| ÐлекÑÑоннÑй компоненÑ: HIP4080 | СкаÑаÑÑ:  PDF PDF  ZIP ZIP |

Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

1

December 1996

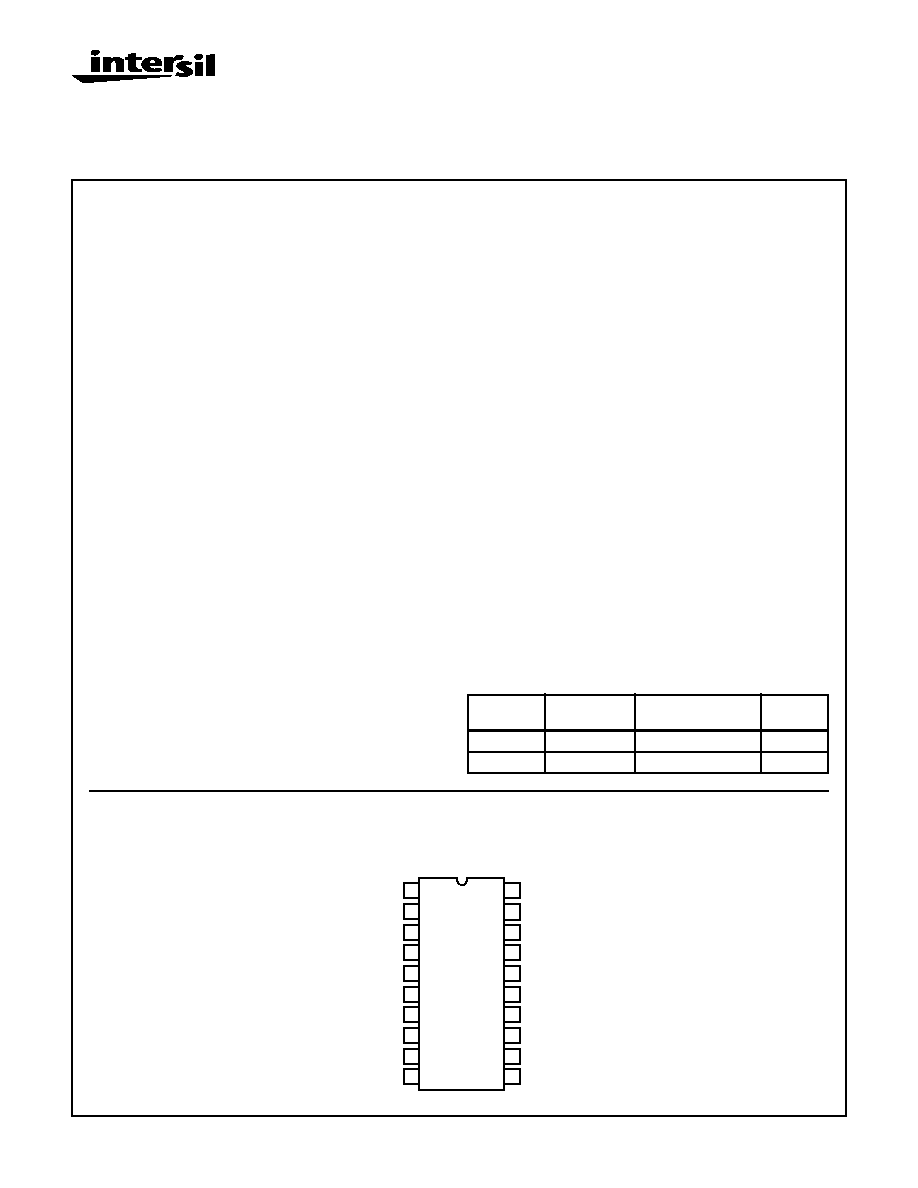

HIP4080

80V/2.5A Peak, High Frequency

Full Bridge FET Driver

Features

· Drives N-Channel FET Full Bridge Including High Side

Chop Capability

· Bootstrap Supply Max Voltage to 95V

DC

· Drives 1000pF Load at 1MHz in Free Air at 50

o

C with

Rise and Fall Times of 10ns (Typ)

· User-Programmable Dead Time

· Charge-Pump and Bootstrap Maintain Upper Bias

Supplies

· DIS (Disable) Pin Pulls Gates Low

· Input Logic Thresholds Compatible with 5V to 15V

Logic Levels

· Very Low Power Consumption

Applications

· Medium/Large Voice Coil Motors

· Full Bridge Power Supplies

· Class D Audio Power Amplifiers

· High Performance Motor Controls

· Noise Cancellation Systems

· Battery Powered Vehicles

· Peripherals

· U.P.S.

Description

The HIP4080 is a high frequency, medium voltage Full Bridge

N-Channel FET driver IC, available in 20 lead plastic SOIC and

DIP packages. The HIP4080 includes an input comparator,

used to facilitate the "hysteresis" and PWM modes of operation.

Its HEN (high enable) lead can force current to freewheel in the

bottom two external power MOSFETs, maintaining the upper

power MOSFETs off. Since it can switch at frequencies up to

1MHz, the HIP4080 is well suited for driving Voice Coil Motors,

switching amplifiers in class D high-frequency switching audio

amplifiers and power supplies.

HIP4080 can also drive medium voltage brush motors, and

two HIP4080s can be used to drive high performance step-

per motors, since the short minimum "on-time" can provide

fine micro-stepping capability.

Short propagation delays of approximately 55ns maximizes

control loop crossover frequencies and dead-times which

can be adjusted to near zero to minimize distortion, resulting

in precise control of the driven load.

The similar HIP4081 IC allows independent control of all 4

FETs in an Full Bridge configuration.

See also, Application Note AN9324 for the HIP4080.

Similar part, HIP4080A, includes under voltage circuitry

which doesn't require the circuitry shown in Figure 30 of this

data sheet.

Pinout

HIP4080 (PDIP, SOIC)

TOP VIEW

Ordering Information

PART

NUMBER

TEMP.

RANGE (

o

C)

PACKAGE

PKG.

NO.

HIP4080IP

-40 to 85

20 Lead PDIP

E20.3

HIP4080IB

-40 to 85

20 Lead SOIC

M20.3

11

12

13

14

15

16

17

18

20

19

10

9

8

7

6

5

4

3

2

1

BHB

HEN

DIS

V

SS

OUT

IN+

HDEL

IN-

LDEL

AHB

BHO

BLO

BLS

V

DD

BHS

V

CC

ALS

ALO

AHS

AHO

File Number

3178.10

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

|

Copyright

©

Intersil Corporation 1999

2

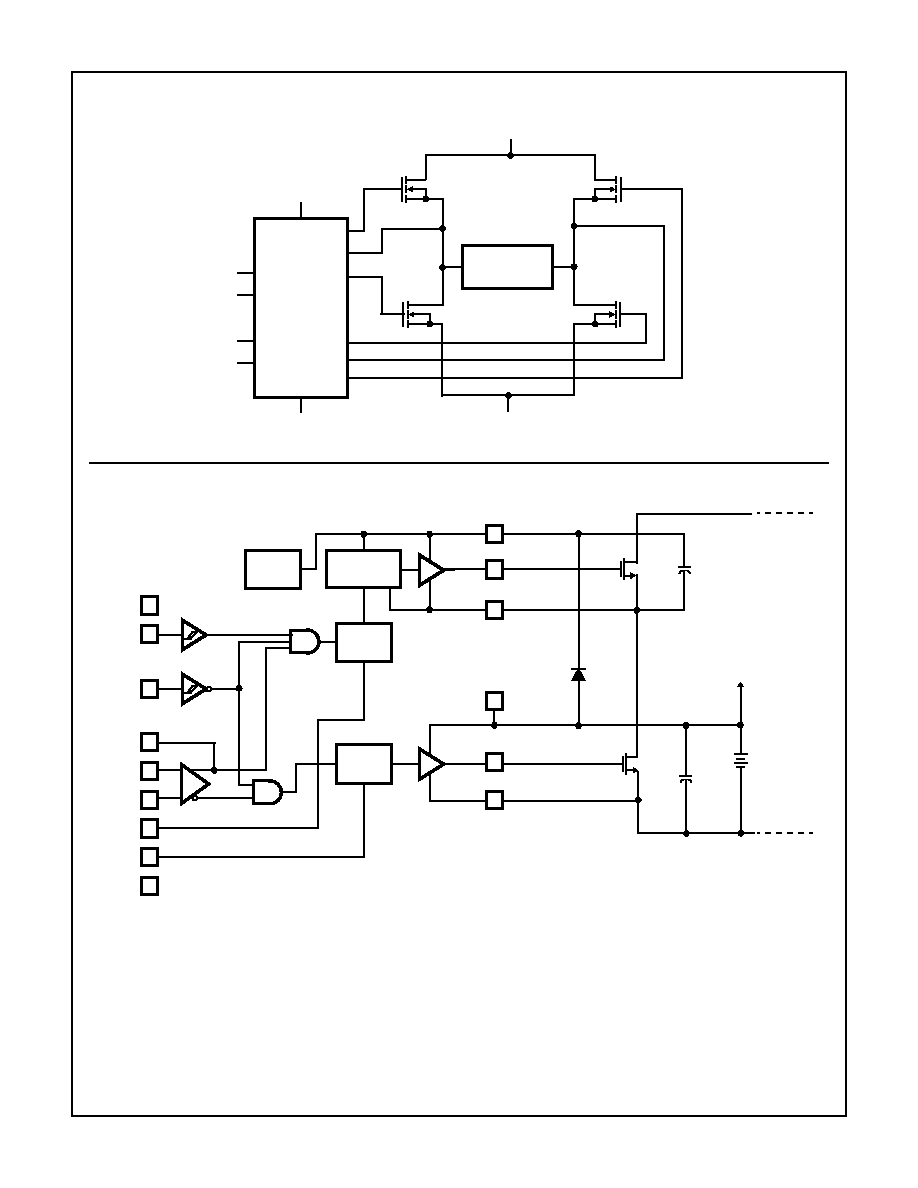

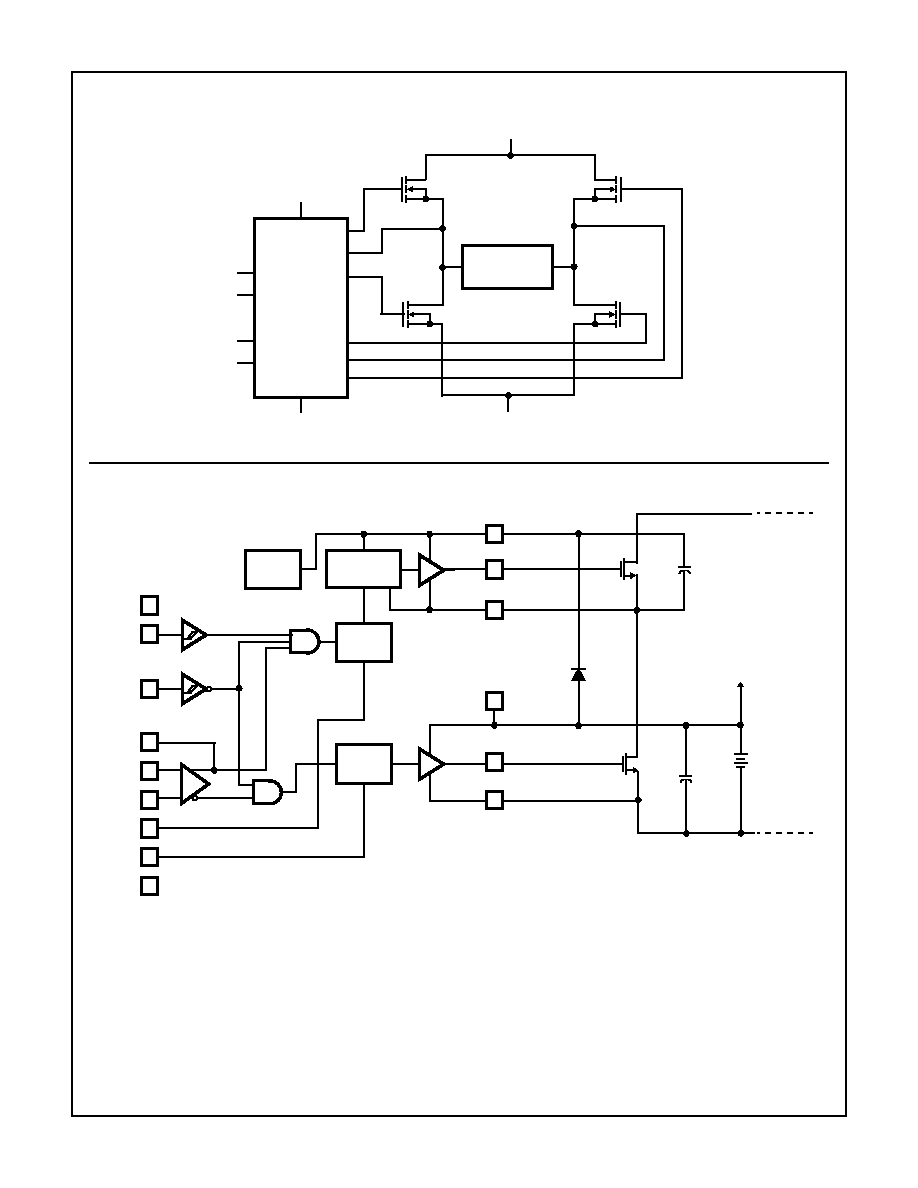

Application Block Diagram

Functional Block Diagram

(1/2 HIP4080)

80V

GND

HIP4080

GND

12V

LOAD

HEN

DIS

IN+

IN-

BHO

BHS

BLO

ALO

AHS

AHO

CHARGE

PUMP

V

DD

HEN

DIS

OUT

IN+

IN

_

HDEL

LDEL

V

SS

TURN-ON

DELAY

+

-

TURN-ON

DELAY

DRIVER

DRIVER

AHB

AHO

AHS

V

CC

ALO

ALS

C

BF

TO V

DD

(PIN 16)

C

BS

D

BS

HIGH VOLTAGE BUS

80V

DC

+12V

DC

LEVEL SHIFT

AND LATCH

14

10

11

12

15

13

16

2

3

5

6

7

8

9

4

BIAS

SUPPLY

HIP4080

3

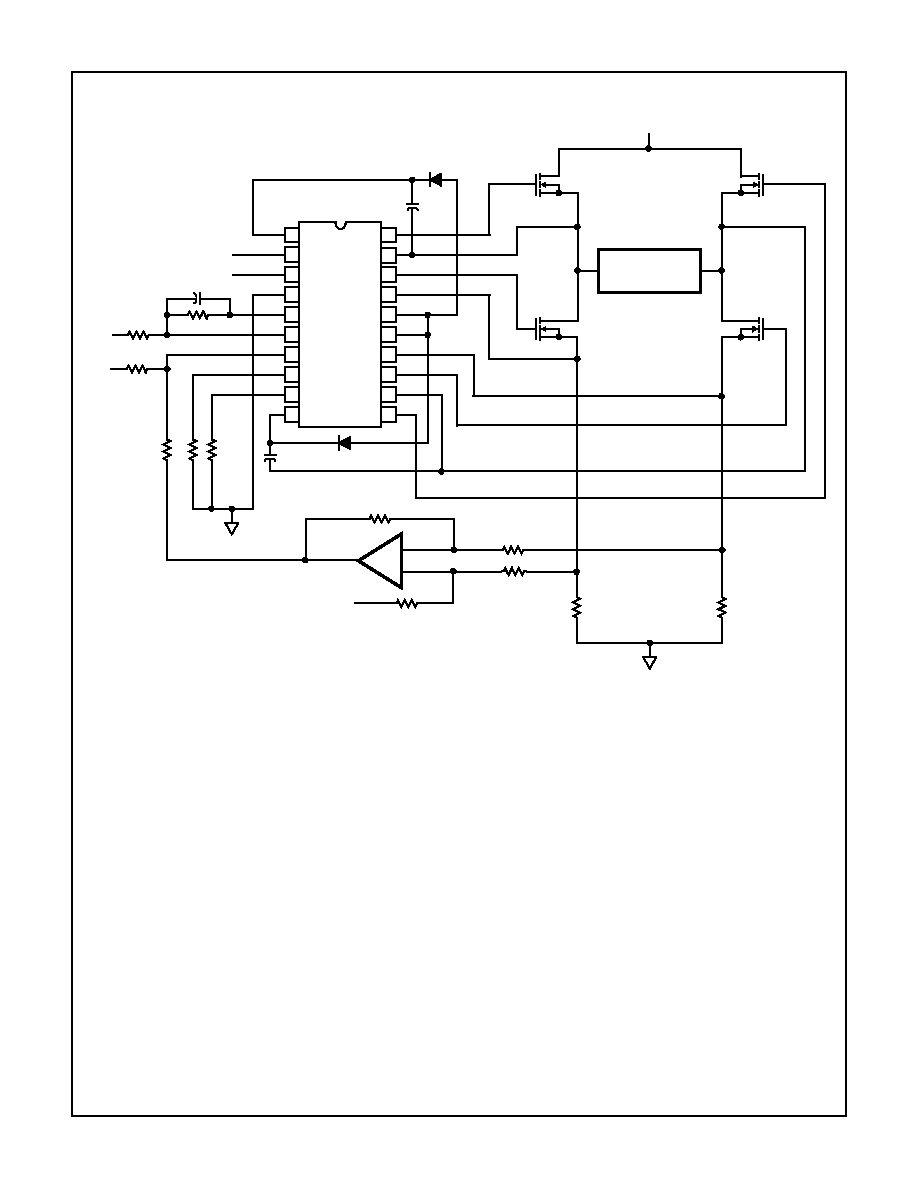

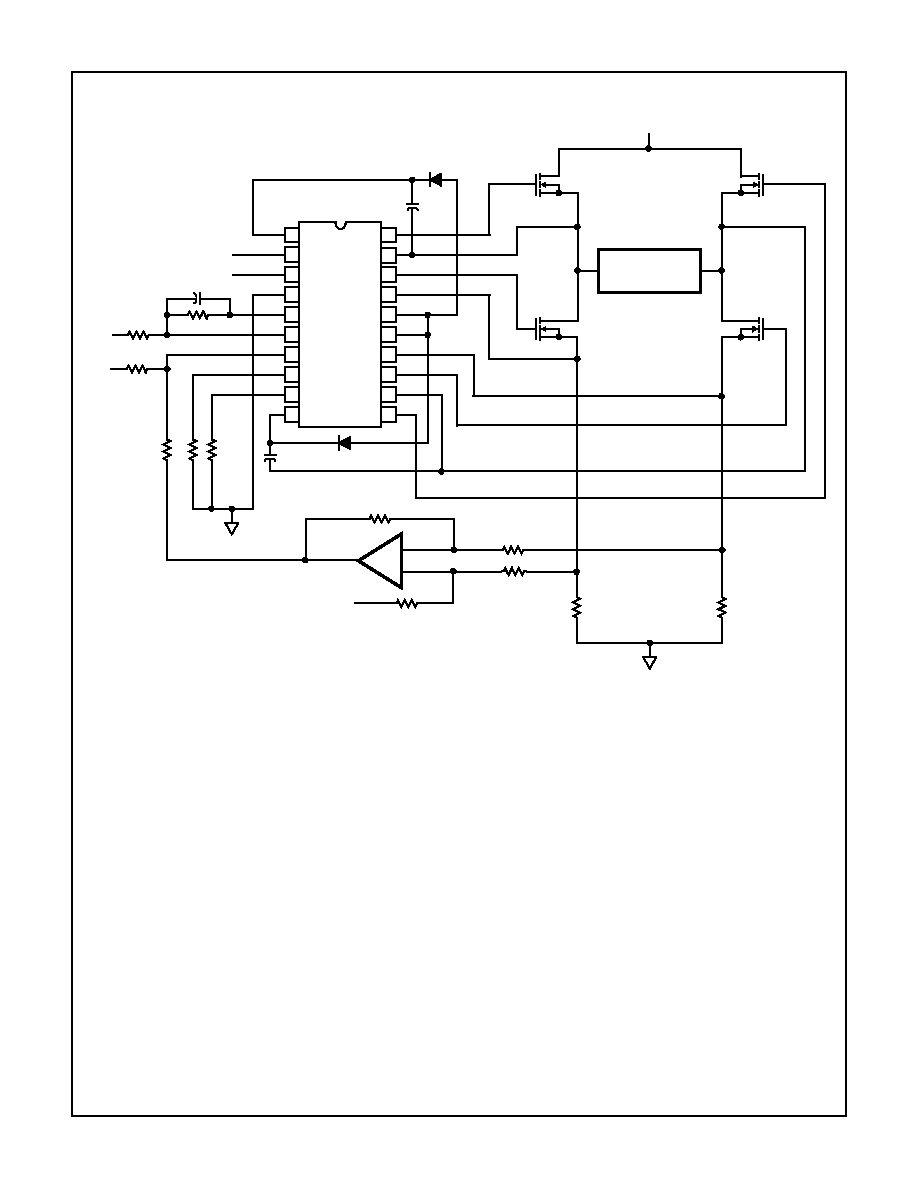

Typical Application (Hysteresis Mode Switching)

