| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: HIP9010 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

4-1

HIP9010

Engine Knock Signal Processor

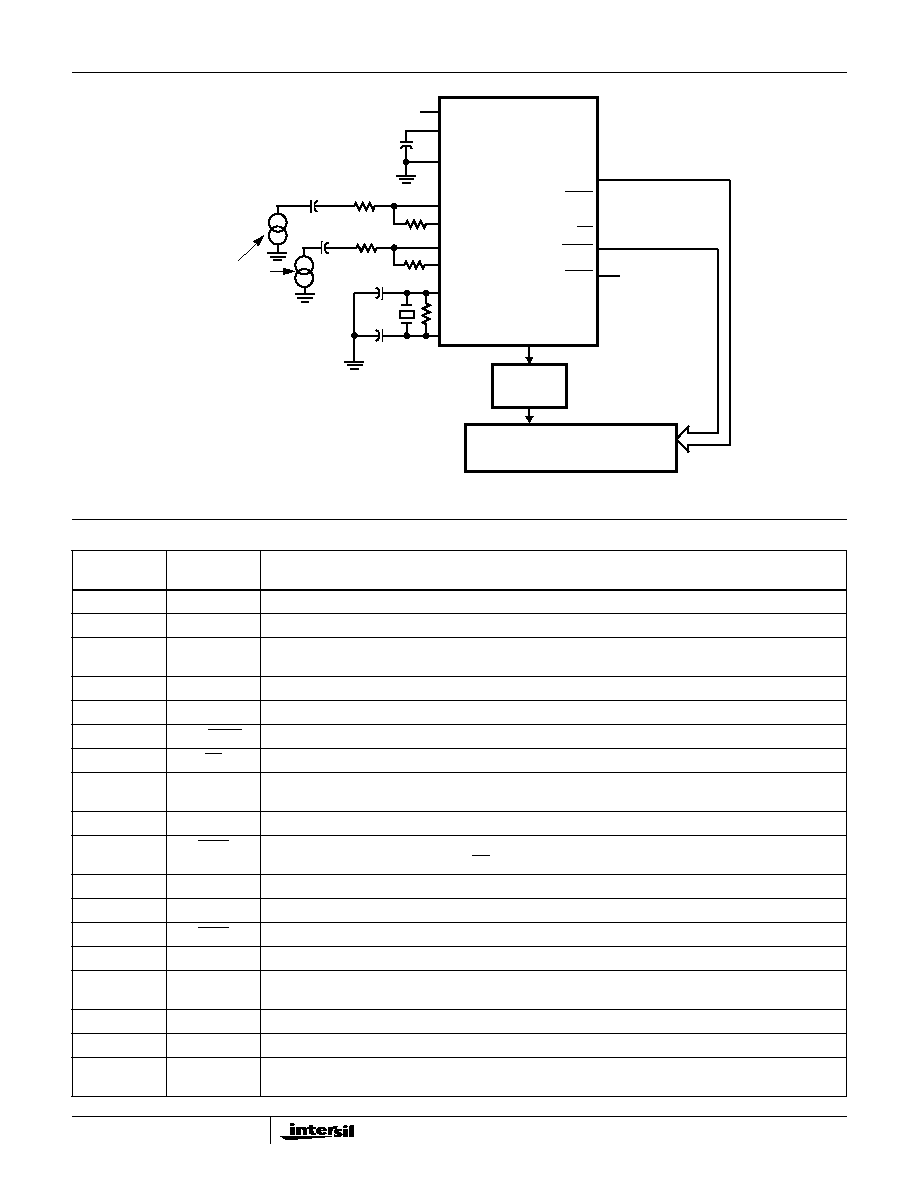

The HIP9010 is used to provide a method of detecting

premature detonation or "Knock" in automotive engines.

A block diagram of this IC is shown in Figure 1. The chip

alternately selects one of the two sensors mounted on the

engine block. Two programmable bandpass filters process

the signal from both sensors, and divides the signal into two

channels. When the engine is not knocking, programmable

gain adjust stages are set to ensure that both the reference

channel and the knock channel contain similar energies.

This technique ensures that the detection system is

comparatively immune to changes in the engine background

noise level. When the engine is knocking, the energy in the

knock channel increases.

