| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: HI5714 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1

January 1998

HI5714

8-Bit, 40/60/75/80 MSPS A/D Converter

Features

∑ Sampling Rate . . . . . . . . . . . . . . . . . . 40/60/75/80 MSPS

∑ Low Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .325mW

∑ 7.65 ENOB at 4.43MHz

∑ Overflow/Underflow Three-State TTL Output

∑ Operates with Low Level AC Clock

∑ Very Low Analog Input Capacitance

∑ No Buffer Amplifier Required

∑ No Sample and Hold Required

∑ TTL Compatible I/O

∑ Pin-Compatible to Philips TDA8714

Applications

∑ Video Digitizing

∑ QAM Demodulator

∑ Digital Cable Setup Box

∑ Tape Drive/Mass Storage

∑ Medical Ultrasound Imaging

∑ Communication Systems

Description

The HI5714 is a high precision, monolithic, 8-bit, Analog-to-

Digital Converter fabricated in Intersil' advanced HBC10

BiCMOS process.

The HI5714 is optimized for a wide range of applications such as

ultrasound imaging, mass storage, instrumentation, and video

digitizing, where accuracy and low power consumption are

essential. The HI5714 is offered in 40 MSPS, 60 MSPS, and 75

MSPS sample rates.

The HI5714 delivers

±

0.4 LSB differential nonlinearity while

consuming only 325mW power (Typical) at 75 MSPS. The

digital inputs and outputs are TTL compatible, as well as

allowing for a low-level sine wave clock input.

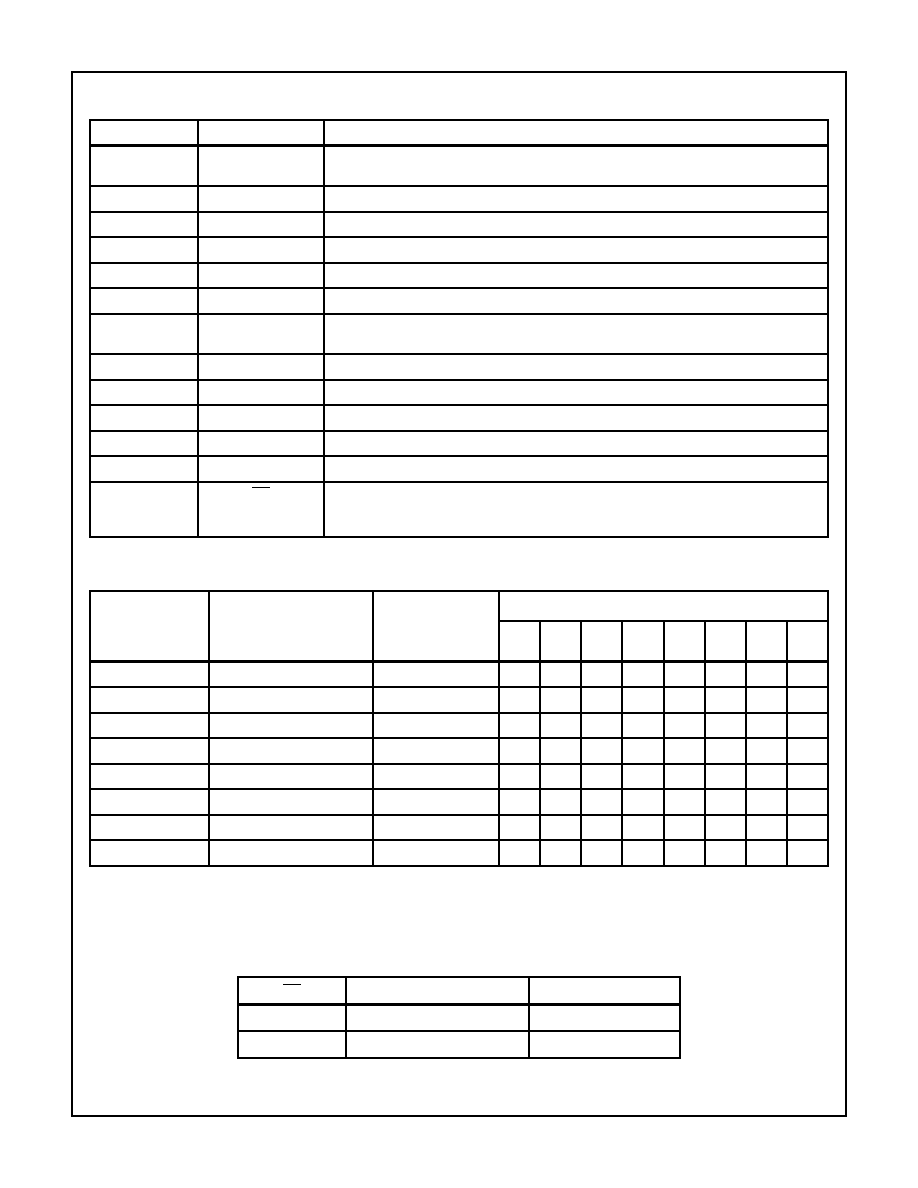

Pinout

HI5714

(SOIC)

TOP VIEW

Ordering Information

PART

NUMBER

TEMP.

RANGE

(

o

C)

PACKAGE

SAMPLING

FREQUENCY

(MHz)

PKG.

NO.

HI5714/4CB

0 to 70

24 Ld SOIC

40

M24.3

HI5714/6CB

0 to 70

24 Ld SOIC

60

M24.3

HI5714/7CB

0 to 70

24 Ld SOIC

75

M24.3

HI5714/8CB

0 to 70

24 Ld SOIC

80

M24.3

HI5714EVAL

25

Evaluation Board

1

2

3

4

5

6

7

8

9

10

11

12

D1

D0

NC

V

RB

NC

AGND

V

CCA

V

IN

V

RT

NC

O/UF

D7

16

17

18

19

20

21

22

23

24

15

14

13

D2

OE

V

CCO2

OGND

V

CCO1

DGND

D4

D5

D6

D3

V

CCD

CLK

File Number

3973.4

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143 | Copyright © Intersil Corporation 1999

2

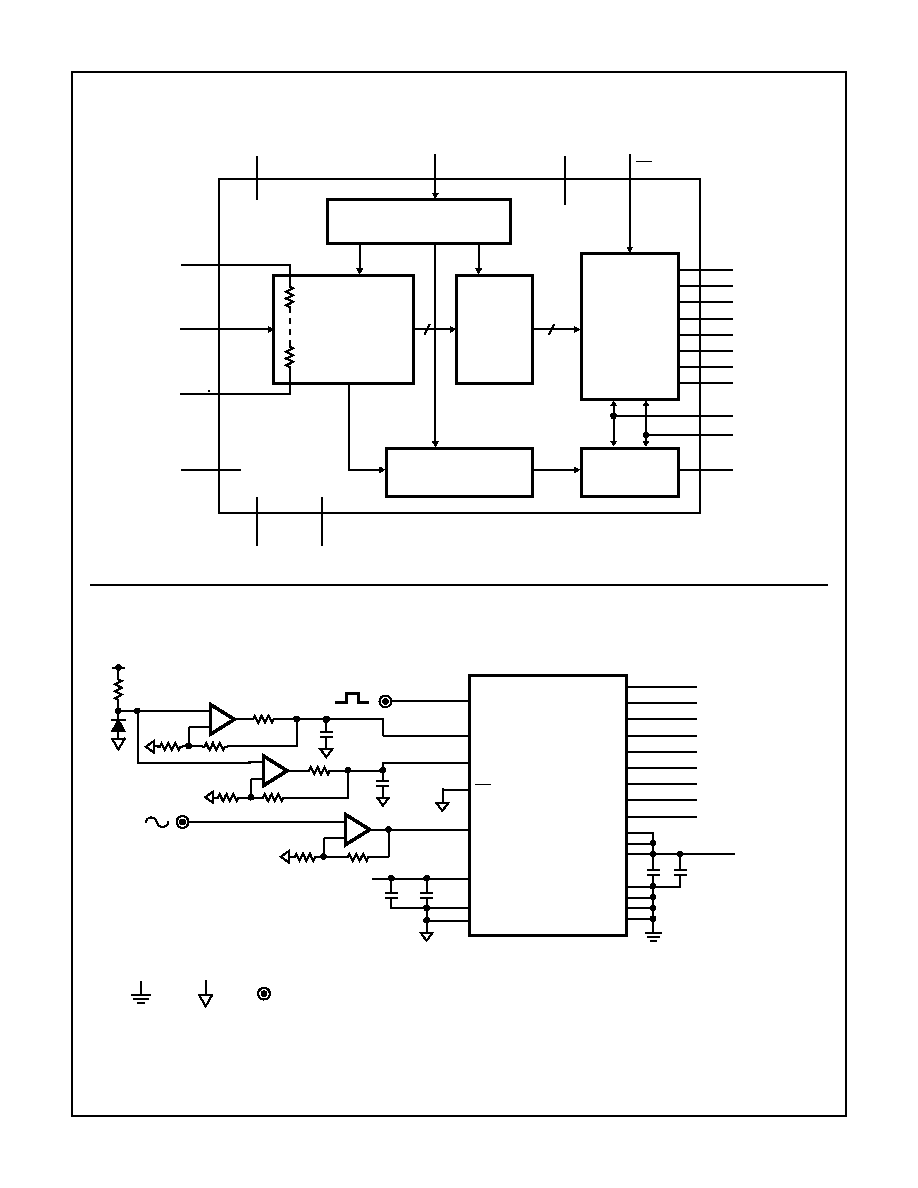

Functional Block Diagram

Typical Application Schematic

NOTES:

1. Pin 5 should be connected to AGND and pins 3 and 10 to DGND to reduce noise coupling into the device.

2. Analog and Digital supplies should be separated and decoupled to reduce digital noise coupling into the analog supply.