6V

80V

12V

12V

DIS

IN

GND

6V

GND

+

-

11

12

13

14

15

16

17

18

20

19

10

9

8

7

6

5

4

3

2

1 BHB

HEN

DIS

V

SS

OUT

IN+

HDEL

IN-

LDEL

AHB

BHO

BLO

BLS

V

DD

BHS

V

CC

ALS

ALO

AHS

AHO

LOAD

HIP4080

4

Absolute Maximum Ratings

Thermal Information

Supply Voltage, V

DD

and V

CC

. . . . . . . . . . . . . . . . . . . -0.3V to 16V

Logic I/O Voltages . . . . . . . . . . . . . . . . . . . . . . . -0.3V to V

DD

+0.3V

Voltage on AHS, BHS . . . . -6.0V (Transient) to 80V (25

o

C to 125

o

C)

Voltage on AHS, BHS . . . . -6.0V (Transient) to 70V (-55

o

C to 125

o

C

Voltage on ALS, BLS . . . . . . . -2.0V (Transient) to +2.0V (Transient)

Voltage on AHB, BHBV

AHS, BHS

-0.3V to V

AHS, BHS

+16VVoltage on

Voltage on ALO, BLO . . . . . . . . . . . . V

ALS, BLS

-0.3V to V

CC

+0.3V

Voltage on AHO, BHO . . . . . . V

AHS, BHS

-0.3V to V

AHB, BHB

+0.3V

Input Current, HDEL and LDEL . . . . . . . . . . . . . . . . . . -5mA to 0mA

Phase Slew Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20V/ns

NOTE: All Voltages relative to pin 4, V

SS

, unless otherwise specified.

Thermal Resistance (Typical, Note 1)

JA

(

o

C/W)

SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

85

PDIP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

75

Maximum Power Dissipation at 85

o

C

SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 470mW

DIP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 530mW

Storage Temperature Range . . . . . . . . . . . . . . . . . . -65

o

C to 150

o

C

Operating Max. Junction Temperature . . . . . . . . . . . . . . . . . 125

o

C

Lead Temperature (Soldering 10s) . . . . . . . . . . . . . . . . . . . . 300

o

C

(SOIC - Lead Tips Only)

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1.

JA

is measured with the component mounted on an evaluation PC board in free air.

Operating Conditions

Supply Voltage, V

DD

and V

CC

. . . . . . . . . . . . . . . . . . . +8V to +15V

Voltage on ALS, BLS . . . . . . . . . . . . . . . . . . . . . . . . . -1.0V to +1.0V

