rotation pulses and an exter-

nally supplied clock.

(To be continued)

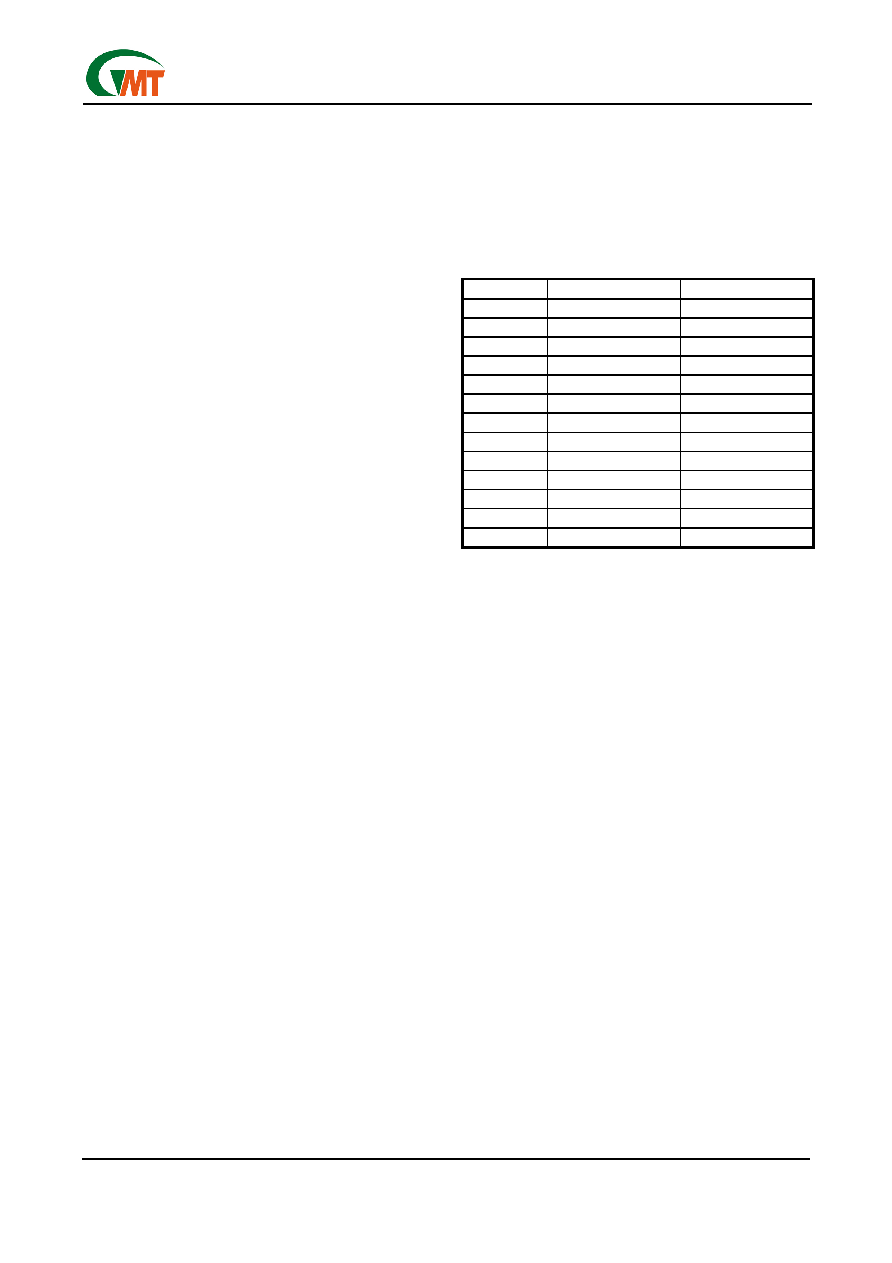

Ordering Information

PART* TEMP.

RANGE PIN-PACKAGE

G768B

-10∞C to +85∞C

16SSOP

RESET

SMBDATA

1

2

3

4

5

6

7

8

OUT1

Vcc

DXP1

DXN

DXP2

GND

GND

16

15

14

13

12

11

10

9

OUT2

SMBCLK

FG2

ALERT

FG1

CLK

16Pin SSOP

Vcc

G768B

Ver 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

2

G768B

Global Mixed-mode Technology Inc.

It uses pulse width modulation (PWM) method and an

on-chip MOSFET to control the fan speed to ±2% of

the programmed speed.

The desired fan speed is also programmed via

SMBus

TM

. The actual fan speed and fan status can be

read via the SMBus

TM

. Short-circuit protection is im-

plemented to prevent damages to the fan and this IC

itself. The G768B also turns on the fans by hardware

watchdog system. The fan controller would fully turn

on both fans when one of the following conditions

happens.

1. when either of the remote temperature is higher than

its own T

MAX

.

2.when either of these two remote diodes is open.

3.when both remote diodes are short

The G768B also contains a microprocessor (µP) su-

pervisory circuit used to monitor the power supplies in

µP and digital systems. They provide excellent circuit

reliability and low cost by eliminating external compo-

nents and adjustments when used with 5V-powered

circuits. This circuit asserts a reset signal whenever

the V

CC

supply voltage declines below a preset

threshold, keeping it asserted for at least 140ms after

V

CC

has risen above the reset threshold. The G768B

has an active-low RESET output. The reset com-

parator is designed to ignore fast transients on V

CC

.

Reset threshold of this circuit is set to 4.38V.

The G768B is available in a small, 16-pin SSOP sur-

face-mount package.

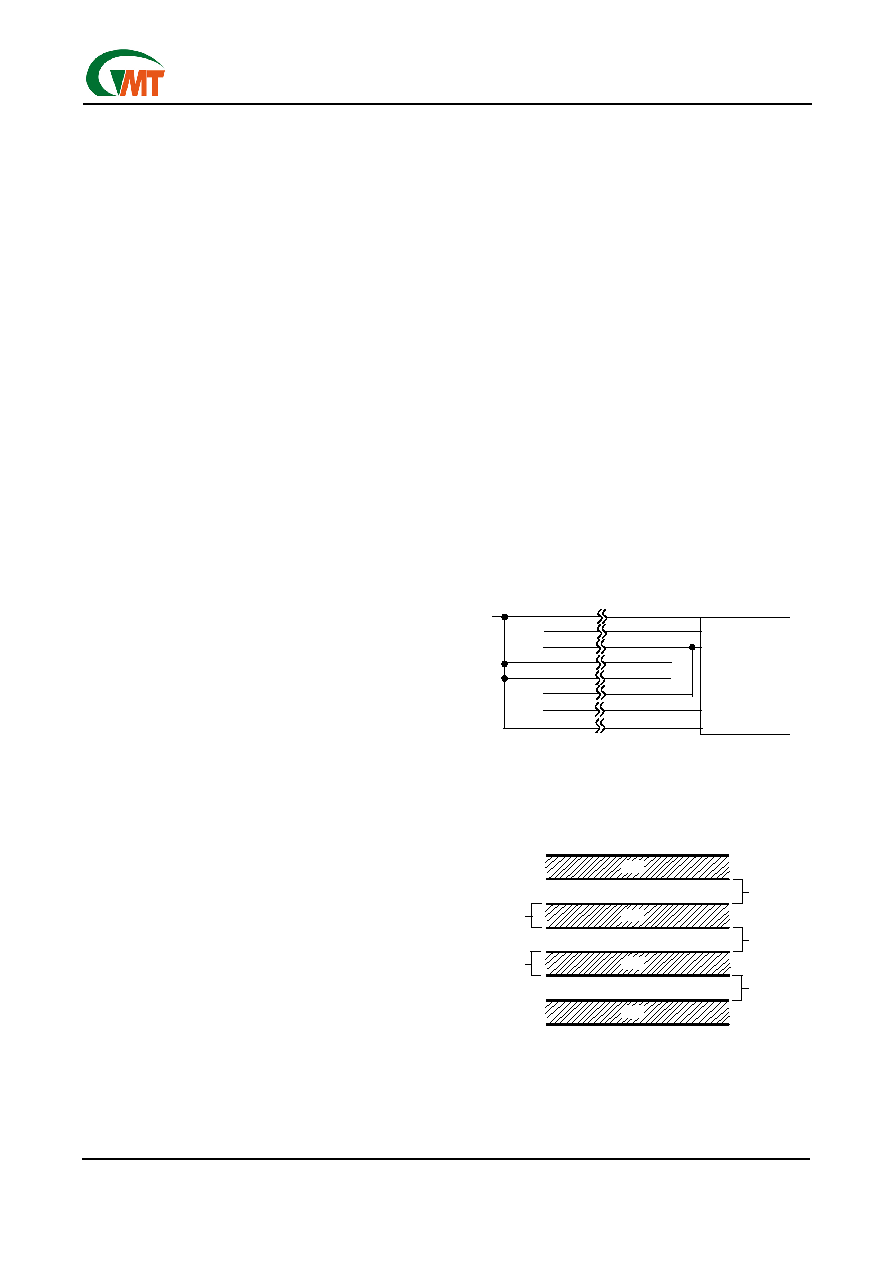

Typical Operating Circuit

INTERRUPT TO µC

10µF

OUT1

FG1

V

CC

DXP1

DXN

DXP2

RESET

GND

2200pF

2200pF

2N3904

2N3904

V

CC

10k EACH

SMBCLK

SMBDATA

CLOCK 32.768kHz

IN

FAN1

FG

10µF

OUT2

FG2

SMBCLK

SMBDATA

ALERT

CLK

10µF

G768B

RESET

µP

IN

FAN2

FG

10µF

INTERRUPT TO µC

10µF

OUT1

FG1

V

CC

DXP1

DXN

DXP2

RESET

GND

2200pF

2200pF

2N3904

2N3904

V

CC

10k EACH

SMBCLK

SMBDATA

CLOCK 32.768kHz

IN

FAN1

FG

10µF

OUT2

FG2

SMBCLK

SMBDATA

ALERT

CLK

10µF

G768B

RESET

µP

IN

FAN2

FG

10µF

Ver 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

3

G768B

Global Mixed-mode Technology Inc.

Absolute Maximum Ratings

Vcc to GND.......................................-0.3V to +6V

DXP1, DXP2 to GND...............0.3V to (Vcc + 0.3V)

DXN to GND.................................-0.3V to +0.8V

SMBCLK, SMBDATA,

ALERT to GND.-0.3V to +6V

SMBDATA,

ALERT Current............-1mA to +50mA

DXN Current...............................................±1mA

ESD Protection (SMBCLK, SMBDATA,

ALERT , hu-

man body model)......................................4000V

ESD Protection (other pins, human body

model).2000V

Continuous Power Dissipation (T

A

= +70∞C) SSOP

(de-rate 8.30mW/∞C above +70∞C)................667mW

Operating Temperature Range.........-10∞C to +85∞C

Junction Temperature.........................+150∞C

Storage temperature Range..............-65∞C to +165∞C

Lead Temperature (soldering,10sec).............+300∞C

Stresses beyond those listed under "Absolute Maximum Ratings" may cause permanent damage to the device. These are

stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in the opera-

tional sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended periods may

affect device reliability.