ANALOG TO DIGITAL

CONVERTER

LATCHES

TTL OUTPUTS

TTL OUTPUT

OVERFLOW/UNDERFLOW

LATCH

CLOCK DRIVER

V

CCA

CLK

V

CCD

OE

V

RT

V

RB

OGND

AGND

DGND

V

CCO1

V

CCO2

O/UF

V

IN

1

2

4

6

7

8

9

11

12

13

14

15

16

17

18

19

20

21

22

23

24

D7

D6

D5

D4

D3

D2

D1

D0

12

13

14

15

23

24

1

2

V

RB

HI5714

V

RT

CLK

DGND

NC

NC

AGND

V

CCA

V

CCD

D7

D6

D5

D4

D3

D2

D1

D0

as close to part as possible.

1nF and 0.1

µ

F CAPS are placed

CLOCK

V

IN

NC

V

IN

OGND

V

CCO

V

CCO

+5VA

O/UF

BNC

DGND

AGND

OE

11

19

21

18

20

3

17

10

16

9

4

8

7

5

6

22

3.6V

1.3V

+5VA

+5VD

1nF

0.1

µ

F

1nF

0.1

µ

F

0.1

0.1

-

+

-

+

-

+

HI5714

3

Absolute Maximum Ratings

T

A

= 25

o

C

Thermal Information

V

CCA

, V

CCD

, V

CCO

. . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +6.0V

V

CCA

- V

CCD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.3V

V

CCO

- V

CCD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.3V

V

CCA

- V

CCO

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.3V

V

IN

, V

CLK

, V

RT

, V

RB

, OE . . . . . . . . . . . . . . . . . . . . . . -0.3V to +6.0V

I

OUT

, Digital Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10mA

Input Current, All Pins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1mA

Digital I/O Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . OGND to V

CCO

Operating Conditions

Temperature Range

HI5714CB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

o

C to 70

o

C

Thermal Resistance (Typical, Note 1)

JA

(

o

C/W)

SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

75

Maximum Junction Temperature (Plastic Package) . . . . . . . . 150

o

C

Maximum Storage Temperature Range . . . . . . . . . -65

o

C to 150

o

C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . . 300

o

C

(SOIC - Lead Tips Only)

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1.

JA

is measured with the component mounted on an evaluation PC board in free air.

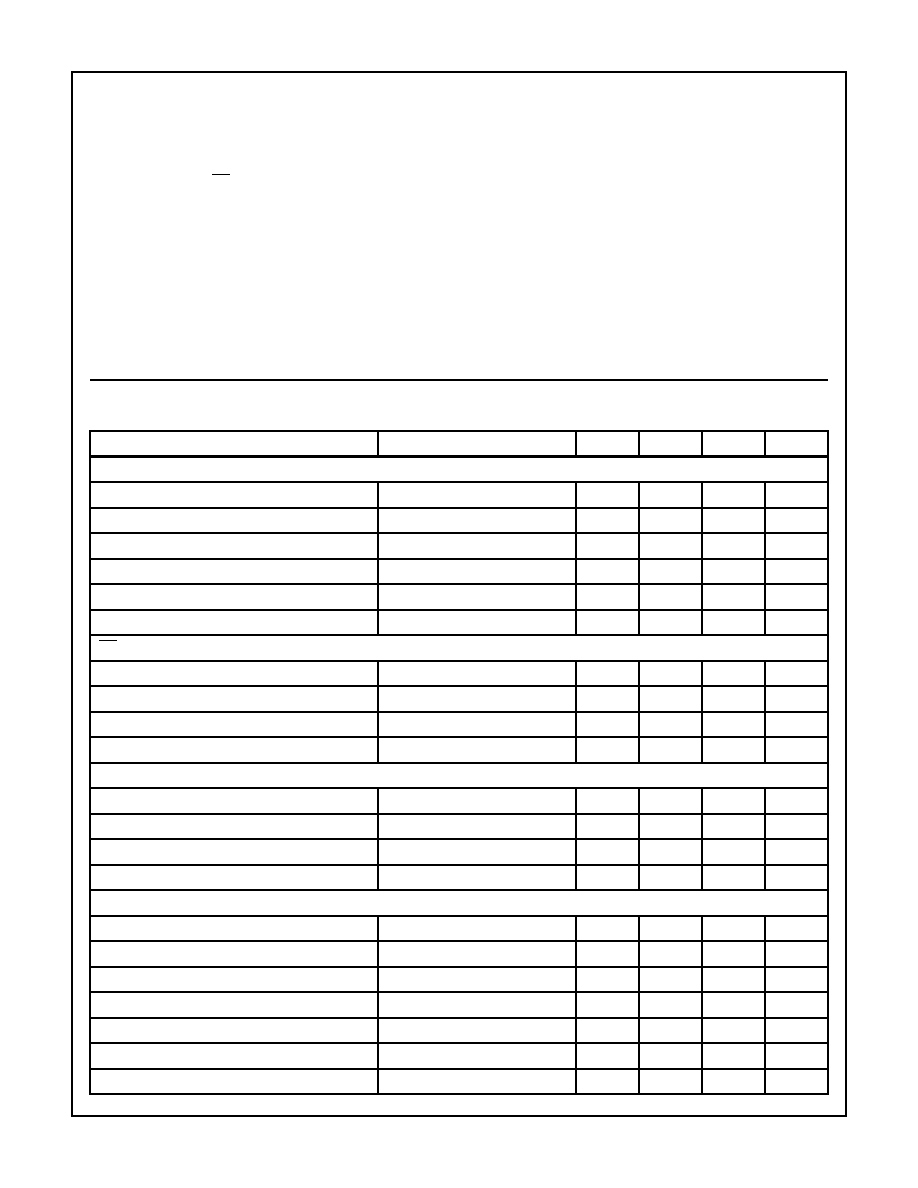

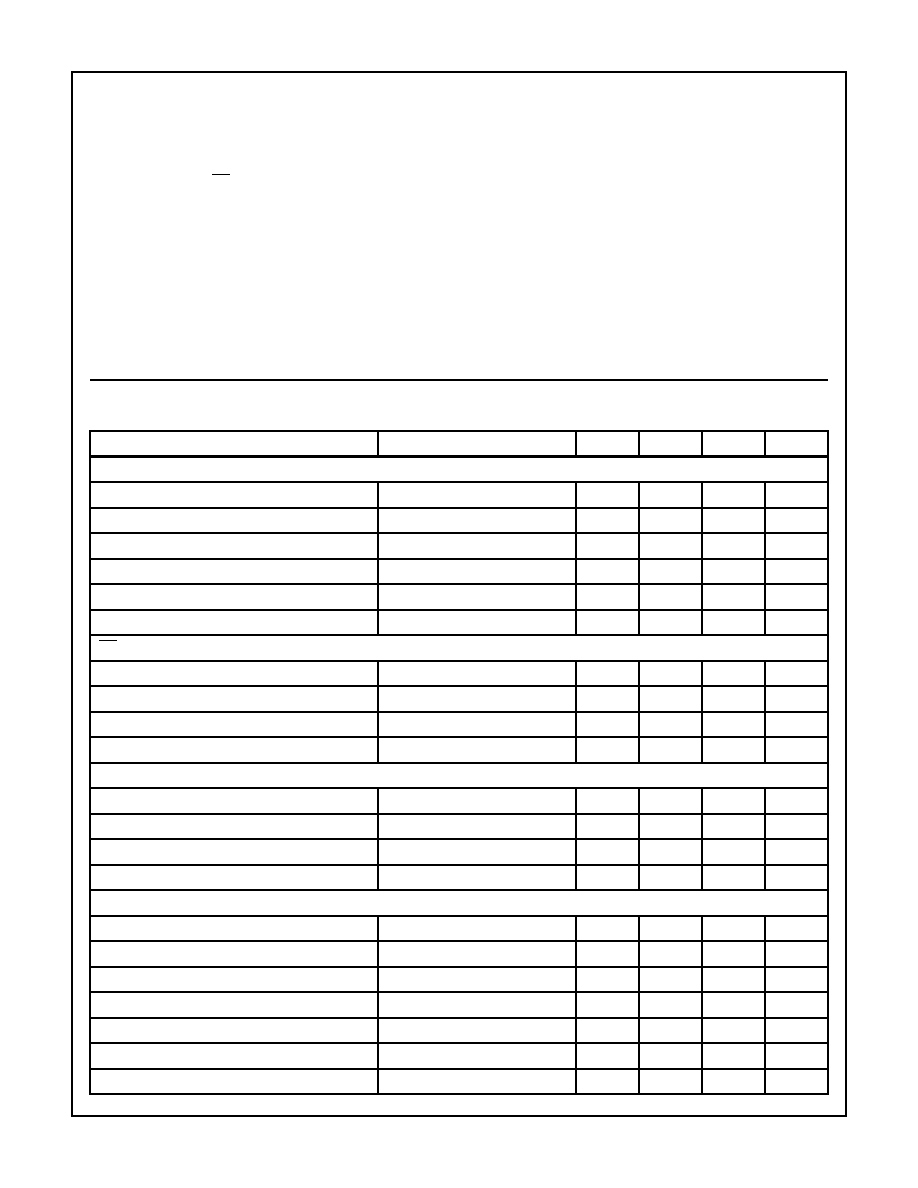

Electrical Specifications

V

CCA

= V

CCD

= V

CCO

= +5V; V

RB

= 1.3V; V

RT

= 3.6V; T

A

= 25

o

C,

Unless Otherwise Specified

PARAMETER

TEST CONDITION

MIN

TYP

MAX

UNITS

CLOCK (Referenced to DGND) (Note 1)