Voltage on AHB, BHB . . . . . . . . V

AHS, BHS

+5V to V

AHS, BHS

+15V

Input Current, HDEL and LDEL. . . . . . . . . . . . . . . . -500

µ

A to -50

µ

A

Operating Ambient Temperature Range . . . . . . . . . . .-40

o

C to 85

o

C

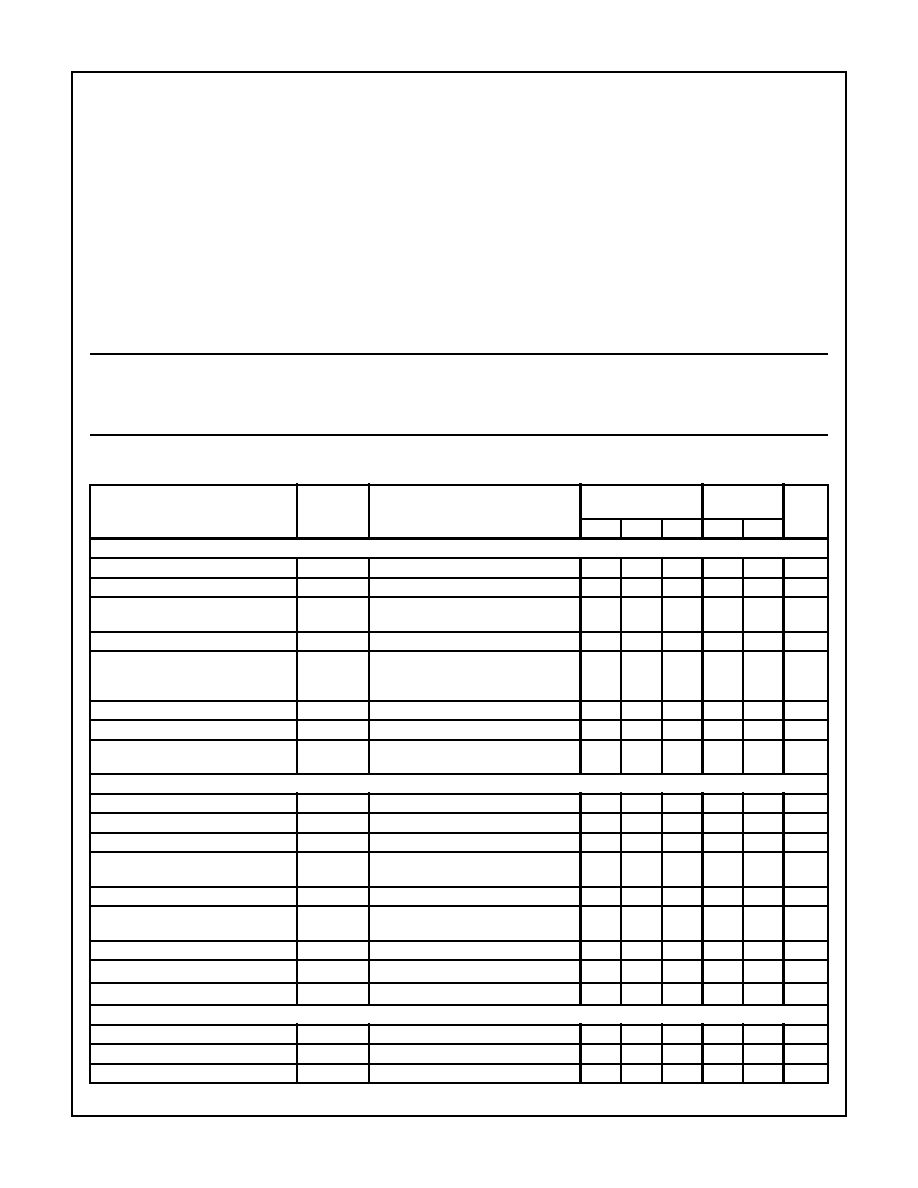

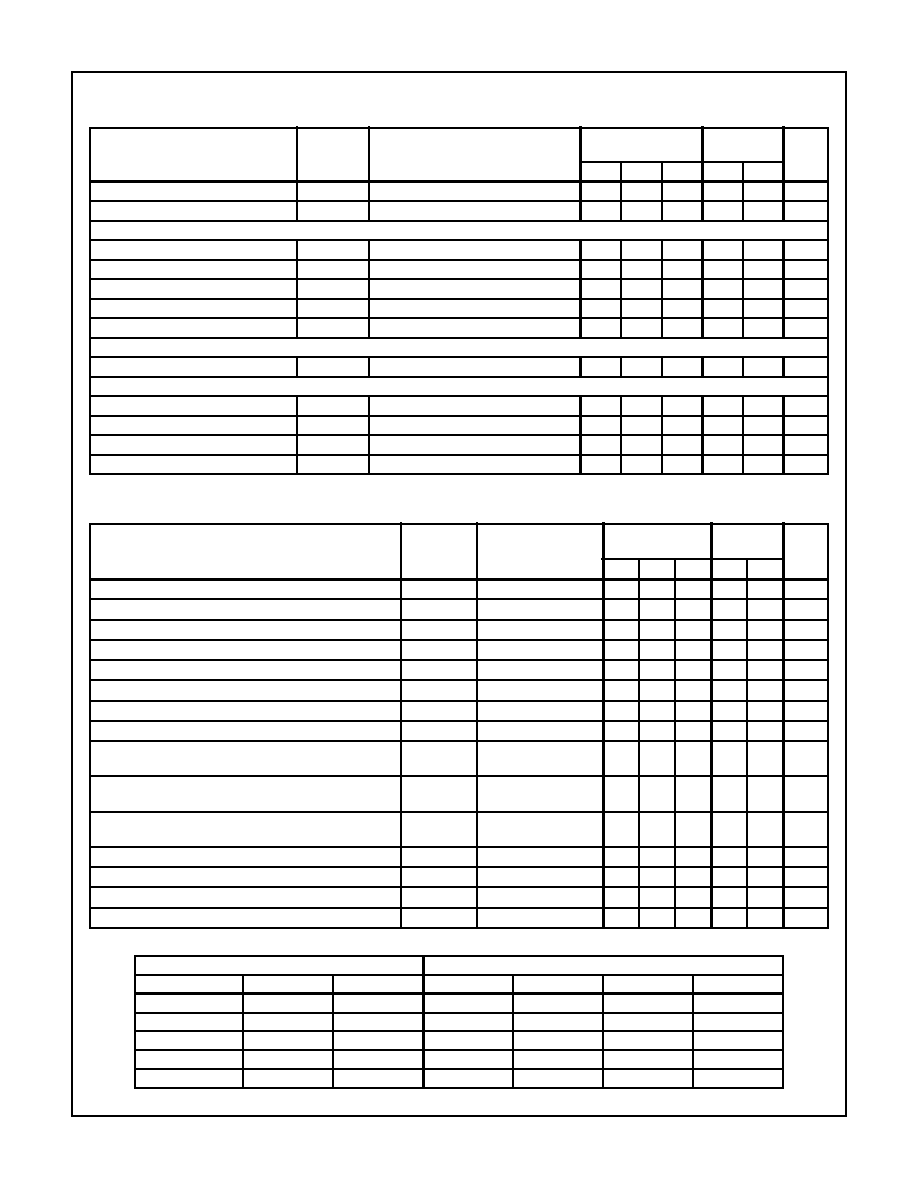

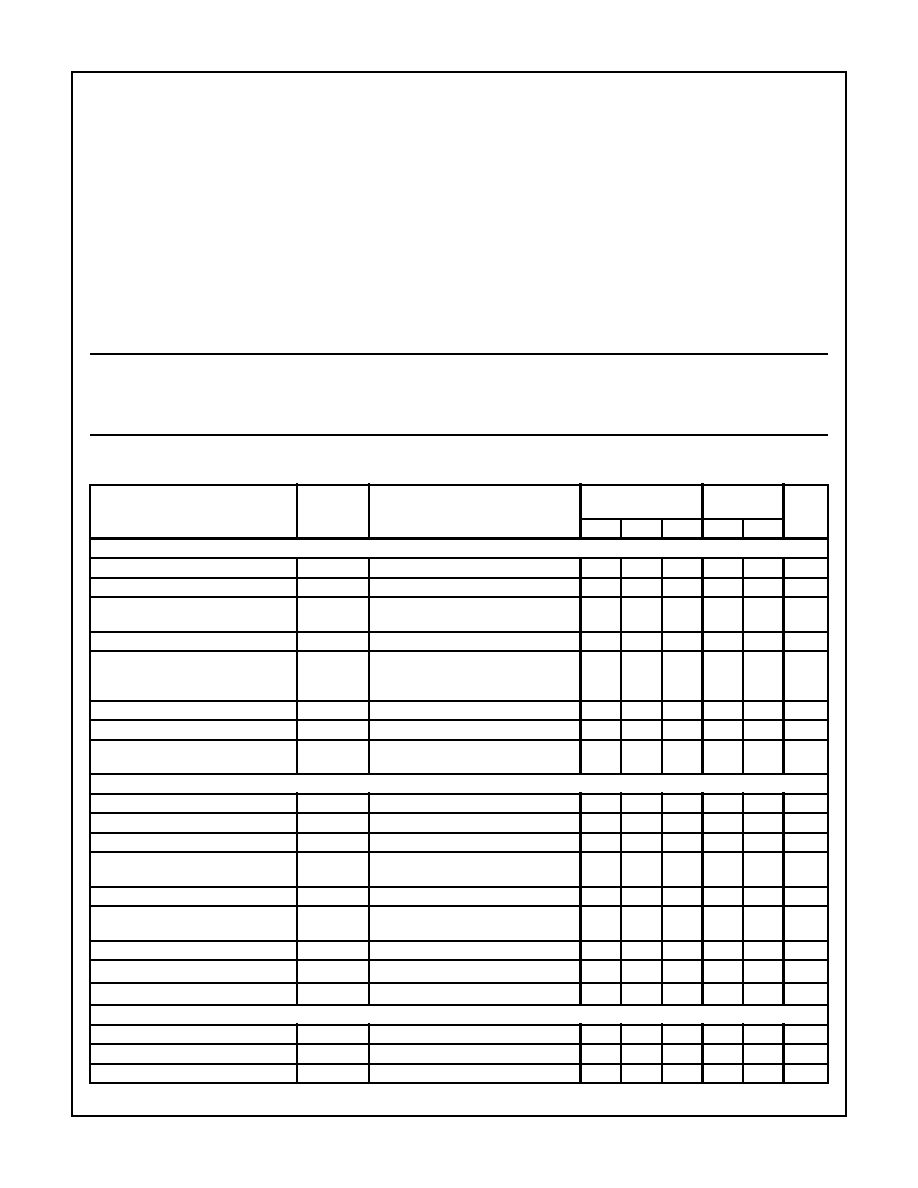

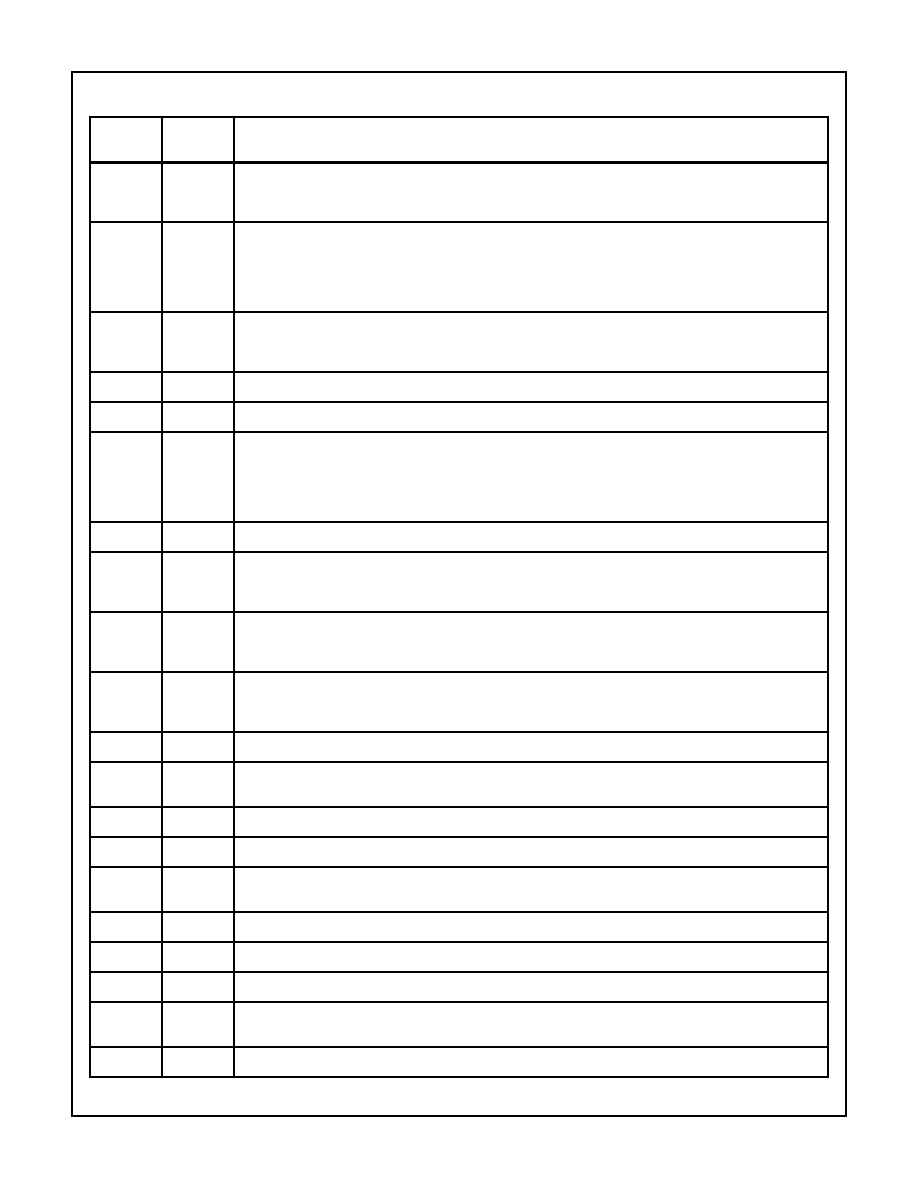

Electrical Specifications

V

DD

= V

CC

= V

AHB

= V

BHB

= 12V, V

SS

= V

ALS

= V

BLS

= V

AHS

= V

BHS

= 0V, R

HDEL

= R

LDEL

= 100K,

and T

A

= 25

o

C, Unless Otherwise Specified

PARAMETERS

SYMBOL

TEST CONDITIONS

T

J

= 25

o

C

T

J

= - 40

o

C

TO 125

o

C

UNITS

MIN

TYP

MAX

MIN

MAX

SUPPLY CURRENTS AND CHARGE PUMPS

V

DD

Quiescent Current

I

DD

IN- = 2.5V, Other Inputs = 0V

8

10.5

13

7

14

mA

V

DD

Operating Current

I

DDO

Outputs switching f = 500kHz

9

11

14

8

15

mA

V

CC

Quiescent Current

I

CC

IN- = 2.5V, Other Inputs = 0V,

I

ALO

= I

BLO

= 0

-

25

80

-

100

µ

A

V

CC

Operating Current

I

CCO

f = 500kHz, No Load

1

1.5

2.0

0.8

3

mA

AHB, BHB Quiescent Current -

Qpump Output Current

I

AHB

, I

BHB

IN- = 2.5V, Other Inputs = 0V, I

AHO

=

I

BHO

= 0, V

DD

= V

CC

= V

AHB

=

V

BHB

= 10V

-50

-30

-15

-60

-10

µ

A

AHB, BHB Operating Current

I

AHBO

,

I

BHBO

f = 500kHz, No Load

0.5

0.9

1.3

0.4

1.7

mA

AHS, BHS, AHB, BHB Leakage Current

I

HLK

V

AHS

= V

BHS

= V

AHB

= V

BHB

= 95V

-

0.02

1.0

-

10

µ

A

AHB-AHS, BHB-BHS Qpump

Output Voltage

V

AHB

- V

AHS

V

BHB

- V

BHS

I

AHB

= I

AHB

= 0, No Load

11.5

12.6

14.0

10.5

14.5

V

INPUT COMPARATOR PINS: IN+, IN-, OUT

Offset Voltage

V

OS

Over Common Mode Voltage Range

-10

0

+10

-15

+15

mV

Input Bias Current

I

IB

0

0.5

2

0

4

µ

A

Input Offset Current

I

OS

-1

0

+1

-2

+2

µ

A

Input Common Mode Voltage Range

CMVR

1

-

V

DD

-1.5

1

V

DD

-1.5

V

Voltage Gain

AVOL

10

25

-

10

-

V/mV

OUT High Level Output Voltage

V

OH

IN+ > IN-, I

OH

= -300

µ

A

V

DD

-0.4

-

-

V

DD

- 0.5

-

V

OUT Low Level Output Voltage

V

OL

IN+ < IN-, I

OL

= 300

µ

A

-

-

0.3

-

0.4

V

High Level Output Current

I

OH

V

OUT

=

6V

-9

-7

-4

-11

-2

mA

Low Level Output Current

I

OL

V

OUT

=

6V

8

10

12

5

14

mA

INPUT PINS: DIS

Low Level Input Voltage

V

IL

Full Operating Conditions

-

-

1.0

-

0.8

V

High Level Input Voltage

V

IH

Full Operating Conditions

2.5

-

-

2.7

-

V

Input Voltage Hysteresis

-

35

-

-

-

mV

HIP4080

5

Low Level Input Current

I

IL

V

IN

= 0V, Full Operating Conditions

-130

-100

-75

-135

-65

µ

A

High Level Input Current

I

IH

V

IN

= 5V, Full Operating Conditions

-1

-

+1

-10

+10

µ

A

INPUT PINS: HEN

Low Level Input Voltage

V

IL

Full Operating Conditions

-

-

1.0

-

0.8

V

High Level Input Voltage

V

IH

Full Operating Conditions

2.5

-

-

2.7

-

V

Input Voltage Hysteresis

-

35

-

-

-

mV

Low Level Input Current

I

IL

V

IN

= 0V, Full Operating Conditions

-260

-200

-150

-270

-130

µ

A

High Level Input Current

I

IH

V

IN

= 5V, Full Operating Conditions

-1

-

+1

-10

+10

µ

A

TURN-ON DELAY PINS: LDEL AND HDEL

LDEL, HDEL Voltage

V

HDEL,

V

I

HDEL

= I

LDEL

= -100

µ

A

4.9

5.1

5.3

4.8

5.4

V

GATE DRIVER OUTPUT PINS: ALO, BLO, AHO, AND BHO

Low Level Output Voltage

V

OL

I

OUT

= 100mA

.70

0.85

1.0

0.5

1.1

V

High Level Output Voltage

V

CC

- V

OH

I

OUT

= -100mA

0.8

0.95

1.1

0.5

1.2

V

Peak Pull-up Current

I

O

+

V

OUT

= 0V

1.7

2.6

3.8

1.4

4.1

A

Peak Pull-down Current

I

O

-

V

OUT

= 12V

1.7

2.4

3.3

1.3

3.6

A

Electrical Specifications

V

DD

= V

CC

= V

AHB

= V

BHB

= 12V, V

SS

= V

ALS

= V

BLS

= V

AHS

= V

BHS

= 0V, R

HDEL

= R

LDEL

= 100K,

and T

A

= 25

o

C, Unless Otherwise Specified (Continued)

PARAMETERS

SYMBOL

TEST CONDITIONS

T

J

= 25

o

C

T

J

= - 40

o

C

TO 125

o

C

UNITS

MIN

TYP

MAX

MIN

MAX

Switching Specifications

V

DD

= V

CC

= V

AHB

= V

BHB

= 12V, V

SS

= V

ALS

= V

BLS

= V

AHS

= V

BHS

= 0V, R

HDEL

= R

LDEL

= 10K,

C

L

= 1000pF, and T

A

= 25

o

C, Unless Otherwise Specified

PARAMETERS

SYMBOL

TEST CONDITIONS

T

J

= 25

o

C

T

J

= - 40

o

C

TO 125

o

C

UNITS

MIN

TYP MAX

MIN

MAX

Lower Turn-off Propagation Delay (IN+/IN- to ALO/BLO)

T

LPHL

-

40

70

-

90

ns

Upper Turn-off Propagation Delay (IN+/IN- to AHO/BHO)

T

HPHL

-

50

80

-

110

ns

Lower Turn-on Propagation Delay (IN+/IN- to ALO/BLO)

T

LPLH

R

HDEL

= R

LDEL

= 10K

-

45

70

-

90

ns

Upper Turn-on Propagation Delay (IN+/IN- to AHO/BHO)

T

HPLH

R

HDEL

= R

LDEL

= 10K

-

70

110

-

140

ns

Rise Time

T

r

-

10

25

-

35

ns

Fall Time

T

f

-

10

25

-

35

ns

Turn-on Input Pulse Width

T

PWIN-ON

R

HDEL

= R

LDEL

= 10K

50

-

-

50

-

ns

Turn-off Input Pulse Width

T

PWIN-OFF

R

HDEL

= R

LDEL

= 10K

40

-

-

40

-

ns

Disable Turn-off Propagation Delay

(DIS - Lower Outputs)

T

DISLOW

-

45

75

-

95

ns

Disable Turn-off Propagation Delay

(DIS - Upper Outputs)

T

DISHIGH

-

55

85

-

105

ns

Disable to Lower Turn-on Propagation Delay

(DIS - ALO and BLO)

T

DLPLH

-

35

70

-

90

ns

Refresh Pulse Width (ALO and BLO)

T

REF-PW

160

260

380

140

420

ns

Disable to Upper Enable (DIS - AHO and BHO)

T

UEN

-

335

500

-

550

ns

HEN-AHO, BHO Turn-off, Propagation Delay

T

HEN-PHL

R

HDEL

= R

LDEL

= 10K

-

35

70

-

90

ns

HEN-AHO, BHO Turn-on, Propagation Delay

T

HEN-PLH

R

HDEL

= R

LDEL

= 10K

-

60

90

-

110

ns

TRUTH TABLE

INPUT

OUTPUT

IN+ > IN-

HEN

DIS

ALO

AHO

BLO

BHO

X

X

1

0

0

0

0

1

1

0

0

1

1

0

0

1

0

1

0

0

1

1

0

0

0

0

1

0

0

0

0

1

0

0

0

HIP4080

6

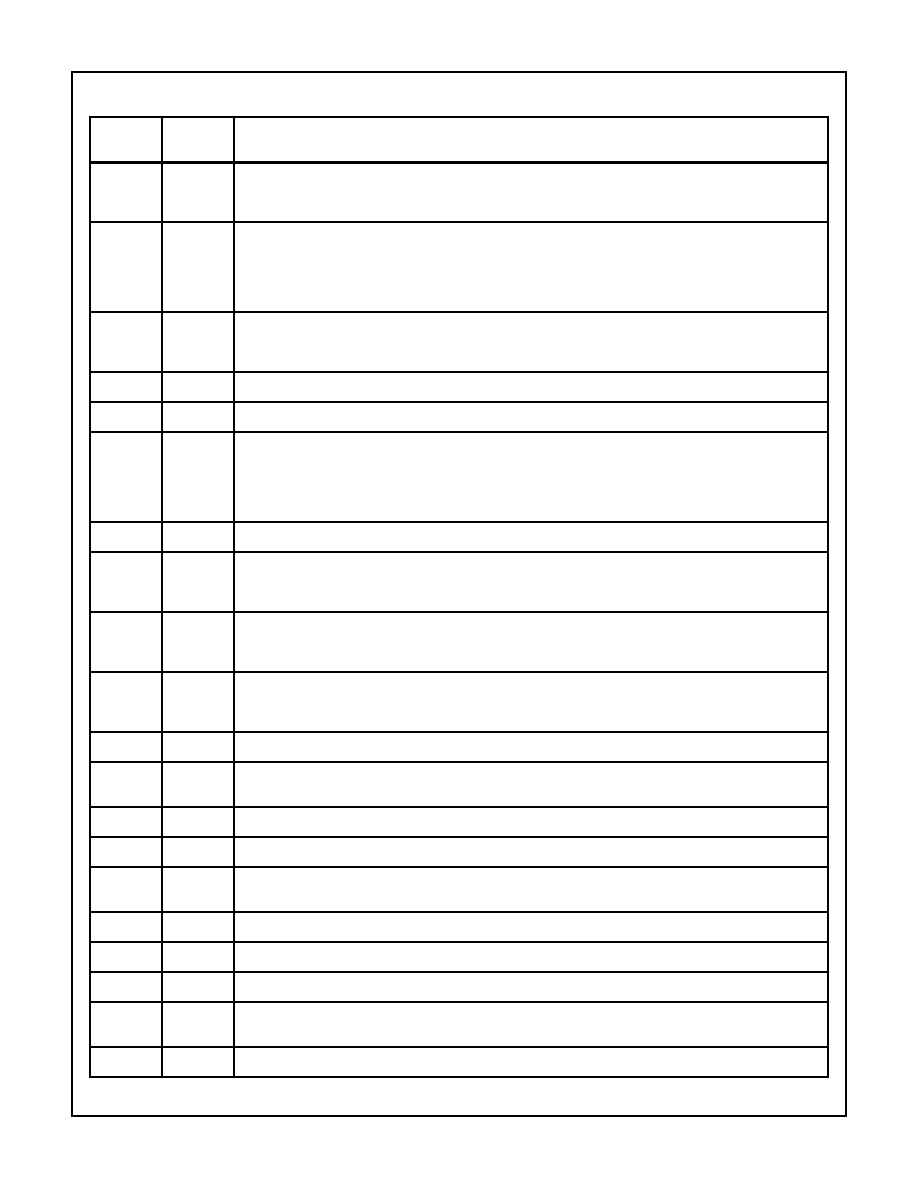

Pin Descriptions

PIN

NUMBER

SYMBOL

DESCRIPTION

1

BHB

B High-side Bootstrap supply. External bootstrap diode and capacitor are required. Connect cathode of boot-

strap diode and positive side of bootstrap capacitor to this pin. Internal charge pump supplies 30

µ

A out of this

pin to maintain bootstrap supply. Internal circuitry clamps the bootstrap supply to approximately 12.8V.

2

HEN

High-side Enable input. Logic level input that when low overrides IN+/IN- (Pins 6 and 7) to put AHO and BHO

drivers (Pins 11 and 20) in low output state. When HEN is high AHO and BHO are controlled by IN+/IN- inputs.

The pin can be driven by signal levels of 0V to 15V (no greater than V

DD

). An internal 100

µ

A pull-up to V

DD

will

hold HEN high, so no connection is required if high-side and low-side outputs are to be controlled by IN+/IN-

inputs.

3

DIS

DISable input. Logic level input that when taken high sets all four outputs low. DIS high overrides all other inputs.

When DIS is taken low the outputs are controlled by the other inputs. The pin can be driven by signal levels of

0V to 15V (no greater than V

DD

). An internal 100

µ

A pull-up to V

DD

will hold DIS high if this pin is not driven.

4

V

SS

Chip negative supply, generally will be ground.

5

OUT

OUTput of the input control comparator. This output can be used for feedback and hysteresis.

6

IN+

Non-inverting input of control comparator. If IN+ is greater than IN- (Pin 7) then ALO and BHO are low level

outputs and BLO and AHO are high level outputs. If IN+ is less than IN- then ALO and BHO are high level out-

puts and BLO and AHO are low level outputs. DIS (Pin 3) high level will override IN+/IN- control for all outputs.

HEN (Pin 2) low level will override IN+/IN- control of AHO and BHO. When switching in four quadrant mode,

dead time in a half bridge leg is controlled by HDEL and LDEL (Pins 8 and 9).

7

IN-

Inverting input of control comparator. See IN+ (Pin 6) description.

8

HDEL

High-side turn-on DELay. Connect resistor from this pin to V

SS

to set timing current that defines the turn-on delay

of both high-side drivers. The low-side drivers turn-off with no adjustable delay, so the HDEL resistor guarantees

no shoot-through by delaying the turn-on of the high-side drivers. HDEL reference voltage is approximately 5.1V.

9

LDEL

Low-side turn-on DELay. Connect resistor from this pin to V

SS

to set timing current that defines the turn-on delay

of both low-side drivers. The high-side drivers turn-off with no adjustable delay, so the LDEL resistor guarantees

no shoot-through by delaying the turn-on of the low-side drivers. LDEL reference voltage is approximately 5.1V.

10

AHB

A High-side Bootstrap supply. External bootstrap diode and capacitor are required. Connect cathode of boot-

strap diode and positive side of bootstrap capacitor to this pin. Internal charge pump supplies 30

µ

A out of this

pin to maintain bootstrap supply. Internal circuitry clamps the bootstrap supply to approximately 12.8V.

11

AHO

A High-side Output. Connect to gate of A High-side power MOSFET.

12

AHS

A High-side Source connection. Connect to source of A High-side power MOSFET. Connect negative side of

bootstrap capacitor to this pin.

13

ALO

A Low-side Output. Connect to gate of A Low-side power MOSFET.

14

ALS

A Low-side Source connection. Connect to source of A Low-side power MOSFET.

15

V

CC

Positive supply to gate drivers. Must be same potential as V

DD

(Pin 16). Connect to anodes of two bootstrap

diodes.

16

V

DD

Positive supply to lower gate drivers. Must be same potential as V

CC

(Pin 15). De-couple this pin to V

SS

(Pin 4).

17

BLS

B Low-side Source connection. Connect to source of B Low-side power MOSFET.

18

BLO

B Low-side Output. Connect to gate of B Low-side power MOSFET.

19

BHS

B High-side Source connection. Connect to source of B High-side power MOSFET. Connect negative side of

bootstrap capacitor to this pin.

20

BHO

B High-side Output. Connect to gate of B High-side power MOSFET.