Features

∑ Two Sensor Inputs

∑ Microprocessor Programmable

∑ Accurate and Stable Filter Elements

∑ Digitally Programmable Gain

∑ Digitally Programmable Time Constants

∑ Digitally Programmable Filter Characteristics

∑ On-Chip Clock

∑ Operating Temperature Range -40

o

C to 125

o

C

Applications

∑ Engine Knock Detector Processor

∑ Analog Signal Processing where Controllable Filter

Characteristics are Required

Pinout

HIP9010

(SOIC)

TOP VIEW

Ordering Information

PART NUMBER

TEMP.

RANGE (

o

C)

PACKAGE

PKG.

NO.

HIP9010AB

-40 to 125

20 Ld SOIC (W)

M20.3

11

12

13

14

15

16

17

18

20

19

10

9

8

7

6

5

4

3

2

1

V

DD

GND

V

MID

INOUT

NC

NC

CS

INT/HOLD

OSCIN

OSCOUT

S0IN

S1FB

S1IN

NC

S0FB

NC

TEST

SCK

MOSI

MISO

Data Sheet

November 1998

File Number

3601.4

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

|

Copyright

©

Intersil Corporation 1999

4-2

HIP9010

Simplified Block Diagram

ANTIALIASING

FIL

TER

3RD ORDER

-

+

-

+

KNOCK FREQUENCY CHANNEL

REFERENCE FREQUENCY CHANNEL

TO SWITCHED

CAPACITOR

NETWORKS

(14) TEST

PROGRAMMABLE

BANDPASS

FILTER

1-20kHz

64 STEPS

PROGRAMMABLE

GAIN

STAGE

1-0.133

64 STEPS

PROGRAMMABLE

BANDPASS

FILTER

1-20kHz

64 STEPS

PROGRAMMABLE

GAIN

STAGE

1-0.133

64 STEPS

ACTIVE

FULL WAVE

RECTIFIER

REGISTERS

AND

STATE MACHINE

SPI

INTERSPACE

POWER SUPPLY

AND

BIAS CIRCUITS

(17) S1IN

(18) S1FB

(20) S0IN

(19) S0FB

(2) GND

OSCIN (9)

OSCOUT (10)

SCK (13)

CS (8)

MOSI (12)

MISO (11)

INT/HOLD (7)

DIFFERENTIAL

TO

SINGLE-ENDED

CONVERTER

AND OUTPUT

DRIVER

PROGRAMMABLE

INTEGRATOR

40-600

µ

s

32 STEPS

ACTIVE

FULL WAVE

RECTIFIER

INOUT (4)

(1) V

DD

(3) V

MID

CLOCK

CHANNEL SELECT

SWITCHES

FIGURE 1.

4-3

Absolute Maximum Ratings

Thermal Information

DC Logic Supply, V

DD

. . . . . . . . . . . . . . . . . . . . . . . . -0.5V to +7.0V

Output Voltage, V

O

. . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to +7.0V

Input Voltage, V

IN

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +7V (Max)

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . -40

o

C to 125

o

C

Thermal Resistance (Typical, Note 1)

JA

(

o

C/W)

SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

115

Maximum Storage Temperature Range, T

STG

. . . . -65

o

C to 150

o

C

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . .150

o

C

Maximum Lead Temperature (Soldering) . . . . . . . . . . . . . . . 300

o

C

At distance 1/16in

±

1/32in (1.59mm

±

0.79mm) from case

for 10s (Max)

(SOIC - Lead Tips Only)

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1.

JA

is measured with the component mounted on an evaluation PC board in free air.