Logic Input Voltage Low, V

IL

0

-

0.8

V

Logic Input Voltage High, V

IH

2.0

-

V

CCD

V

Logic Input Current Low, I

IL

V

CLK

= 0.4V

-400

-

-

µ

A

Logic Input Current High, I

IH

V

CLK

= 2.7V

-

-

300

µ

A

Input Impedance, Z

IN

f

CLK

= 75MHz (Note 8)

-

2

-

k

Input Capacitance, C

IN

f

CLK

= 75MHz (Note 8)

-

4.5

-

pF

OE (Referenced to DGND)

Logic Input Voltage Low, V

IL

0

-

0.8

V

Logic Input Voltage High, V

IH

2.0

-

V

CCD

V

Logic Input Current Low, I

IL

V

IL

= 0.4V

-400

-

-

µ

A

Logic Input Current High, I

IH

V

IH

= 2.7V

-

-

20

µ

A

V

IN

(Referenced to AGND)

Input Current Low, I

IL

V

IN

= 1.2V

-

0

-

µ

A

Input Current High, I

IH

V

IN

= 3.5V

-

100

180

µ

A

Input Impedance, Z

IN

f

IN

= 4.43MHz

-

10

-

k

Input Capacitance, C

IN

f

IN

= 4.43MHz

-

14

-

pF

REFERENCE INPUT

Bottom Reference Range, V

RB

1.2

1.3

1.6

V

Top Reference Range, V

RT

3.5

3.6

3.9

V

Reference Range, V

REF

(V

RT

- V

RB

)

1.9

2.3

2.7

V

Reference Current, I

REF

-

10

-

mA

Reference Ladder Resistance, R

LAD

-

240

-

R

LADTC

-

0.24

-

/

o

C

Bottom Offset Voltage, V

OB

(Note 4)

-

255

-

mV

HI5714

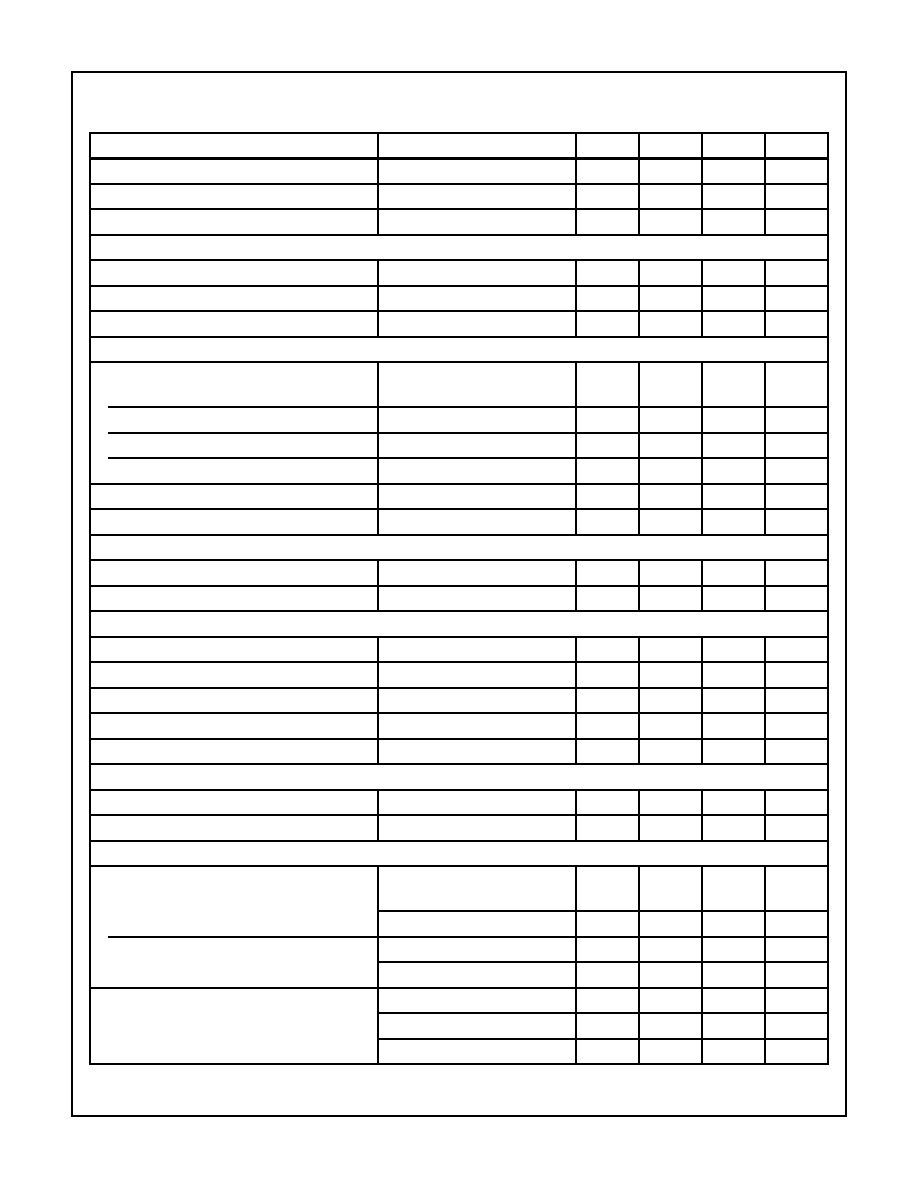

4

V

OBTC

(Note 4)

-

136

-

µ

V/

o

C

Top Offset Voltage, V

OT

(Note 4)

-

-300

-

mV

V

OTTC

(Note 4)

-

480

-

µ

V/

o

C

DIGITAL OUTPUTS (D0 to D7 and O/UF Referenced to OGND)

Logic Output Voltage Low, V

OL

I

O

= 1mA

0

-

0.4

V

Logic Output Voltage High, V

OH

I

O

= -0.4mA

2.7

-

V

CCO

V

Output Leakage Current, I

D

0.4V < V

OUT

< V

CCO

-20

-

+20

µ

A

SWITCHING CHARACTERISTICS (Notes 3, 4) See Figure 9

Sample Rate, f

CLK

HI5714/8

80

-

-

MHz

HI5714/7

75

-

-

MHz

HI5714/6

60

-

-

MHz

HI5714/4

40

-

-

MHz

Clock Pulse Width High, t

CPH

6

-

-

ns

Clock Pulse Width Low, t

CPL

6

-

-

ns

ANALOG SIGNAL PROCESSING (f

CLK

= 40MHz)

Differential Gain, DG

(Notes 5, 8)

-

1.0

-

%

Differential Phase, DP

(Notes 5, 8)

-

0.05

-

degree

HARMONICS (f

CLK

= 75MHz)

Second Harmonic, H2

f

IN

= 4.43MHz

-

-63

-

dB

Third Harmonic, H3

f

IN

= 4.43MHz

-

-65

-

dB

Total Harmonic Distortion, THD

f

IN

= 4.43MHz

-

-59

-

dB

Spurious Free Dynamic Range, SFDR

f

IN

= 4.43MHz

-

62

-

dB

Analog Input Bandwidth (-3dB)

-

18

-

MHz

TRANSFER FUNCTION

Differential Linearity Error, DNL

(Note 6)

-

±

0.4

-

LSB

Integral Linearity Error, INL

(Note 6)

