| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: IRPT4052 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

page 1

IRPT 4052

Revised 3/25/97

PD 6.096

TM

Integrated Power Stage for 7.5 hp Motor Drives

IRPT4052

PRELIMINARY

∑ 7.5 hp (5.5kW) power output

Industrial rating at 150% overload for 1 minute

∑ 380 - 480V AC input, 50/60Hz

∑ Available as complete system or sub-system assemblies

Power Assembly

∑ 3-phase rectifier bridge

∑ 3-phase short circuit rated, ultrafast IGBT inverter

∑ HEXFREDTM UltraFastTM soft recovery free-wheeling

diode

∑ NTC temperature sensor

∑ Pin-to-base plate isolation 2500V rms

∑ Easy-to-mount package

∑ Case temperature range -25 C to 125 C operational

Driver-

Plus Board

∑ Capacitor filter with precharge current limit

∑ Isolated gate drive circuits

∑ On-board local power supply for gate driver and

capacitor precharge control

∑ MOV surge suppression at input

∑ Isolated inverter current feedback

∑ Short circuit, earth/ground fault, over-temperature

protection

∑ Input and output terminals;

optional external brake

∑ Control interface connector

Figure 1. The IRPT4052C

within a motor

control system

page 2

IRPT 4052

System Description

The IRPT4052C

provides the complete

power conversion function for a 7.5hp (5.5kW) variable voltage,

variable frequency, AC motor controller. The

combines a power assembly IRPT4052A with a Driver-Plus

Board IRPT4052D. Figure 1 shows the block diagram of the

within an AC motor control system.

The power assembly contains a 3-phase input bridge rectifier,

3-phase IGBT inverter and a thermistor mounted on an Insulated

Metal Substrate (IMS) power board. It is designed for easy

mounting to a heat sink.

The Driver-Plus Board contains DC link capacitors, capacitor

pre-charge function, isolated IGBT gate drive circuits, shutdown

protection, isolated trip and current feedback signals, and local

power supply. It interfaces to the power assembly via soldered

connector pins. Terminal blocks are provided on the Driver-Plus

Board for all end-user external connections to the

.

Output power is Pulse-Width Modulated (PWM), 3-phase,

variable-frequency, variable voltage controlled by externally

generated user provided PWM controller for inverter IGBT

switching. The PWM input signals and feedback signals are opti-

cally isolated from the power circuit.

The IRPT4052C offers several benefits to the drive manufac-

turer as listed below:

∑ It eliminates component selection, design layout, intercon-

nection, gate drive, local power supply, thermal sensing,

current sensing, and protection.

∑ It provides committed power semiconductor losses and

junction temperatures.

∑ Gate drive and protection circuits are designed to closely

match the operating characteristics of the power semicon-

ductors. This allows power losses to be minimized and

power rating to be maximized to a greater extent than is

possible by designing with individual components.

∑ Optimized layout for performance and efficiency is pro-

vided.

∑ Low inductance system reduces noise and snubber require-

ments.

[

specifications and ratings are given for

system input and output voltage and current, power losses

and heat sink requirements over a range of operating con-

ditions.

system ratings are verified by IR

in final testing.]

Power Assembly

The IRPT4052A power assembly consists of input rectifiers,

NTC thermistor, output inverter and connectors mounted on an

Insulated Metal Substrate (IMS) substrate. The input side em-

ploys surface mount 1600V rated SMD-220 rectifier diodes and

the inverter section employs surface mount SMD-10, 1200V

IGBT Co-pack switches. The NTC thermistor mounted near the

inverter provides temperature sensing capability. The lead spac-

ing on the power assembly meets UL840 pollution level 2

requirements.

The power circuit and layout are carefully designed to mini-

mize inductance in the power path, to reduce noise during

inverter operation and to improve the inverter efficiency. The

power level interfaces to the Driver-Plus Board through solder

pins, minimizing assembly and alignment. The power assembly

is designed to be mounted to a heat sink with five screw mount

positions, one in each corner and a fifth near the center, in order

to insure good thermal contact between the IMS and the heat

sink.

The IRPT4052D Driver-

Plus Board

The Driver-Plus Board, shown in figure 3, is the interface be-

tween the controller and the power stage. It contains the IGBT

gate drivers, sensing and protection circuitry, feedback and local

power supply. It also houses the DC link capacitors, relay and

relay control circuit used for implementing the capacitor pre-

charge function. Figure 4 provides detailed functional block

diagrams of the IRPT4052D.