Electrical Specifications

V

DD

= 5V,

±

5%, GND = 0V, Clock Frequency 4MHz,

±

0.5%, T

A

= -40

o

C to 125

o

C,

Unless Otherwise Specified

PARAMETER

SYMBOL

TEST CONDITIONS

MIN

TYP

MAX

UNITS

DC ELECTRICAL CHARACTERISTICS

Quiescent Supply Current

I

DD

V

DD

= 5.25V, GND = 0V

3

7.5

12

mA

Midpoint Voltage, Pin 3

V

MID

V

DD

= 5.0V, I

L

= 2mA Source

2.3

2.45

2.55

V

Midpoint Voltage, Pin 3

V

MID

V

DD

= 5.0V, I

L

= 0mA

2.4

2.5

2.6

V

Input Leakage, Pin 14

IL

TEST

Measured at V

DD

= 5.0V

-

-

3

µ

A

Internal Pull-Up Resistance, Pin 14

R

TEST

V

DD

= 5.0V, I Measure = 15

µ

A

30

100

200

K

Leakage of Pins 7, 8, 12 and 13

I

L

Measured at GND and V

DD

= 5V

-

-

±

3

µ

A

Low Input Voltage, Pins 7, 8, 12 and 13

V

IL

-

-

30

% of V

DD

High Input Voltage, Pins 7, 8, 12 and 13

V

IH

70

-

-

% of V

DD

Low Level Output, Pin 11

V

OL

I

SOURCE

= 4mA

0.01

-

0.30

V

Leakage Pin 11

I

L

Measured at GND and V

DD

= 5V

-

-

±

10

µ

A

Low Level Output, Pin 10

V

OL

I

SOURCE

= 500

µ

A, V

DD

= 5V

-

-

1.5

V

High Level Output, Pin 10

V

OH

I

SINK

= -500

µ

A, V

DD

= 5V

4.4

-

-

V

INPUT AMPLIFIERS

S0FB and S1FB High Output Voltage

V

OUT

HI

100

µ

A I

SINK

, V

DD

= 5V

4.7

4.9

-

V

S0FB and S1FB Low Output Voltage

V

OUT

LO

100

µ

A I

SOURCE

, V

DD

= 5V

-

15

200

mV

S0FB and S1FB Closed Loop

A

CL

Input Resistor = 1M

,

Feedback Resistor = 49.9k

-25

-26

-27

dB

S0FB and S1FB Closed Loop

A

CL

Input Resistor = 47.5k

,

Feedback Resistor = 475k

18

20

21

dB

ANTIALIASING FILTER

Response 1kHz to 20kHz,

Referenced to 1kHz

BW

Test Mode, 70mV

RMS

Input to S0FB or

S1FB, Output Pin 4

-

-2

-

dB

Attenuation at 180kHz

Referenced to 1kHz

ATEN

Test Mode, 70mV

RMS

Input to S0FB or

S1FB, Output Pin 4

-10

-15

-

dB

PROGRAMMABLE FILTERS

Peak to Peak Voltage Output

V

OUTP-P

Run Mode

3.5

4.0

-

V

P-P

Filters Q (Note 2)

Q

Run Mode

-

2.5

-

Q

PROGRAMMABLE GAIN AMPLIFIERS

Percent Amplifier Gain Deviation

Per Table 2

%G

Run Mode

-

±

1

-

%

HIP9010

4-4

INTEGRATOR

Integrator Offset Voltage

INTGV

IO

By Design

-

0.1

-

mV

Integrator Reset Voltage

V

RESET

Pin 4 Voltage at Initiation of

Integration Cycle. V

DD

= 5V

430

500

570

mV

Integrator Droop after 500

µ

s

V

DROOP

Hold Mode, Pin 7 = 0V, V

DD

= 5V,

Pin 4 set to 20% to 80% of V

DD

-

±

3

±

50

mV

OUTPUT AND SAMPLE AND HOLD

Differential to Single Ended

Converter Offset Voltage

DIFV

IO

By Design

-

0.1

-

mV

Change in Converter Output

DIFOUT

Run Mode, 500

µ

A, Sinking to No Load

-

±

1

±

3

mV

SYSTEM GAIN DEVIATION

Gain Deviation from "Ideal Equation"

Correlation, Factor - 5.0%

V

OUT

-

V

RESET

Run Mode, maximum signal output

from Input Amplifier <2.25V

P-P

,

Equation Output x 0.95 + Device

Reset Voltage. For Total V

OUT

4.7V

-8%,

±

100mV

Equation

x 0.95

-V

RESET

8%,

±

100mV

V

NOTE:

2. Q = f

O

/BW, Where: f

O

= Center Frequency, BW = 3dB bandwidth.