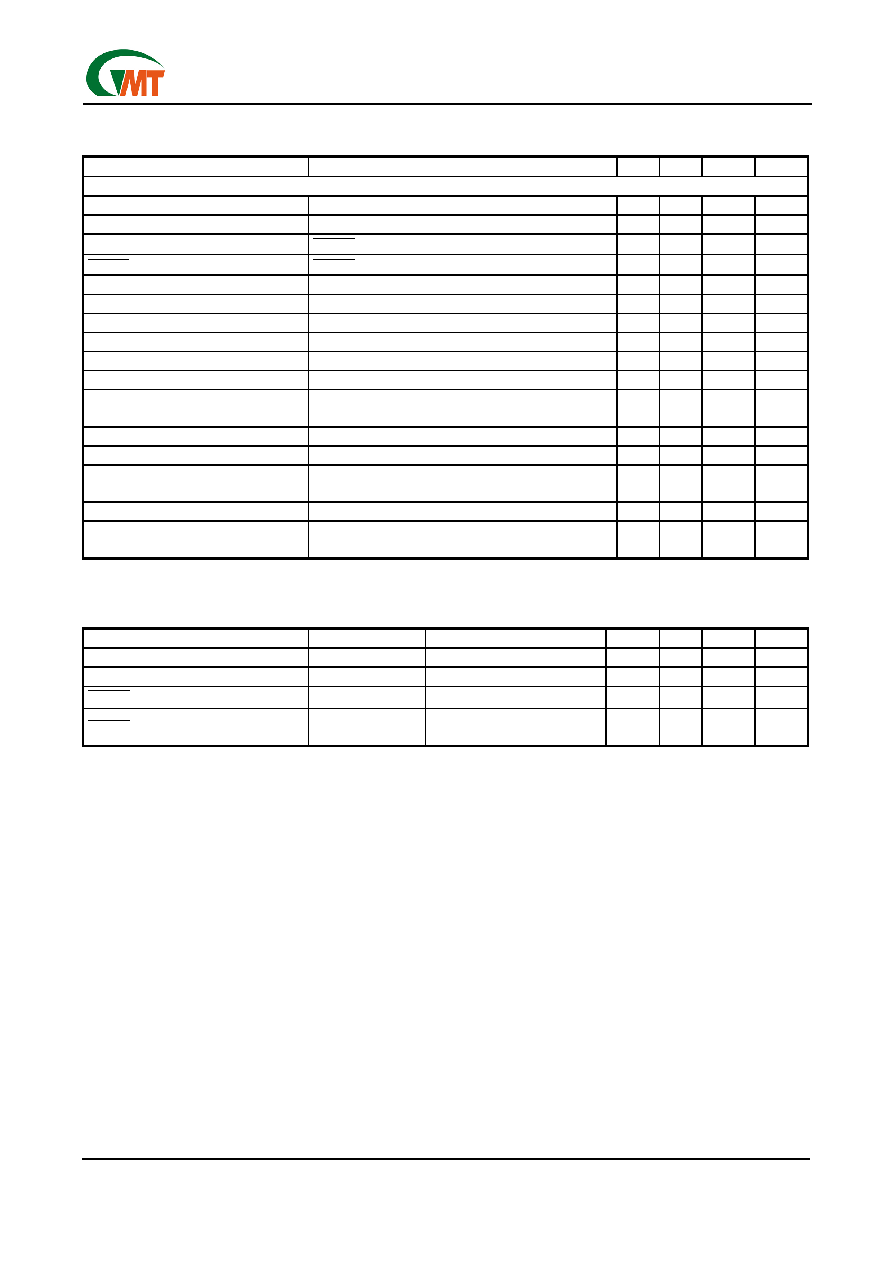

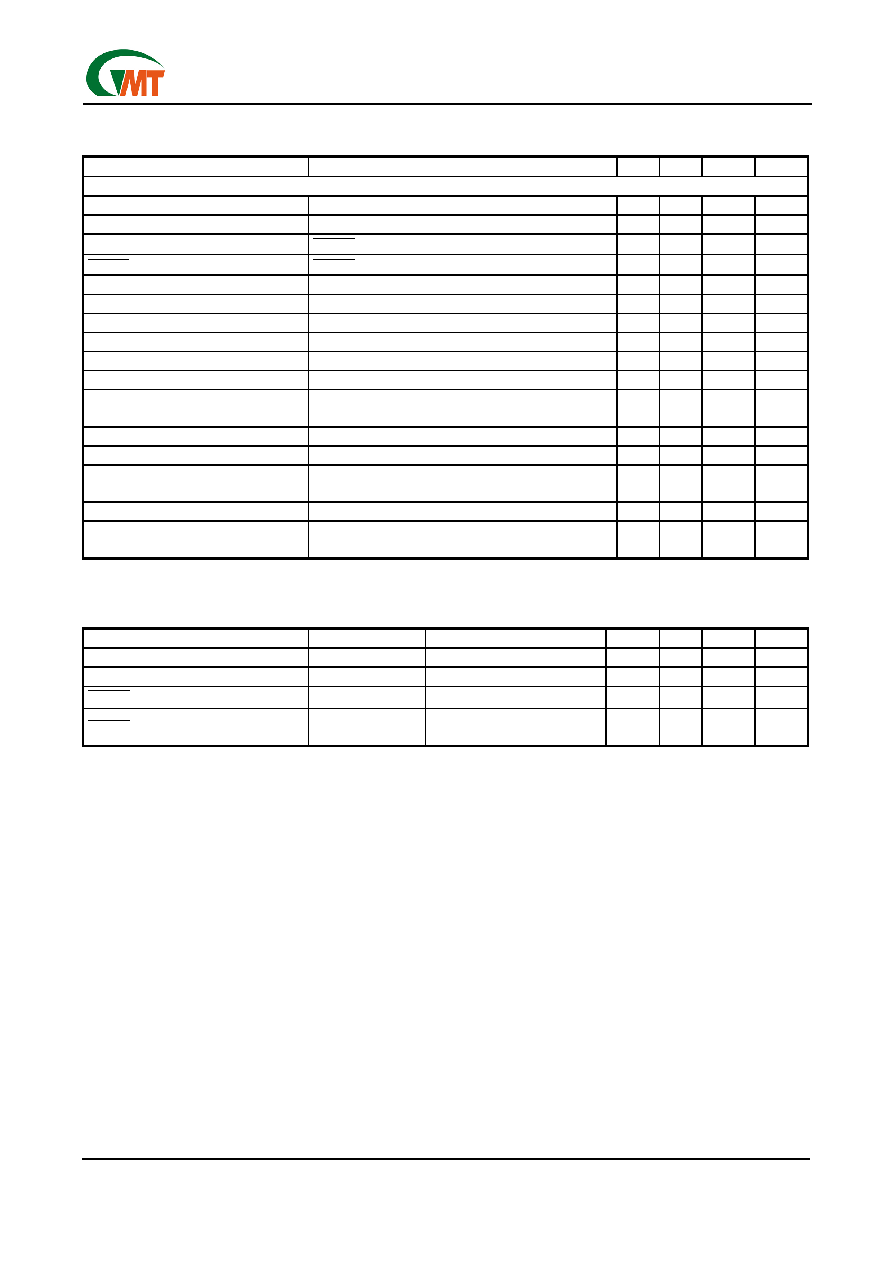

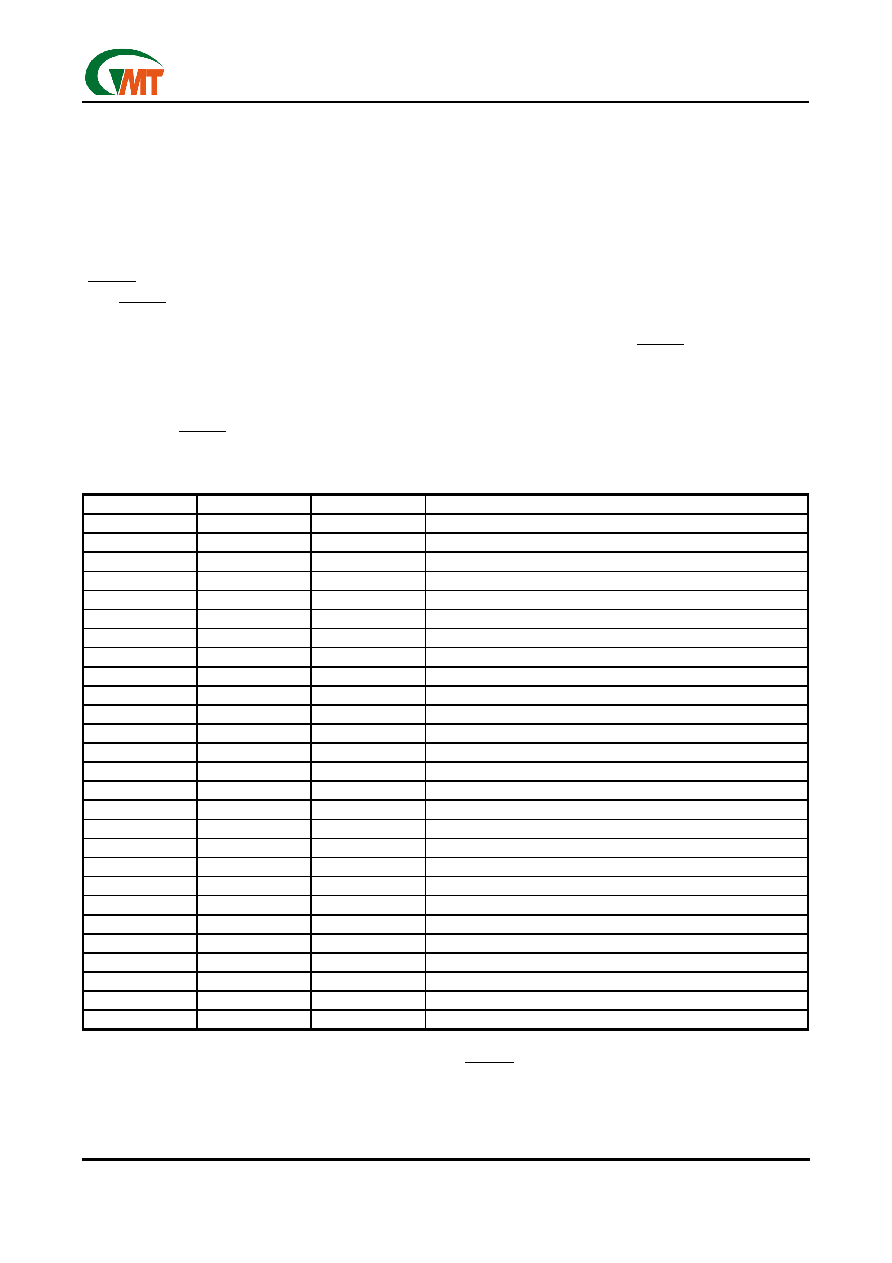

Electrical Characteristics

(Vcc = + 5V, T

A

= 60∞C, unless otherwise noted.)

PARAMETER CONDITIONS

MIN

TYP

MAX

UNITS

Temperature Sensor

Temperature Resolution(Note 1)

Monotonicity guaranteed

8

Bits

T

R

= 0∞C to +125∞C

-5

5

Temperature Error, Remote Diode (Notes 2

and 3)

T

R

= 60∞C to +100∞C

-3

3

∞C

Temperature Error, Local Diode

(Notes 1 and 2)

Including long-term drift

T

A

= +60∞C to +100∞C

-3.5

3.5

∞C

Supply-Voltage

Range

4.5 5 5.5 V

Under-voltage Lockout Threshold

Vcc input, disables A/D conversion, rising edge

2.6 2.8 2.95

V

Under-voltage Lockout Hysteresis

50

mV

Power-On Reset Threshold

Vcc , falling edge

1.0 1.7

2.5

V

POR Threshold Hysteresis

50

mV

SMBus static

3

10

Standby Supply Current

Logic inputs forced to Vcc or

GND

Hardware or software

standby, SMBCLK at 10kHz

200

µA

0.25 conv/sec

250 300

Average Operating Supply Current

Auto-convert mode, average

measured over 4sec. Logic

inputs forced to Vcc or GND

2.0 conv/sec

300 350

µA

Conversion Time

From stop bit to conversion complete(all channels)

94

125 156

ms

Conversion Rate Timing Error

Auto-convert mode

-25

25

%

High

level

120 160 200

Remote-Diode Source Current

DXP forced to 1.5V

Low level

15

20

25

µA

Fan Controller

Supply voltage

V

CC

4.5 5 5.5 V

Shutdown current

Both fans' speed = 0rpm

2

5

µA

MOSFET on resistance

Each channel

0.2 0.25

Short-circuit current limit

Each channel

0.5

A

Input logic low

VIL

0.8

V

Input logic high

VIH

2.4

V

Average Output current

Each channel

350

mA

FG input Positive-going threshold voltage

V

CC

=5V

1.8

V

FG input Negative-going threshold voltage

V

CC

=5V

0.7

V

FG input Hysteresis voltage

V

CC

=5V

1.1

V

Ver 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

4

G768B

Global Mixed-mode Technology Inc.

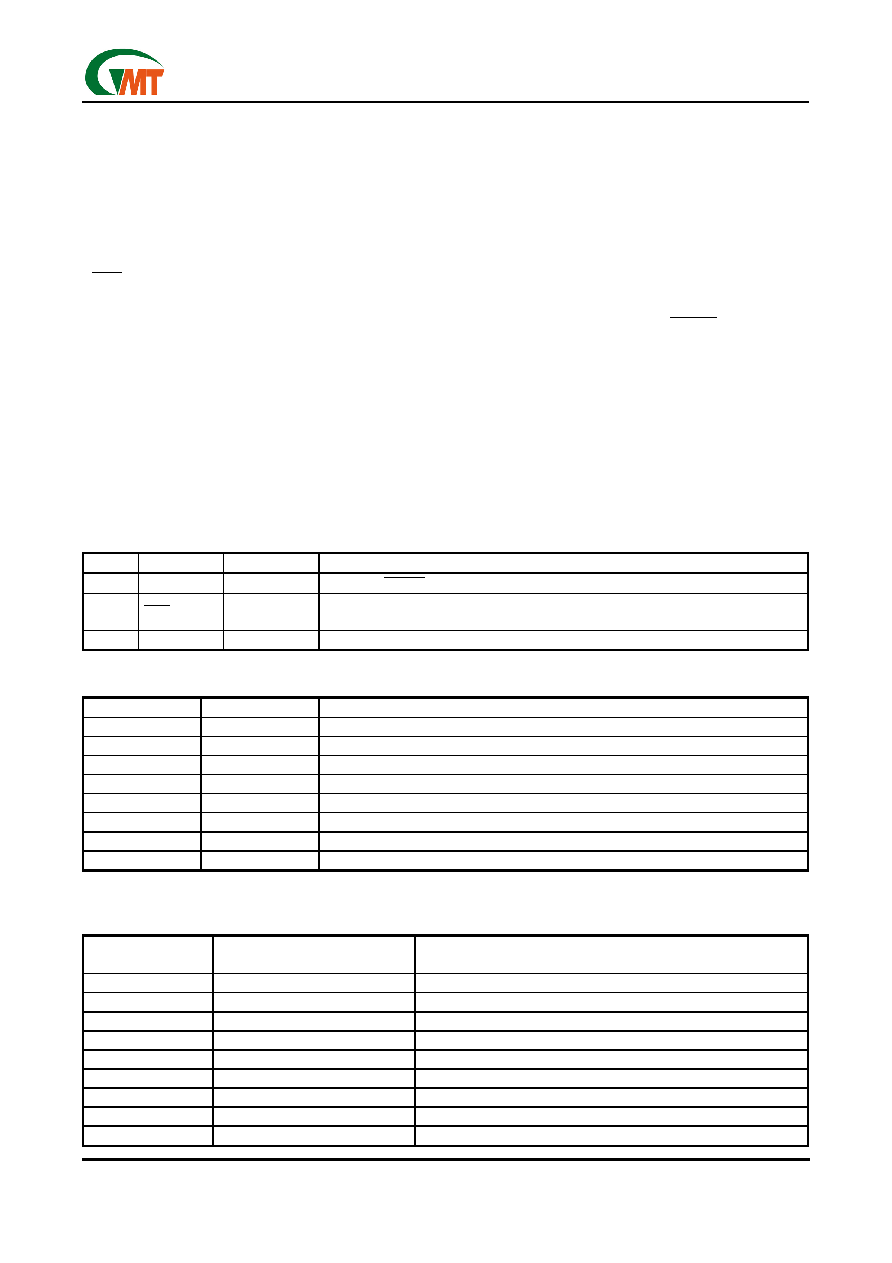

Electrical Characteristics

(continued)

(Vcc = + 5V, T

A

= 60∞C, unless otherwise noted.)

