| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: IRPLLNR1 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

1

Reference Design Data Sheet (August, 1997)

IRPLLNR1

POWIRLIGHT

TM

REFERENCE DESIGN : LINEAR BALLAST

Features

∑

Drive 2X40WT12

∑

Universal Input (90-255Vac)

∑

High Power Factor (0.99) & Low THD

∑

High-Frequency Operation (40kHz)

∑

Lamp Filament Preheating

∑

Lamp Fault Protection with Auto-Restart

∑

Over Temperature Protection

∑

IR2153 HVIC Ballast Controller

Description

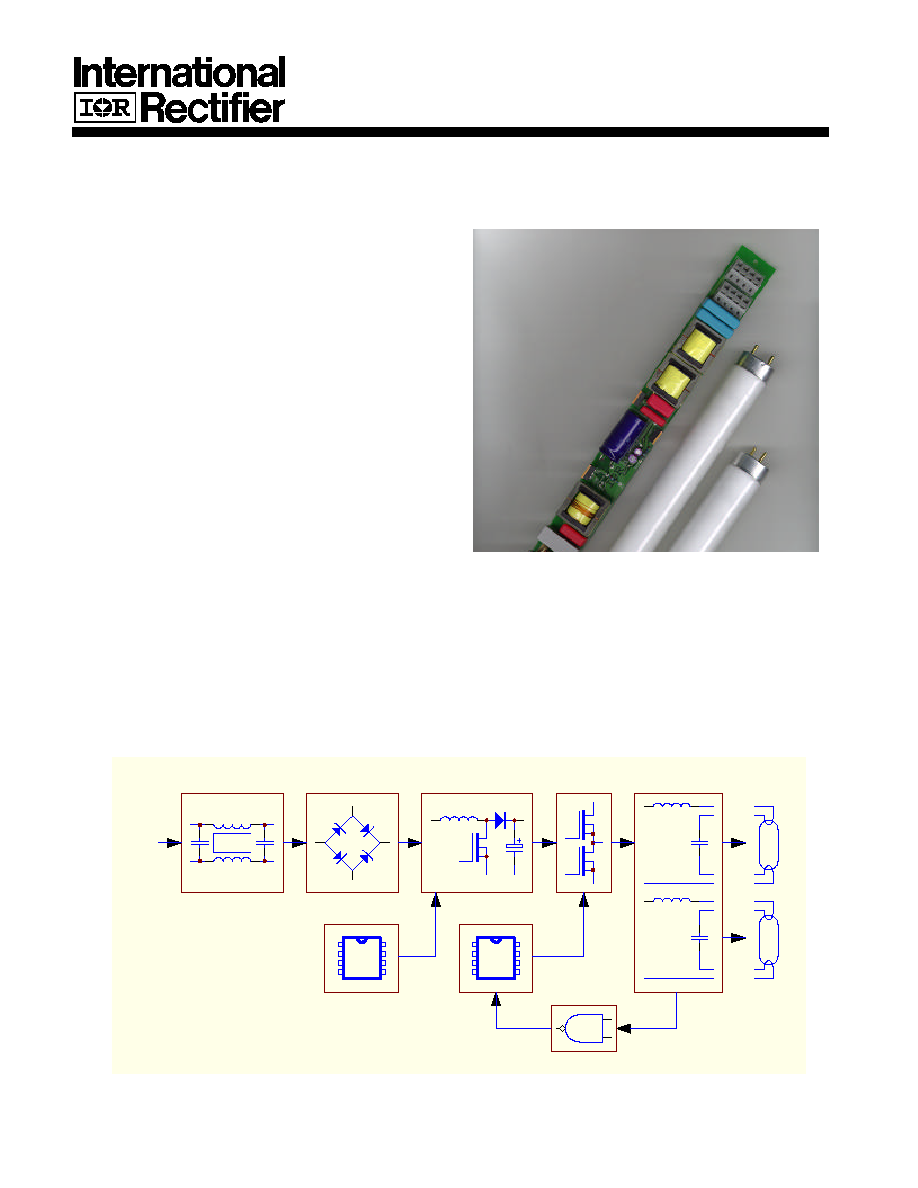

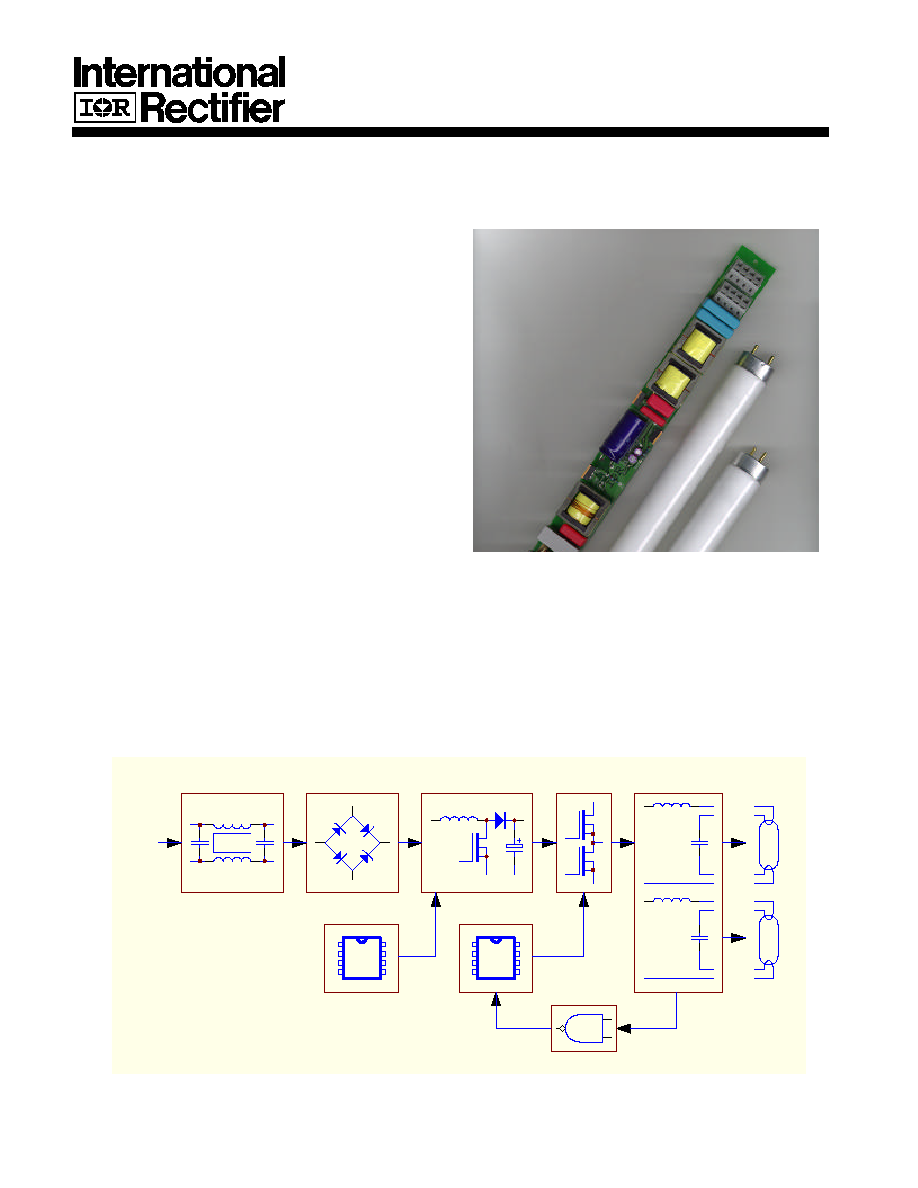

The IRPLLNR1 is a high efficiency, high

power factor, non-dimmable electronic ballast

designed for linear fluorescent lamp types.