Ideal Equation

When the two filters are set to the same frequency and the input signal is present for the periods T

IN

, then:

G

R

and G

K

= Programed Gain of Reference and Knock channels.

T

IN

= Time input signal is present In ms.

T

C

= Programmed integrator time constant ms.

N = Number of cycles of input signal.

f

Q

= Frequency of input signal. Assumes both filters are programmed to the same frequency.

V

RESET

= Integrator Reset Voltage.

1.273 = 4/

R

F

= Feedback resistor value.

R

IN

= Signal input resistor value.

For example, assume 300mV

P-P

input with the time constant programmed to 300

µ

s and the Integration time is 1.2ms. The R

F

/R

IN

ratio is one and

the Reference channel is programmed to a Gain of 0.188. The Knock channel is then automatically set to a gain of one. The input signal is contin-

uous for the total integration time, T

IN

.

Electrical Specifications

V

DD

= 5V,

±

5%, GND = 0V, Clock Frequency 4MHz,

±

0.5%, T

A

= -40

o

C to 125

o

C,

Unless Otherwise Specified (Continued)

PARAMETER

SYMBOL

TEST CONDITIONS

MIN

TYP

MAX

UNITS

INTOUT volts

(

)

Input signal (V

P

P

≠

)

R

F

R

IN

----------

◊

G

K

1.273

N

TC (ms)

f

Q

(kHz)

◊

---------------------------------------------------

◊

◊

G

R

1.273

N

TC (ms)

f

Q

(kHz)

◊

---------------------------------------------------

◊

◊

≠

V

RESET

+

=

INTOUT volts

(

)

Input signal (V

P

P

≠

)

R

F

R

IN

----------

◊

1.273

T

IN

TC

---------

G

K

G

R

≠

(

)

◊

V

RESET

+

=

INTOUT volts

(

)

0.3V (V

P

P

≠

)

1.273

1.2ms

0.300ms

-----------------------

1.000

0.188

≠

(

)