-

±

0.75

-

LSB

EFFECTIVE NUMBER OF BITS

ENOB

HI5714/4 (f

CLK

= 40MHz)

f

IN

= 4.43MHz

-

7.65

-

Bits

f

IN

= 7.5MHz

-

7.5

-

Bits

HI5714/6 (f

CLK

= 60MHz)

f

IN

= 4.43MHz

-

7.65

-

Bits

f

IN

= 7.5MHz

-

7.5

-

Bits

HI5714/7 (f

CLK

= 75MHz)

f

IN

= 4.43MHz

-

7.4

-

Bits

f

IN

= 7.5MHz

-

7.15

-

Bits

f

IN

= 10MHz

-

6.8

-

Bits

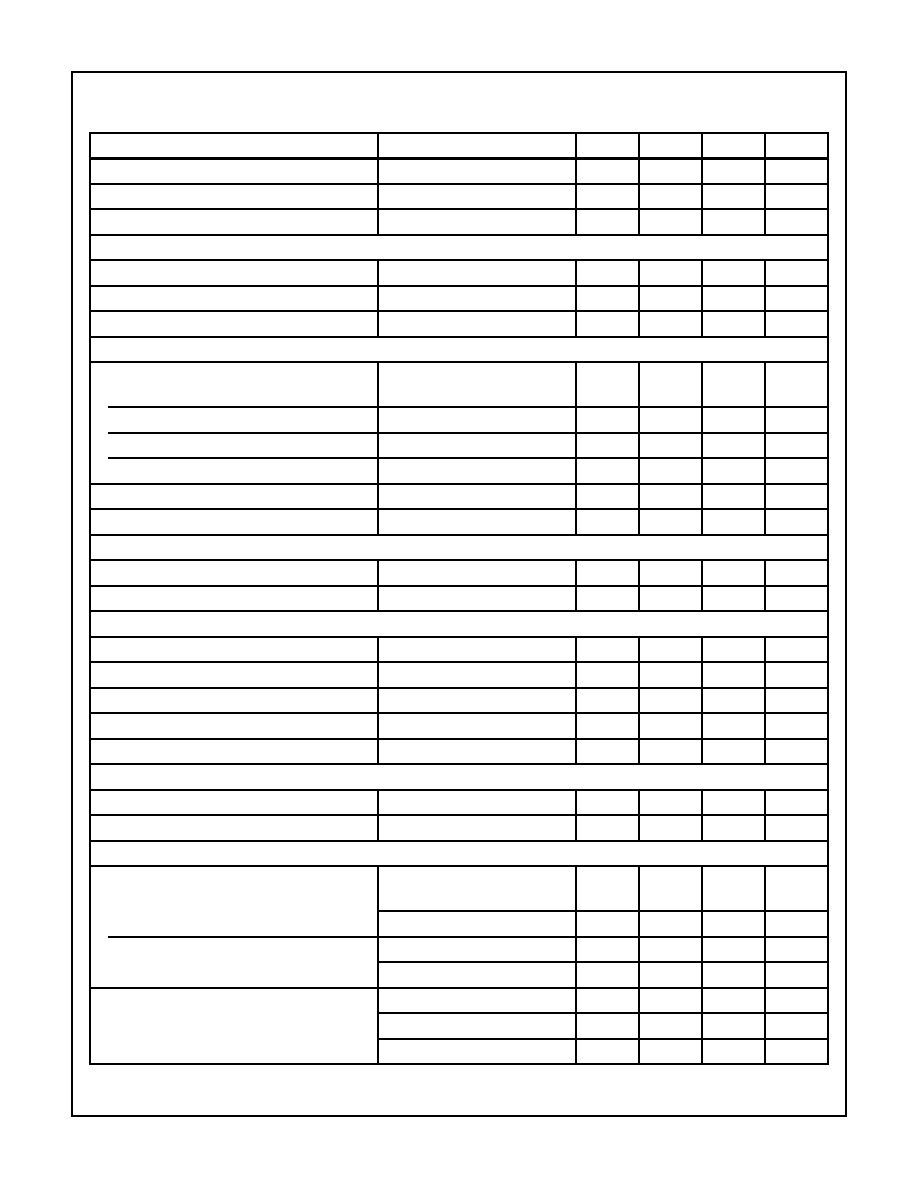

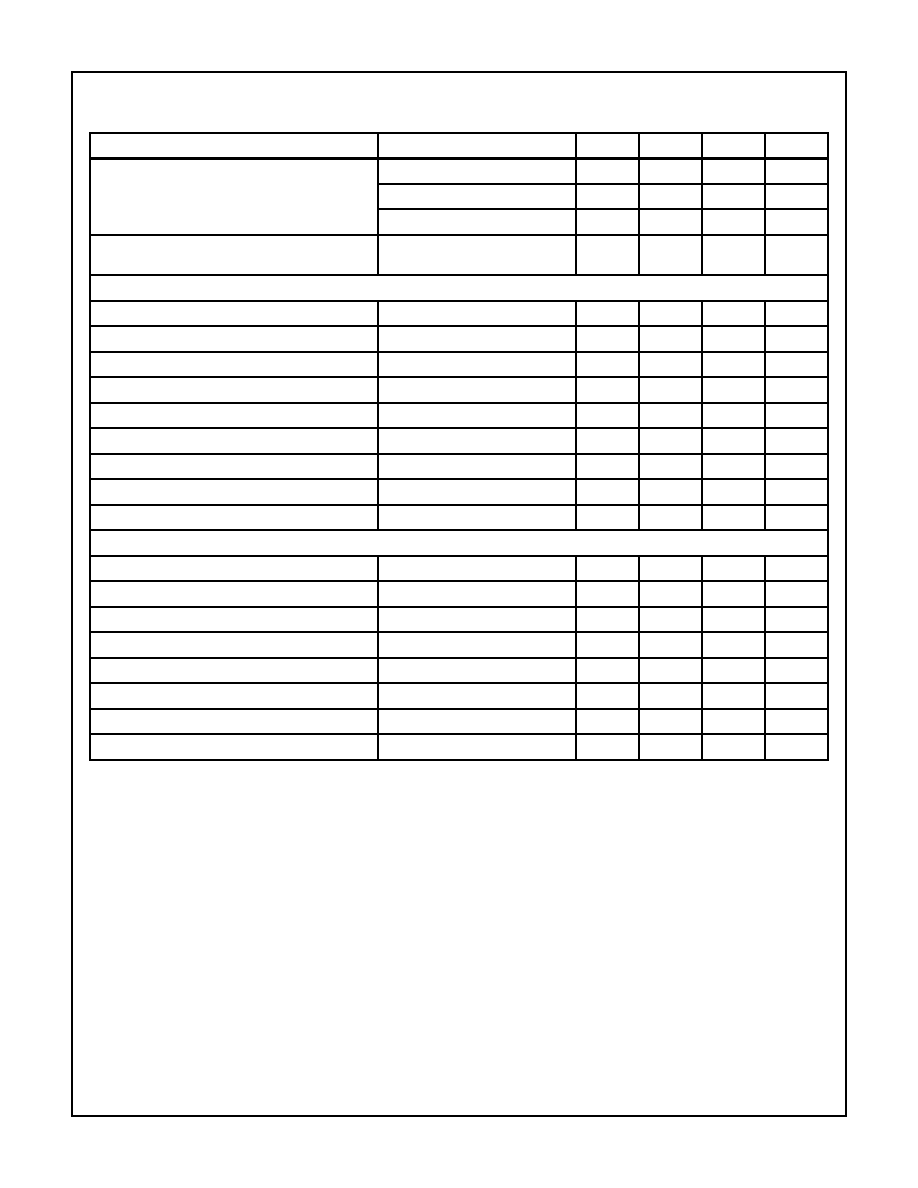

Electrical Specifications

V

CCA

= V

CCD

= V

CCO

= +5V; V

RB

= 1.3V; V

RT

= 3.6V; T

A

= 25

o

C,

Unless Otherwise Specified (Continued)

PARAMETER

TEST CONDITION

MIN

TYP

MAX

UNITS

HI5714

5

HI5714/8 (f

CLK

= 80MHz)

f

IN

= 4.43MHz

-

7.3

-

Bits

f

IN

= 7.5MHz

-

7.0

-

Bits

f

IN

= 10MHz

-

6.64

-

Bits

Bit Error Rate, BER

(Note 7)

-

10

-11

-

Times/

Sample

TIMING (f

CLK

= 75MHz) See Figures 1, 2

Sampling Delay, t

SD

-

-

2

ns

Output Hold Time, t

HD

5

-

-

ns

Output Delay Time, t

D

HI5714/4/6/7

-

10

13

ns

Output Delay Time, t

D

HI5714/8

-

10

12.25

ns

Output Enable Delay, t

PZH

Enable to High

-

14.6

-

ns

Output Enable Delay, t

PZL

Enable to Low

-

17.8

-

ns

Output Disable Delay, t

PHZ

Disable from High

-

5.3

-

ns

Output Disable Delay, t

PLZ

Disable from Low

-

6.7

-

ns

Aperture Jitter, t

AJ

-

50

-

ps

POWER SUPPLY CHARACTERISTICS

Analog Power Supply Range, V

CCA

4.75

5.0

5.25

V

Digital Power Supply Range, V

CCD

4.75

5.0

5.25

V

Output Power Supply Range, V

CCO

4.75

5.0

5.25

V

Total Supply Current

-

65

75

mA

Supply Current, I

CCA

-

30

-

mA

Supply Current, I

CCD

-

26

-

mA

Supply Current, I

CCO

-

9

-

mA

Power Dissipation

-

325

375

mW

NOTES:

1. Dissipation rating assumes device is mounted with all leads soldered to printed circuit board.

2. The supply voltages V

CCA

and V

CCD

may have any value between -0.3V and +6V as long as the difference V

CCA

- V

CCD

lies between

-0.3V and +0.3V.

3. In addition to a good layout of the digital and analog ground, it is recommended that the rise and fall times of the clock not be less than 1ns.