The design contains an active power factor

correction circuit for universal voltage input

and a ballast control circuit using the IR2153

for controlling the lamp. Other features

include EMI filtering, transient protection and

lamp fault protection. The IRPLLNR1 is

intended as a reference design to be used as

development tool to speed up customers'

time to market.

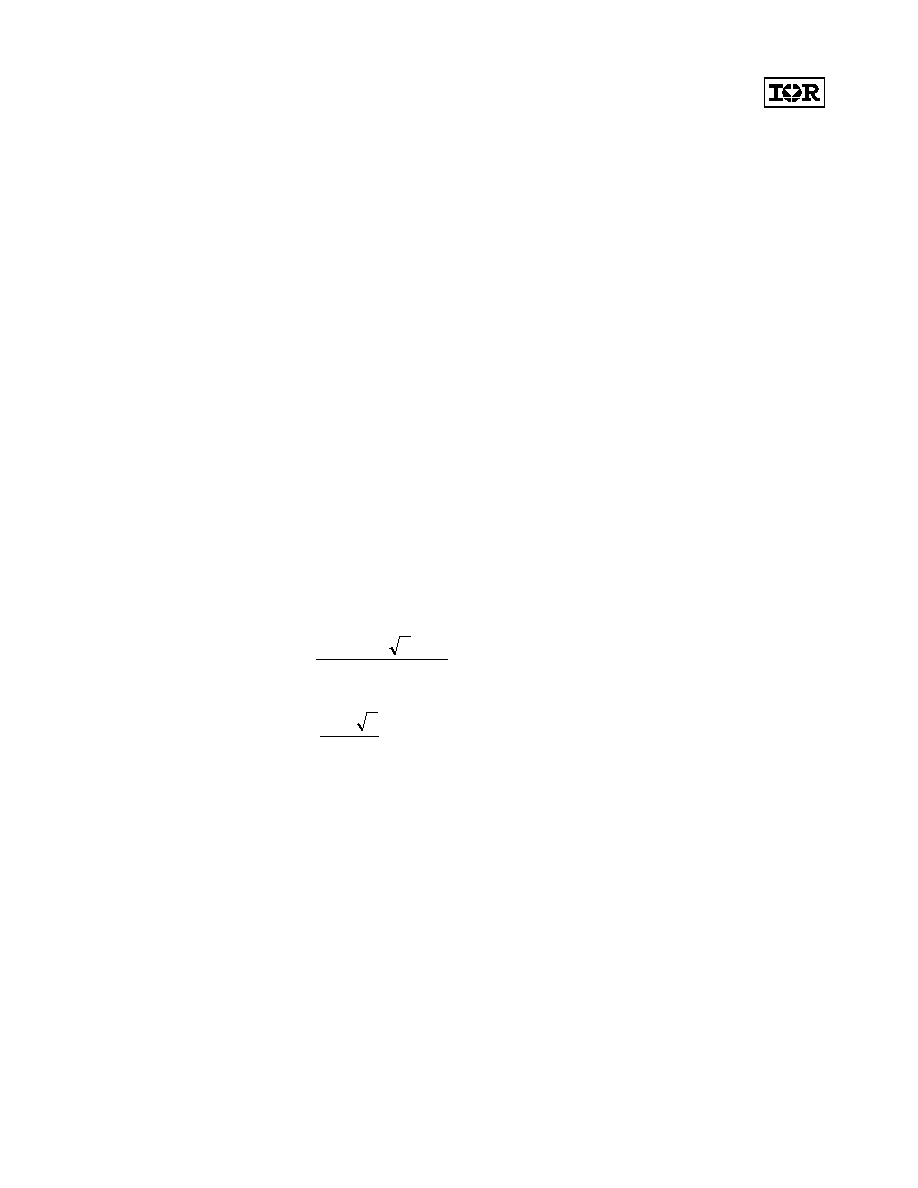

Block Diagram

EMI Filter

Half-Bridge

PFC

Rectifier

Output Stage

Fault Logic

Line

Lamps

IR2153

PFC Control

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

2

IRPLLNR1

Electrical Characteristics

Parameter

Units

Value

Lamp Type

2/40T12

Input Power

[W]