PARAMETER CONDITIONS

MIN

TYP

MAX

UNITS

SMBus Interface

Logic Input High Voltage

SMBCLK, SMBDATA; Vcc = 4.5V to 5.5V

2.4

V

Logic Input Low Voltage

SMBCLK, SMBDATA; Vcc = 4.5V to 5.5V

0.8

V

Logic Output Low Sink Current

ALERT , SMBDATA forced to 0.4V

6 mA

ALERT Output High Leakage Current ALERT forced to 5.5V

1 µA

Logic Input Current

Logic inputs forced to Vcc or GND

-2

2

µA

SMBus Input Capacitance

SMBCLK, SMBDATA

5

pF

SMBus Clock Frequency

(Note 4)

DC

100

kHz

SMBCLK Clock Low Time

t

LOW

, 10% to 10% points

4.7

µs

SMBCLK Clock High Time

t

HIGH

, 90% to 90% points

4

µs

SMBus Start-Condition Setup Time

4.7

µs

SMBus Repeated Start-Condition

Setup Time

t

SU :

STA ,

90% to 90% points

500

ns

SMBus Start-Condition Hold Time

t

HD: STA ,

10% of SMBDATA to 90% of SMBCLK

4

µs

SMBus Start-Condition Setup Time

t

SD: STO ,

90% of SMBDATA to 10% of SMBDATA

4

µs

SMBus Data Valid to SMBCLK Ris-

ing-Edge Time

t

SU: DAT ,

10% or 90% of SMBDATA to 10% of

SMBCLK

800

ns

SMBus Data-Hold Time

t

HD : DAT

(Note 5)

0

µs

SMBCLK Falling Edge to SMBus

Data-Valid Time

Master clocking in data

1

µs

Electrical Characteristics

(continued)

(V

CC

=full range, T

A

= 60∞C, unless otherwise noted.)

PARAMETER SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

Reset Threshold

V

TH

4.2

4.4

4.5

V

Reset Active Timeout Period

340 ms

RESET

Output Voltage Low

V

OL

V

CC

=V

TH

min I

SINK

=3.2mA

0.4

V

RESET

Output Voltage High

V

OH

V

CC

>V

TH

max

I

SOURCE

=5.0mA

V

CC

-1.5

V

Note 1: Guaranteed but not 100% tested.

Note 2: Quantization error is not included in specifications for temperature accuracy. For example, if the G768B

device temperature is exactly +66.7∞C, or +68∞C (due to the quantization error plus the +1/2∞C offset

used for rounding up) and still be within the guaranteed ±3∞C error limits for the +60∞C to +100∞C tem-

perature range. See Table3.

Note 3: A remote diode is any diode-connected transistor from Table1. T

R

is the junction temperature of the re-

mote diode. See Remote Diode Selection for remote diode forward voltage requirements.

Note 4: The SMBus logic block is a static design that works with clock frequencies down to DC. While slow op-

eration is possible, it violates the 10kHz minimum clock frequency and SMBus specifications, and may

monopolize the bus.

Note 5: Note that a transition must internally provide at least a hold time in order to bridge the undefined region

(300ns max) of SMBCLK's falling edge.

Ver 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

5

G768B

Global Mixed-mode Technology Inc.

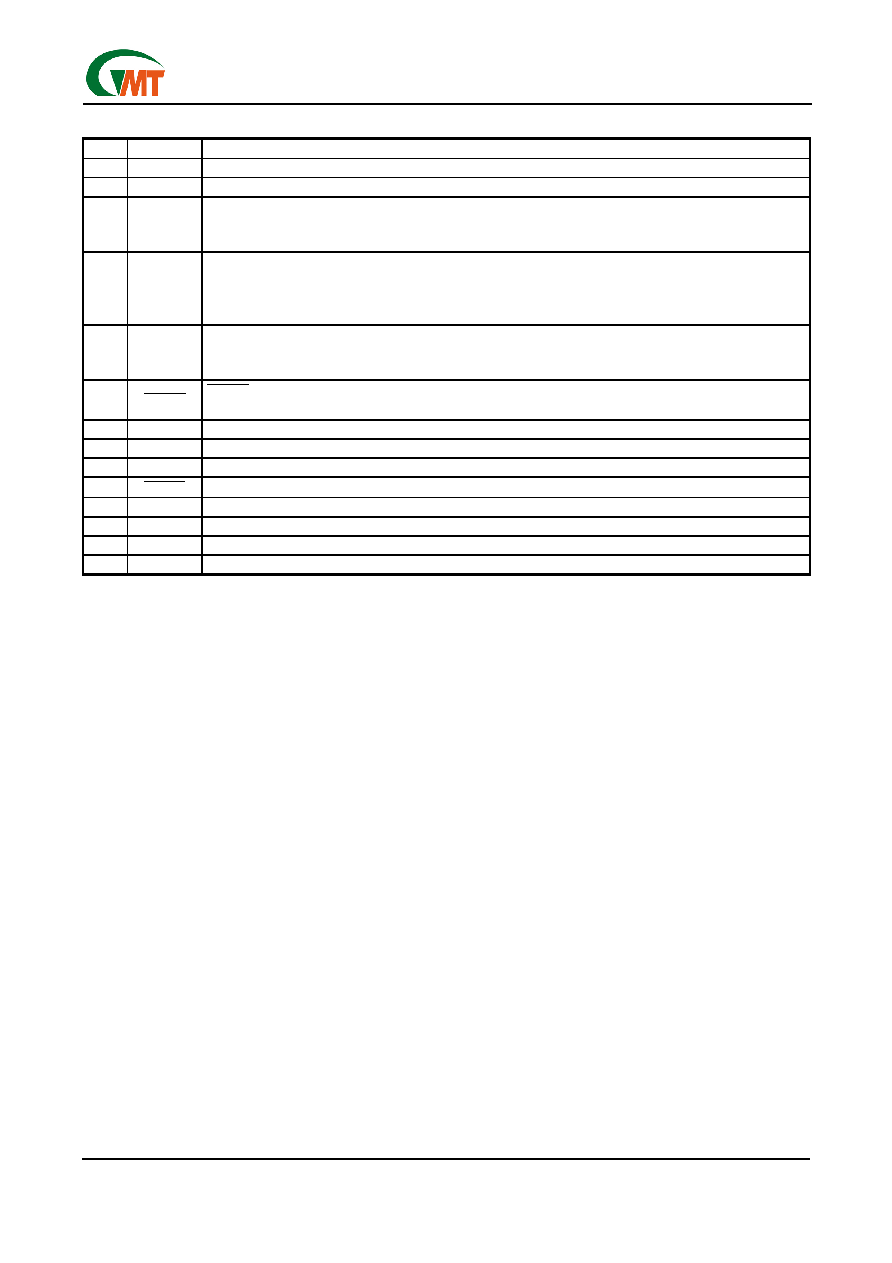

Pin Description

PIN NAME

FUNCTION

1

OUT1

PWM output, connect to fan 1

2,15

Vcc

Supply Voltage Input , 4.5V to 5.5V. Bypass to GND with a 0.1µF capacitor.

3 DXP1

Combined Current Source and A/D Positive Input for remote-diode channel 1. Do not leave DXP1 floating;

tie DXP1 to DXN if no remote diode on channel 1 is used. Place a 2200pF capacitor between DXP1 and

DXN for noise filtering.

4 DXN

Combined Current Sink and A/D Negative Input. DXN is common negative node of both remote diodes on

channel 1 and 2. The traces of DXP1-DXN and DXP2-DXN pairs should be routed independently. The

common DXN should be connected together as close as possible to the IC. DXN is internally connected to

the GND pin for signal ground use.

5 DXP2

Combined Current Source and A/D Positive Input for remote-diode channel 2. Do not leave DXP2 floating;

tie DXP2 to DXN if no remote diode on channel 2 is used. Place a 2200pF capacitor between DXP2 and

DXN for noise filtering.

6

RESET

RESET

Output remains low while V

CC

is below the reset threshold, and for 240ms after V

CC

rises above

the reset threshold.

7,8 GND

Ground

9

CLK

Clock input for fan speed measurement.

10

FG1

Fan1 pulse input.

11

ALERT SMBus Alert (interrupt) Output, open drain.

12

SMBDATA SMBus Serial-Data Input / Output, open drain.

13

FG2

Fan2 pulse input.

14

SMBCLK SMBus Serial-Clock Input.

16

OUT2

PWM output, connect to fan 2.

Detailed Description

The G768B (patents pending) is a 4-in-1 IC. It consists

of one temperature sensor, 2 fan speed controllers

and provides system-reset function.

The temperature sensor is designed to work in conjunc-

tion with an external micro-controller (µC) or other intel-

ligence in thermostatic, process-control, or monitoring

applications. The µC is typically a power-management

or keyboard controller, generating SMBus serial com-

mands by "bit-banging" general-purpose input-output

(GPIO) pins or via a dedicated SMBus interface block.

Essentially a 12-bit serial analog-to-digital converter

(ADC) with a sophisticated front end, the G768B con-

tains a switched current source, a multiplexer, an ADC,

an SMBus interface, 2 fan controllers, a reset circuit

and associated control logic (Figure 1).

Temperature data from the ADC is loaded into two

data registers, where it is automatically compared with

data previously stored in four over/under-temperature

alarm registers.

ADC and Multiplexer

The ADC is an averaging type that integrates over a

60ms period (each channel, typical), with excellent

noise rejection.

The multiplexer automatically steers bias currents

through the remote and local diodes, measures their

forward voltages, and computes their temperatures. All

channels are converted automatically once the con-

version process has started, either in free-running or

single-shot mode. If one of the three channels is not

used, the device still performs all measurements, and

the user can simply ignore the results of the unused

channel. If the remote diode channel is unused, tie

DXPx to DXN rather than leaving the pins open.

The DXN input is internally connected to the ground

node inside the chip to set up the analog to digital

(A/D) inputs for a differential measurement. The

worst-case DXP-DXN differential input voltage range

is 0.25V to 0.95V.

Excess resistance in series with the remote diode causes

about +1/2∞C error per ohm. Likewise, 200µV of offset

voltage forced on DXP-DXN causes about 1∞C error.

Ver 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

6

G768B

Global Mixed-mode Technology Inc.

Fig 1. Functional Diagram

A/D Conversion Sequence

If a Start command is written (or generated automati-

cally in the free-running auto-convert mode), all three

channels are converted, and the results of all meas-

urements are available after the end of conversion. A

BUSY status bit in the status byte shows that the de-

vice is actually performing a new conversion; however,

even if the ADC is busy, the results of the previous

conversion are always available.

Remote-Diode Selection

Temperature accuracy depends on having a

good-quality, diode-connected small-signal transistor.

Accuracy has been experimentally verified for all of

the devices listed in Table 1. The G768B can also di-

rectly measure the die temperature of CPUs and other

integrated circuits having on-board tempera-

ture-sensing diodes. The transistor must be a

small-signal type with a relatively high forward voltage;

otherwise, the A/D input voltage range can be violated.

The forward voltage must be greater than 0.25V at

10µA; check to ensure this is true at the highest ex-

pected temperature. The forward voltage must be less

than 0.95V at 200A; check to ensure this is true at the

lowest expected temperature. Large power transistors

don't work at all. Also, ensure that the base resistance

is less than 100

. Tight specifications for forward

current gain (+50 to +150, for example) indicate that

the manufacturer has good process controls and that

the devices have consistent VBE characteristics.

Thermal Mass and Self-Heating

Thermal mass can seriously degrade the G768B's

effective accuracy. The thermal time constant of the

SSOP-16 package is about 140sec in still air. For the

G768B junction temperature to settle to within +1∞C

after a sudden +100∞C change requires about five

time constants or 12 minutes. The use of smaller

packages for remote sensors, such as SOT23s, im-

proves the situation. Take care to account for thermal

gradients between the heat source and the sensor,

and ensure that stray air current across the sensor

package do not interfere with measurement accuracy.

Self-heating can significantly affect the measurement

accuracy. Remote-sensor self-heating due to the di-

ode current source is negligible. For the local diode,

the worst-case error occurs when auto converting at

the fastest rate and simultaneously sinking maximum

current at the ALERT output, and both fans are work-

ing at low speeds.