4. Analog input voltages producing code 00 up to and including FF.

V

OB

(Bottom Offset Voltage) is the difference between the analog input which produces data equal to 00 and the Bottom Reference

Voltage (V

RB

).

V

OBTC

(Bottom Offset Voltage Temperature Coefficient) is the variation of V

OB

with temperature.

V

OT

(Top Offset Voltage) is the difference between the Top Reference Voltage (V

RT

) and the analog input which produces data output

equal to FF.

V

OTTC

(Top Offset Voltage Temperature Coefficient) is the variation of V

OT

with temperature.

5. Input is standard 5 step video test signal. A 12-bit R reconstruct DAC and VM700 are used for measurement.

6. Full scale sinewave, f

IN

= 4.43MHz.

7. f

CLK

= 75MHz, f

IN

= 4.43MHz, V

IN

=

±

8 LSB at code 128, 50% Clock duty cycle.

8. Parameter is guaranteed by design, not production tested.

Electrical Specifications

V

CCA

= V

CCD

= V

CCO

= +5V; V

RB

= 1.3V; V

RT

= 3.6V; T

A

= 25

o

C,

Unless Otherwise Specified (Continued)

PARAMETER

TEST CONDITION

MIN

TYP

MAX

UNITS

HI5714

6

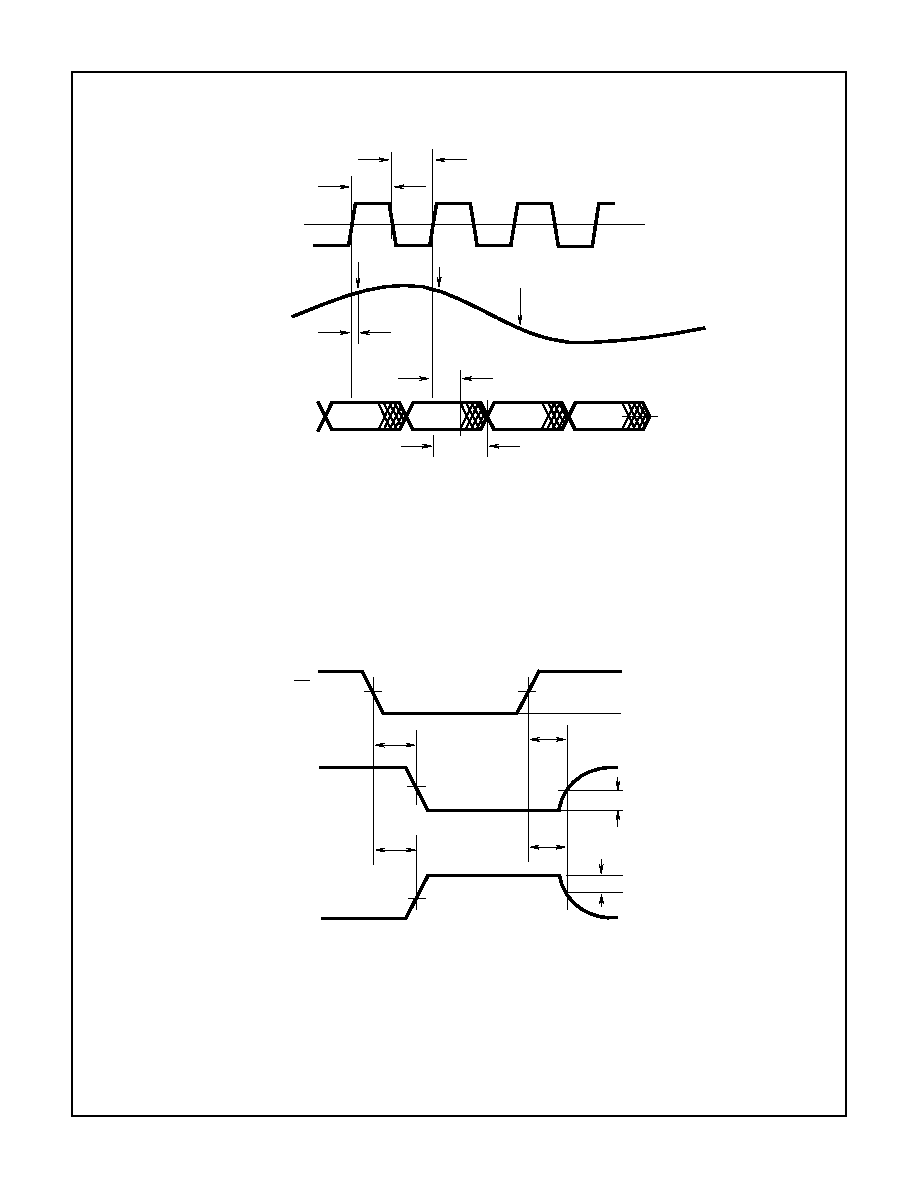

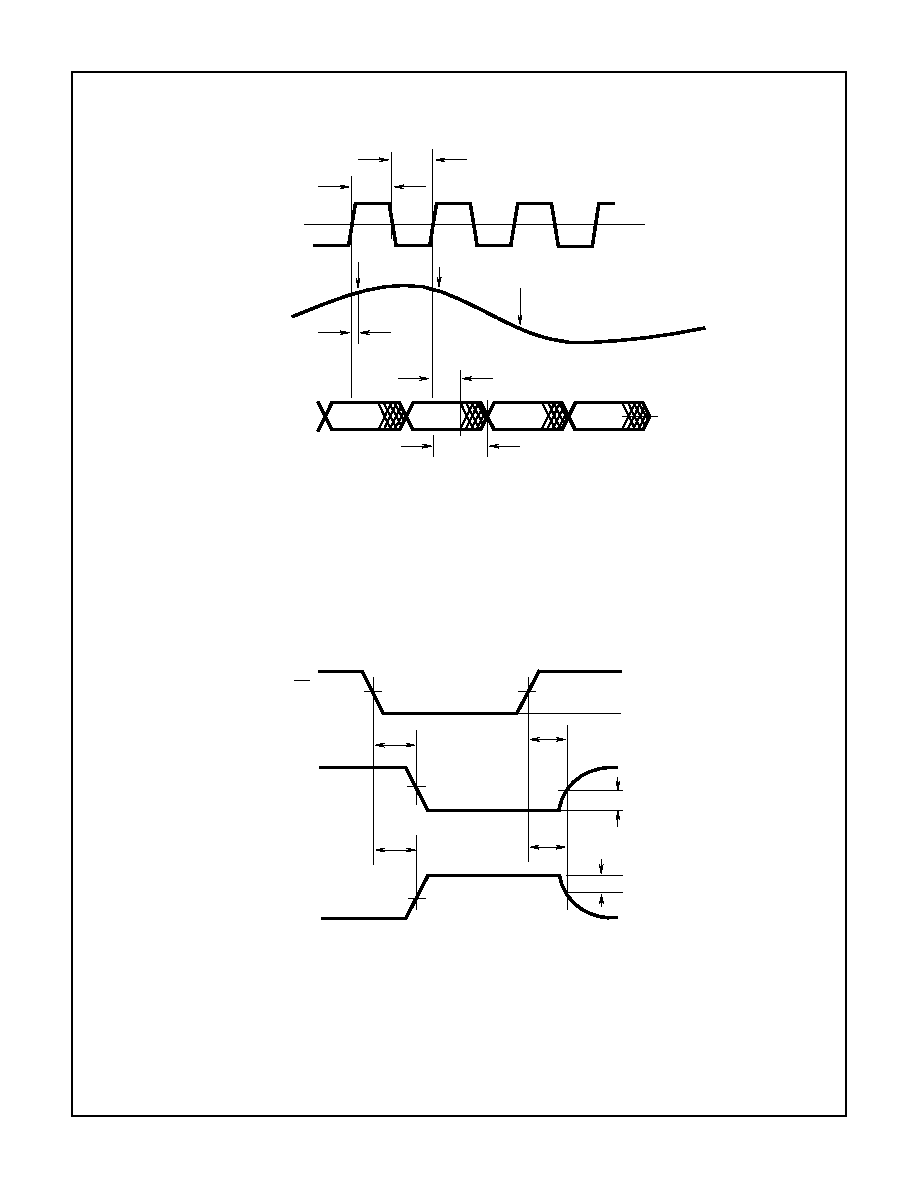

Timing Waveforms

FIGURE 1. INPUT-TO-OUTPUT TIMING

FIGURE 2. THREE-STATE TIMING CIRCUIT

ANALOG

INPUT

CLOCK

INPUT

DATA (D0-D7)