80 +/- 7%

Input Current (120VAC)

[A]

0.67

Pre-heat Output Frequency

[kHz]

50

Pre-heat Output Voltage

[Vpp]

350

Pre-heat Time

[s]

2.0

Running Output Frequency

[kHz]

39.0 +/- 4%

Running Output Voltage

[V]

100

Input A.C. Voltage Range

[VAC]

90..255VAC/50/60Hz

Input D.C. Voltage Range

[VDC]

100..350

Ambient Temperature Range

[∫C]

0..50

Power Factor

0.99

Total Harmonic Distortion

[%]

<15%

Maximum Output Ignition Voltage

[Vpp]

1200

Note: Other lamp types require a new ballast type with different component values.

Note: Tolerances were achieved with trimming.

Lamp Fault Protection Characteristics

Lamps

Ballast

Restart Operation

Lamp 1 or Lamp 2

lower cathode broken

Deactivates

Lamp exchange or recycle line voltage

Lamp1 or Lamp 2

upper cathode broken

Deactivates if non-

zvs occurs

Exchange damaged lamp or recycle

line voltage

Both Lamps

upper cathodes broken

Deactivates

Lamp exchange or recycle line voltage

Lamp1 or Lamp2

non-strike (cathodes intact)

Deactivates

Lamp exchange or recycle line voltage

Open-Circuit (no lamps)

Deactivates

Lamp exchange or recycle line voltage

Short-Circuit (false hook-up)

Deactivates

Lamp exchange or recycle line voltage

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

3

IRPLLNR1

Functional Description

Overview

The IRPLLNR1 consists of a power factor front end, a ballast control section, a resonant lamp

output stage and shutdown circuitry. The power factor controller is a boost converter

operating in critically continuous, free-running frequency mode. The ballast control section

provides frequency modulation control of a traditional RCL series-parallel lamp resonant

output circuit and is easily adaptable to a wide variety of lamp types. The shutdown section

consists of lamp circuit current detection and comparator logic for safe turn-off and smooth

auto re-starting. All functional descriptions are referred to the IRPLLNR1 schematic.

Power Factor Control

The power factor controller section consists of the LinFinity LX1562 Power Factor Controller IC

(IC1), MOSFET M1, inductor L3, diode D5, capacitor C8 and additional biasing, sensing and

compensation components (see schematic). This IC was chosen for its minimal component

count, low start-up supply current and robust error amplifier. This is a boost topology designed

to step-up and regulate the output DC bus voltage while drawing sinusoidal input current from

the line (low THD) which is "in phase" with the AC input line voltage (HPF). The charging

current of L3 is sensed in the source of M1 (R7) and the zero-crossing of the inductor current,

as it charges the DC bus capacitor C8, is sensed by a secondary winding on L3. The result is

critically continuous, free-running frequency operation where:

L

V V

V

P V f

in

out

in

out out s

3

2

2

2

=

-

(

)

(1)

I

P

V

L

out

in

p

=

2 2

min

(2)

where,

=

efficiency

V

in

=

nominal AC input voltage

V

out

=

DC bus voltage

P

out

=

lamp power

f

s

=

switching frequency

The value of the boost inductor (L3) can be calculated and the core should be dimensioned to

not saturate at the worst case peak inductor currents (

I

L

p

) for the desired input voltage range.

For universal input, the boost inductor has been dimensioned for the highest peak currents

which occur at low line (90VAC). Because of the wide input voltage range, performance can

vary. It is recommended that the boost inductor be redimensioned for the exact desired input

voltage plus tolerances (+/- 15%).