HIP4080

7

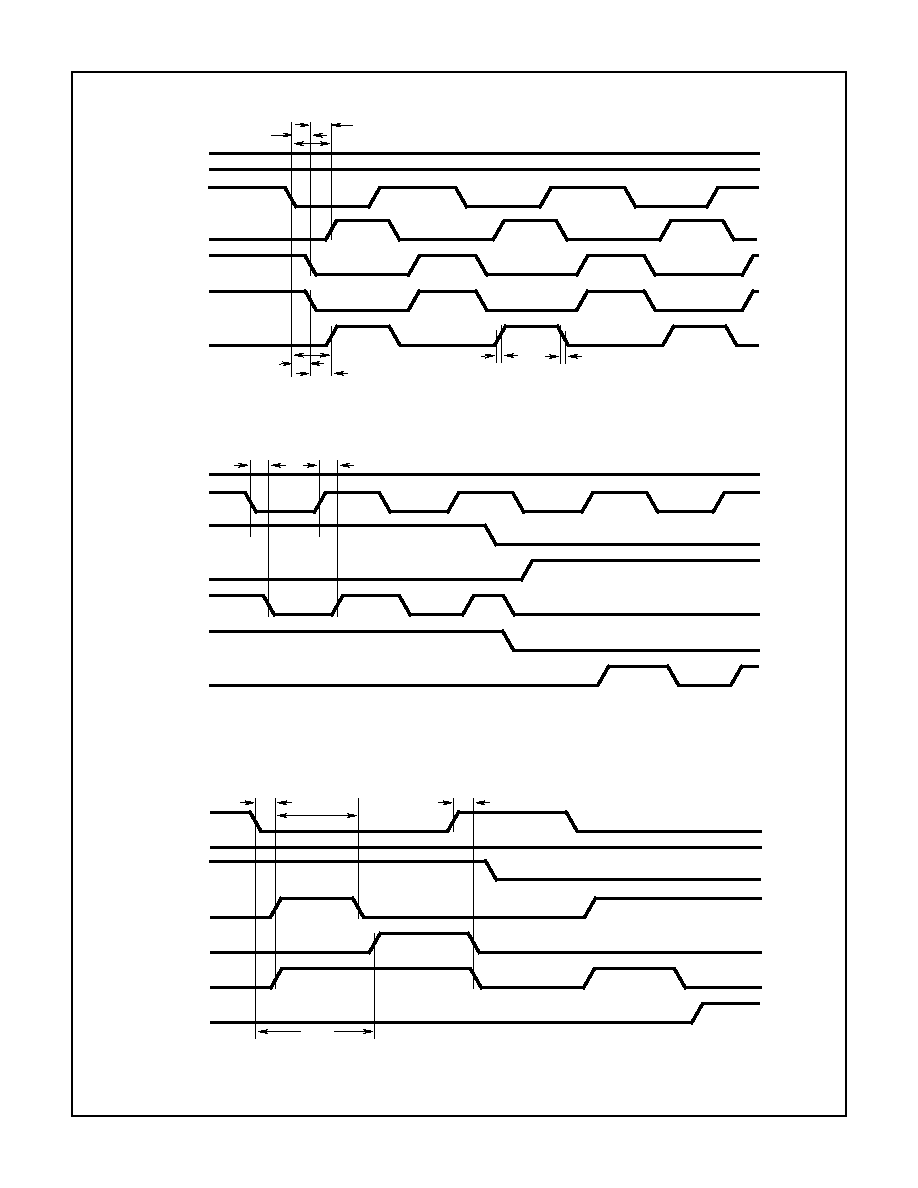

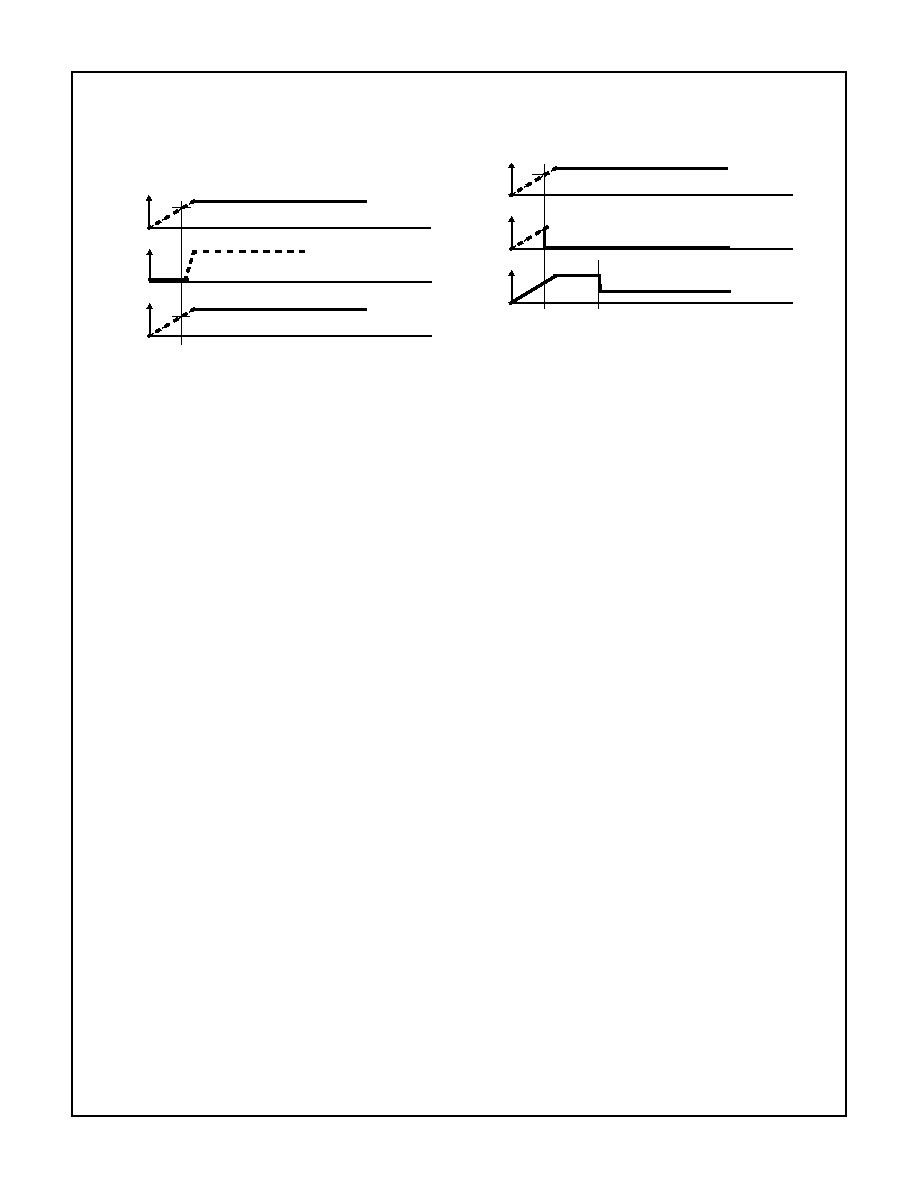

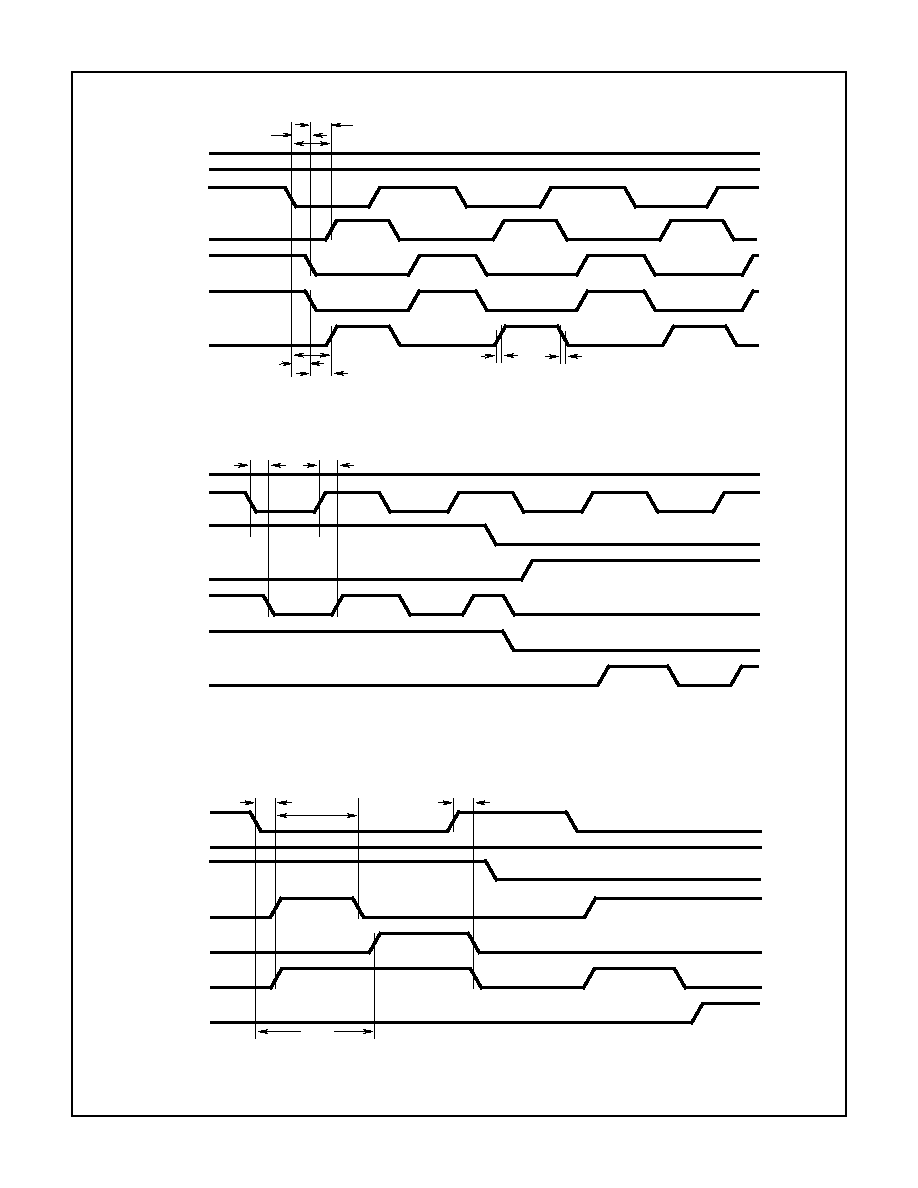

Timing Diagrams

FIGURE 1. BI-STATE MODE

FIGURE 2. HIGH SIDE CHOP MODE

FIGURE 3. DISABLE FUNCTION

HEN = 1

ALO

AHO

BLO

T

LPHL

T

HPLH

T

r

(10% - 90%)

T

f

(90% - 10%)

T

DT

DIS = 0

T

HPHL

T

LPLH

T

DT

IN+ > IN-

BHO

HEN

ALO

AHO

BLO

T

HEN-PLH

T

HEN-PHL

IN+ > IN-

BHO

DIS = 0

HEN = 1

AHO

BLO

DIS

T

REF-PW

T

DLPLH

IN+ > IN-

BHO

T

DIS

T

UEN

ALO

HIP4080

8

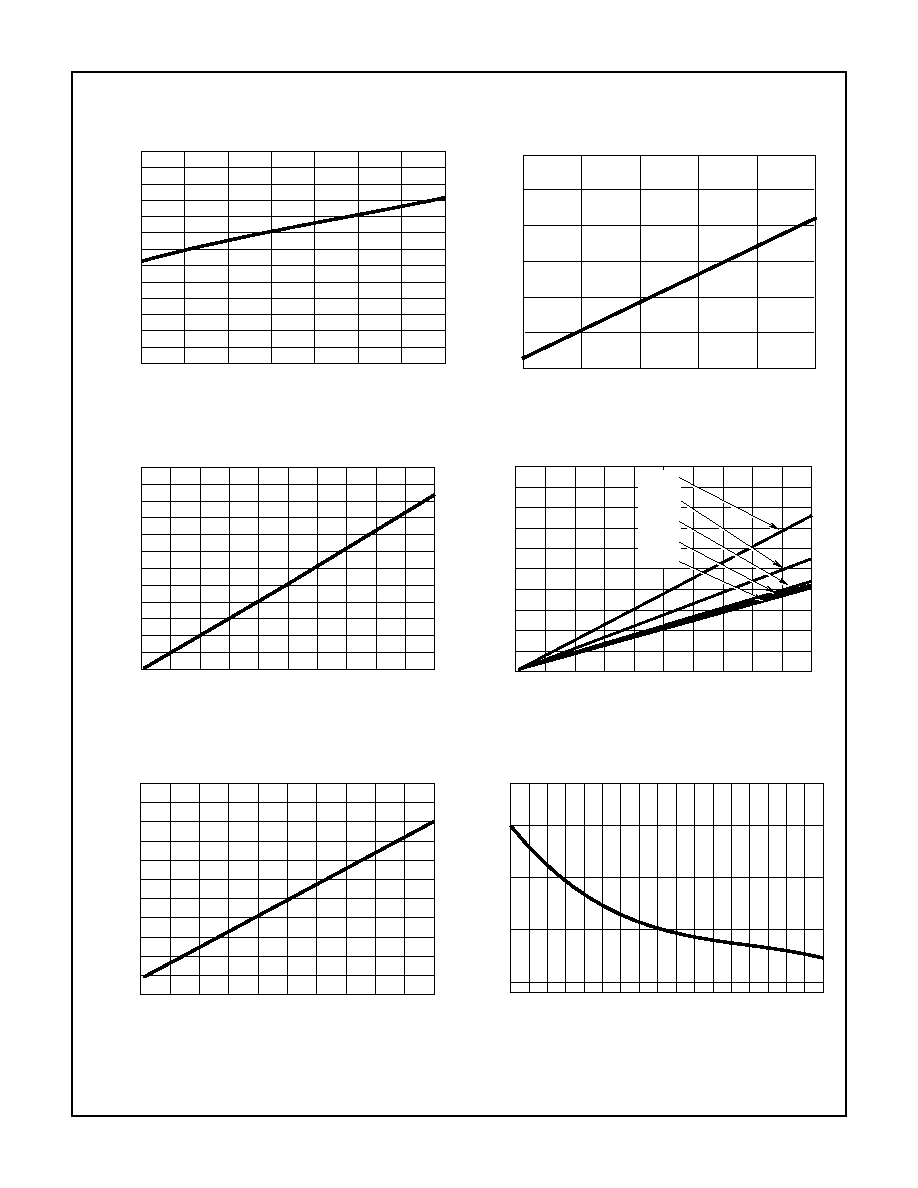

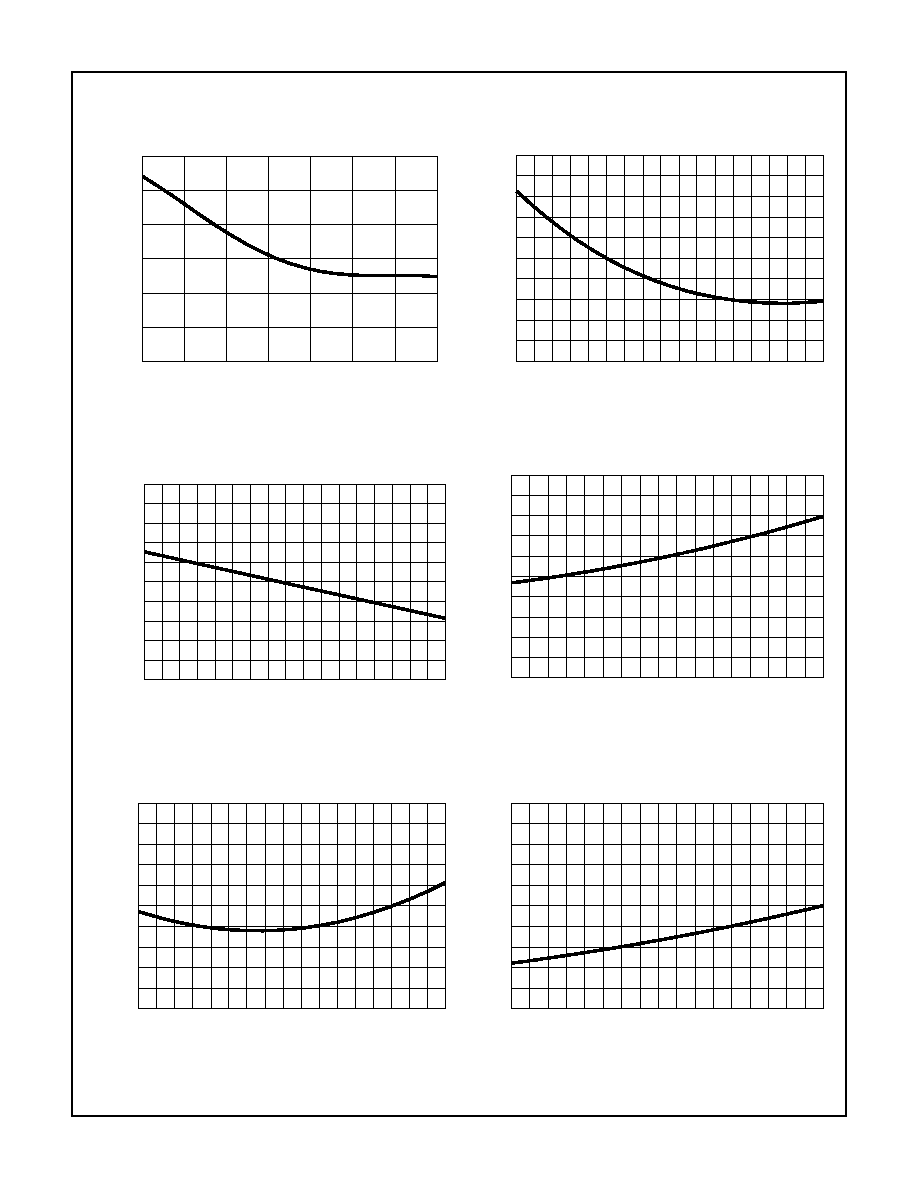

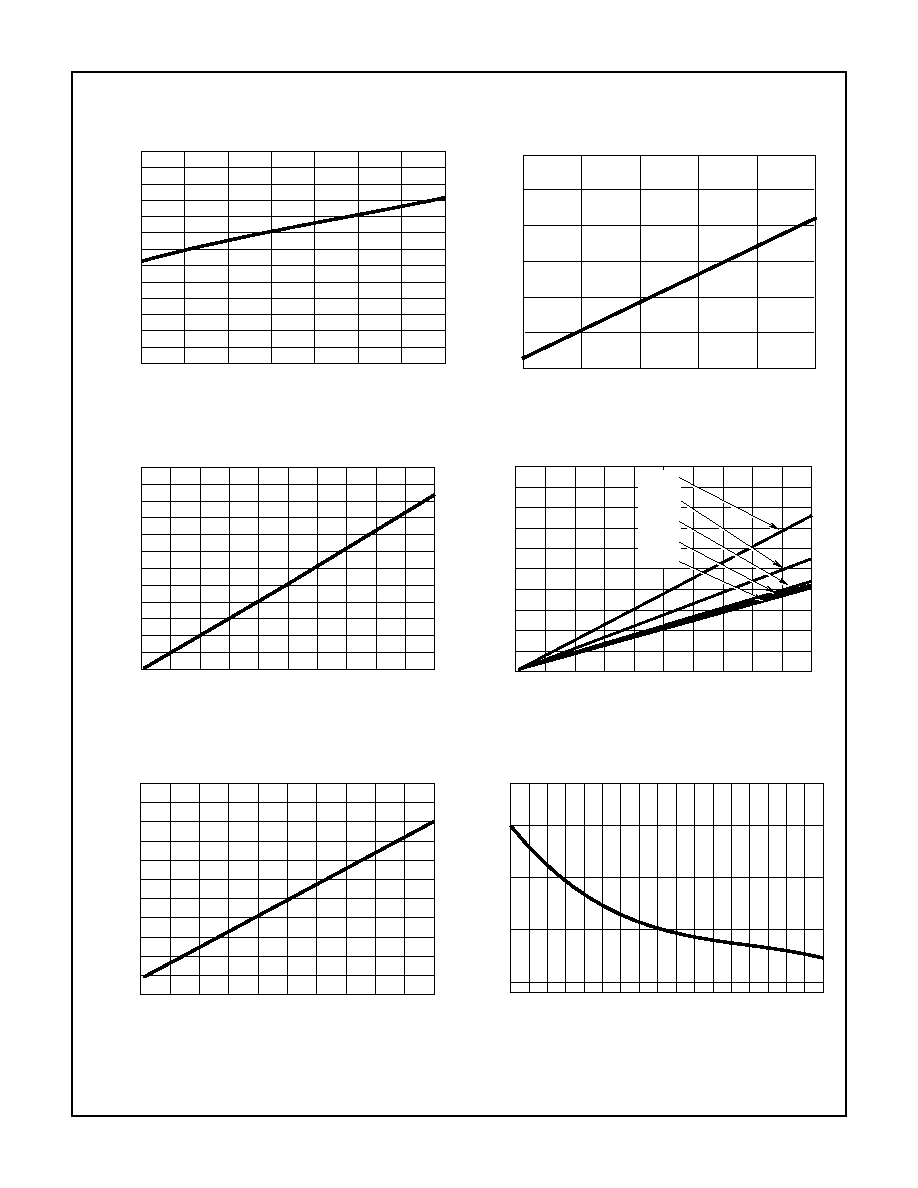

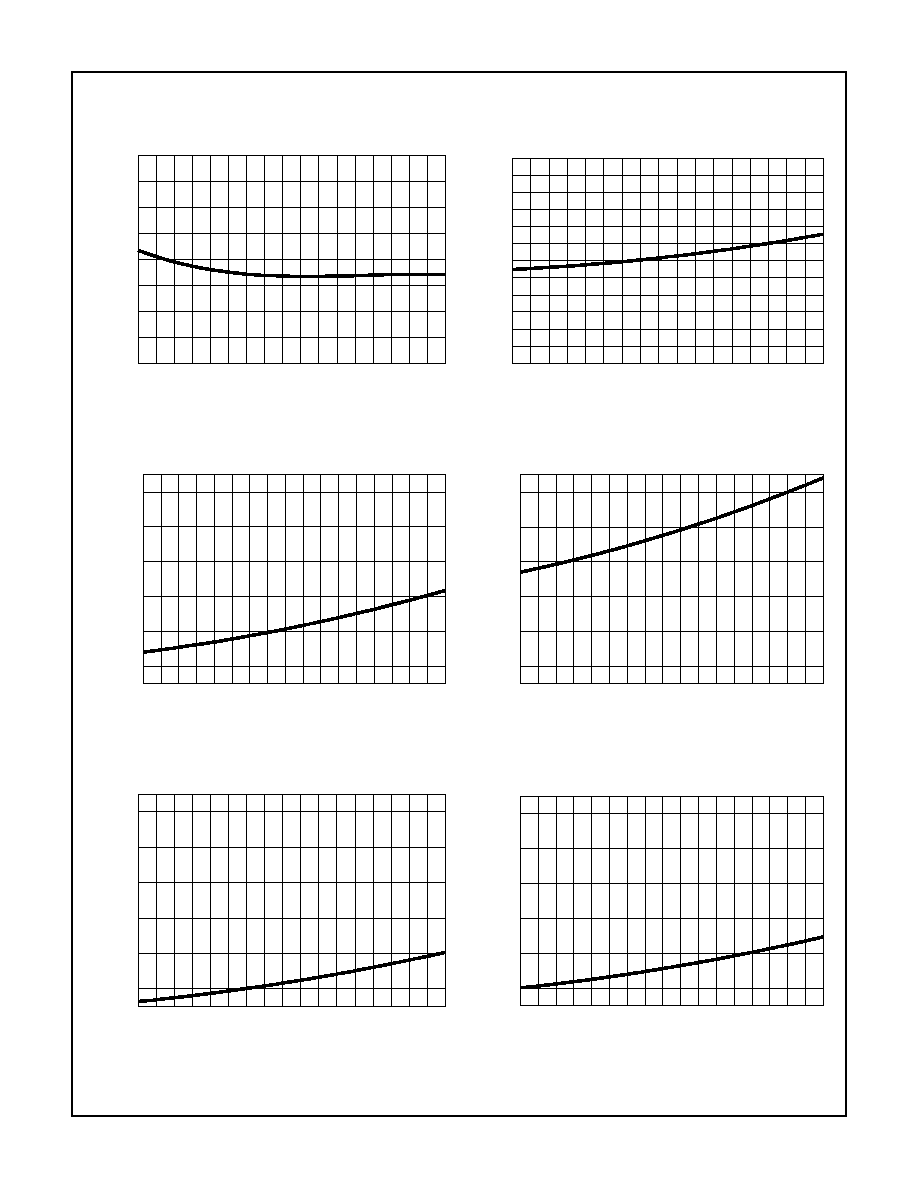

Typical Performance Curves

V

DD

= V

CC

= V

AHB

= V

BHB

= 12V, V

SS

= V

ALS

= V

BLS

= V

AHS

= V

BHS

= 0V,

R

HDEL

= R

LDEL

= 100K, and T

A

= 25

o

C, Unless Otherwise Specified

FIGURE 4. QUIESCENT I

DD

SUPPLY CURRENT vs V

DD

SUPPLY VOLTAGE

FIGURE 5. I

DDO

, NO-LOAD I

DD

SUPPLY CURRENT vs

FREQUENCY (kHz)