The gate drive circuits deliver on/off gate drive signals to the

IGBTs' gates, corresponding with input PWM control signals

IN1 through IN6. The PWM gate normally allows the input

PWM control signal to pass to the input opto-isolators of the

gate drive circuits. The conduction periods of the inverter

switches essentially mimic those demanded by the PWM input

signals.

Figure 2. IRPT4052A Power Assembly

page 3

IRPT 4052

During power-up and power-down, or in the event of

overcurrent (OI) or overtemperture (OT), the latch inhibits the

PWM gate, deactivating the gate drive circuits and shutting off

the inverter.

The relay control circuit delivers an on/off signal via an

opto-isolator to the relay driver which controls the relay (K1).

The relay contact is open during power-up, inserting the resistor

R in series with the DC bus capcitor and limiting the capacitor

charging current. In normal operation, the relay contact is closed.

If the AC line voltage falls below 300V or if one input phase is

lost, or if the DC line voltage falls to less than 82% of the peak

line voltage, the relay contact opens.

The UV circuit senses the voltage of the local power supply,

and sends a signal via an opto-isolator to the latch in the event of

undervoltage. The UV circuit normally activates the latch only

during power-up and power-down, preventing the IGBTs from

being turned on when the local power supply voltage is too low

for proper IGBT switching.

The current signal processing circuit receives inputs from

current transformers connected in series with the input lines and

the DC bus capacitor. The output of the current signal processing

circuit, IFB, is essentially an isolated replica of the inverter input

current. An isolated current feedback signal, I

FB

, is provided as

an output of the IRPT4052A. If the inverter current exceeds the

trip level of 45A, I

FB

also activates the latch.

The thermistor activates the latch if the temperature of the

IMS substrate exceeds a set level. The 15V isolated power sup-

ply used to power the IRPT4052 should be the same as the one

for the PWM generation, otherwise the protection functions will

be disabled.

The switching power supply delivers a nominal 18V DC out-

put, referenced to the negative DC bus, N. This feeds the gate

drive, relay control and under voltage (UV) circuits, which are

optically isolated from the control input section, and therefore

require their own local power source.

Figure 3. IRPT4052D Driver-

Plus Board

page 4

IRPT 4052

Figure 4. IRPT4052C Basic Architecture

INPUT RECTIFIER

P

Q2

Q4

Q6

Q1

Q3

Q5

RT2

RT1

W

V

U

E6

G6

E5

G5

E4

G4

E3

G3

E2

G2

E1

G1

N

P

RP

T

S

R

RELAY

CONTACT

(K1)

SWITCHING

POWER

SUPPLY

CURRENT

SIGNAL

PROCESSING

12 13 14

18

4

5

6

POWER TB

CN6B

OUTPUT RECTIFIER

IMS POWER ASSEMBLY

RT2

RT1

W

V

U

E6

G6

E5

G5

E4

G4

E3

G3

E2

G2

E1

G1

N

P

RP

T

S

R

THERMISTOR

DC LINK CAPS

PRE-

CHARGER

RELAY DRIVER

AND

RELAY COIL

(K1)