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

4

IRPLLNR1

Ballast Control

The ballast control section includes a voltage-controlled oscillator (VCO) (Q1, C20, D9 and

C13) connected to the IR2153 ballast controller IC (IC3) and programmed to different

operating frequencies with a voltage divider (R17, R41, R42, R51, C12). It drives the lamp

resonant output stage (L4, C21 and L5, C23) to the preheat, ignition and running operating

conditions by changing the voltage at the base of Q1 and therefore the frequency of the half-

bridge switches. During preheat, the half-bridge operating frequency is set by R42 and is fixed

for a duration of time determined by the charging time of capacitor C28 to a threshold voltage

(see

Ballast Control Logic and Timing Diagram). This heats the lamp filaments to their

emission temperature before the lamp ignites. This increases the life of the lamp and

decreases ignition voltages and currents, yielding reduced maximum voltage and current

ratings of the lamp resonant output stage and the half-bridge power MOSFETs (M4, M5).

When the voltage on capacitor C28 exceeds the threshold voltage (voltage on C10), R51 is

switched to ground through a comparator of IC4 (pin2) sweeping the voltage on the base of

Q1 to ground momentarily, therefore sweeping the frequency lower towards the resonance

frequency for ignition. The ignition frequency is the minimum frequency of the VCO defined

as,

f

C

R

ignition

=

+

1

113

13

20

75

. (

)(

)

(3)

During the ignition ramp, C12 charges at a much slower rate than C20, resulting in the voltage

at the base of Q1 increasing after ignition to a value determined by the parallel connected

resistor R51. R51 sets the final running frequency where the lamp is driven to the

manufacturer's recommended lamp power rating. The running frequency of the lamp resonant

output stage for selected component values is defined as,

f

LC

P

CV

LC

P

CV

V

V

L C

run

Lamp

Lamp

Lamp

Lamp

DCbus

Lamp

=

-

+

-

-

-

1

2

1

2

1

2

4

1

2

2

2

2

2

2

2

2

2

(4)

where,

L

=

Lamp resonant circuit inductor

[H]

C

=

Lamp resonant circuit capacitor

[F]

P

Lamp

=

Lamp running power

[W]

V

Lamp

=

Lamp running voltage amplitude

[V]

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

5

IRPLLNR1

Fault Protection

The shutdown circuitry consists of 2 quad comparator ICs (IC2 and IC4), a current detection

filter (R21, R22, C16 and D12), a pull-up lamp removal circuit (R23, R24, R25, R26, D16 and

C22), and over-current sensing resistors (R47, R48, R49, R43, R44, R46, D10 and D19). A

more detailed diagram of the logic circuitry is given in the

Ballast Control Logic and Timing

sections of this paper. The current detection filter rectifies and integrates a measurement of

the lamp resonant current from the source of the lower MOSFET of the half-bridge and

compares it against a fixed threshold voltage. Should the current exceed the threshold in the

event of over-current due to a non-strike condition of the lamp or non-zero voltage switching of

the half-bridge due to an open circuit or broken lamp cathodes, the CT pin of the IR2153 is

latched below the internal shutdown threshold (1/6 Vcc) and the ballast is shutdown.

In the event of a lamp exchange, the latch is reset with the pull-up network at the lamp,

and the CT pin of the IR2153 is held below the internal shutdown threshold in an

unlatched

state (see

Timing Diagram). When a new lamp is re-inserted, the ballast performs an auto

restart without a recycling of the input line voltage. During a lamp removal, the frequency is

also reset to the preheat frequency to avoid damage to the half-bridge switches due to below-

resonance operation which can occur upon re-insertion of the lamp. For a dual lamp ballast, a

second pull-up network is added to the second lamp (R27, R28, R29, R30) and is `OR-ed'

together with the first lamp. If either lamp is removed during running, the ballast is shutdown.

In the event of a broken

upper cathode by either lamp during normal operation, non zero-

voltage switching occurs at the half-bridge and will be detected by the current detection filter at

source of the lower MOSFET of the half-bridge. Both half-bridge MOSFETs are latched off.

Should the DC bus decrease below a fixed threshold voltage during an undervoltage

condition of the line voltage, the frequency is shifted back up to the preheat frequency to fulfill

zero-voltage switching of the half-bridge, and the latch is disabled. This prevents latch-up

during a fast cycling of the line voltage or a brown out.