FIGURE 6. SIDE A, B FLOATING SUPPLY BIAS CURRENT vs

FREQUENCY (LOAD = 1000pF)

FIGURE 7. I

CCO

, NO-LOAD I

CC

SUPPLY CURRENT vs

FREQUENCY (kHz) TEMPERATURE

FIGURE 8. I

AHB

, I

BHB

, NO-LOAD FLOATING SUPPLY BIAS

CURRENT vs FREQUENCY

FIGURE 9. COMPARATOR INPUT CURRENT I

L

vs

TEMPERATURE AT V

CM

= 5V

8

10

12

14

2.0

4.0

6.0

8.0

10.0

12.0

14.0

I

DD

SUPPL

Y CURRENT (mA)

V

DD

SUPPLY VOLTAGE (V)

13

12.5

12.0

11.5

11.0

10.5

10

200

400

600

800

1000

SUPPL

Y CURRENT (mA)

SWITCHING FREQUENCY (kHz)

0

100

200

300

400

500

600

700

800

900 1000

0.0

5.0

10.0

15.0

20.0

25.0

30.0

FLO

A

TING SUPPL

Y BIAS CURRENT (mA)

SWITCHING FREQUENCY (kHz)

0

100

200

300

400

500

600

700

800

900 1000

0.0

1.0

2.0

3.0

4.0

5.0

I

CC

SUPPL

Y CURRENT (mA)

SWITCHING FREQUENCY (kHz)

75

o

C

25

o

C

125

o

C

-40

o

C

0

o

C

0

200

400

600

800

1000

-0.2

0.2

0.6

1.0

1.4

1.8

FREQUENCY (kHz)

FLO

A

TING SUPPL

Y BIAS CURRENT (mA)

-40

-20

0

20

40

60

80

100

120

0.5

1.0

COMP

ARA

T

OR INPUT CURRENT (

µ

A)

JUNCTION TEMPERATURE (

o

C)

HIP4080

9

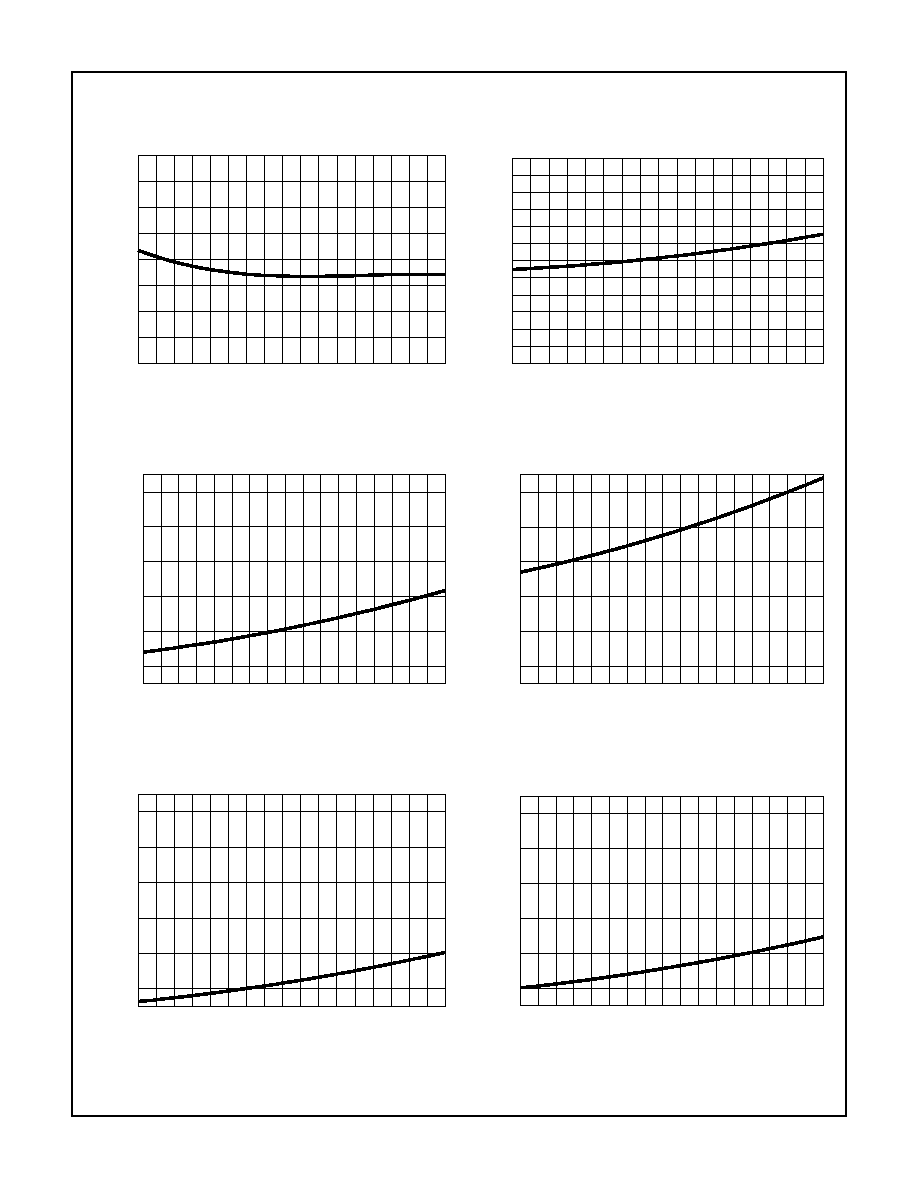

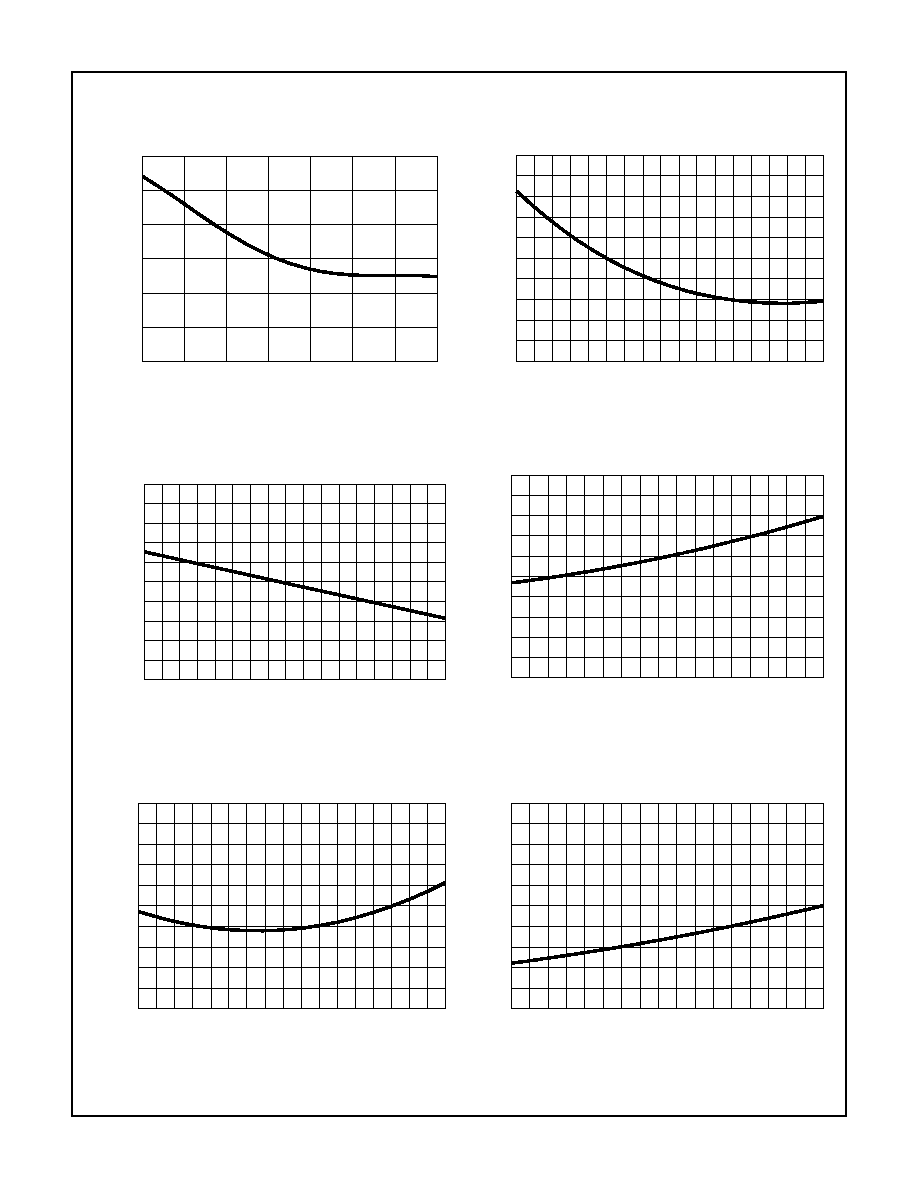

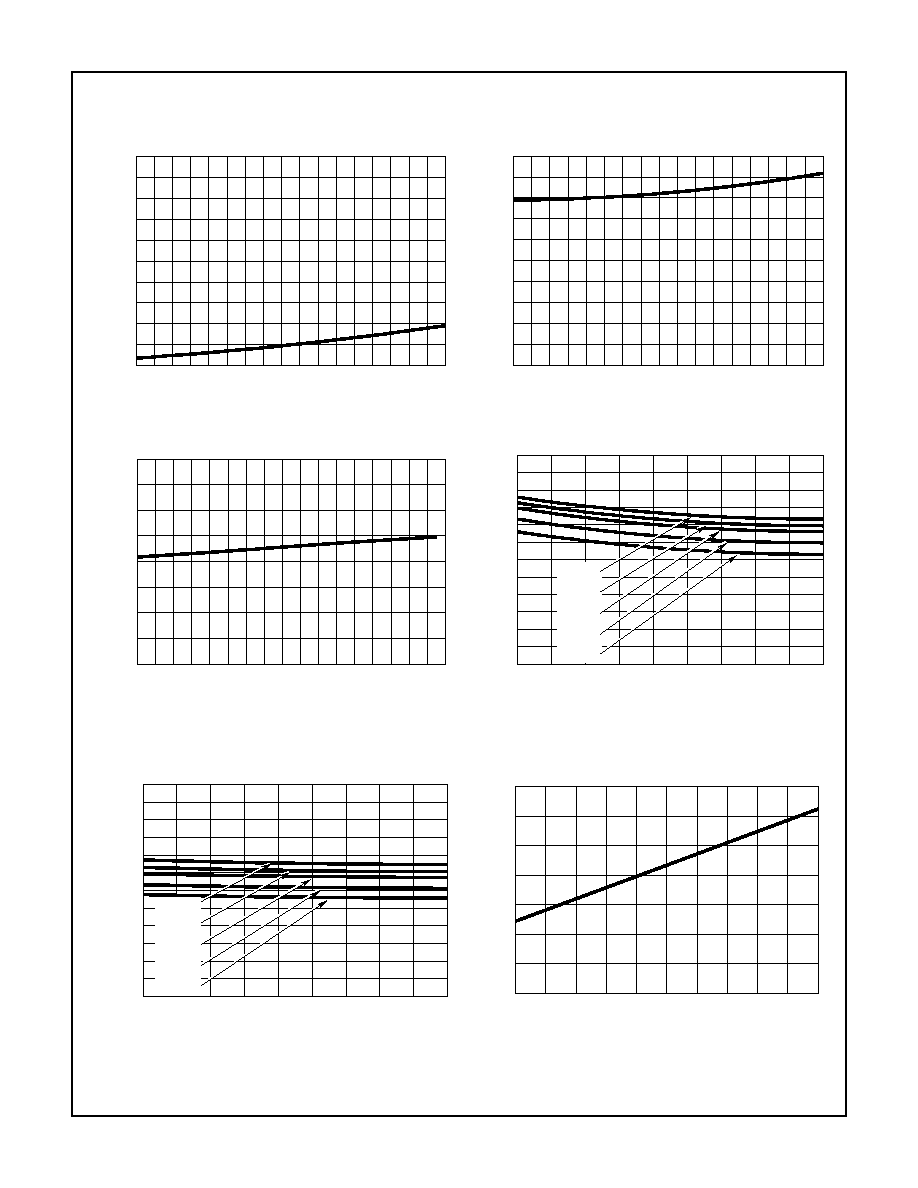

FIGURE 10. DIS LOW LEVEL INPUT CURRENT I

IL

vs

TEMPERATURE

FIGURE 11. HEN LOW LEVEL INPUT CURRENT I

IL

vs

TEMPERATURE

FIGURE 12. AHB - AHS, BHB - BHS NO-LOAD CHARGE PUMP

VOLTAGE vs TEMPERATURE

FIGURE 13. UPPER DISABLE TURN-OFF PROPAGATION

DELAY T

DISHIGH

vs TEMPERATURE

FIGURE 14. DISABLE TO UPPER ENABLE T

UEN

PROPAGATION DELAY vs TEMPERATURE

FIGURE 15. LOWER DISABLE TURN-OFF PROPAGATION

DELAY T

DISLOW

vs TEMPERATURE

Typical Performance Curves

V

DD

= V

CC

= V

AHB

= V

BHB

= 12V, V

SS

= V

ALS

= V

BLS

= V

AHS

= V

BHS

= 0V,

R

HDEL

= R

LDEL

= 100K, and T

A

= 25

o

C, Unless Otherwise Specified (Continued)

-50

-25

0

25

50

75

100

125

-120

-110

-100

-90

LO

W LEVEL INPUT CURRENT (

µ

A)

JUNCTION TEMPERATURE (

o

C)

-40

-20

0

20

40

60

80

100

120

-230

-220

-210

-200

-190

-180

LO

W LEVEL INPUT CURRENT (

µ

A)

JUNCTION TEMPERATURE (

o

C)

-40

-20

0

20

40

60

80

100

120

10.0

11.0

12.0

13.0

14.0

15.0

NO-LO

AD FLO

A

TING CHARGE PUMP V

O

L

T

A

GE

JUNCTION TEMPERATURE (

o

C)

-40

-20

0

20

40

60

80

100

120

30

40

50

60

70

80

PR

OP

A

G

A

TION DELA

Y (ns)

JUNCTION TEMPERATURE (

o

C)

-40

-20

0

20

40

60

80

100

120

300

320

340

360

380

400

PR

OP

A

G

A

TION DELA

Y (ns)

JUNCTION TEMPERATURE (

o

C)

-40

-20

0

20

40

60

80

100

120

30

40

50

60

70

80

PR

OP

A

G

A

TION DELA

Y (ns)

JUNCTION TEMPERATURE (

o

C)

HIP4080

10

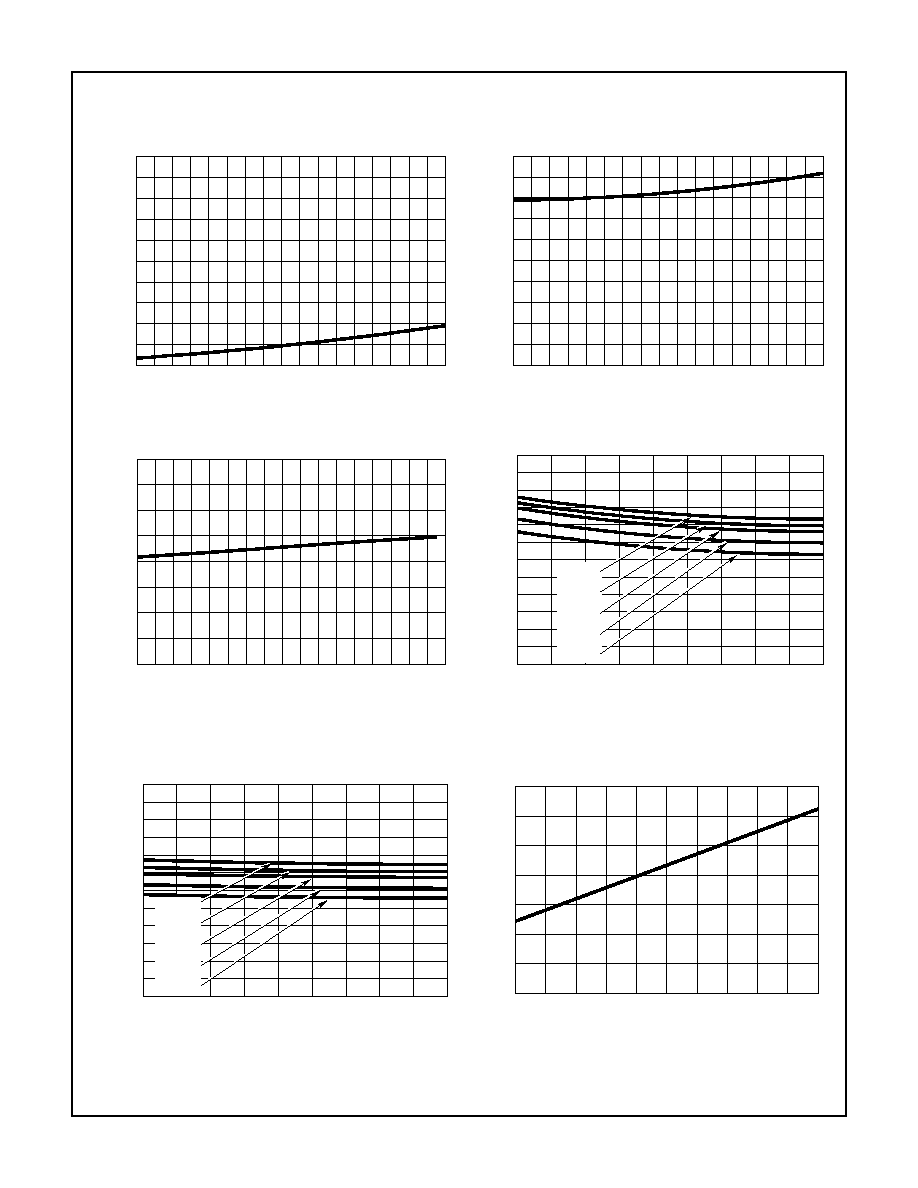

FIGURE 16. T

REF-PW

REFRESH PULSE WIDTH vs

TEMPERATURE

FIGURE 17. DISABLE TO LOWER ENABLE T

DLPLH

PROPAGATION DELAY vs TEMPERATURE

FIGURE 18. UPPER TURN-OFF PROPAGATION DELAY T

HPHL

vs TEMPERATURE

FIGURE 19. UPPER TURN-ON PROPAGATION DELAY T

HPLH

vs TEMPERATURE

FIGURE 20. LOWER TURN-OFF PROPAGATION DELAY T

LPHL

vs TEMPERATURE

FIGURE 21. LOWER TURN-ON PROPAGATION DELAY T

LPLH

vs

TEMPERATURE

Typical Performance Curves

V

DD

= V

CC

= V

AHB

= V

BHB

= 12V, V

SS

= V

ALS

= V

BLS

= V

AHS

= V

BHS

= 0V,

R

HDEL

= R

LDEL

= 100K, and T

A

= 25

o

C, Unless Otherwise Specified (Continued)

-40

-20

0

20

40

60

80

100

120

175

225

275

325

375

REFRESH PULSE WIDTH (ns)

JUNCTION TEMPERATURE (

o

C)

-40

-20

0

20

40

60

80

100

120

20

30

40

50

60

70

80

PR

OP

A

G

A

TION DELA

Y (ns)

JUNCTION TEMPERATURE (

o

C)

-40

-20

0

20

40

60

80

100

120

40.0

50.0

60.0

70.0

80.0

90.0

PR

OP

A

G

A

TION DELA

Y (ns)

JUNCTION TEMPERATURE (

o

C)