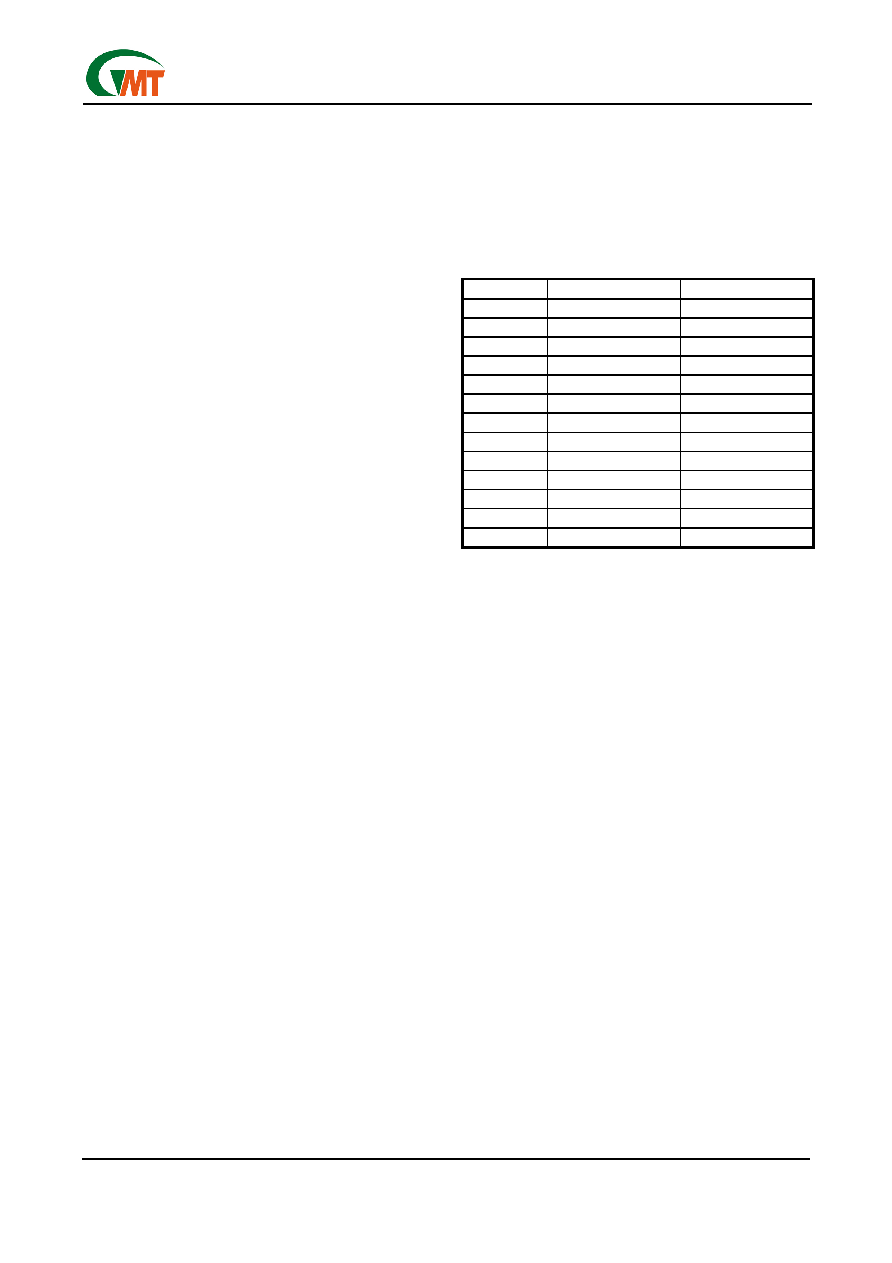

Table 1. Remote-Sensor Transistor Manufacturers

MANUFACTURER MODEL

NUMBER

Philips PMBS

3904

Motorola(USA) MMBT3904

National Semiconductor(USA)

MMBT3904

Note:Transistors must be diode-connected (base short

-ed to collector).

DXP2

FAN CONTROL

FAN CONTROL

CONTROL

LOGIC

SMBUS

REGISTERS

MUX

ADC

RESET

CIRCUIT

OUT1

FG1

OUT2

FG2

SMBCLK

SMBDATA

ALERT

RESET

V

CC

+

+

+

DXP1

DXN

+

INTERNAL GROUND

CLK

DXP2

FAN CONTROL

FAN CONTROL

CONTROL

LOGIC

SMBUS

REGISTERS

MUX

ADC

RESET

CIRCUIT

OUT1

FG1

OUT2

FG2

SMBCLK

SMBDATA

ALERT

RESET

V

CC

+

+

+

DXP1

DXN

+

INTERNAL GROUND

CLK

Ver 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

7

G768B

Global Mixed-mode Technology Inc.

ADC Noise Filtering

The ADC is an integrating type with inherently good

noise rejection, especially of low-frequency signals

such as 60Hz/120Hz power-supply hum. Micro-power

operation places constraints on high-frequency noise

rejection; therefore, careful PC board layout and

proper external noise filtering are required for

high-accuracy remote measurements in electrically

noisy environments.

High-frequency EMI is best filtered at DXP and DXN

with an external 2200pF capacitor. This value can be

increased to about 3300pF(max), including cable ca-

pacitance. Higher capacitance than 3300pF introduces

errors due to the rise time of the switched current

source.

Nearly all noise sources tested cause the ADC meas-

urements to be higher than the actual temperature,

typically by +1∞C to 10∞C, depending on the frequency

and amplitude (see Typical Operating Characteristics).

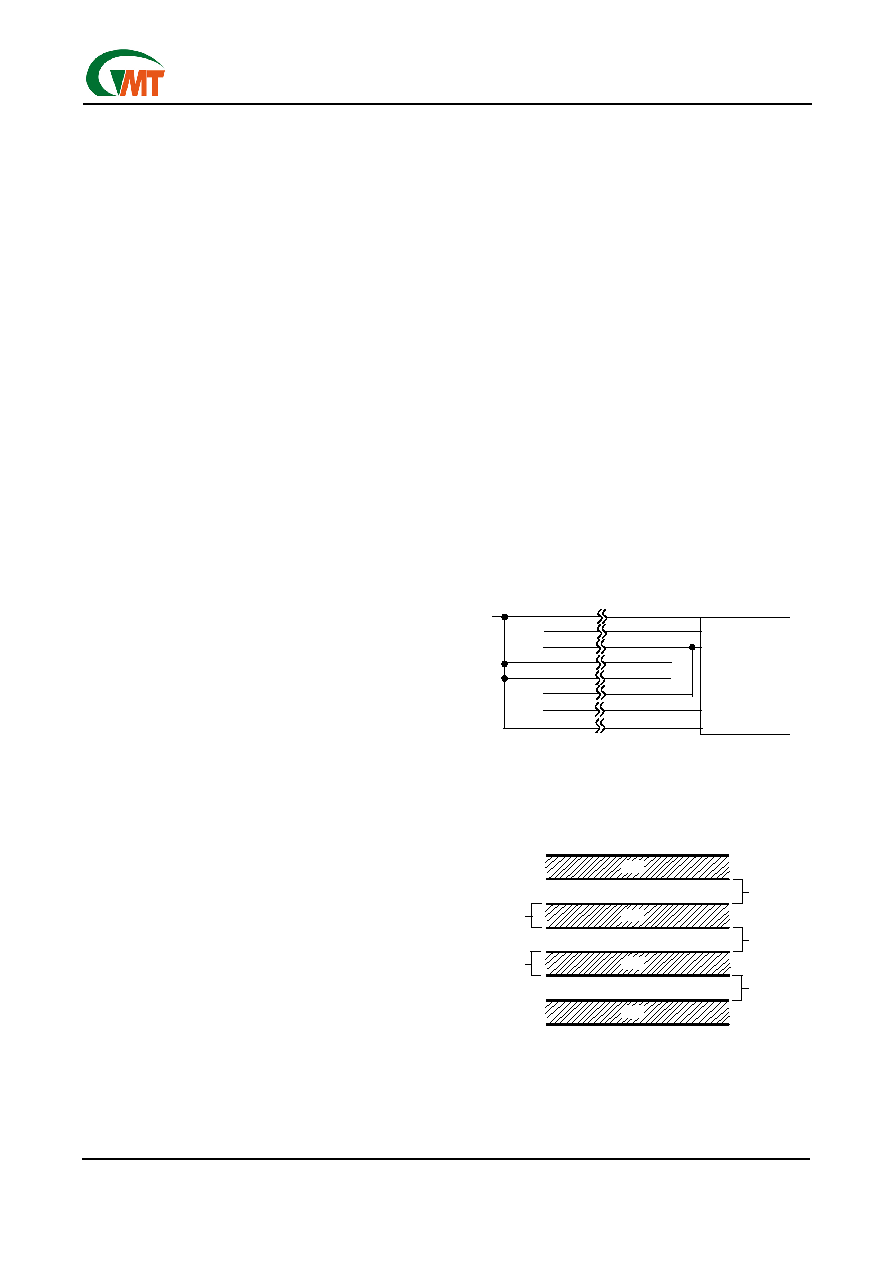

PC Board Layout

Place the G768B as close as practical to the remote

diode. In a noisy environment, such as a computer

motherboard, this distance can be 4 in. to 8 in. (typical)

or more as long as the worst noise sources (such as

CRTs, clock generators, memory buses, and ISA/PCI

buses) are avoided.

Do not route the DXP-DXN lines next to the deflection

coils of a CRT. Also, do not route the traces across a

fast memory bus, which can easily introduce +30∞C

error, even with good filtering, Otherwise, most noise

sources are fairly benign.

Route the DXP and DXN traces in parallel and in close

proximity to each other, away from any high-voltage

traces such as +12VDC. Leakage currents from PC

board contamination must be dealt with carefully,

since a 20M

leakage path from DXP to ground

causes about +1∞C error.

Route the 2 pairs of DXP1-DXN and DXP2-DXN

traces independently (Figure 2a). Connect the com-

mon DXN as close as possible to the DXN pin on IC

(Figure 2a).

Connect guard traces to GND on either side of the

DXP-DXN traces (Figure 2b). With guard traces in

place, routing near high-voltage traces is no longer an

issue.

Route through as few vias and crossunders as possi-

ble to minimize copper/solder thermocouple effects.

When introducing a thermocouple, make sure that

both the DXP and the DXN paths have matching

thermocouples. In general, PC board- induced ther-

mocouples are not a serious problem, A copper-solder

thermocouple exhibits 3µV/∞C, and it takes about

200µV of voltage error at DXP-DXN to cause a +1∞C

measurement error. So, most parasitic thermocouple

errors are swamped out.

Use wide traces. Narrow ones are more inductive and

tend to pick up radiated noise. The 10 mil widths and

spacing recommended on Figure 2 aren't absolutely

necessary (as they offer only a minor improvement in

leakage and noise), but try to use them where practi-

cal.

Keep in mind that copper can't be used as an EMI

shield, and only ferrous materials such as steelwork

will. Placing a copper ground plane between the

DXP-DXN traces and traces carrying high-frequency

noise signals do not help reduce EMI.

PC Board Layout Checklist

Place the G768B close to a remote diode.

Keep traces away from high voltages (+12V bus).

Keep traces away from fast data buses and CRTs.

Use recommended trace widths and spacing.

Place a ground plane under the traces

Use guard traces flanking DXP and DXN and con-

necting to GND.

Route two DXPx-DXN pairs independently

Connect the common DXN as close as possible to

the DXN pin on IC.

Place the noise filter and the 0.1F Vcc bypass

capacitors close to the G768B.

Fig 2(a) Connect the common DXN as close as

possible to the DXN pin on IC.

Fig 2 (b) Recommended DXP/DXN PC

DXP1

DXN

DXN

DXP2

DXP1

DXN

G768B

DXP2

GND

Chip Boundary

GND

DXP1

DXN

DXN

DXP2

DXP1

DXN

G768B

DXP2

GND

Chip Boundary

GND

GND

DXP

DXN

GND

10 MILS

MINIMUM

10 MILS

10 MILS

10 MILS

GND

GND

DXP

DXP

DXN

DXN

GND

GND

10 MILS

MINIMUM

10 MILS

10 MILS

10 MILS

Ver 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

8

G768B

Global Mixed-mode Technology Inc.

Twisted Pair and Shielded Cables

For remote-sensor distances longer than 8 in., or in

particularly noisy environments, a twisted pair is rec-

ommended. Its practical length is 6 feet to 12feet (typi-

cal) before noise becomes a problem, as tested in a

noisy electronics laboratory. For longer distances, the

best solution is a shielded twisted pair like that used

for audio microphones. Connect the twisted pair to

DXP and DXN and the shield to GND, and leave the

shield's remote end unterminated.

Excess capacitance at DX_limits practical remote

sensor distances (see Typical Operating Characteris-

tics), For very long cable runs, the cable's parasitic

capacitance often provides noise filtering, so the

2200pF capacitor can often be removed or reduced in

value. Cable resistance also affects remote-sensor

accuracy; 1

series resistance introduces about + 1∞C

error.

Low-Power Standby Mode

Standby mode disables the ADC and reduces the sup-

ply-current drain to less than 10µA. Enter standby

mode via the RUN/STOP bit in the configuration byte

register. In standby mode, all data is retained in mem-

ory, and the SMB interface is alive and listening for

reads and writes. This is valid for temperature sensor

only.