OUTPUTS

t

D

t

DS

t

HD

2.4V

1.4V

0.4V

1.4V

t

CPL

t

CPH

SAMPLE N

SAMPLE N + 1

SAMPLE N + 2

D

N

-

2

D

N

-

1

D

N + 1

D

N

OE

DIGITAL

OUTPUT

DIGITAL

OUTPUT

t

PZL

t

PZH

t

PLZ

t

PHZ

1.4V

1.4V

0V

0V

V

OH

V

OL

0.3V

0.3V

3.5V

INPUT

4V

HI5714

7

Typical Performance Curves

FIGURE 3. TOTAL I

CC

vs TEMPERATURE

FIGURE 4. INTEGRAL LINEARITY ERROR vs TEMPERATURE

FIGURE 5. DIFFERENTIAL LINEARITY ERROR vs

TEMPERATURE

FIGURE 6. REFERENCE RESISTANCE vs TEMPERATURE

FIGURE 7. V

OT

vs TEMPERATURE

FIGURE 8. V

OB

vs TEMPERATURE

70

60

50

40

30

20

10

0

-40 -30

-20 -10

0

10

20

30

40

50

60

70

80

TEMPERATURE (

o

C)

mA

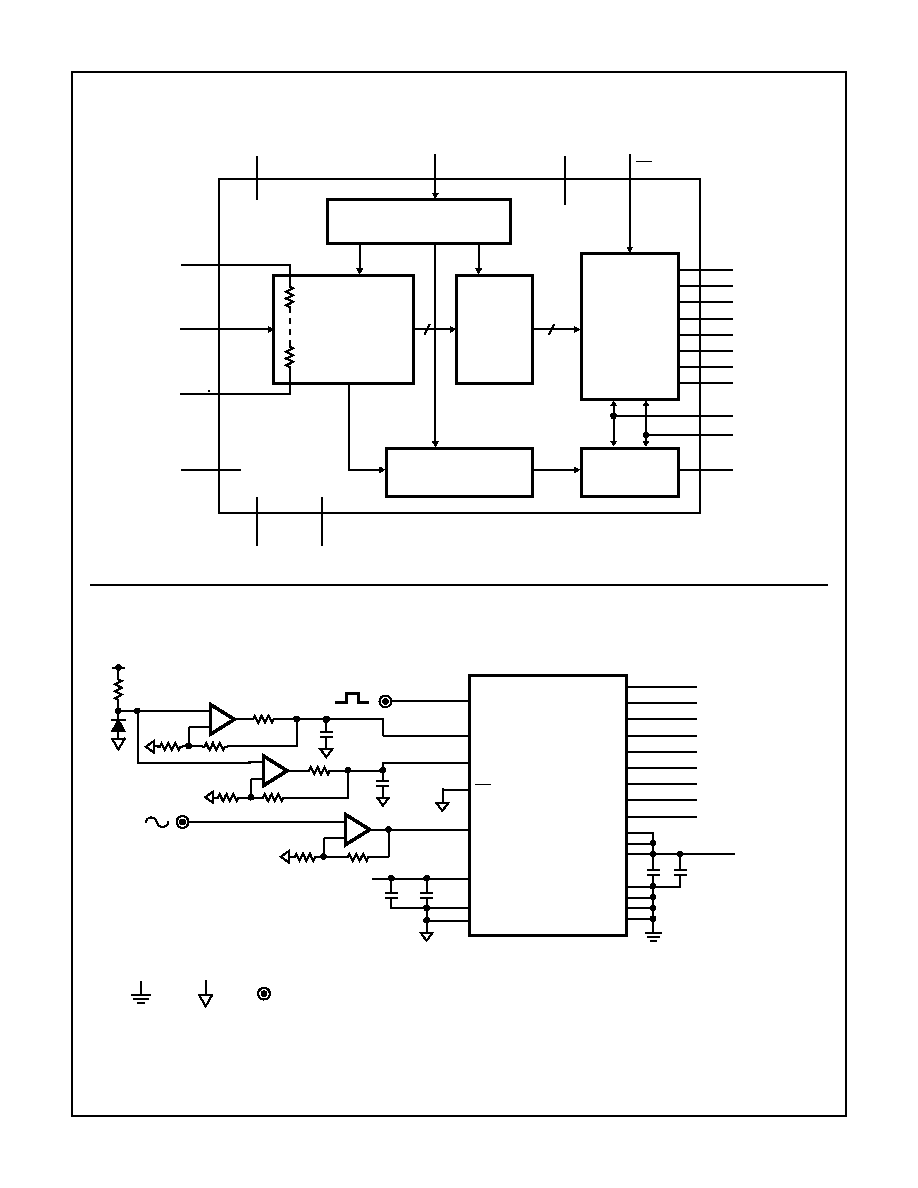

0

-0.1

-0.2

-0.3

-0.4

-0.5

-0.6

-0.7

-0.8

-0.9

-1.0

-40 -30 -20 -10

0

10

20

30

40

50

60

70

80

TEMPERATURE (

o

C)

LSB

90

-0.3

-0.4

-0.5

-0.6

-0.7

-0.8

-0.9

-1.0

-40 -30 -20 -10

0

10

20

30

40

50

60

70

80

TEMPERATURE (

o

C)

LSB

-0.2

-0.1

0

90

270

260

250

240

230

220

210

200

-40 -30 -20

-10

0

10

20

30

40

50

60

70

80

TEMPERATURE (

o

C)

OHMS

280

-230

-240

-250

-260

-270

-280

-290

-320

-40 -30 -20 -10

0

10

20

30

40

50

60

70

80

TEMPERATURE (

o

C)

mV

-220

-300

-310

250

240

230

210

-40 -30 -20 -10

0

10

20

30

40

50

60

70

80

TEMPERATURE (

o

C)

mV

260

220

HI5714

8

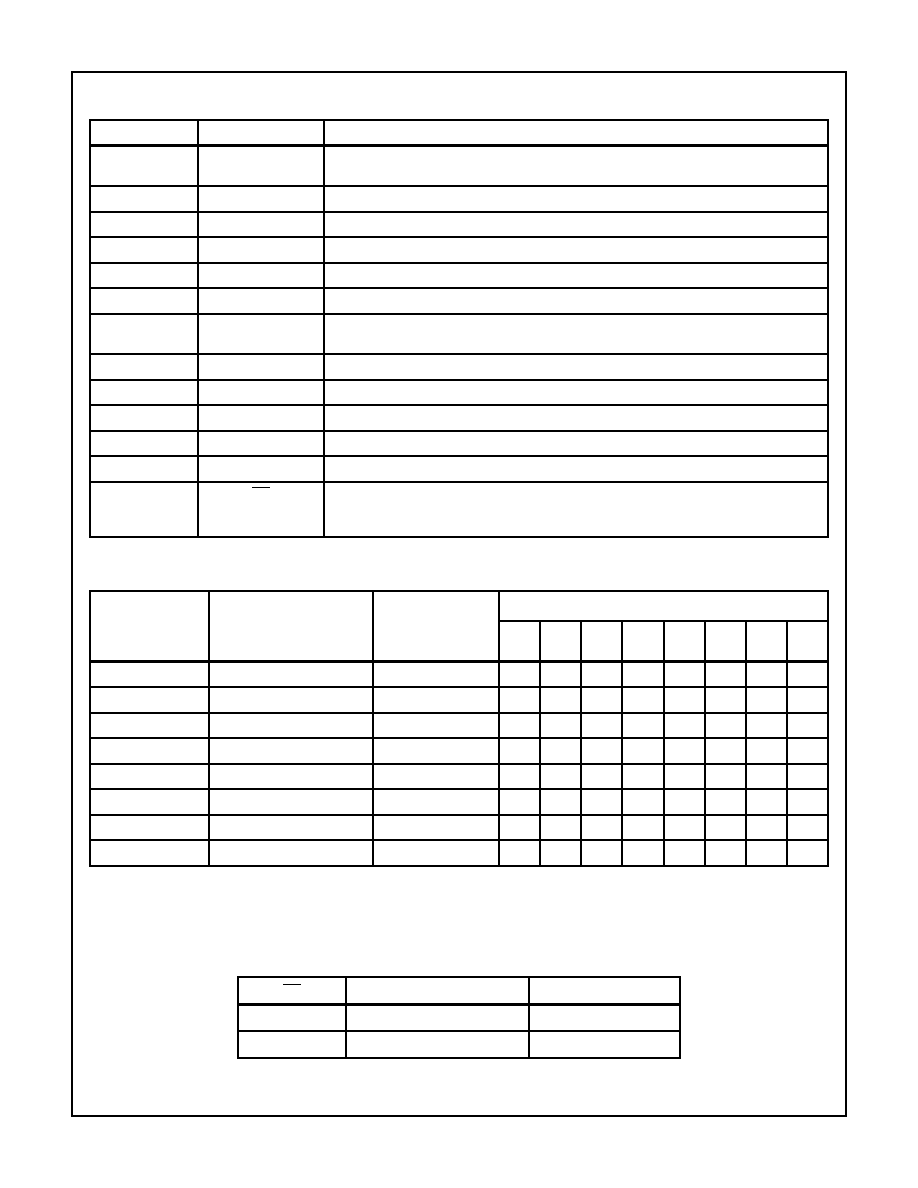

Pin Descriptions

PIN NUMBER

SYMBOL

DESCRIPTION

1, 2, 12-15,

23, 24

D0 to D7

Digital Outputs, D0 (LSB) to D7 (MSB).

4

V

RB

Bottom Reference Voltage Input. Range: 1.2V to 1.6V.

6

AGND

Analog Ground.

7

V

CCA

Analog +5V.

8

V

IN

Analog Input.

9

V

RT

Top Reference Voltage Input. Range: 3.5V to 3.9V.