-40

-20

0

20

40

60

80

100

120

40.0

50.0

60.0

70.0

80.0

90.0

PR

OP

A

G

A

TION DELA

Y (ns)

JUNCTION TEMPERATURE (

o

C)

-40

-20

0

20

40

60

80

100

120

40.0

50.0

60.0

70.0

80.0

90.0

PR

OP

A

G

A

TION DELA

Y (ns)

JUNCTION TEMPERATURE (

o

C)

-40

-20

0

20

40

60

80

100

120

40.0

50.0

60.0

70.0

80.0

90.0

PR

OP

A

G

A

TION DELA

Y (ns)

JUNCTION TEMPERATURE (

o

C)

HIP4080

11

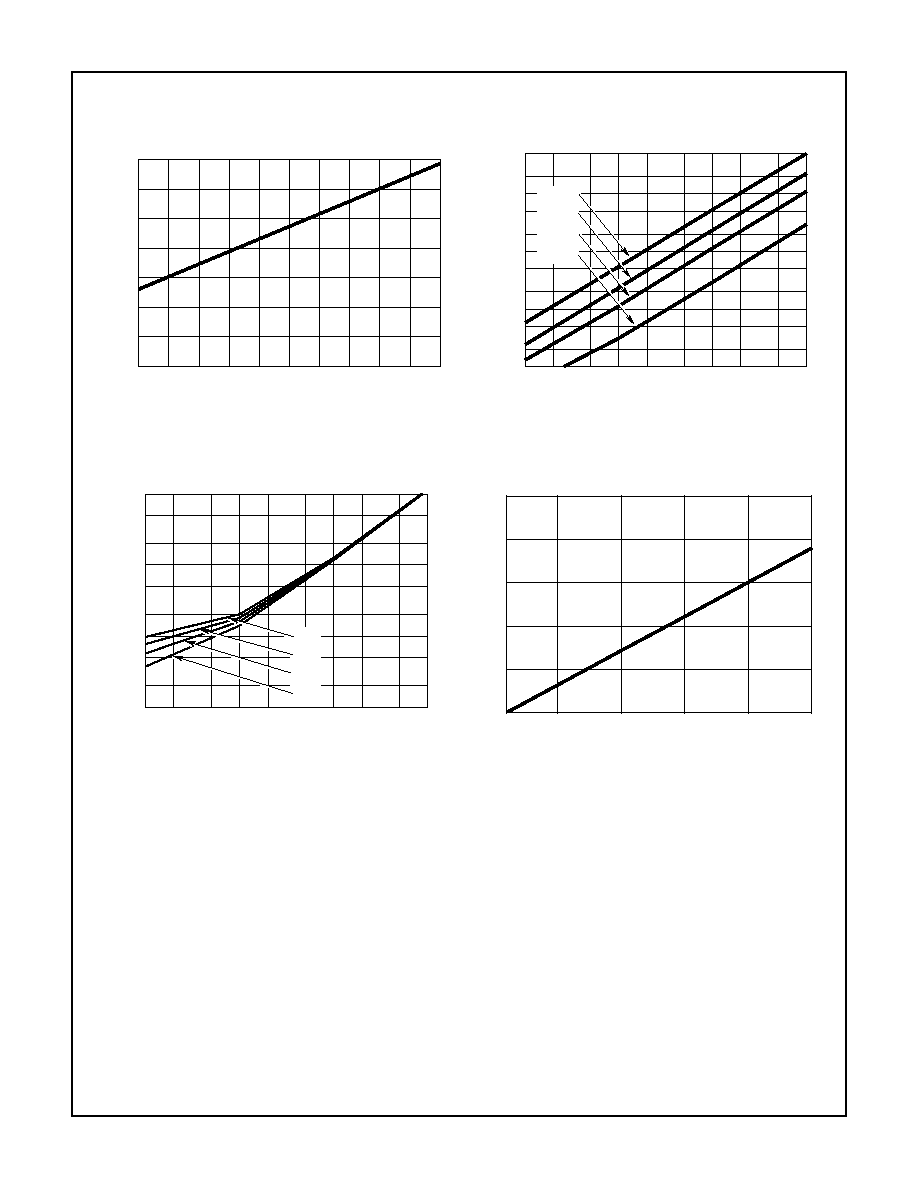

FIGURE 22. GATE DRIVE FALL TIME T

F

vs TEMPERATURE

FIGURE 23. GATE DRIVE RISE TIME T

R

vs TEMPERATURE

FIGURE 24. V

LDEL

, V

HDEL

VOLTAGE vs TEMPERATURE

FIGURE 25. HIGH LEVEL OUTPUT VOLTAGE, V

CC

- V

OH

vs

BIAS SUPPLY AND TEMPERATURE AT 100mA

FIGURE 26. LOW LEVEL OUTPUT VOLTAGE V

OL

vs BIAS

SUPPLY AND TEMPERATURE AT 100mA

FIGURE 27. PEAK PULLDOWN CURRENT I

O

vs BIAS SUPPLY

VOLTAGE

Typical Performance Curves

V

DD

= V

CC

= V

AHB

= V

BHB

= 12V, V

SS

= V

ALS

= V

BLS

= V

AHS

= V

BHS

= 0V,

R

HDEL

= R

LDEL

= 100K, and T

A

= 25

o

C, Unless Otherwise Specified (Continued)

-40

-20

0

20

40

60

80

100

120

8.5

9.5

10.5

11.5

12.5

13.5

GA

TE DRIVE F

ALL TIME (ns)

JUNCTION TEMPERATURE (

o

C)

-40

-20

0

20

40

60

80

100

120

8.5

9.5

10.5

11.5

12.5

13.5

TURN-ON RISE TIME (ns)

JUNCTION TEMPERATURE (C)

-40

-20

0

20

40

60

80

100

120

4.0

4.5

5.0

5.5

6.0

HDEL, LDEL INPUT V

O

L

T

A

GE (V)

JUNCTION TEMPERATURE (

o

C)

6

8

10

12

14

0

250

500

750

1000

1250

1500

V

CC

- V

OH

(mV)

BIAS SUPPLY VOLTAGE (V)

75

o

C

25

o

C

125

o

C

-40

o

C

0

o

C

6

8

10

12

14

0

250

500

750

1000

1250

1500

V

OL

(mV)

BIAS SUPPLY VOLTAGE (V)

75

o

C

25

o

C

125

o

C

-40

o

C

0

o

C

6

7

8

9

10

11

12

13

14

15

16

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

GA

TE DRIVE SINK CURRENT (A)

V

DD

, V

CC

, V

AHB

, V

BHB

(V)

HIP4080

12

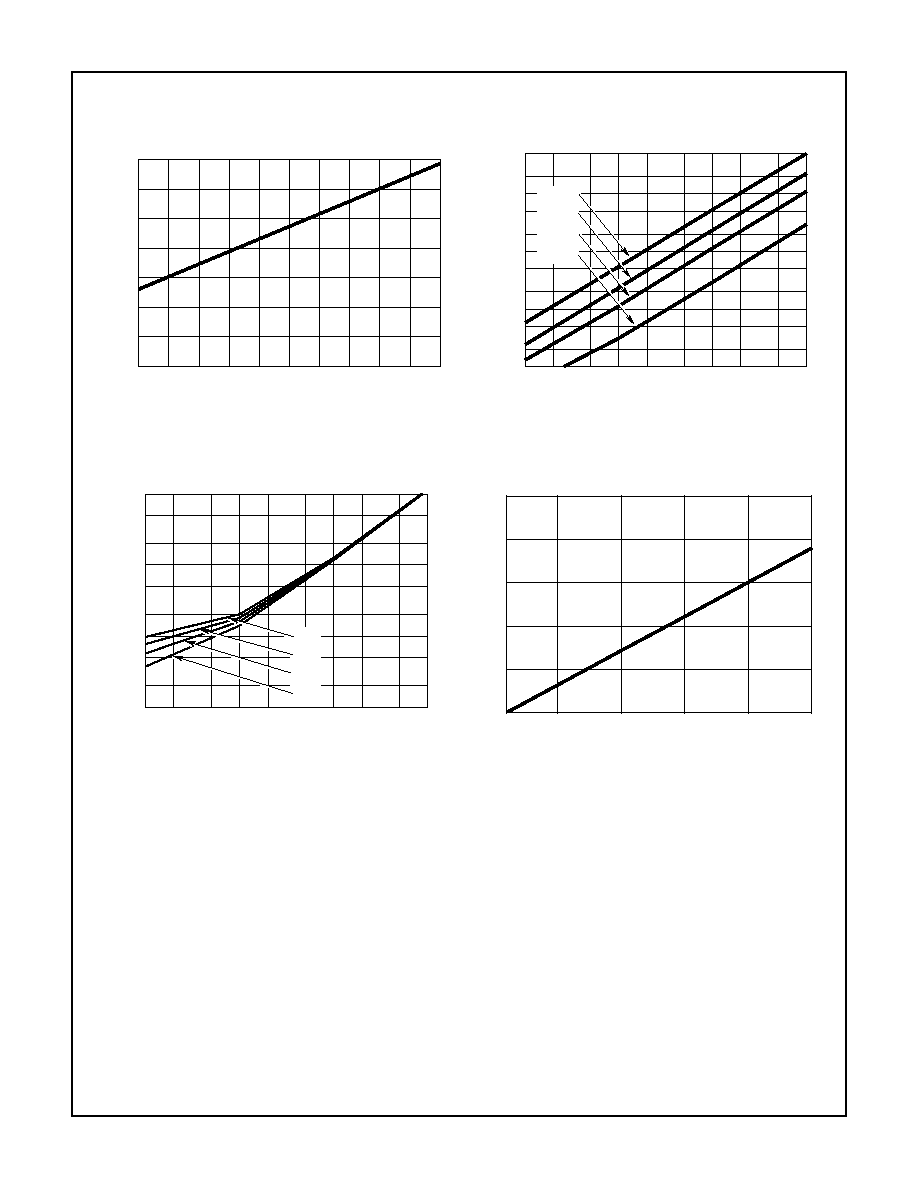

FIGURE 28. PEAK PULLUP CURRENT I

O+

vs SUPPLY

VOLTAGE

FIGURE 29. LOW VOLTAGE BIAS CURRENT I

DD

AND I

CC

(LESS QUIESCENT COMPONENT) vs

FREQUENCY AND GATE LOAD CAPACITANCE

FIGURE 30. HIGH VOLTAGE LEVEL-SHIFT CURRENT vs

FREQUENCY AND BUS VOLTAGE

FIGURE 31. MINIMUM DEAD-TIME vs DEL RESISTANCE

Typical Performance Curves

V

DD

= V

CC

= V

AHB

= V

BHB

= 12V, V

SS

= V

ALS

= V

BLS

= V

AHS

= V

BHS

= 0V,

R

HDEL

= R

LDEL

= 100K, and T

A

= 25

o

C, Unless Otherwise Specified (Continued)

6

7

8

9

10

11

12

13

14

15

16

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

GA

TE DRIVE SINK CURRENT (A)

V

DD

, V

CC

, V

AHB

, V

BHB

(V)

1

10

100

1000

2

5

20

50

500

200

0.1

1

10

100

500

50

5

0.5

200

20

2

0.2

LO

W V

O

L

T

A

GE BIAS CURRENT (mA)

SWITCHING FREQUENCY (kHz)

3,000

1,000

10,000

100

1

10

100

1000

2

5

20

50

200

500

1

10

100

1000

2

5

20

50

200

500

LEVEL-SHIFT CURRENT (

µ

A)

SWITCHING FREQUENCY (kHz)

60V

40V

80V

20V

10

50

100

150

200

250

0

30

60

90

120

150

HDEL/LDEL RESISTANCE (k

)

DEAD-TIME (ns)

HIP4080

13

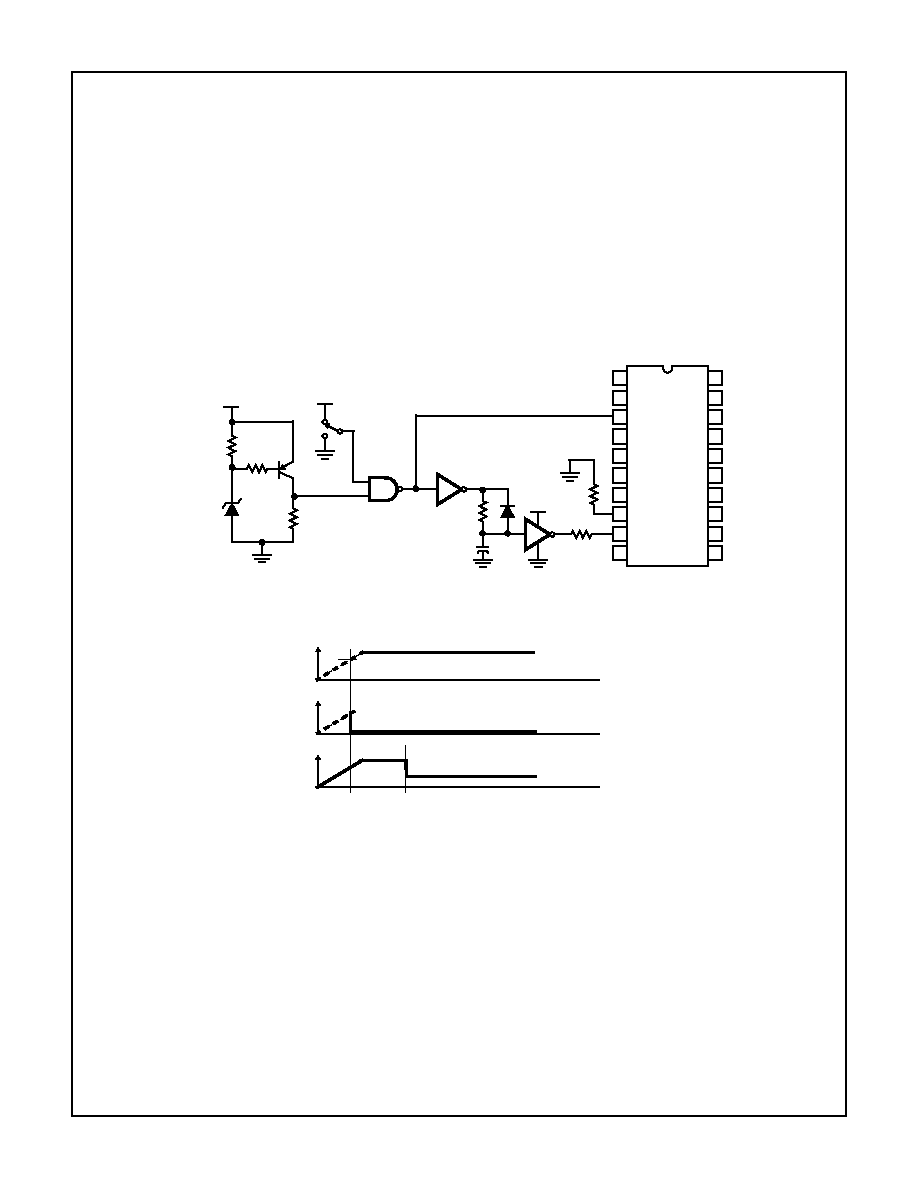

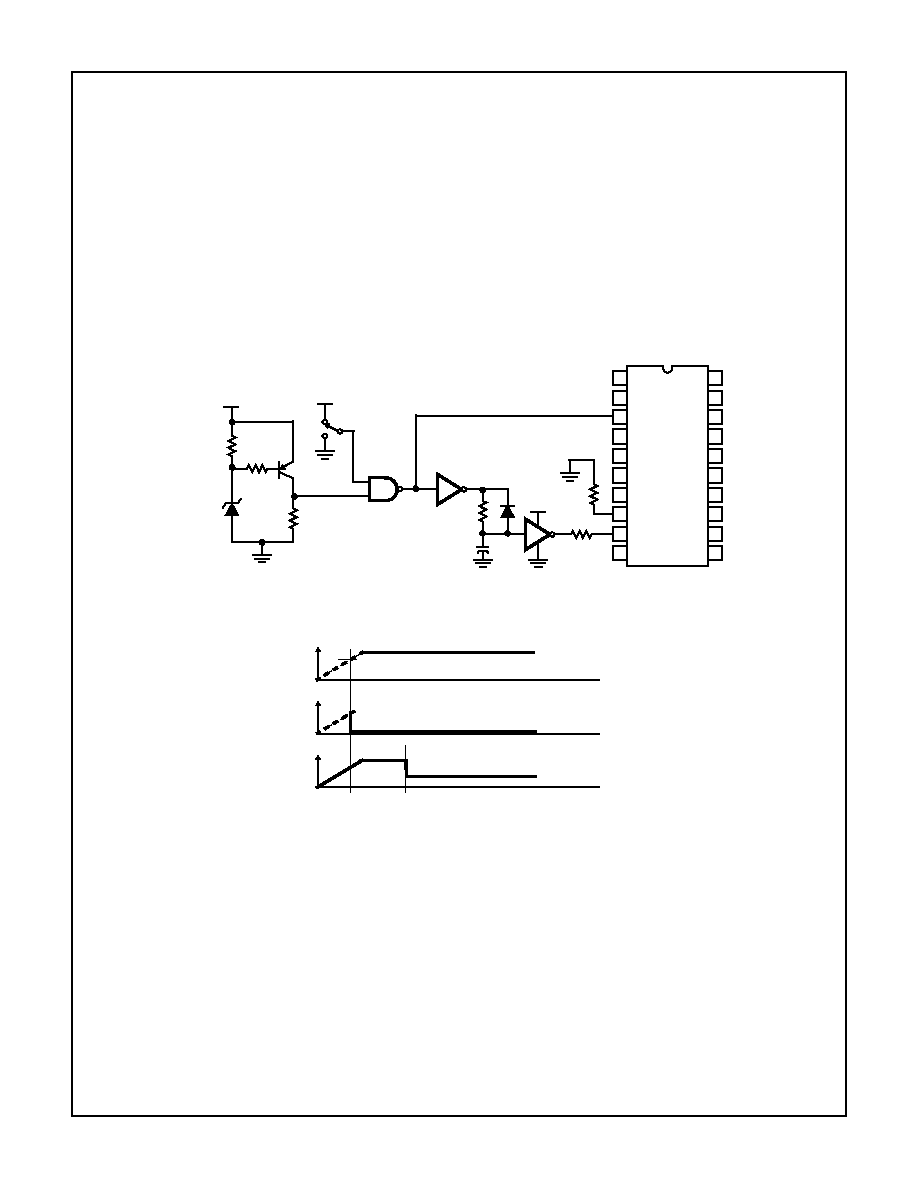

HIP4080 Power-up Application Information

The HIP4080 H-Bridge Driver IC requires external circuitry

to assure reliable start-up conditions of the upper drivers. If

not addressed in the application, the H-Bridge power MOS-

FETs may be exposed to shoot-through current, possibly

leading to MOSFET failure. Following the instructions below

will result in reliable start-up.

The HIP4080 does not have an input protocol like the

HIP4081 that keeps both lower power MOSFETs off other

than through the DIS pin. IN+ and IN- are inputs to a com-

parator that control the bridge in such a way that only one of

the lower power devices is on at a time, assuming DIS is low.

However, keeping both lower MOSFETs off can be accom-

plished by controlling the lower turn-on delay pin, LDEL,

while the chip is enabled, as shown in Figure 32. Pulling

LDEL to V

DD

will indefinitely delay the lower turn-on delays

through the input comparator and will keep the lower MOS-

FETs off. With the lower MOSFETs off and the chip enabled,

i.e. DIS = low, IN+ or IN- can be switched through a full

cycle, properly setting the upper driver outputs. Once this is

accomplished, LDEL is released to its normal operating

point. It is critical that IN+/IN- switch a full cycle while LDEL

is held high, to avoid shoot-through. This start-up procedure

can be initiated by the supply voltage and/or the chip enable

command by the circuit in Figure 32.