Standby mode is not a shutdown mode. With activity

on the SMBus, extra supply current is drawn (see

Typical Operating Characteristics). In software

standby mode, the G768B can be forced to perform

temperature measurement via the one-shot command,

despite the RUN/STOP bit being high.

Supply-current drain during the 125ms conversion

period is always about 500µA. Slowing down the con-

version rate reduces the average supply current (see

Typical Operating Characteristics). In between con-

versions, the instantaneous supply current is about

25µA due to the current consumed by the conversion

rate timer. In standby mode, supply current drops to

about 3µA. at very low supply voltages (under the

power-on-reset threshold).

Fan Controller

The fan speed is measured by counting the number of

the CLK pin period between the rising edges of two

fan speed pulses on FG pin. In this way, we are actu-

ally measuring the period of the fan speed. To avoid

the cost of doing division to obtain the speed, this

count number, N, is used in the PWM control algo-

rithm, thus, the desired fan speed should be pro-

grammed by writing the corresponding count number.

The count number is given by:

N = (CLK x 30) / (rpm x P)

N : Count Number

P : FG pulses number per revolution of fan.

For CLK = 32768Hz, P = 2

N = 491520 / rpm

For CLK = 16384Hz, P = 2

N = 245762 / rpm

Some selected count numbers are shown below

Table 2. Count numbers for P=2

rpm CLK=32768Hz

CLK=16384Hz

968

---

254

1935 254

127

2000 246

123

3000 164

82

4000 123

61

5000 98

49

6000 82

41

7000 70

35

8000 61

31

9000 55

27

10000 49

25

20000 25

12

30000 16

8

To stop the fan, program the fan speed register to 255. This

also makes the fan controller into power saving mode.

Controlling Fan at Lower Speed

For stably controlling fans at lower rotataion speed,

three schemes are recommended as below:

1.Use larger decoupling capacitors between

FAN_OUT and GND.

2.Shunt a capacitor of 1µF-2µF on FG pin to GND.

3.Use fans with open-collector FG outputs.

When controlling fans under lower rotation speed, the

output voltage of FAN_OUT would be too low for fan

to generate recognizable FG signals.

Using decouple capacitors on FAN_OUT and FG is to

increase the SNR on FG pins. While Using fans with

open-collector FG outputs can thoroughly solve the

problem, because the logic high level of FG would be

fixed to 5V.

Reset Immunity Negative-Going V

CC

Transients

In addition to issuing a reset to the microprocessor (µP)

during power-up, power-down, and brownout condi-

tions, the G768B is relatively immune to short duration

negative-going V

CC

transients (glitches).

Typically, for the G768B, a V

CC

transient that goes

100mV below the reset threshold and lasts 20µs or

less will not cause a reset pulse. A 0.1µF bypass ca-

pacitor mounted as close as possible to the V

CC

pin

provides additional transient immunity.

Ver 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

9

G768B

Global Mixed-mode Technology Inc.

Ensuring a Valid Reset Output Down to V

CC

= 0V

When V

CC

falls below 1V, the G768B RESET output

no longer sinks current-it becomes an open circuit.

Therefore, high-impedance CMOS logic inputs con-

nected to RESET can drift to undetermined voltages.

This presents no problem in most applications, since

most µP and other circuitry is inoperative with V

CC

be-

low 1V. However, in applications where RESET must

be valid down to 0V, adding a pull-down resistor to

RESET causes any stray leakage currents to flow to

ground, holding RESET low (Figure 3). R1's value is

not critical; 100k

is large enough not to load

RESET and small enough to pull RESET to ground.

Interfacing to Ps with Bi-directional Reset Pins

Ps with bi-directional reset pins (such as the Motorola

68HC11 series) can connect to the G768B reset out-

put. If, for example, the G768B RESET output is as-

serted high and the µP wants to pull it low, indetermi-

nate logic levels may result. To correct this, connect a

4.7k

resistor between the G768B RESET output

and the µP reset I/O (Figure 4). Buffer the G768B

RESET output to other system components.

Benefits of Highly Accurate Reset Threshold

Most µP supervisor Ics have reset threshold voltages

between 5% and 10% below the value of nominal sup-

ply voltages. This ensures a reset will not occur within

5% of the nominal supply, but will occur when the sup-

ply is 10% below nominal.

When using Ics rated at only the nominal supply ±5%

this leaves a zone of uncertainty where the supply is

between 5% and 10% low, and where the reset may or

may not be asserted.

The G768B use highly accurate circuitry to ensure that

reset is asserted close to the 5% limit, and long before

the supply has declined to 10% below nominal.

Fig 3. RESET Valid to V

CC

= Ground Circuit

SMBus Digital Interface

From a software perspective, the G768B appears as a

set of byte-wide registers that contain temperature

data, alarm threshold values, fan speed data, or con-

trol bits, A standard SMBus 2-wire serial interface is

used to read temperature data and write control bits

and alarm threshold data. Each A/D and fan control

channel within the device responds to the same

SMBus slave address for normal reads and writes.

The G768B employs four standard SMBus protocols:

Write Byte, Read Byte, Send Byte, and Receive Byte

(Figure 5). The shorter Receive Byte protocol allows

quicker transfers, provided that the correct data regis-

ter was previously selected by a Read Byte instruction.

Use caution with the shorter protocols in multi-master

systems, since a second master could over-write the

command byte without informing the first master.

The temperature data format is 7bits plus sign in

twos-complement form for each channel, with each

data bit representing 1∞C (Table3), transmitted MSB

first. Measurements are offset by +1/2∞C to minimize

internal rounding errors; for example, +99.6∞C is re-

ported as +100∞C.

Fig 4. Interfacing to µPs with Bi-directional Reset I/O

V

CC

G768B

RESET

GND

R1

100k

V

CC

G768B

RESET

GND

R1

100k

V

CC

G768B

RESET

GND

BUFFER

RESET

GND

V

CC

µP

4.7k

BUFFERED RESET

TO OTHER SYSTEM

COMPONENTS

V

CC

G768B

RESET

GND

BUFFER

RESET

GND

V

CC

µP

4.7k

BUFFERED RESET

TO OTHER SYSTEM

COMPONENTS

Ver 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

10

G768B

Global Mixed-mode Technology Inc.

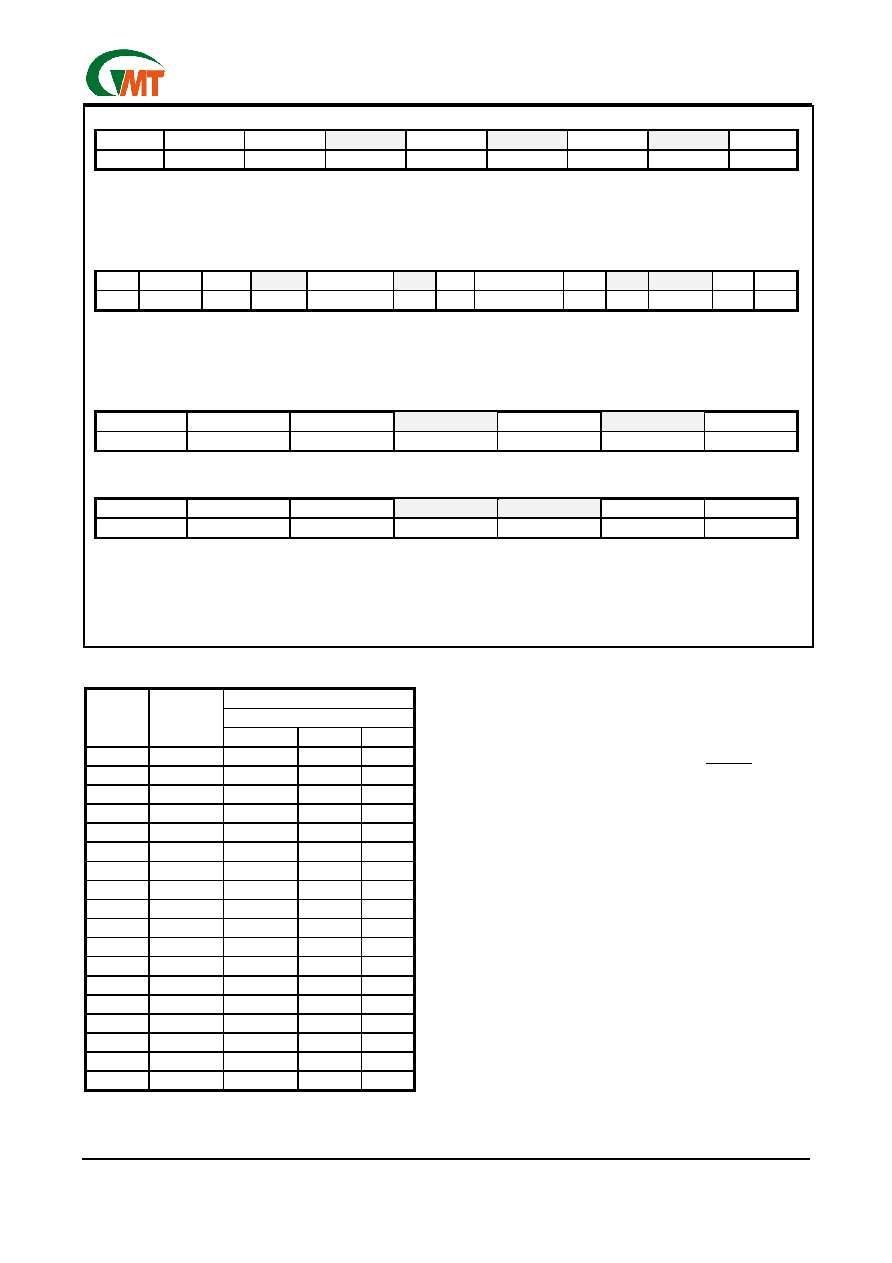

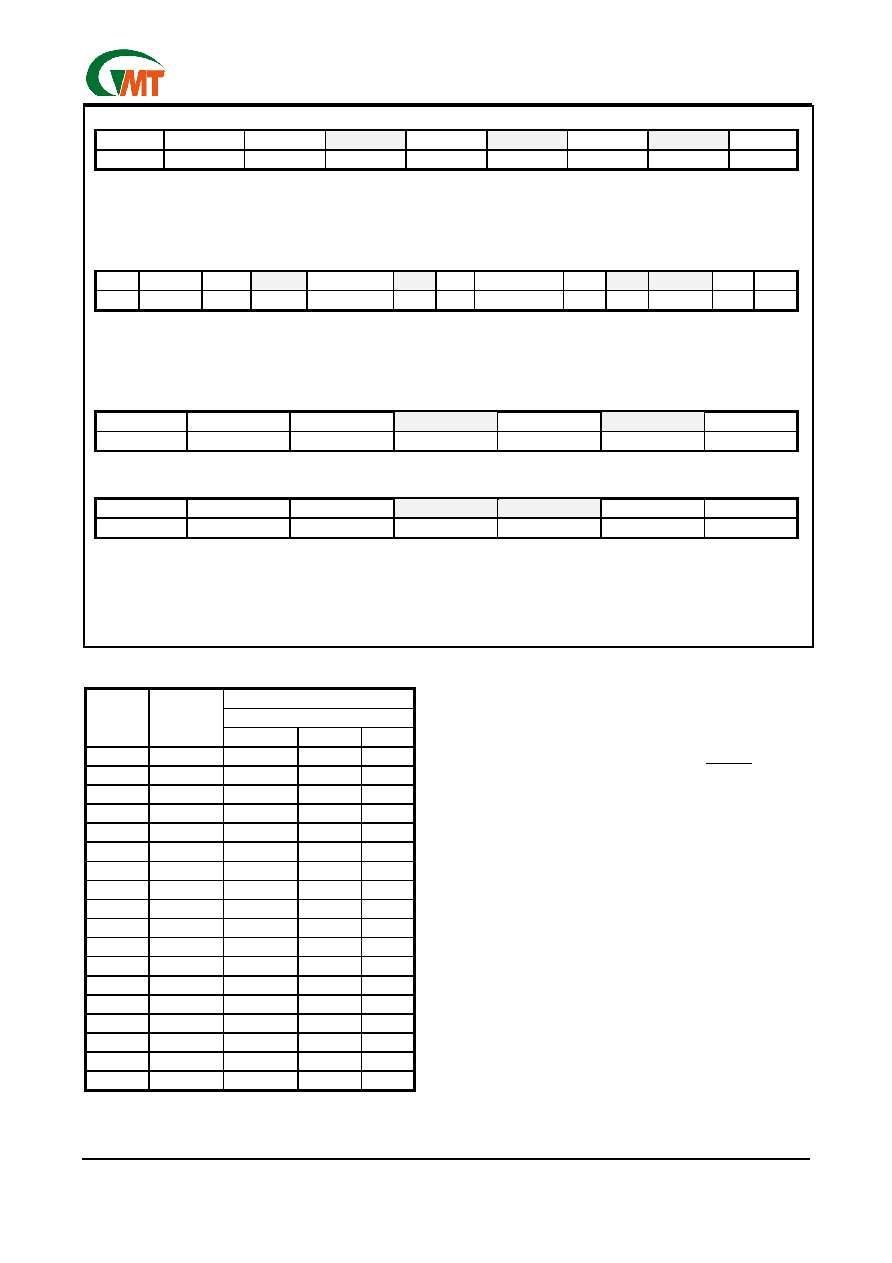

Write Byte Format

S Address WR ACK

Command

ACK

DATA

ACK

P

7

bits

8

bits 8

bits 1

Slave Address: equivalent to chip-select line of a 3-wire interface

Command Byte: selects, which register you, are writing to

Data Byte: data goes into the register set by the command byte (to set thresholds, configuration masks, and

sampling rate)

Read Byte Format

S Address WR ACK

Command ACK

S Address RD

ACK DATA

/// P

7 bits

8 bits

7 bits

8 bits

Slave Address: equivalent to chip- select line

Command Byte: selects, which register you, are reading from

Slave Address: repeated due to change in data-flow direction

Data byte: reads from the register set by the command byte

Send Byte Format

S Address WR ACK

Command

ACK

P

7

bits

8

bits

Command Byte: sends command with no data usually used for one-shot command

Receive Byte Format

S Address RD ACK

Data

/// P

7

bits

8

bits

Data Byte: reads data from the register commanded by the last Read Byte or Write

Byte transmission; also used for SMBus Alert Response return address

S = Start condition Shaded = Slave transmission P = Stop condition /// = Not acknowledged

Fig 5. SMBus Protocols

Table 3. Data Format (Twos-Complement)

DIGITAL OUTPUT

DATA BITS

TEMP.