◊

◊

◊

V

RESET

1.24V

0.500V

1.74V

=

+

=

+

=

HIP9010

4-5

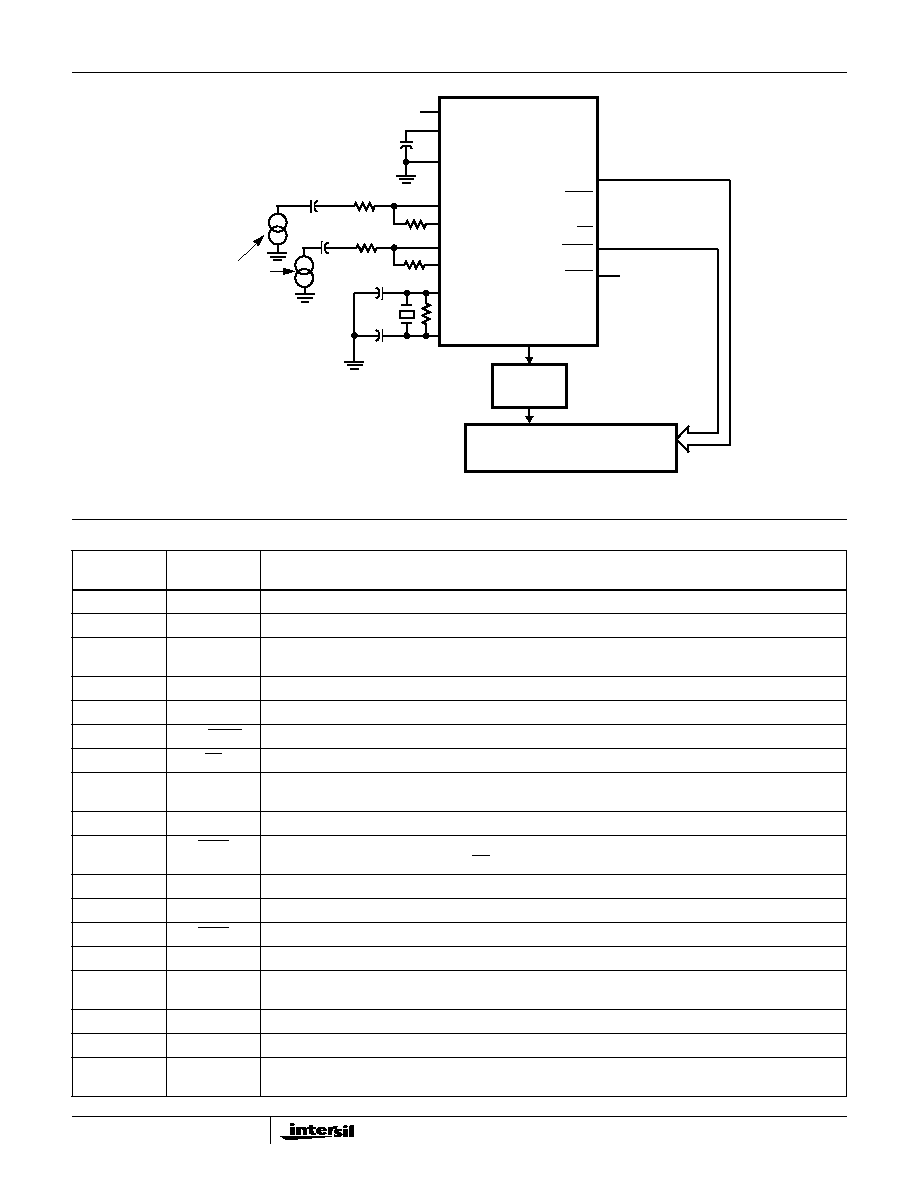

+5V

HIP9010

MICROPROCESSOR

SPI BUS

C3, 0.022

µ

F

C2, 3.3nF

C1, 3.3nF

R1

R4

R3

4MHz

A/D

CONVERTER

V

DD

V

MID

GND

S1IN

S1FB

S0IN

S0FB

OSCIN

OSCOUT

INTOUT

MOSI

MISO

SCK

CS

INT/HOLD

TEST

TRANSDUCERS

R2

FIGURE 2. SIMPLIFIED BLOCK DIAGRAM OF THE HIP9010 IN AN AUTOMOTIVE APPLICATION

20pF

20pF

1M

Pin Descriptions

PIN

NUMBER

SYMBOL

DESCRIPTION

1

V

DD

5V power input.

2

GND

This terminal is tied to ground.

3

V

MID

This terminal is tied to the internal mid-supply generator and is brought out for supply bypassing by a 0.022

µ

F

capacitor.

4

INTOUT

Buffered output of the integrator.

5 and 6

NC

These terminals are not internally connected. DO NOT USE.

7

INT/HOLD

Selects whether the chip is in the Integrate Mode (Input High) or in the Hold Mode (Input Low).

8

CS

A low input on this pin enables the chip to communicate over the SPI bus.

9

OSCIN

Input to inverter used for the oscillator circuit. A 4MHz crystal or ceramic resonator is connected between this

pin and pin 10. To bias the inverter, a 1.0M

to 10M

resistor is usually connected between this pin and pin 10.

10

OSCOUT

Output of the inverter used for the oscillator. See pin 9 above.

11

MISO

Output of the chip SPI data bus. It is the inversion of the chip DATAIN line. This is an open drain output. The

output must be disabled by placing the CS High when the chip is not selected.

12

MOSI

Input of the chip SPI data bus. Data length is eight bits.

13

SCK

Input from the SPI clock. Normally high, the data is clocked to the chip internal circuitry on the rising clock edge.

14

TEST

A low on this pin places the chip in the test mode. For normal operation this terminal is tied high or left open.

15 and 16

NC

These terminals are not internally connected. DO NOT USE.

17

S1IN

Inverting input to sensor one amplifier. A resistor is tied from this summing input to the transducer. A second

resistor is tied between this terminal and terminal 18, S1FB to establish the gain of the amplifier.

18

S1FB

Output of the sensor one amplifier. This terminal is used to apply feedback.

19

S0FB

Output of the sensor zero amplifier. This terminal is used to apply feedback.

20

S0IN

Inverting input to sensor zero amplifier. A resistor is tied from this summing input to the transducer. A second

resistor is tied between this terminal and terminal 19, S0FB to establish the gain of the amplifier.

HIP9010