11

12

13

14

15

16

17

18

20

19

10

9

8

7

6

5

4

3

2

1 BHB

HEN

DIS

V

SS

OUT

IN+

HDEL

IN-

LDEL

AHB

BHO

BLO

BLS

V

DD

BHS

V

CC

ALS

ALO

AHS

AHO

100K

RDEL

RDEL

V

DD

0.1

µ

F

2N3906

V

DD

ENABLE

V

DD

56K

8.2V

56K

100K

FIGURE 32.

V

DD

DIS

LDEL

=10ms

t1

t2

8.3V TO 9.1V (ASSUMING 5% ZENER TOLERANCE)

12V, FINAL VALUE

5.1V

NOTES:

2. Between t1 and t2 the IN+ and IN- inputs must cause the OUT pin to go through one complete cycle (transition order is not important). If

the ENABLE pin is low after the under-voltage circuit is satisfied, the ENABLE pin will initiate the 10ms time delay during which the IN+

and IN- pins must cycle at least once.

3. Another product, HIP4080A, incorporates undervoltage circuitry which eliminates the need for the above power up circuitry.

FIGURE 33. TIMING DIAGRAM FOR FIGURE 32

HIP4080

14

HIP4080

1

2

3

1

3

1

3

6

5

1

2

3

2

1

12

13

1

3

10

11

1

2

3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

L1

R21

Q1

Q3

Q4

R22

L2

R23

C1

C3

JMPR1

R24

R30

R31

C2

R34

C4

CR2

CR1

Q2

JMPR5

JMPR3

JMPR2

JMPR4

R33

C5

C6

CX

CY

C8

U1

CW

CW

+

B+

IN2

IN1

BO

OUT/BLI

IN-/AHI

COM

IN+/ALI

+12V

+12V

BLS

AO

HEN/BHI

ALS

CD4069UB

CD4069UB

CD4069UB

CD4069UB

HIP4080/81

SECTION

CONTROL LOGIC

POWER SECTION

DRIVER SECTION

AHO

AHB

AHS

LDEL

ALO

HDEL

ALS

IN-/AHI

V

CC

IN+/ALI

V

DD

OUT/BLI

BLS

V

SS

BLO

DIS

BHS

HEN/BHI

BHO

BHB

R29

U2

U2

U2

U2

4

3

V

DD

CD4069UB

U2

8

9

CD4069UB

U2

V

DD

ENABLE

O

100K

0.1MFD

I

TO DIS

2N3906

56K

8.2V

56K

O

2

2

2

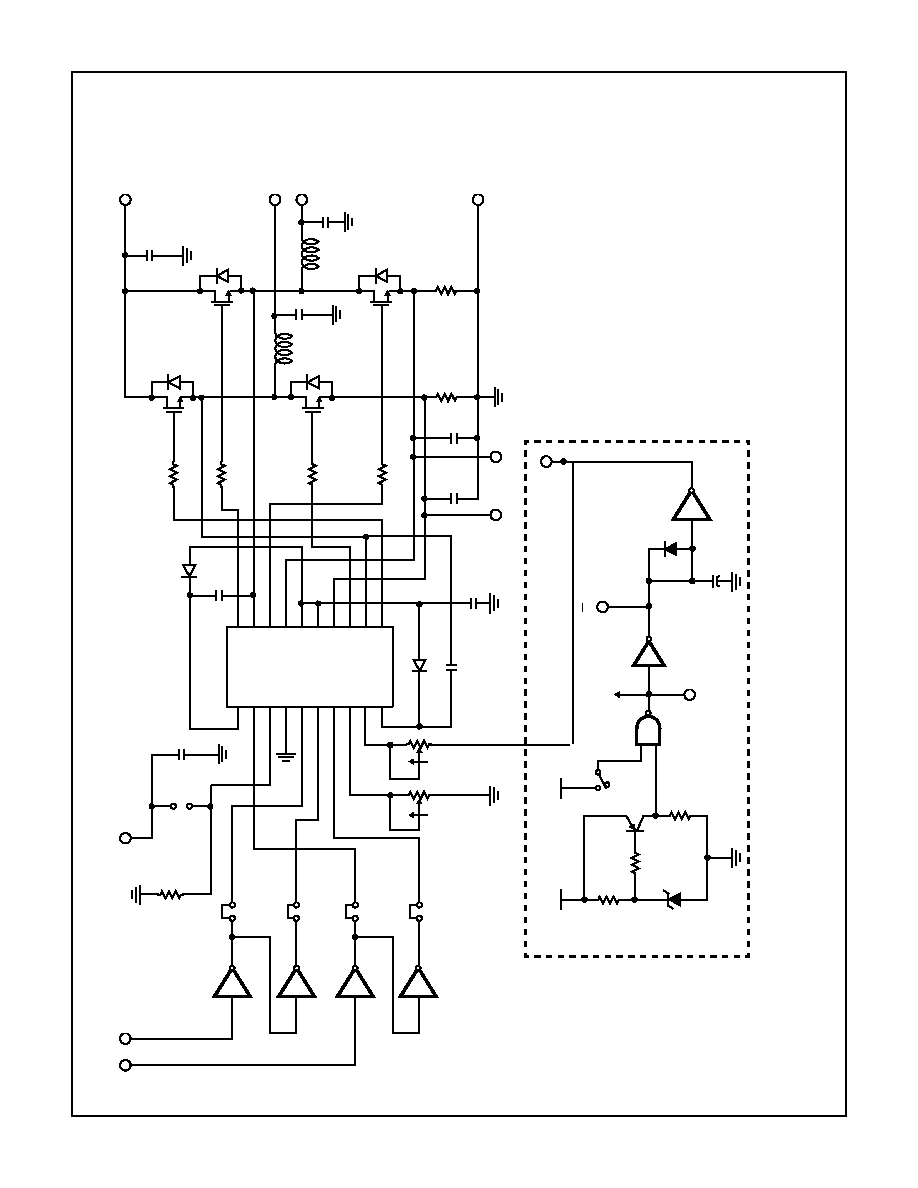

NOTES:

4. Circuit inside dashed area must be hardwired and

is not included on the evaluation board.

5. Device CD4069UB PIN 7 = COM, Pin 14 = +12V.

6. Components L1, L2, C1, C2, CX, CY, R30, R31,

are not supplied. refer to Application Note for de-

scription of input logic operation to determine

jumper locations for JMPR1 - JMPR4.

FIGURE 34. HIP4080 EVALUATION PC BOARD SCHEMATIC

15

HIP4080

R22

1

Q3

L1

C1

JMPR2

JMPR5

R31

R33

CR2

R23

R24

R27

R28

R26

1

Q4

1

Q2

JMPR3

U1

R21

GND

L2

C3

C2

C4

JMPR4

JMPR1

R30

CR1

U2

R34

BO

AO

R32

I

O

C8

R29

C7

C6

C5

CY

CX

1

Q1

COM

+12V

B+

IN1

IN2

AHO

BHO

ALO

BLO

BLS

BLS

LDEL

HDEL

DIS

ALS

ALS

O

+

+

HIP4080/81

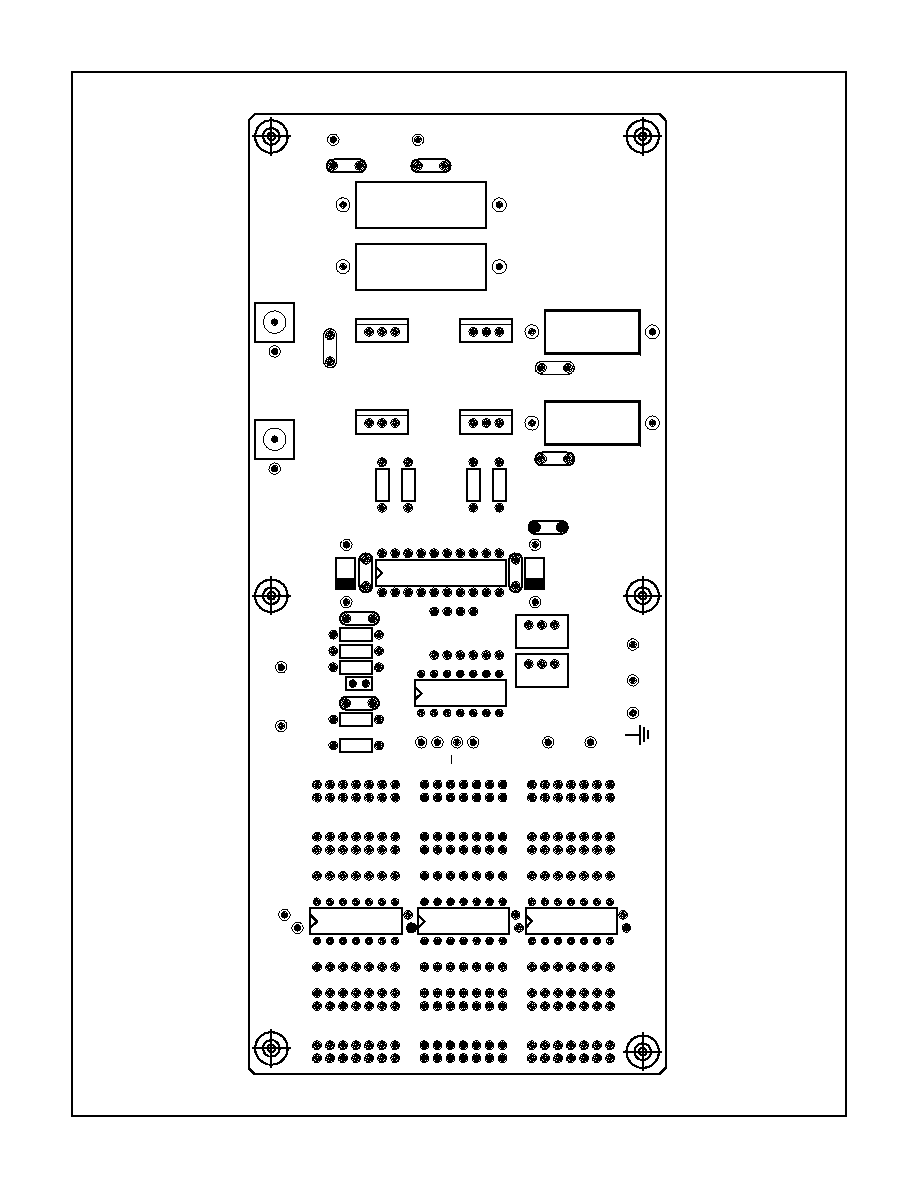

FIGURE 35. HIP4080 EVALUATION BOARD SILKSCREEN

16

Supplemental Information for HIP4080

and HIP4081 Power-Up Application

The HIP4080 and HIP4081 H-Bridge Driver ICs require

external circuitry to assure reliable start-up conditions of the

upper drivers. If not addressed in the application, the

H-bridge power MOSFETs may be exposed to shoot-

through current, possibly leading to MOSFET failure. Follow-

ing the instructions below will result in reliable start-up.

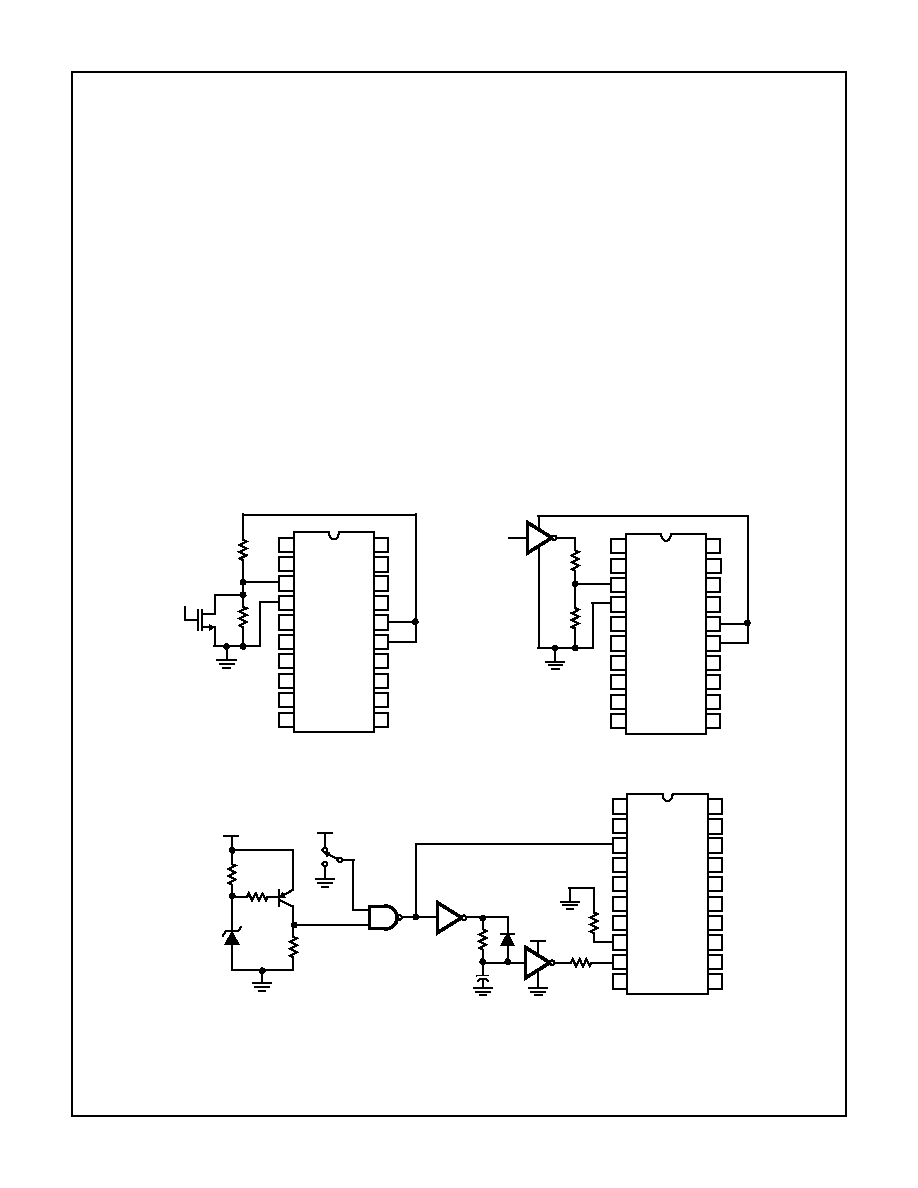

HIP4081

The HIP4081 has four inputs, one for each output. Outputs

ALO and BLO are directly controlled by input ALI and BLI.

By holding ALI and BLI low during start-up no shoot-through

conditions can occur. To set the latches to the upper drivers

such that the driver outputs, AHO and BHO, are off, the DIS

pin must be toggled from low to high after power is applied.

This is accomplished with a simple resistor divider, as shown

below in Figure 36. As the V

DD

/V

CC

supply ramps from zero

up, the DIS voltage is below its input threshold of 1.7V due to

the R1/R2 resistor divider. When V

DD

/V

CC

exceeds approxi-

mately 9V to 10V, DIS becomes greater than the input

threshold and the chip disables all outputs. It is critical that

ALI and BLI be held low prior to DIS reaching its threshold

level of 1.7V while V

DD

/V

CC

is ramping up, so that shoot

through is avoided. After power is up the chip can be

enabled by the ENABLE signal which pulls the DIS pin low.

HIP4080

The HIP4080 does not have an input protocol like the

HIP4081 that keeps both lower power MOSFETs off other

than through the DIS pin. IN+ and IN- are inputs to a com-

parator that control the bridge in such a way that only one of

the lower power devices is on at a time, assuming DIS is low.

However, keeping both lower MOSFETs off can be accom-

plished by controlling the lower turn-on delay pin, LDEL,

while the chip is enabled, as shown in Figure 37. Pulling

LDEL to V

DD

will indefinitely delay the lower turn-on delays

through the input comparator and will keep the lower MOS-

FETs off. With the lower MOSFETs off and the chip enabled,

i.e., DIS = low, IN+ or IN- can be switched through a full

cycle, properly setting the upper driver outputs. Once this is

accomplished, LDEL is released to its normal operating

point. It is critical that IN+/IN- switch a full cycle while LDEL

is held high, to avoid shoot-through. This start-up procedure

can be initiated by the supply voltage and/or the chip enable

command by the circuit in Figure 37.

FIGURE 36.

FIGURE 37.

11

12

13

14

15

16

17

18

20

19

10

9

8

7

6

5

4

3

2

1 BHB

BHI

DIS

V

SS

BLI

ALI

HDEL

AHI

LDEL

AHB

BHO

BLO

BLS

V

DD

BHS

V

CC

ALS

ALO

AHS

AHO

3.3K

R2

ENABLE

R1

15K

11

12

13

14

15

16

17

18

20

19

10

9

8

7

6

5

4

3

2

1 BHB

BHI

DIS

V

SS

BLI

ALI

HDEL

AHI

LDEL

AHB

BHO

BLO

BLS

V

DD

BHS

V

CC

ALS

ALO

AHS

AHO

3.3K

R2

R1

15K

ENABLE

11

12

13

14

15

16

17

18

20

19

10

9

8

7

6

5

4

3

2

1 BHB

HEN

DIS

V

SS

OUT

IN+

HDEL

IN-

LDEL

AHB

BHO

BLO

BLS

V

DD

BHS

V

CC

ALS

ALO

AHS

AHO

100K

RDEL

RDEL

V

DD

0.1

µ

F

2N3906

V

DD

ENABLE

V

DD

56K

8.2V

56K

100K

HIP4080

17

Timing Diagrams

NOTE:

7. ALI and/or BLI may be high after t1, whereupon the ENABLE pin

may also be brought high.

FIGURE 38.

NOTE:

8. Between t1 and t2 the IN+ and IN- inputs must cause the OUT pin

to go through one complete cycle (transition order is not impor-

tant). If the ENABLE pin is low after the undervoltage circuit is

satisfied, the ENABLE pin will initiate the 10ms time delay during

which the IN+ and IN- pins must cycle at least once.

FIGURE 39.