LATCH

OI, OT, UV

PWM GATE

OPTO ISOLATION

RELAY CONTROL

AND UV

CAP SENSE

CT

+18

GATE DRIVER CIRCUITS

OPTO ISOLATION

POWER TB

CN6B

SIGNAL

TB

1

2

3

16

7

8

9

19 20 15

GND

R S T

P U V W

N

IN6

IN5

IN4

IN3

CN5

IN2

IN1

UV

OT

OI

RESET

KIFB

SFT

CHG

BUS

RIPPLE

IFB

≠15

COM

+15

Driver-

Plus Board

page 5

IRPT 4052

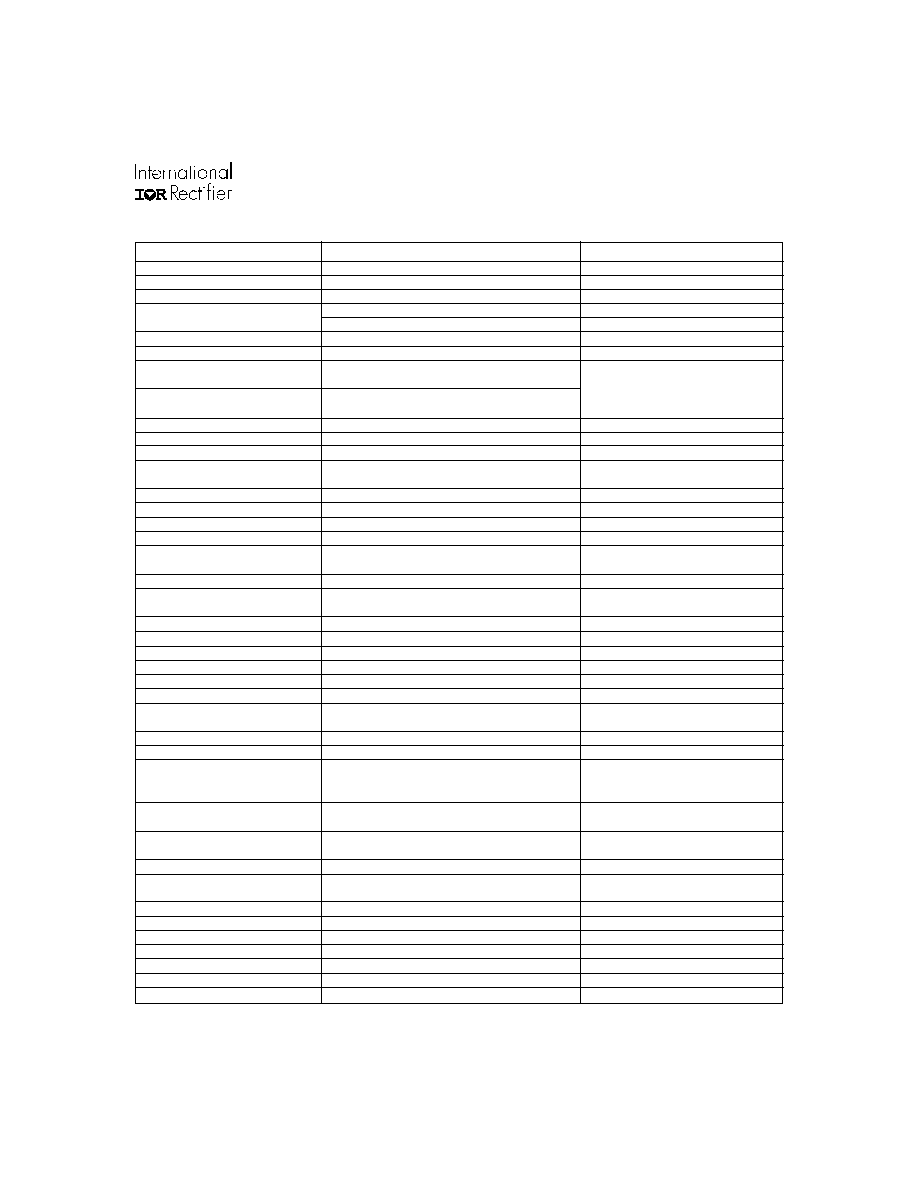

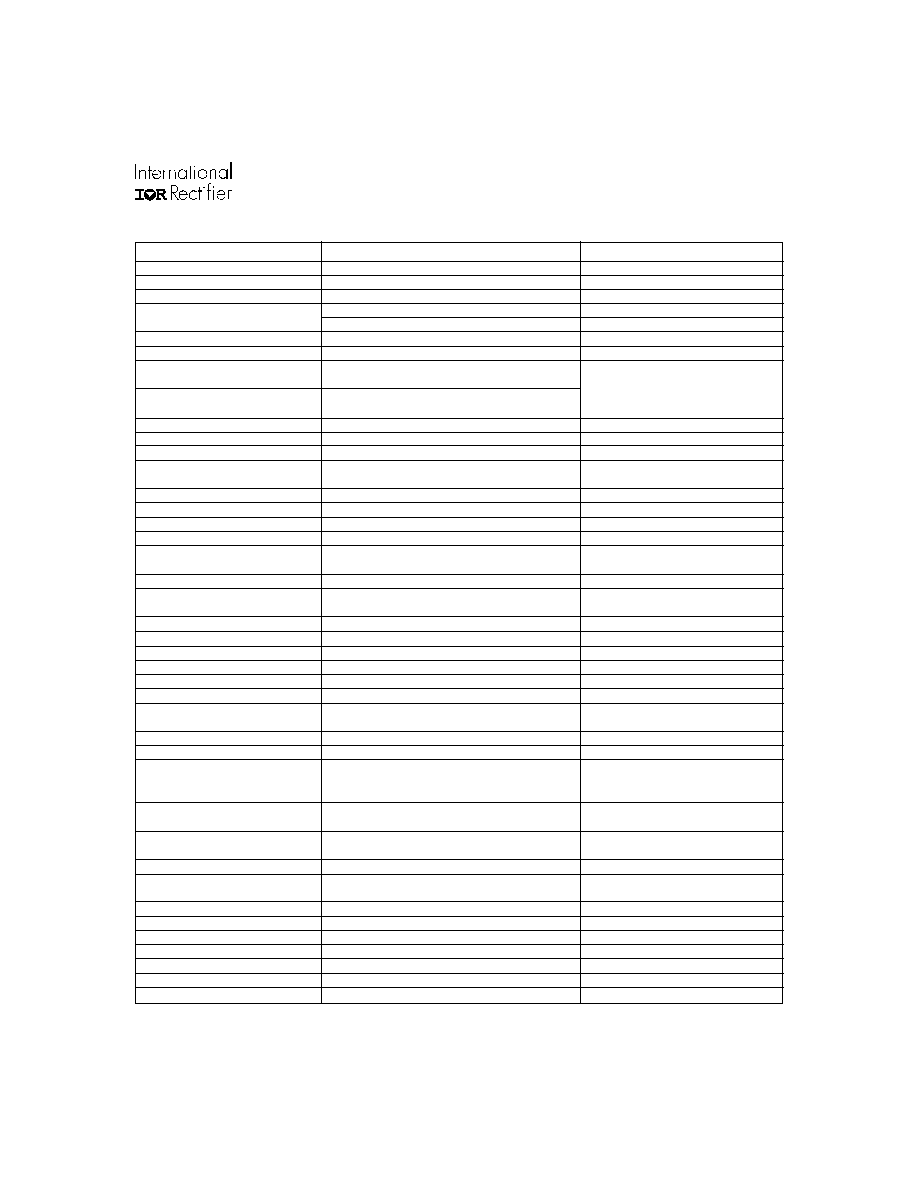

PARAMETERS

VALUES

CONDITIONS

Input Power

Voltage

380V, -15%, 480V +10%, 3-phase

Frequency

50 - 60Hz

Input current

20A rms

T

A

= 40∞C, R

thSA

= 0.148∞C/W

300 A peak

10ms half-cycle, non-repetitive surge

Output Power

Voltage

0 - 480V rms

defined by external PWM control

Nominal motor hp (kW)

7.5hp (5.5 kW) nominal full load power

V

in

= 440VAC

150% overload for 1 minute

PWM frequency = 4kHz, f

∞

=60Hz,

Nominal motor current

12.5A rms nominal full load current

T

A

= 40∞C, R

thSA

= 0.148∞C/W

18.75A rms 150% overload for 1 minute

DC Link

DC link voltage

850V maximum

Control Inputs

Control power

15V ±5%, 200mA positive supply

15V ±5%, 10mA negative supply

PWM input signals IN1 - IN6

15V, 10mA, ±10% (max rise/fall time 150nsec)

input signals uninhibited internally

Input resistance IN1 - IN6

720 ohms ±5%

input signals inhibited internally

Pulse deadtime

2.5