(

∞

∞

∞

∞C)

ROUND

TEMP.

(

∞

∞

∞

∞C)

SIGN MSB LSB

+130.00 +127

0

111 1111

+127.00 +127

0

111 1111

+126.50 +127

0

111 1111

+126.00 +126

0

111 1110

+25.25 +25

0

001 1001

+0.50 +1

0 000

0001

+0.25 +0

0 000

0000

+0.00 +0

0 000

0000

-0.25 +0

0 000

0000

-0.50 +0

0 000

0000

-0.75 -1

1 111

1111

-1.00 -1

1 111

1111

-25.00 -25

1 110

0111

-25.50 -25

1 110

0110

-54.75 -55

1 100

1001

-55.00 -55

1 100

1001

-65.00 -65

1 011

1111

-70.00 -65

1 011

1111

Alarm Threshold Registers

Four registers store alarm threshold data, with

high-temperature (THIGH) and low-temperature

(TLOW) registers for each A/D channel. If either

measured temperature equals or exceeds the corre-

sponding alarm threshold value, an ALERT interrupt

is asserted.

The power-on-reset (POR) state of both THIGH regis-

ters is full scale (0111 1111, or +127∞C). The POR

state of both TLOW registers is 1100 1001 or -55∞C.

Diode Fault Alarm

There is a continuity fault detector at DXP that detects

whether the remote diode has an open-circuit condi-

tion. At the beginning of each conversion, the diode

fault is checked, and the status byte is updated. This

fault detector is a simple voltage detector; if DXP rises

above V

CC

- 1V (typical) due to the diode current

source, a fault is detected. Note that the diode fault

isn't checked until a conversion is initiated, so imme-

diately after power-on reset the status byte indicates

no fault is present, even if the diode path is broken.

Ver: 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

11

G768B

Global Mixed-mode Technology Inc.

If the remote channel is shorted (DXP to DXN or DXP

to GND), the ADC reads 0000 0000 so as not to trip

either the THIGH or TLOW alarms at their POR set-

tings. In applications that are never subjected to 0∞C in

normal operation, a 0000 0000 result can be checked

to indicate a fault condition in which DXP is acciden-

tally short circuited. Similarly, if DXP is short cir-

cuited to V

CC

, the ADC reads +127∞C for both remote

and local channels, and the device alarms.

ALERT Interrupts

The ALERT interrupt output signal is latched and can

only be cleared by reading the Alert Response ad-

dress. Interrupts are generated in response to THIGH

and TLOW comparisons and when the remote diode is

disconnected (for continuity fault detection). The in-

terrupt does not halt automatic conversions; new tem-

perature data continues to be available over the SMBus

interface after ALERT is asserted. The interrupt output

rupt output pin is open-drain so that device can share

a common interrupt line. The interrupt rate can never

exceed the conversion rate.

The interface responds to the SMBus Alert Response

address, an interrupt pointer return-address feature

(see Alert Response Address section). Prior to taking

corrective action, always check to ensure that an in-

terrupt is valid by reading the current temperature.

Alert Response Address

The SMBus Alert Response interrupt pointer provides

quick fault identification for simple slave devices that

lack the complex, expensive logic needed to be a bus

master. Upon receiving an ALERT interrupt signal, the

host master can broadcast a Receive Byte transmission

to the Alert Response slave address (0001 100). Then

any slave device that generated an interrupt attempts to

identify itself by putting its own address on the bus.

Table 4. Command-Byte Bit Assignments

REGISTER COMMAND POR

STATE

FUNCTION

RRTE2 00h

0000

0000b

Read 2nd remote temperature: returns latest temperature

RRTE1

01h

0000 0000b

Read 1st remote temperature: returns latest temperature

RSL

02h

N/A

Read status byte (flags, busy signal)

RCL

03h

0000 0000b

Read configuration byte

RCRA

04h

0000 0010b

Read conversion rate byte

RRHI2

05h

0111 1111b (127) Read 2nd remote THIGH limit

RRLS2

06h

1100 1001b(-55) Read 2nd remote TLOW limit

RRHI1

07h

0111 1111b (127) Read 1st remote THIGH limit

RRLS1

08h

1100 1001b (-55) Read 1st remote TLOW limit

WCA

09h

N/A

Write configuration byte

WCRW

0Ah

N/A

Write conversion rate byte

WRHA2

0Bh

N/A

Write 2nd remote THIGH limit

WRLN2

0Ch

N/A

Write 2nd remote TLOW limit

WRHA1

0Dh

N/A

Write 1st remote THIGH limit

WRLN1

0Eh

N/A

Write 1st remote TLOW limit

OSHT

0Fh

N/A

One-shot command (use send-byte format)

SET_CNT1

10h

1111 1111b

Write 1st fan programmed speed register

ACT_CNT1

11h

1111 1111b

Read 1st fan actual speed register

FAN_STA1

12h

10b

Read 1st fan status register

SET_CNT2

20h

1111 1111b

Write 2nd fan programmed speed register

ACT_CNT2

21h

1111 1111b

Read 2nd fan actual speed register

FAN_STA2

22h

10b

Read 2nd fan status register

CHIP_TMP

30h

0000 0000b

On-chip temperature

TMAX1 31h

0100 0110b (70)

1st remote Tmax

THYST1 32h

0011 1100b (60) 1st remote Thyst

TMAX2 33h

0100 0110b (70) 2nd remote Tmax

THYST2 34h

0011 1100b (60) 2nd remote Thyst

The Alert Response can activate several different slave

devices simultaneously, similar to the SMBus General

Call. If more than one slave attempts to respond, bus

arbitration rules apply, and the device with the lower

address code wins. The losing device does

not generate an acknowledge and continues to hold the

ALERT line low until serviced (implies that the host

interrupt input is level sensitive). Successful reading of

the alert response address clears the interrupt latch.

Ver: 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

12

G768B

Global Mixed-mode Technology Inc.

Command Byte Functions

The 8-bit command byte register (Table 4) is the mas-

ter index that points to the various other registers

within the G768B. The register's POR state is 0000

0000, so that a Receive Byte transmission (a protocol

that lacks the command byte) that occurs immediately

after POR returns the current local temperature data.

The one-shot command immediately forces a new

conversion cycle to begin. In software standby mode

( RUN /STOP bit = high), a new conversion is begun,

after which the device returns to standby mode. If a

conversion is in progress when a one-shot command

is received in auto-convert mode (RUN/STOP bit = low)

between conversions, a new conversion begins, the

conversion rate timer is reset, and the next automatic

conversion takes place after a full delay elapses.

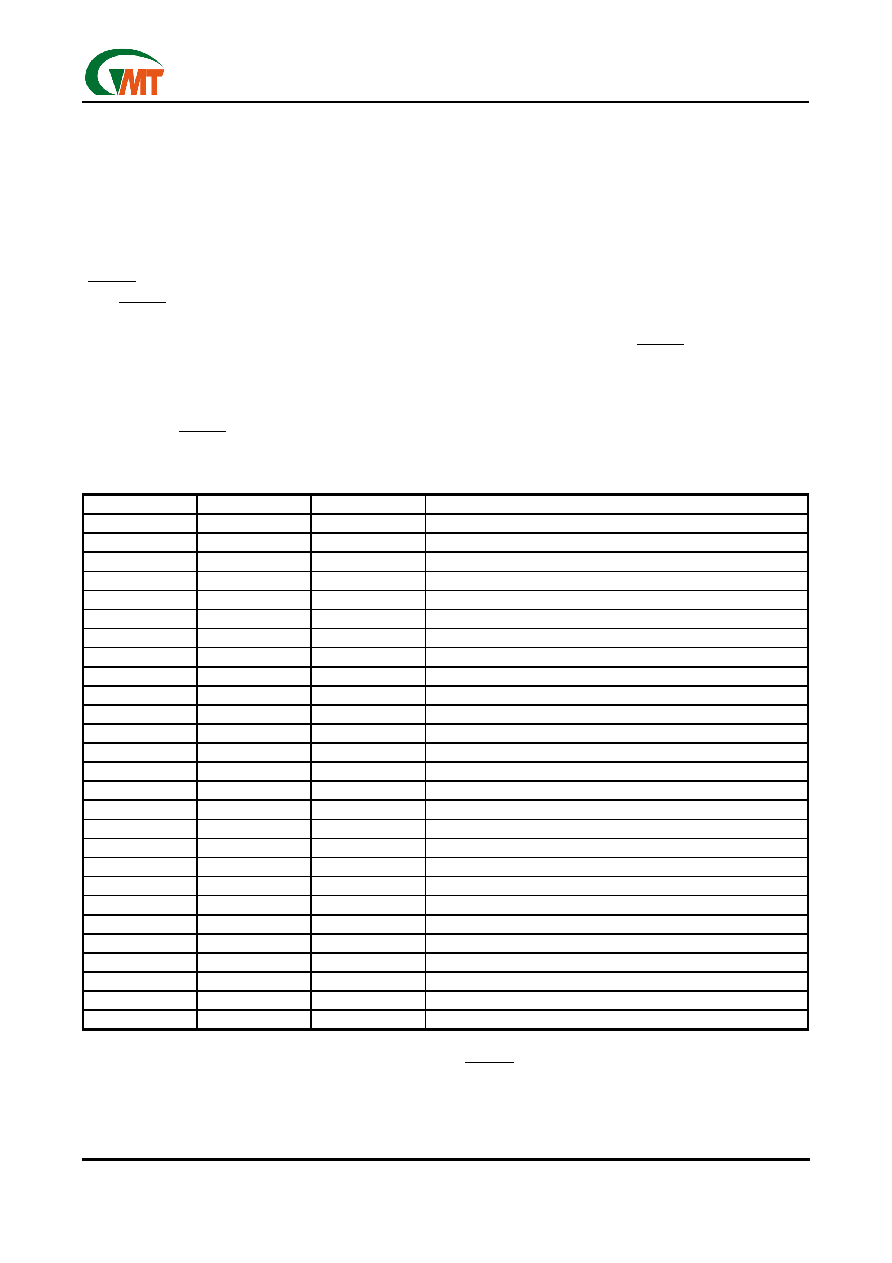

Thermal Configuration Byte Functions

The configuration byte register (Table 5) is used to

mask (disable) interrupts and to put the device in

software standby mode. The lower six bits are inter-

nally set to (XX1111), making them "don't care" bits.

Write

zeros to these bits. This register's contents can be

read back over the serial interface.

Thermal Status Byte Functions

The thermal status byte register (02h) (Table 6) indi-

cates which (if any) temperature thresholds have been

exceeded. This byte also indicates whether or not the

ADC is converting and whether there is an open circuit

in the remote diode DXPx-DXN path. After POR, the

normal state of all the flag bits is zero, assuming none

of the alarm conditions are present. The status byte is

cleared by any successful read of the status, unless

the fault persists. Note that the ALERT interrupt latch

is not automatically cleared when the status flag bit is

cleared.

When reading the status byte, you must check for in-

ternal bus collisions caused by asynchronous ADC

timing, or else disable the ADC prior to reading the

status byte (via the RUN/STOP bit in the configuration

byte). In one-shot mode, read the status byte only af-

ter the conversion is complete, which is 150ms max

after the one-shot conversion is commanded.

Table 5. Configuration-Byte Bit Assignments

BIT NAME

POR

STATE

FUNCTION

7 (MSB)

MASK

0

Masks all ALERT interrupts when high.

6

RUN

/ STOP

0

Standby mode control bit. If high, the device immediately stops converting and enters

standby mode. If low, the device converts in either one-shot or timer mode.

5-0

RFU

0

Reserved for future use

Table 6. Status-Byte Bit Assignments

BIT NAME

FUNCTION

7(MSB)

BUSY

A high indicates that the ADC is busy converting.

6

RHIGH2*

A high indicates that the 2

nd

diode high-temperature alarm has activated.

5

RLOW2*

A high indicates that the 2

nd

diode low-temperature alarm has activated.

4

RHIGH1*

A high indicates that the 1

st

diode high-temperature alarm has activated.

3

RLOW1*

A high indicates that the 1

st

diode low-temperature alarm has activated.

2

OPEN*

A high indicates a remote-diode continuity (open-circuit) fault.

1

RFU

Reserved for future use (returns 0)

0(LSB)

RFU

Reserved for future use (returns 0)

*These flags stay high until cleared by POR, or until the status byte register is read.