11

O/UF

Underflow/Overflow Digital Output. Goes high if the analog input goes above or below the

reference (V

RB

, V

RT

) minus the offset.

16

CLK

Clock Input.

17

DGND

Digital GND.

18

V

CCD

Digital +5V.

19, 21

V

CCO1

, V

CCO2

Digital +5V for Digital Output Stage.

20

OGND

Digital Ground for Digital Output Stage.

22

OE

Output Enable

High: Digital outputs are three-stated.

Low: Digital outputs are active.

TABLE 1. A/D CODE TABLE

CODE

DESCRIPTION

(NOTE 1)

INPUT VOLTAGE

V

RT

= 3.6V

V

RB

= 1.3V

O/UF

BINARY OUTPUT CODE

D7

D6

D5

D4

D3

D2

D1

D0

Underflow

<1.555V

1

0

0

0

0

0

0

0

0

0

1.555V

0

0

0

0

0

0

0

0

0

1

-

0

-

-

-

-

-

-

-

-

-

-

0

-

-

-

-

-

-

-

-

-

-

0

-

-

-

-

-

-

-

-

254

-

0

1

1

1

1

1

1

1

0

255

3.300V

0

1

1

1

1

1

1

1

1

Overflow

>3.300V

1

1

1

1

1

1

1

1

1

NOTE:

1. The voltages listed above represent the ideal transition of each output code shown as a function of the reference voltage, including the

typical reference offset voltages.

TABLE 2. MODE SELECTION

OE

D7 to D0

O/UF

1

High Impedance

High Impedance

0

Active: Binary

Active

HI5714

9

Detailed Description

Theory of Operation

The HI5714 design utilizes a folding and interpolating

architecture. This architecture reduces the number of com-

parators, reference taps, and latches, thereby reducing

power requirements, die size and cost.

A folding A/D converter operates basically like a 2 step

subranging converter by using 2 lower resolution converters

to do a course and subranged fine conversion. A more com-

plete description is given in the application note "Using the

HI5714 Evaluation Module" (AN9517).

Reference Input, V

RT

and V

RB

The HI5714 requires an external reference to be connected

to pins 4 and 9, V

RB

and V

RT

.

It is recommended that adequate high frequency decoupling

be provided at the reference input pin in order to minimize

overall converter noise. A 0.1

µ

F and a 1nF capacitor as

close as possible to the reference pins work well.

V

RT

must be kept within the range of 3.5V to 3.9V and V

RB

within 1.2V to 1.6V. If the reference voltages go outside their

respective ranges, the input folding amplifiers may saturate

giving erroneous digital data. The range for (V

RT

- V

RB

) is

1.9V to 2.7V, which defines the analog input range.

Digital Control and Clock Requirements

The HI5714 provides a standard high-speed interface to

external TTL logic families.

The outputs can be three-stated by setting the OE input (pin

22) high.

The clock input operates at standard TTL levels as well as a low

level sine wave around the threshold level. The HI5714 can oper-

ate with clock frequencies from DC to 75MHz. The clock duty

cycle should be 50%

±

10% to ensure rated performance. Duty

cycle variation, within the specified range, has little effect on per-

formance. Due to the clock speed it is important to remember

that clock jitter will affect the quality of the digital output data.

The clock can be stopped at any time and restarted at a later

time. Once restarted the digital data will be valid at the

second rising edge of the clock plus the data delay time.

Digital Outputs and O/UF Output

The digital outputs are standard TTL type outputs. The

HI5714 can drive 1 to 3 TTL inputs depending on the input

current requirements.

Should the analog input exceed the top or bottom reference

the over/underflow output (pin 11) will go high. Should the

analog input exceed the top reference voltage, V

RT

, the

digital outputs will remain at all 1s until the analog input goes

below V

RT

. Also, should the analog input go below the bot-

tom reference voltage, V

RB

, the digital outputs will remain at

all 0s until the analog input goes above V

RT

.

Analog Input

The analog input will accept a voltage within the reference

voltage levels, V

RB

and V

RT

, minus some offset. The offset is

specified in the Electrical Specifications table.

The analog input is relatively high impedance (10k

) but

should be driven from a low impedance source. The input

capacitance is low (14pF) and there is little kickback from the

input, so a series resistance is not necessary but it may help

to prevent the driving amplifier from oscillating.

The input bandwidth is typically 18MHz. Exceeding 18MHz

will result in sparkle at the digital outputs. The bandwidth

remains constant at clock rates up to 75MHz.

Supply and Ground Considerations

In order to keep digital noise out of the analog signal path,

the HI5714 has separate analog and digital supply and

ground pins. The part should be mounted on a board that

provides separate low impedance connections for the analog

and digital supplies and grounds.

The analog and digital grounds should be tied together at

one point near the HI5714. The grounds can be connected

directly, through an inductor (ferrite bead), or a low valued

resistor. DGND and AGND can be tied together. To help min-

imize noise, tie pin 5 (NC) to AGND and pins 3 (NC) and 10

(NC) to DGND.

For best performance, the supplies to the HI5714 should be

driven by clean, linear regulated supplies. The board should

also have good high frequency leaded decoupling capacitors

mounted as close as possible to the converter. Capacitor

leads must be kept as short as possible (less than

1

/

2

inch

total length). A 0.1

µ

F and a 1nF capacitor as close as possi-

ble to the pin works well. Chip capacitors will provide better

high frequency decoupling but leaded capacitors appear to

be adequate.

If the part is to be powered by a single supply, then the

analog supply pins should be isolated by ferrite beads from

the digital supply pins. This should help minimize noise on

the analog power pins.

Refer to Application Note AN9214, "Using Intersil High

Speed A/D Converters", for additional considerations when

using high speed converters.

Increased Accuracy

Further calibration of the ADC can be done to increase

absolute level accuracy. First, a precision voltage equal to

the ideal VIN

-FS

+ 0.5 LSB is applied at V

IN

. Adjust V

RB

until the 0 to 1 transition occurs on the digital output. Next, a

voltage equal to the ideal VIN

+FS

- 1.5 LSB is applied at V

IN

.

V

RT

is then adjusted until the 254 to 255 transition occurs on

the digital output.

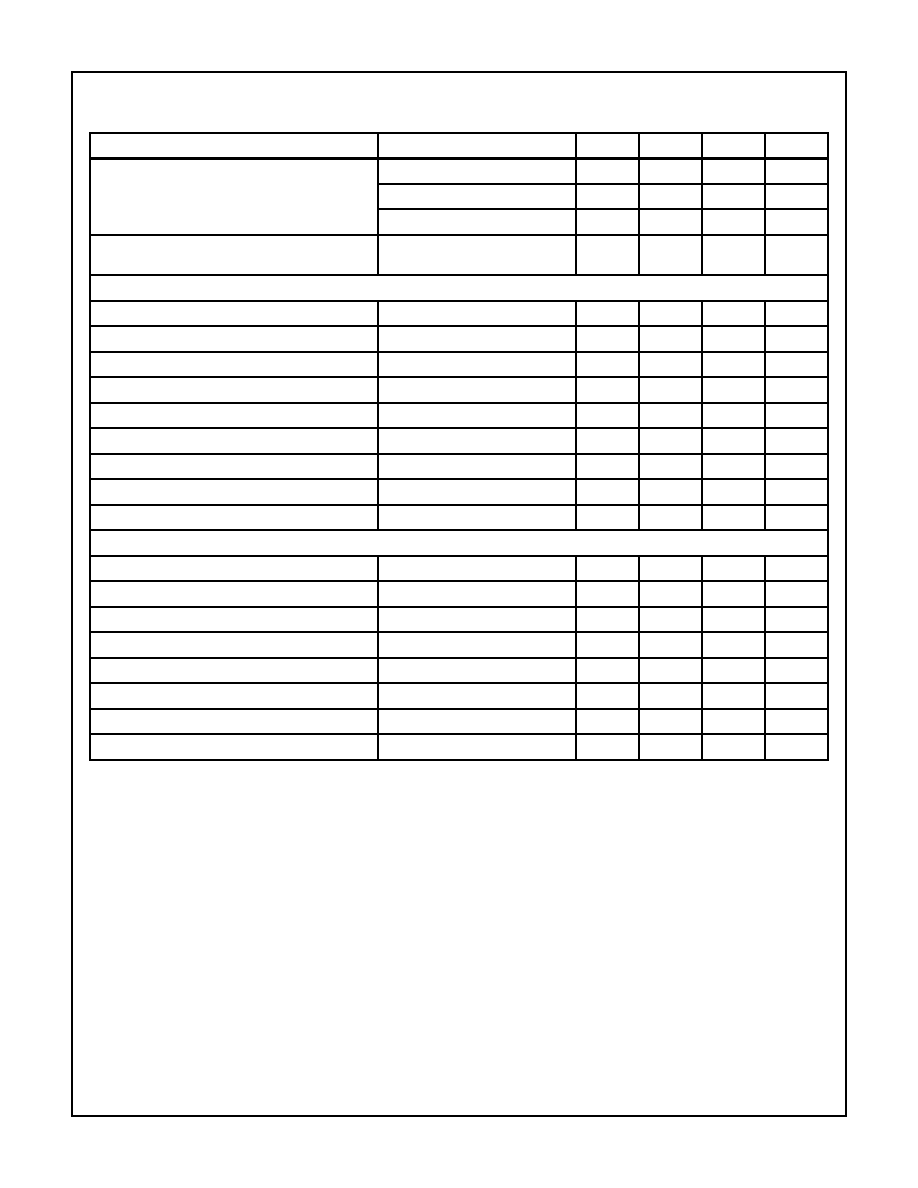

Applications

Figures 3 and 4 show two possible circuit configurations, AC

coupled with a DC restore circuit and DC coupled with a DC

offset amplifier.