µsec, minimum

Minimum input pulse duration

1.0

µsec

Maximum pulse duration for

20ms

each upper IGBT

RESET

15V active high, CMOS input

(min duration 1

µsec)

SFT CHG

2 mA pull-down to energize relay

(overrides internal control)

Protection

Output current trip level

45A peak, ±10%

Overtemperature trip level

100∞C, ±5%

Ground current trip level

40A peak, ±10%

Short circuit shutdown time

1.5

µsec typical

output terminals shorted

Feedback Signals

Current feedback signal, IFB

100mV/A ±10%

max. DC offset 200mV

Overcurrent trip signal, OI

active high, 15V CMOS

Overtemp trip signal, OT

active high, 15V CMOS

15V high 4.7k pull-up, <0.5V low at 1.0mA;

BUS RIPPLE

high-to-low transition at V

bus

=82% peak

of line voltage

UV

15V high, 10k pull-up, during UV

<0.5 low at 1mA with no UV

Relay coil feedback, K1FB

15V high when relay coil energized; low when

relay coil de-energized

Capacitor Precharge

DC bus capacitor precharge time

400msecs max

measured from input line closure;

line voltage > 300V

Module

Isolation voltage

2500V rms

pin-to-baseplate, 60Hz, 1 min.

Operating case temperature

-25∞C to 125∞C

95% RH max. (non-condensing)

Mounting torque

5 Nm

M5 screw type

System Environment

Ambient operating temp. range

0 to 40∞C

95% RH max. (non-condensing)

Storage temp.range

-25∞C to 60∞C

Specifications