Table 7. Conversion-Rate Control Byte

DATA

CONVERSION

RATE (Hz)

Temperature Sensor Average

Supply Current (

µ

µ

µ

µA TYP, at Vcc = 5V)

00h 0.0625

30

01h 0.125

33

02h 0.25

35

03h 0.5

48

04h 1

70

05h 2

128

06h 4

225

07h 8

425

08h to FFh

RFU

-

Ver: 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

13

G768B

Global Mixed-mode Technology Inc.

Table 8. RLTS and RRTE Temp Register Update Timing Chart

OPERATING

MODE

CONVERSION

INITIATED BY:

NEW CONVERSION RATE

(CHANGED VIA WRITE TO CRW)

TIME UNTIL RLTS AND

RRTE ARE UPDATED

Auto-Convert

Power-on reset

N/A (0.25Hz)

156ms max

Auto-Convert

1-shot command, while idling

between automatic conversions

N/A

156ms max

Auto-Convert

1-shot command that occurs

during a conversion

N/A

When current conversion is

complete (1-shot is ignored)

Auto-Convert Rate

timer

0.0625Hz

20sec

Auto-Convert Rate

timer

0.125Hz

10sec

Auto-Convert Rate

timer

0.25Hz

5sec

Auto-Convert Rate

timer

0.5Hz

2.5sec

Auto-Convert Rate

timer

1Hz

1.25sec

Auto-Convert Rate

timer

2Hz

625ms

Auto-Convert Rate

timer

4Hz

312.5ms

Auto-Convert

Rate timer

8Hz

237.5ms

Software Standby RUN/STOP bit

N/A

156ms

Software Standby 1-shot command

N/A

156ms

To check for internal bus collisions, read the status

byte. If the least significant seven bits are ones, dis-

card the data and read the status byte again. The

status bits LHIGH, LLOW, RHIGH, and RLOW are

refreshed on the SMBus clock edge immediately fol-

lowing the stop condition, so there is no danger of

losing temperature-related status data as a result of

an internal bus collision. The OPEN status bit (diode

continuity fault) is only refreshed at the beginning of a

conversion, so OPEN data is lost. The ALERT inter-

rupt latch is independent of the status byte register, so

no false alerts are generated by an internal bus colli-

sion.

When auto-converting, if the THIGH and TLOW limits

are close together, it's possible for both high-temp and

low-temp status bits to be set, depending on the

amount of time between status read operations (espe-

cially when converting at the fastest rate). In these

circumstances, it's best not to rely on the status bits to

indicate reversals in long-term temperature changes

and instead use a current temperature reading to es-

tablish the trend direction.

Temperature Conversion Rate Byte

The conversion rate register (Table 7) programs the

time interval between conversions in free running

auto-convert mode. This variable rate control reduces

the supply current in portable-equipment applications.

The conversion rate byte's POR state is 02h (0.25Hz).

The G768B looks only at the 3 LSB bits of this register,

so the upper 5 bits are "don't care" bits, which should

be set to zero. The conversion rate tolerance is ±25%

at any rate setting.

Valid A/D conversion results for all channels are avail-

able one total conversion time (125ms nominal, 156ms

156ms maximum) after initiating a conversion, whether

conversion is initiated via the RUN/STOP bit, one-shot

command, or initial power-up. Changing the conver-

sion rate can also affect the delay until new results are

available. See Table 8.

Programmed fan speed register

The programmed fan speed registers (10h for fan 1,

20h for fan 2) are read/write registers. They contain

the count number of the desired fan speed. Power up

default is FFh.

Actual fan speed register

The actual fan speed registers (11h for fan 1, 21h for

fan 2) are read only. They contain the count number of

the actual fan speed. Power up default is FFh.

Fan status register

The fan status registers (12h for fan1, 22h for fan 2)

are read only. Its bit 0 is set to 1 when the actual fan

speed is ±20% outside the desired speed. Its bit 1 is

set to 1 when fan speed is below 1920 rpm. Power up

default is 0000_0010b.

Watchdog for fan control

Four temperature threshold registers intervene the

control of fans. Both pin OUT1 and pin OUT2 go high

when one of the remote temperature, DX1 and DX2,

rises above the respective Tmax. The control is not

released until both temperature values drop below

their Thyst. Besides, the fan controller also fully turns

on both fans when either of the two remote diodes is

open or both are short.

The power-up default values for Tmax and Thyst are

+70∞C and +60∞C, respectively. This allows the

G768B to be used in the occasion when system fails

and loses the fan control of G768B.

Ver: 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

14

G768B

Global Mixed-mode Technology Inc.

Slave Addresses

The G768B appears to the SMBus as one device hav-

ing a common address for all the ADC and fan control

channels. The device address is fixed to be 7Ah for

write and 7Bh for read.

The G768B also responds to the SMBus Alert Response

slave address (see the Alert Response Address section).

POR and UVLO

The G768B has a volatile memory. To prevent am-

biguous power-supply conditions from corrupting the

data in memory and causing erratic behavior, a POR

voltage detector monitors Vcc and clears the memory

if Vcc falls below 1.7V (typical, see Electrical Charac-

teristics table). When power is first applied and Vcc

rises above 1.75V (typical), the logic blocks begin op-

erating, although reads and writes at V

CC

levels below

3V are not recommended. A second Vcc comparator,

the ADC UVLO comparator, prevents the ADC from

converting until there is sufficient headroom (Vcc =

2.8V typical).

Power-Up Defaults:

Interrupt latch is cleared.

ADC begins auto /converting at a 0.25Hz rate.

Command byte is set to 00h to facilitate quick re-

mote Receive Byte queries.

THIGH and TLOW registers are set to max and

min limits, respectively.

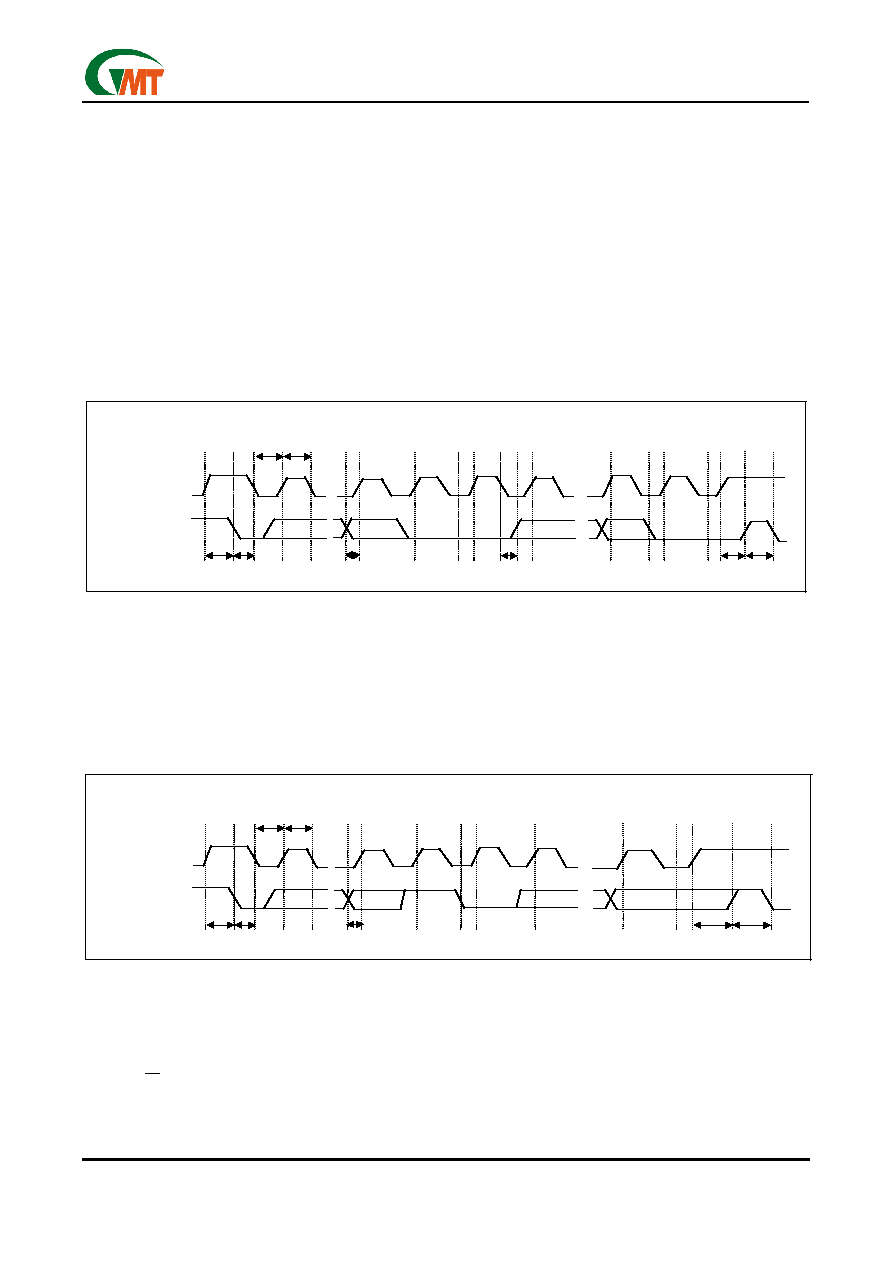

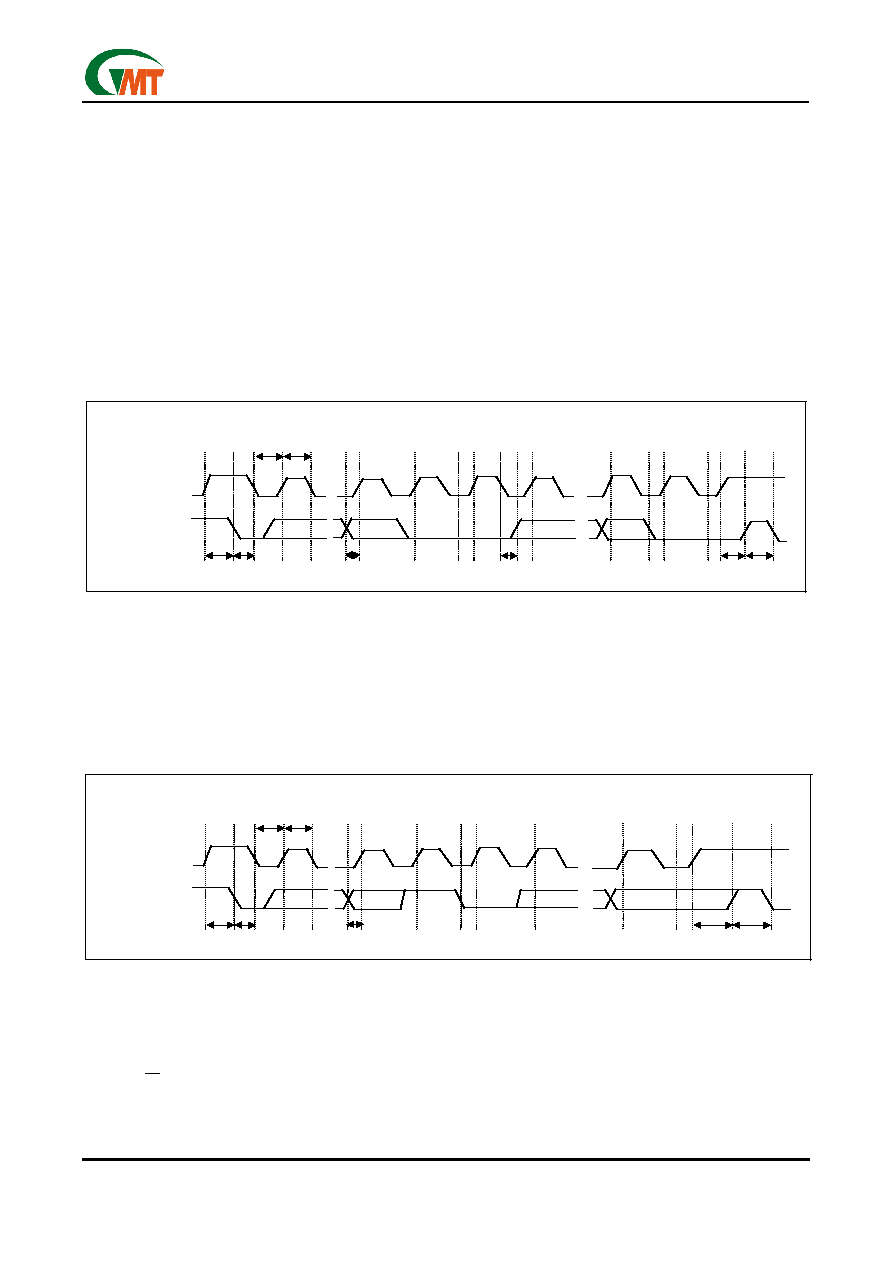

Figure 6. SMBus Write Timing Diagram

A = start condition

H = LSB of data clocked into slave

B = MSB of address clocked into slave

I = slave pulls SMBDATA line low

C = LSB of address clocked into slave

J = acknowledge clocked into master

D = R / W bit clocked into slave

K = acknowledge clocked pulse

E = slave pulls SMBData line low

L = stop condition data executed by slave

F = acknowledge bit clocked into master

M = new start condition

G = MSB of data clocked into slave

Figure 7. SMBus Read Timing Diagram

A = start condition

G = MSB of data clocked into master

B = MSB of address clocked into slave

H = LSB of data clocked into master

C = LSB of address clocked into slave

I = acknowledge clocked pulse

D = R / W bit clocked into slave

J = stop condition

E = slave pulls SMBDATA line low

K= new start condition

F =acknowledge bit clocked into master

SMBCLK

SMBDATA

A

B

C

D

E F

G

H

I J

K

L

M

t

SU:STA

t

HD:STA

t

SU:DAT

t

HD:DAT

t

SU:STO

t

BUF

t

LOW

t

HIGH

SMBCLK

SMBDATA

A

B

C

D

E F

G

H

I

J

K

t

SU:STA

t

HD:STA

t

SU:DAT

t

SU:STO

t

BUF

t

LOW

t

HIGH

SMBCLK

SMBDATA

A

B

C

D

E F

G

H

I

J

K

t

SU:STA

t

HD:STA

t

SU:DAT

t

SU:STO

t

BUF

t

LOW

t

HIGH

Ver: 1.3

Oct 28, 2002

TEL: 886-3-5788833

http://www.gmt.com.tw

15

G768B

Global Mixed-mode Technology Inc.