Due to the high clock rate, FCT (TTL/CMOS) or FAST (TTL)

glue logic should be used. FCT logic will tend to have large

overshoots if not loaded. Long traces (>2 or 3 inches) should

be terminated to maintain signal integrity.

HI5714

10

FIGURE 9. TYPICAL AC COUPLED INPUT WITH DC RESTORE

FIGURE 10. TYPICAL DC COUPLED INPUT

FIGURE 11. 8-BIT VIDEO COMPONENTS

12

13

14

15

23

24

1

2

V

RB

HI5714

V

RT

CLK

DGND

NC

NC

AGND

V

CCA

V

CCD

D7

D6

D5

D4

D3

D2

D1

D0

CLOCK

V

IN

NC

V

IN

OGND

V

CCO

V

CCO

+5VA

O/UF

OE

11

19

21

18

20

3

17

10

16

9

4

8

7

5

6

22

3.6V

1.3V

+5VA

+5VD

10

0.1

10

0.1

0.1

0.1

SAMPLE

PULSE

DC RESTORE

-

+

-

+

12

13

14

15

23

24

1

2

V

RB

HI5714

V

RT

CLK

DGND

NC

NC

AGND

V

CCA

V

CCD

D7

D6

D5

D4

D3

D2

D1

D0

CLOCK

V

IN

NC

V

IN

OGND

V

CCO

V

CCO

+5VA

O/UF

OE

11

19

21

18

20

3

17

10

16

9

4

8

7

5

6

22

3.6V

1.3V

+5VA

+5VD

10

0.1

10

0.1

0.1

0.1

+5VA

OFFSET

-

+

-

+

-

+

A/D

D/A

DSP/

µ

P

REFERENCE

ICL8069

AMP

AMP

HA5020 (Single)

HA5022 (Dual)

HA5024 (Quad)

HA5013 (Triple)

HFA1105 (Single)

HFA1205 (Dual)

HFA1405 (Quad)

HI5714 (8-Bit)

HSP9501

HSP48410

HSP48908

HSP48901

HSP48212

HSP43881

HSP43168

HI1171 (8-Bit)

CA3338 (8-Bit)

HI5721 (10-Bit)

HA5020 (Single)

HA2842 (Single)

HFA1115 (Single)

HFA1212 (Dual)

HFA1412 (Quad)

CMOS Logic Available in FCT

HSP9501: Programmable Data Buffer

HSP48410: Histogrammer/accumulating Buffer, 10-Bit Pixel Resolution, 4K x 4K Frame Size

HSP48908: 2-D Convolver, 3 x 3 Kernal Convolution, 8-Bit

HSP48901: 3 x 3 Image Filter, 30MHz, 8-Bit

HSP48212: Video Mixer

HSP43881: Digital Filter, 30MHz, 1-D and 2-D Fir Filters

HSP43168: Dual Fir Filter, 10-Bit, 33/45MHz

HI3050 (10-Bit)

HI5714

11

Timing Definitions

Aperture Delay: Aperture delay is the time delay between

the external sample command (the rising edge of the clock)

and the time at which the signal is actually sampled. This

delay is due to internal clock path propagation delays.

Aperture Jitter: This is the RMS variation in the aperture

delay due to variation of internal clock path delays.

Data Latency

After the analog sample is taken, the data on the bus is out-

put at the next rising edge of the clock. This is due to the out-

put latch of the converter. This delay is specified as the data

latency. After the data latency time, the data representing

each succeeding sample is output at the following clock

pulse. The digital data lags the analog input by 1 cycle.

Static Performance Definitions

Offset Error and Full-Scale Error use a measured value of

the external voltage reference to determine the ideal plus

and minus full-scale values. The results are all displayed in

LSBs.

Bottom Offset Voltage (V

OB

)

The first code transition should occur at a level 0.5 LSB

above the negative full-scale. Bottom offset voltage is

defined as the deviation of the actual code transition from

this point.

Top Offset Voltage (V

OT

)

The last code transition should occur for a analog input that

is 1.5 LSBs below positive full-scale. Top Offset Voltage is

defined as the deviation of the actual code transition from

this point.

Differential Linearity Error (DNL)

DNL is the worst case deviation of a code width from the

ideal value of 1 LSB. The converter is guaranteed to have no

missing codes.

Integral Linearity Error (INL)

INL is the worst case deviation of a code center from a best

fit straight line calculated from the measured data.

Dynamic Performance Definitions

Fast Fourier Transform (FFT) techniques are used to evalu-

ate the dynamic performance of the HI5714. A low distortion

sine wave is applied to the input, it is sampled, and the out-

put is stored in RAM. The data is then transformed into the

frequency domain with a 2048 point FFT and analyzed to

evaluate the dynamic performance of the A/D. The sine wave

input to the part is 0.5dB down from full scale for these tests.

The distortion numbers are quoted in dBc (decibels with

respect to carrier) and DO NOT include any correction fac-

tors for normalizing to full scale.

Signal-to-Noise Ratio (SNR)

SNR is the measured RMS signal to RMS noise at a speci-

fied input and sampling frequency. The noise is the RMS

sum of all of the spectral components except the fundamen-

tal and the first five harmonics.

Signal-to-Noise + Distortion Ratio (SINAD)

SINAD is the measured RMS signal to RMS sum of all other

spectral components below the Nyquist frequency excluding

DC.

Effective Number Of Bits (ENOB)

The effective number of bits (ENOB) is derived from the

SINAD data. ENOB is calculated from:

ENOB = (SINAD - 1.76) / 6.02

2nd and 3rd Harmonic Distortion

This is the ratio of the RMS value of the 2nd and 3rd

harmonic component respectively to the RMS value of the

measured input signal.

Full Power Input Bandwidth

Full power bandwidth is the frequency at which the ampli-

tude of the digitally reconstructed output has decreased 3dB

below the amplitude of the input sine wave. The input sine

wave has a peak-to-peak amplitude equal to the difference

between the top reference voltage input and the bottom ref-

erence voltage input. The bandwidth given is measured at

the specified sampling frequency.

HI5714

12

Die Characteristics

DIE DIMENSIONS:

134 mils x 134 mils x 19 mils

±

1 mil

METALLIZATION:

Type: AlSiCu

Thickness: M1 - 8k

≈

, M2 - 17k

≈

SUBSTRATE POTENTIAL (Powered Up):

GND (0.0V)

PASSIVATION:

Type:

Sandwich Passivation*

Undoped Silicon Glass (USG) + Nitride

Thickness: USG - 8k

≈

, Nitride - 4.2k

≈

Total 12.2k

≈

+ 2k

≈

WORST CASE CURRENT DENSITY:

1.6 x 10

4

A/cm

2

TRANSISTOR COUNT:

3714

DIE ATTACH:

Silver Filled Epoxy

Metallization Mask Layout

HI5714

DO

D1

D2

D3

OE

O/UF

D7

D6

D5

D4

V

RB

AGND

V

CCA

V

RT

V

IN

V

CC02

OGND

V

CC01

DGND

V

CCD

CLK

HI5714

13

HI5714

Small Outline Plastic Packages (SOIC)

INDEX

AREA

E

D

N

1

2

3

-B-

0.25(0.010)

C A

M

B S

e

-A-

L

B

M

-C-

A1

A

SEATING PLANE

0.10(0.004)

h x 45

o

C

H

0.25(0.010)

B

M

M

NOTES:

1. Symbols are defined in the "MO Series Symbol List" in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension "D" does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm

(0.006 inch) per side.

4. Dimension "E" does not include interlead flash or protrusions. Inter-

lead flash and protrusions shall not exceed 0.25mm (0.010 inch) per

side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. "L" is the length of terminal for soldering to a substrate.

7. "N" is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width "B", as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch)

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact

M24.3

(JEDEC MS-013-AD ISSUE C)

24 LEAD WIDE BODY SMALL OUTLINE PLASTIC PACKAGE

SYMBOL

INCHES

MILLIMETERS

NOTES

MIN

MAX

MIN

MAX

A

0.0926

0.1043

2.35

2.65

-

A1

0.0040

0.0118

0.10

0.30

-

B

0.013

0.020

0.33

0.51

9

C

0.0091

0.0125

0.23

0.32

-

D

0.5985

0.6141

15.20

15.60

3

E

0.2914

0.2992

7.40

7.60

4

e

0.05 BSC

1.27 BSC

-

H

0.394

0.419

10.00

10.65

-

h

0.010

0.029

0.25

0.75

5

L

0.016

0.050

0.40

1.27

6

N

24

24

7

0

o

8

o

0

o

8

o

-

Rev. 0 12/93

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com