V

DD

DIS

ALI, BLI

8.5V TO 10.5V (ASSUMES 5% RESISTORS)

1.7V

12V, FINAL VALUE

V

DD

DIS

LDEL

=10ms

t1

t2

8.3V TO 9.1V (ASSUMING 5% ZENER TOLERANCE)

12V, FINAL VALUE

5.1V

HIP4080

18

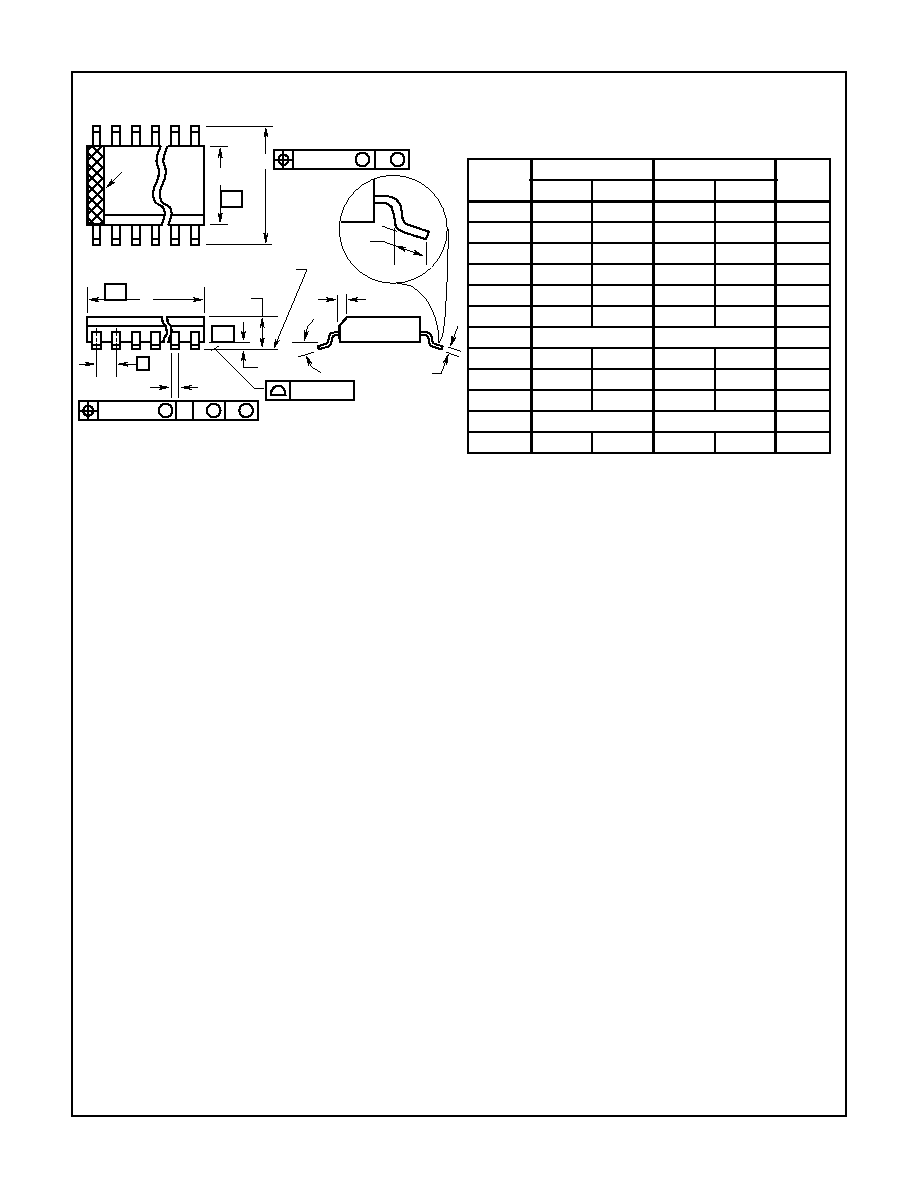

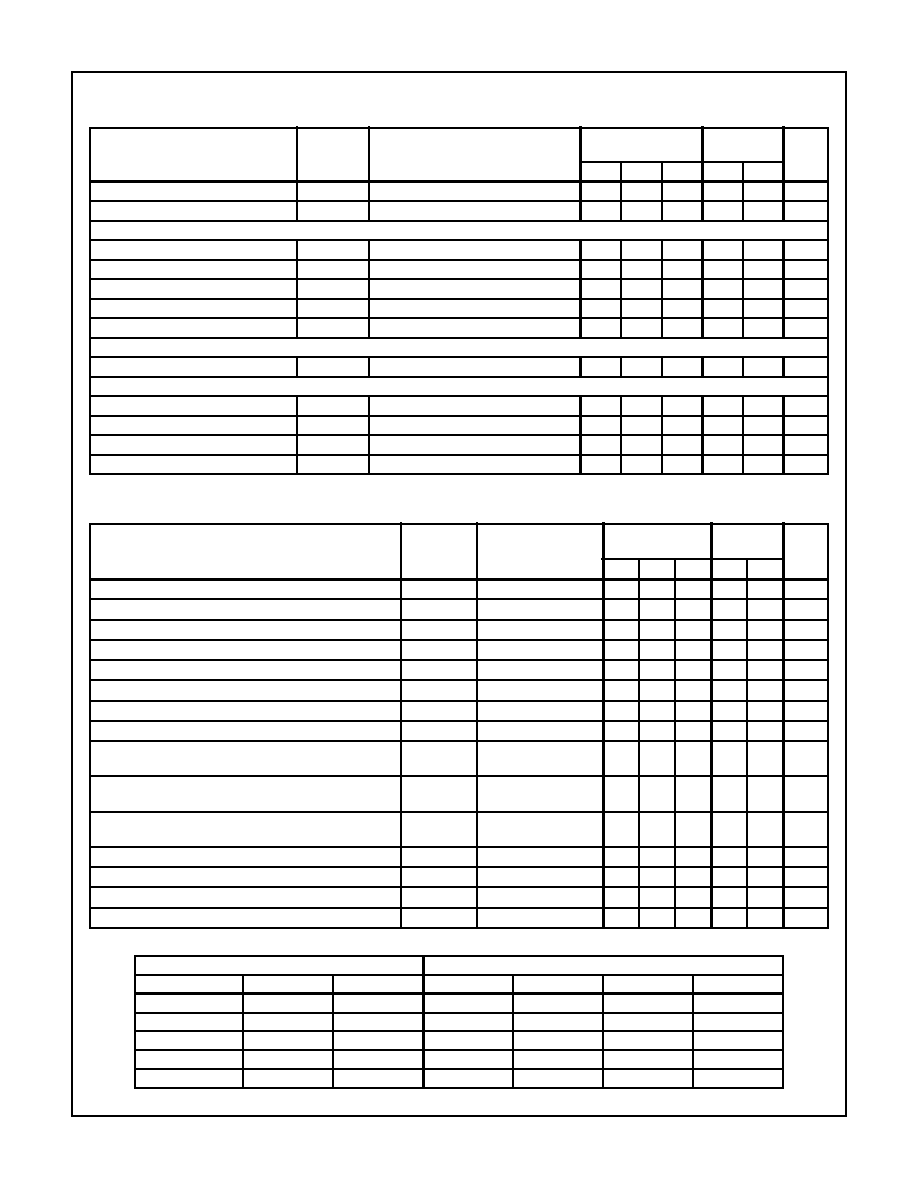

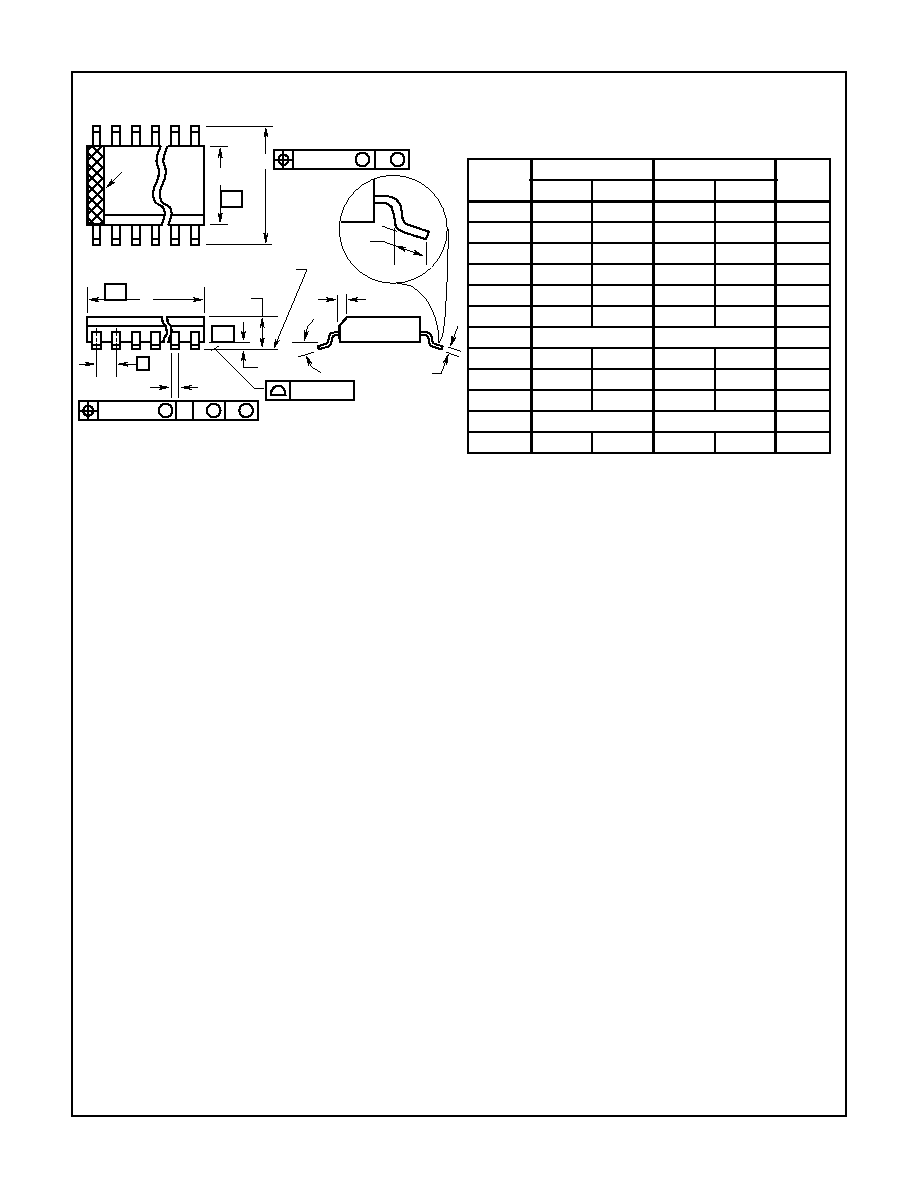

HIP4080

NOTES:

1. Symbols are defined in the "MO Series Symbol List" in Section

2.2 of Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension "D" does not include mold flash, protrusions or gate

burrs. Mold flash, protrusion and gate burrs shall not exceed

0.15mm (0.006 inch) per side.

4. Dimension "E" does not include interlead flash or protrusions. In-

terlead flash and protrusions shall not exceed 0.25mm (0.010

inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual

index feature must be located within the crosshatched area.

6. "L" is the length of terminal for soldering to a substrate.

7. "N" is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width "B", as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch)

10. Controlling dimension: MILLIMETER. Converted inch dimen-

sions are not necessarily exact.

INDEX

AREA

E

D

N

1

2

3

-B-

0.25(0.010)

C A

M

B S

e

-A-

L

B

M

-C-

A1

A

SEATING PLANE

0.10(0.004)

h x 45

o

C

H

0.25(0.010)

B

M

M

M20.3

(JEDEC MS-013-AC ISSUE C)

20 LEAD WIDE BODY SMALL OUTLINE PLASTIC PACKAGE

SYMBOL

INCHES

MILLIMETERS

NOTES

MIN

MAX

MIN

MAX

A

0.0926

0.1043

2.35

2.65

-

A1

0.0040

0.0118

0.10

0.30

-

B

0.013

0.0200

0.33

0.51

9

C

0.0091

0.0125

0.23

0.32

-

D

0.4961

0.5118

12.60

13.00

3

E

0.2914

0.2992

7.40

7.60

4

e

0.050 BSC

1.27 BSC

-

H

0.394

0.419

10.00

10.65

-

h

0.010

0.029

0.25

0.75

5

L

0.016

0.050

0.40

1.27

6

N

20

20

7

0

o

8

o

0

o

8

o

-

Rev. 0 12/93

Small Outline Plastic Packages (SOIC)

19

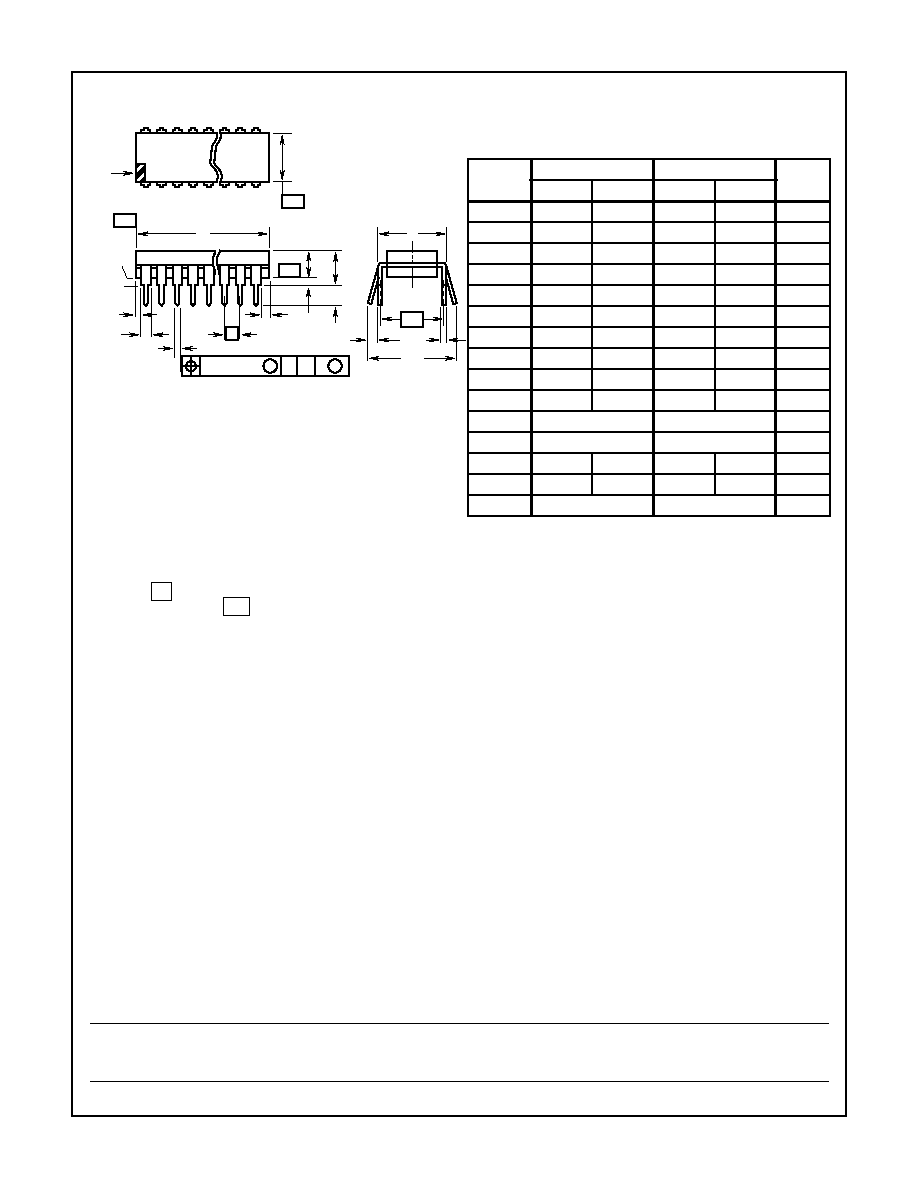

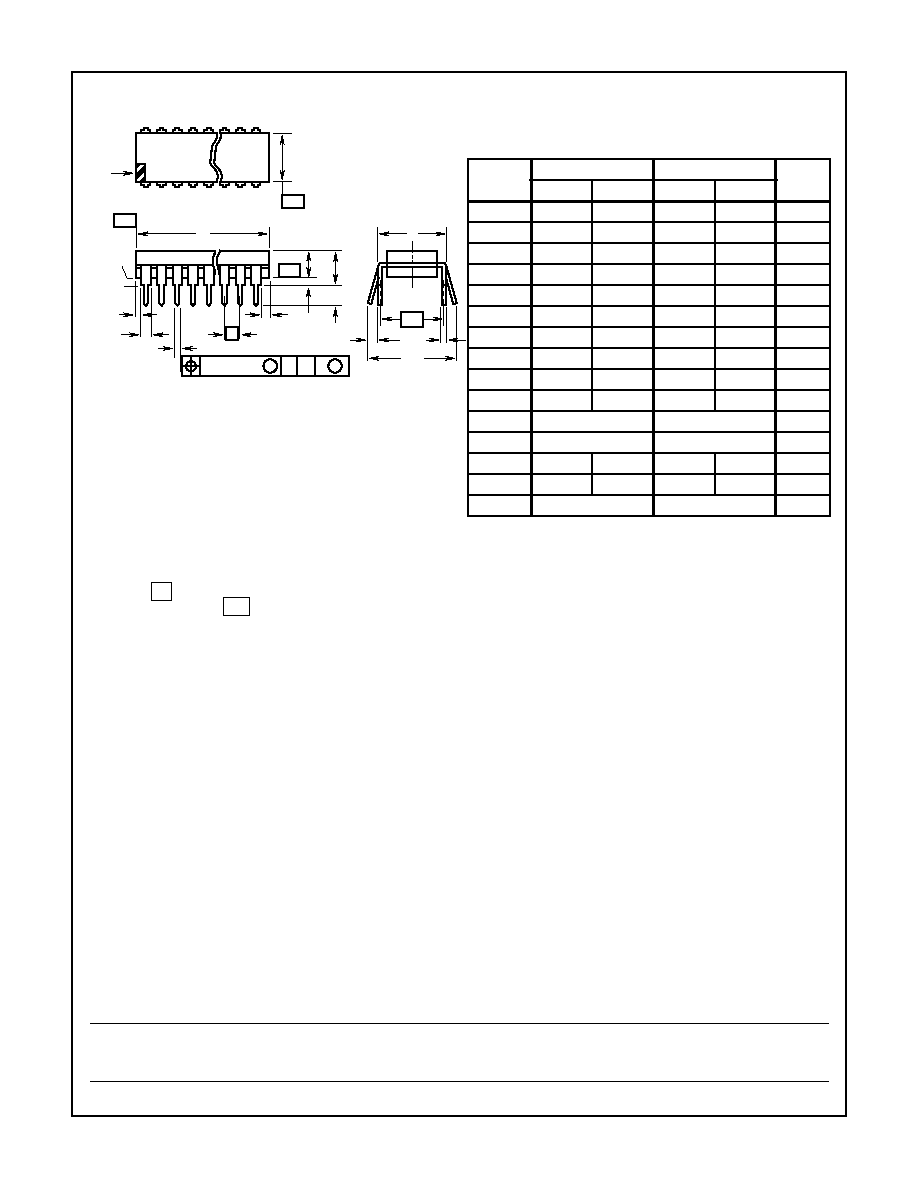

HIP4080

E20.3

(JEDEC MS-001-AD ISSUE D)

20 LEAD DUAL-IN-LINE PLASTIC PACKAGE

SYMBOL

INCHES

MILLIMETERS

NOTES

MIN

MAX

MIN

MAX

A

-

0.210

-

5.33

4

A1

0.015

-

0.39

-

4

A2

0.115

0.195

2.93

4.95

-

B

0.014

0.022

0.356

0.558

-

B1

0.045

0.070

1.55

1.77

8

C

0.008

0.014

0.204

0.355

-

D

0.980

1.060

24.89

26.9

5

D1

0.005

-

0.13

-

5

E

0.300

0.325

7.62

8.25

6

E1

0.240

0.280

6.10

7.11

5

e

0.100 BSC

2.54 BSC

-

e

A

0.300 BSC

7.62 BSC

6

e

B

-

0.430

-

10.92

7

L

0.115

0.150

2.93

3.81

4

N

20

20

9

Rev. 0 12/93

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between

English and Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the "MO Series Symbol List" in Section

2.2 of Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated

in JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protru-

sions. Mold flash or protrusions shall not exceed 0.010 inch

(0.25mm).

6. E and

are measured with the leads constrained to be per-

pendicular to datum

.

7. e

B

and e

C

are measured at the lead tips with the leads uncon-

strained. e

C

must be zero or greater.

8. B1 maximum dimensions do not include dambar protrusions.

Dambar protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3,

E28.3, E42.6 will have a B1 dimension of 0.030 - 0.045 inch

(0.76 - 1.14mm).

C

L

E

e

A

C

e

B

e

C

-B-

E1

INDEX

1 2 3

N/2

N

AREA

SEATING

BASE

PLANE

PLANE

-C-

D1

B1

B

e

D

D1

A

A2

L

A1

-A-

0.010 (0.25)

C

A

M

B S

e

A

-C-

Dual-In-Line Plastic Packages (PDIP)

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com