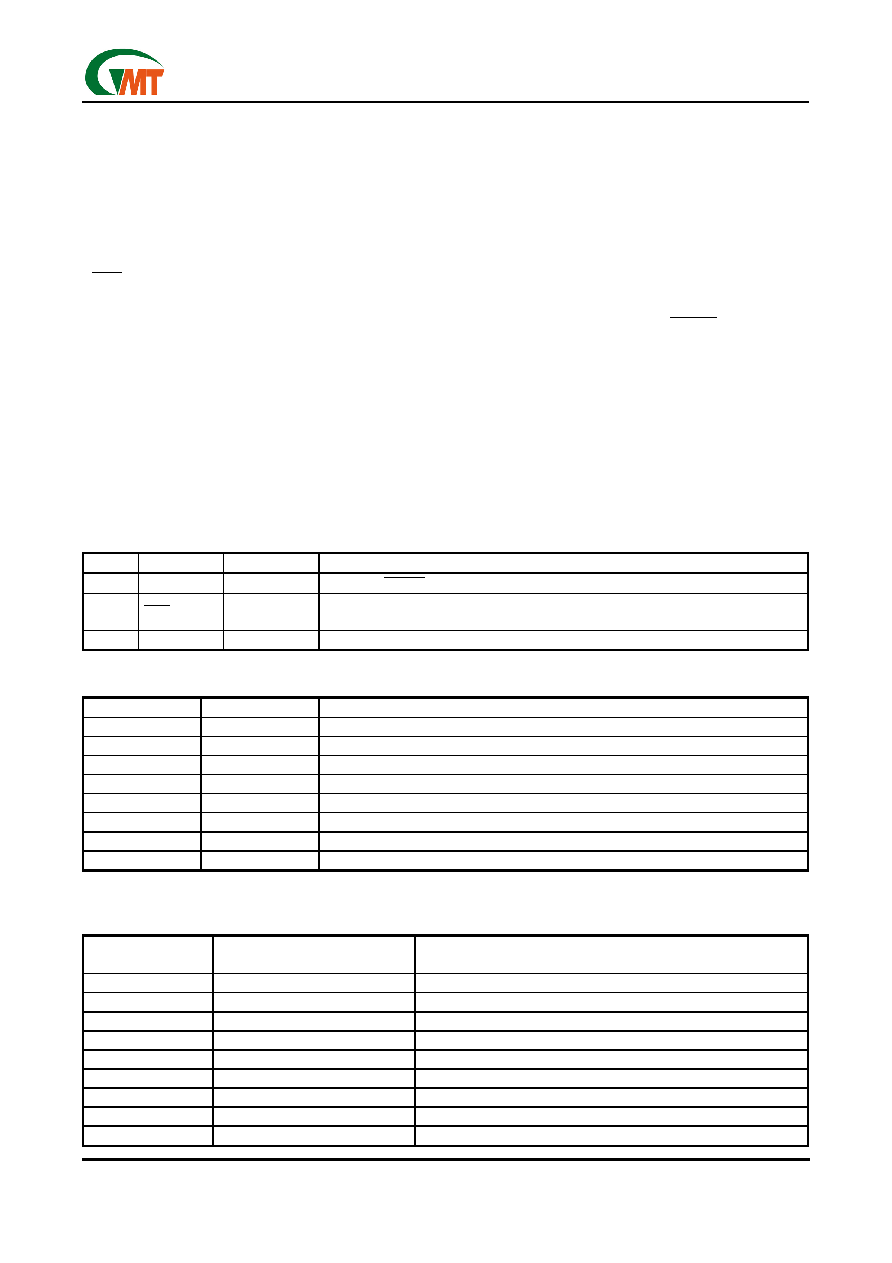

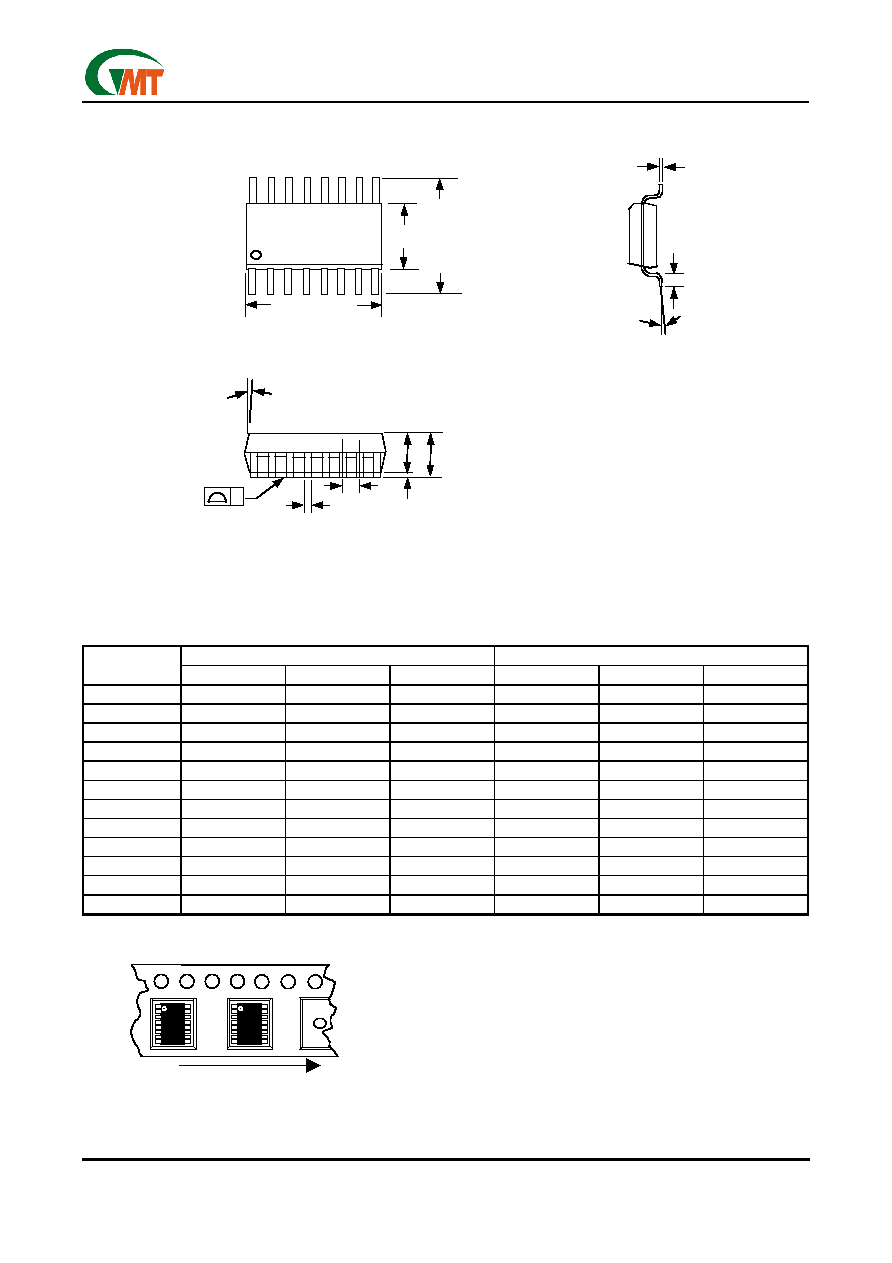

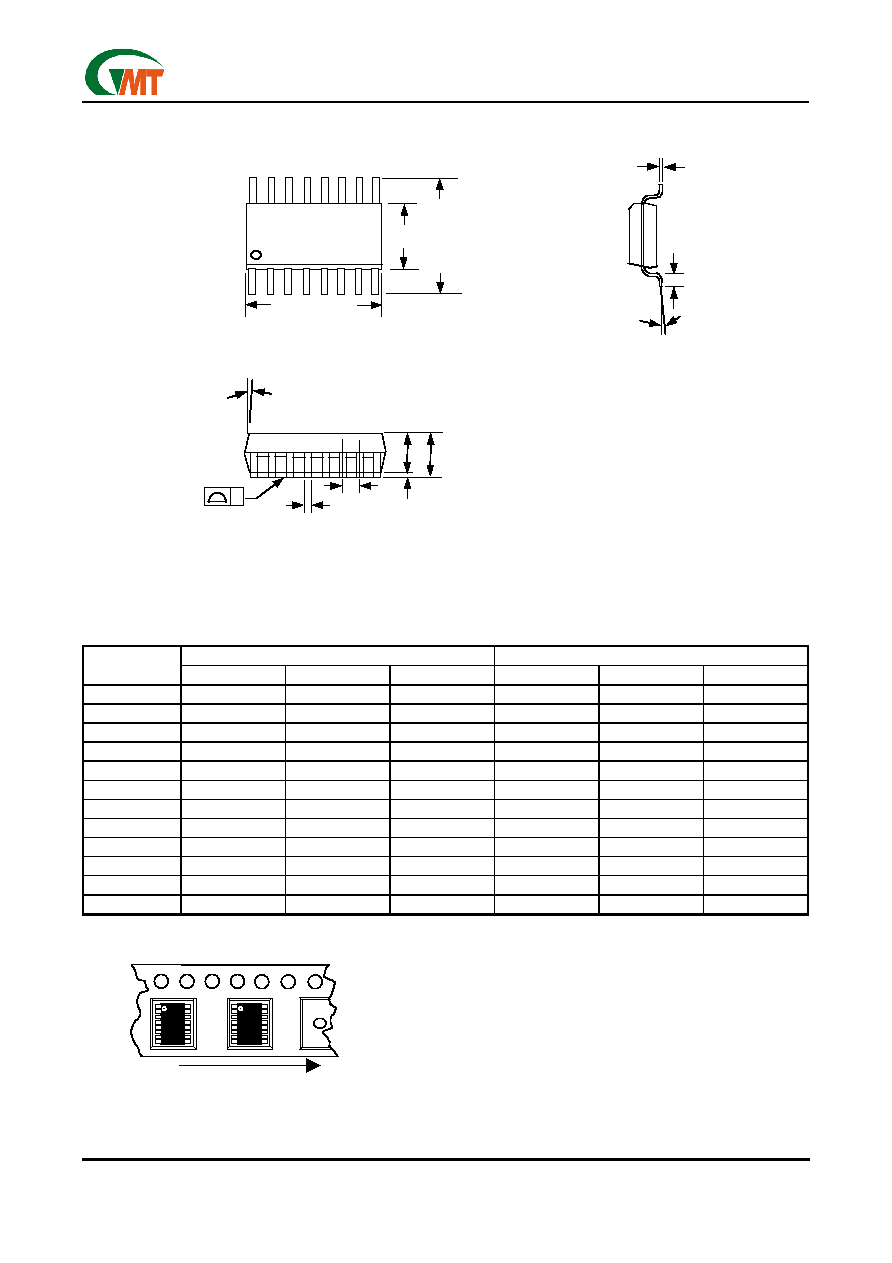

Package Information

Note:

1. Package body sizes exclude mold flash and gate burrs

2. Dimension L is measured in gage plane

3. Tolerance 0.10mm unless other wise specified

4. Controlling dimension is millimeter converted inch dimensions are not necessarily exact.

DIMENSION IN MM

DIMENSION IN INCH

SYMBOLS

MIN NOM MAX MIN NOM MAX

A 1.35 1.60 1.75 0.053 0.064 0.069

A1 0.10 ----- 0.25 0.004

----- 0.010

A2 ----- 1.45 ----- ----- 0.057

-----

b 0.20 0.25 0.30 0.008 0.010 0.012

C 0.19 ----- 0.25

0.007

----- 0.010

D 4.80 ----- 5.00

0.189

----- 0.197

E 5.80 ----- 6.20

0.228

----- 0.244

E1 3.80 ----- 4.00 0.150

----- 0.157

e ----- 0.64 ----- ----- 0.025

-----

L 0.40 ----- 1.27

0.016

----- 0.050

y ----- ----- 0.10 ----- ----- 0.004

0∫ ----- 8∫ 0∫ ----- 8∫

Taping Specification

GMT Inc. does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and GMT Inc. reserves the right at any time without notice to change said circuitry and specifications.

D

E1

E

7

∞

(4X)

A1

A2

A

e

b

y

C

L

Feed Direction

Typical SSOP Package Orientation

Feed Direction

Typical SSOP Package Orientation