IRPLLNR1

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

6

Trimming

The final ballast running input power during production can vary due to tolerances in L, C,

VBUS, frun and manufacturing of the lamp. Trimming is therefore recommended. An

insulated jumper wire (JP1) is connected over resistor R50 to accommodate for this. If the

final run frequency exceeds the nominal specified run frequency by 4% (39kHz), the input

power will be too low, and the ballast may not ignite the lamp and/or deactivate in the event of

a non-strike condition. This is because RT (R20) programs the minimum operating frequency

which corresponds to the ignition frequency. If this frequency is too high, the resulting lamp

voltage may be too low to ignite the lamp and the resulting current may be too low to reach the

current limit threshold. Shifting this frequency up or down shifts all other operating frequencies

in the same direction. In this case, JP1 should be cut in two places and removed. This will

connect R50 in series with R20 and decrease all operating frequencies slightly. The running

lamp power, ignition voltage and ignition current will also increase. All of these parameters

should be carefully tested during production.

IRPLLNR1

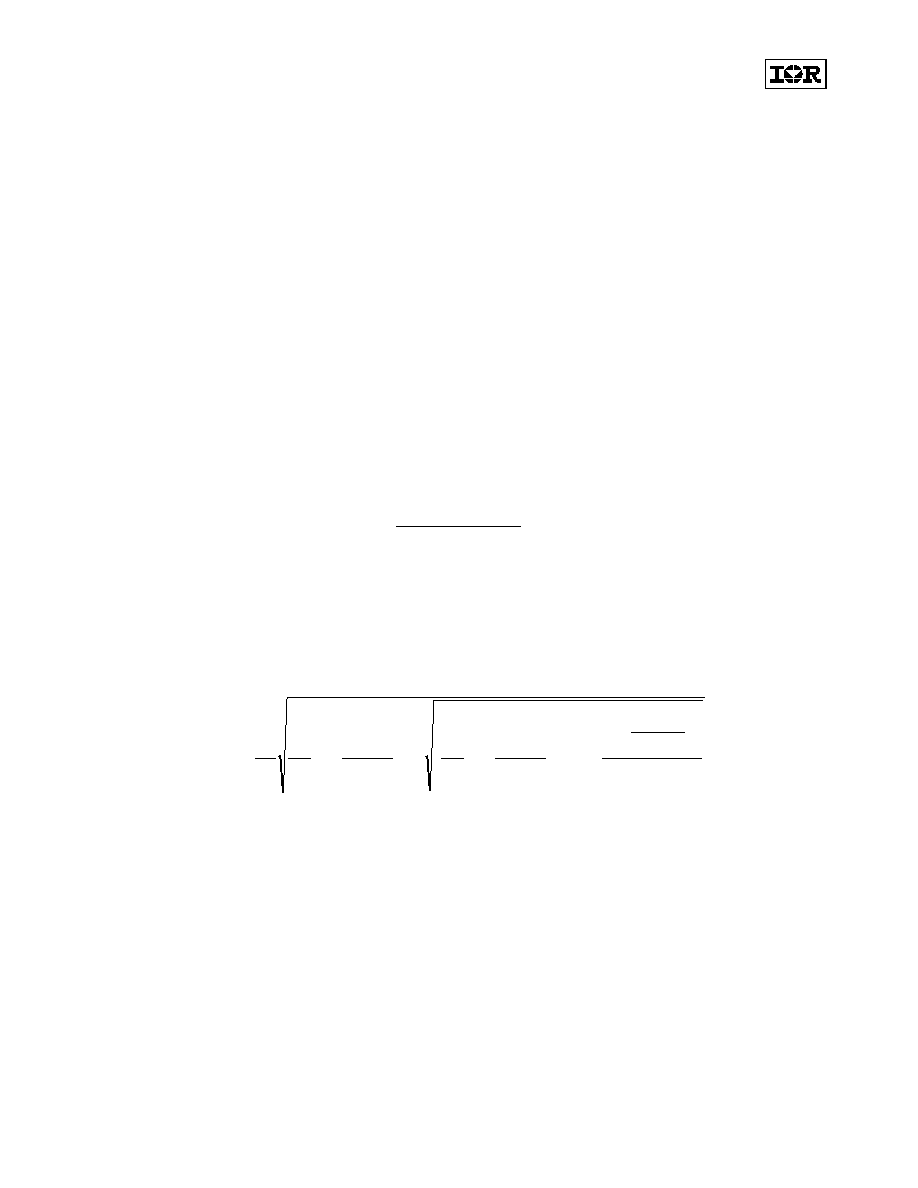

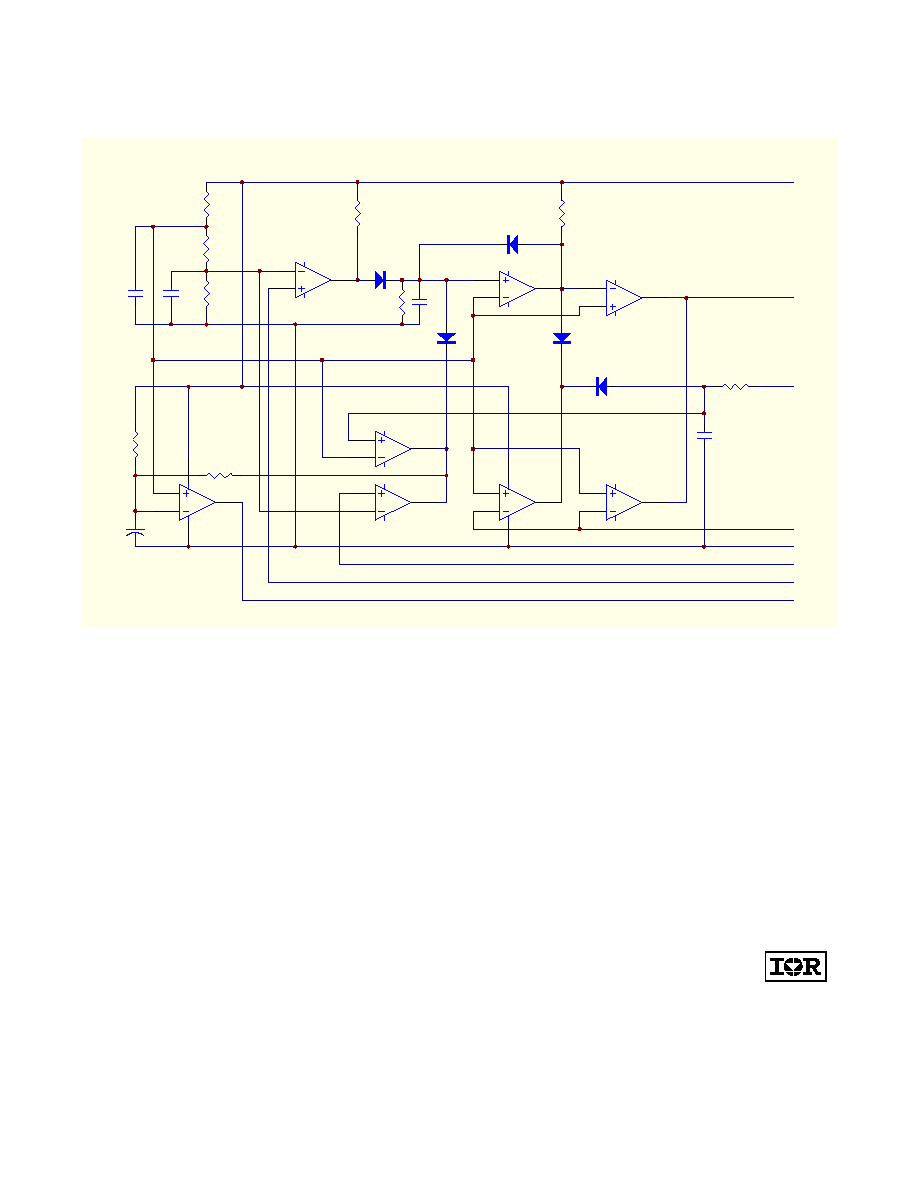

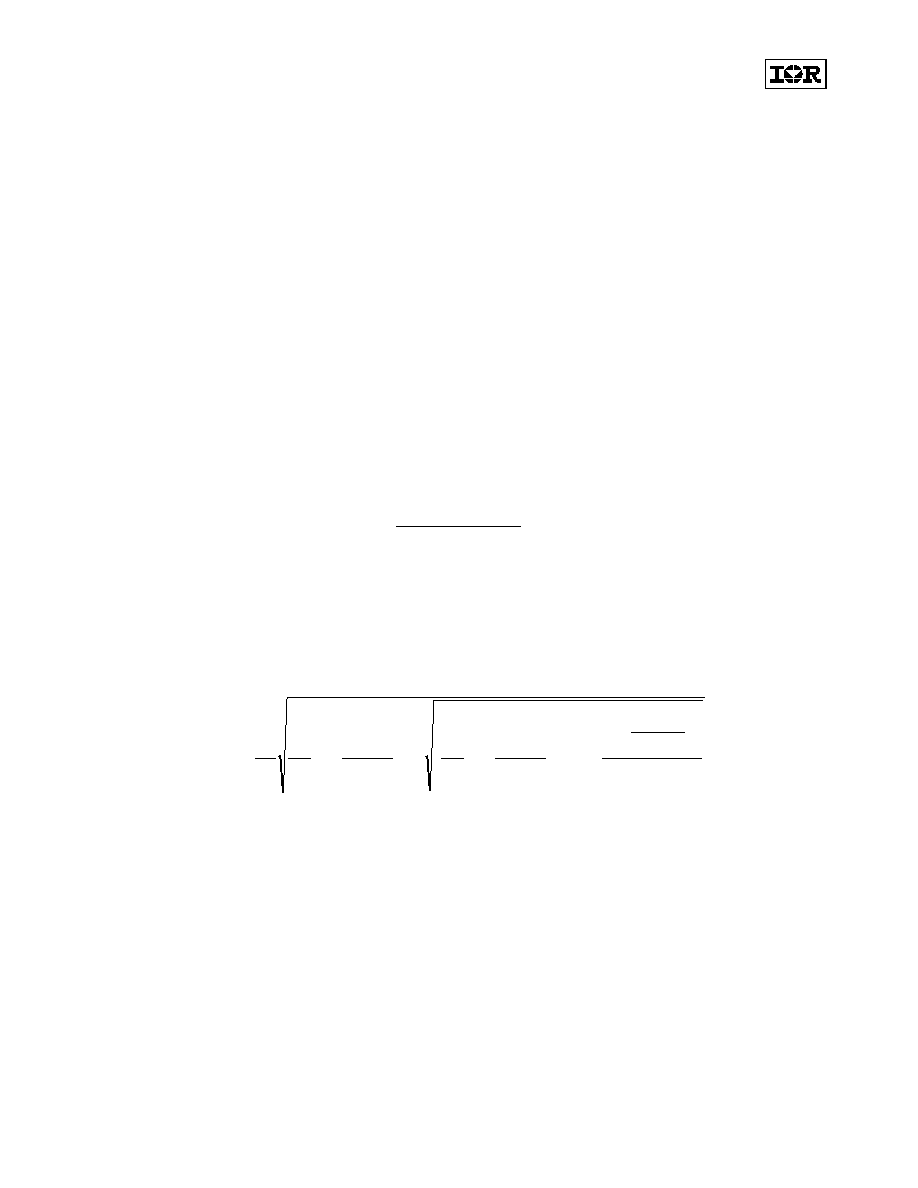

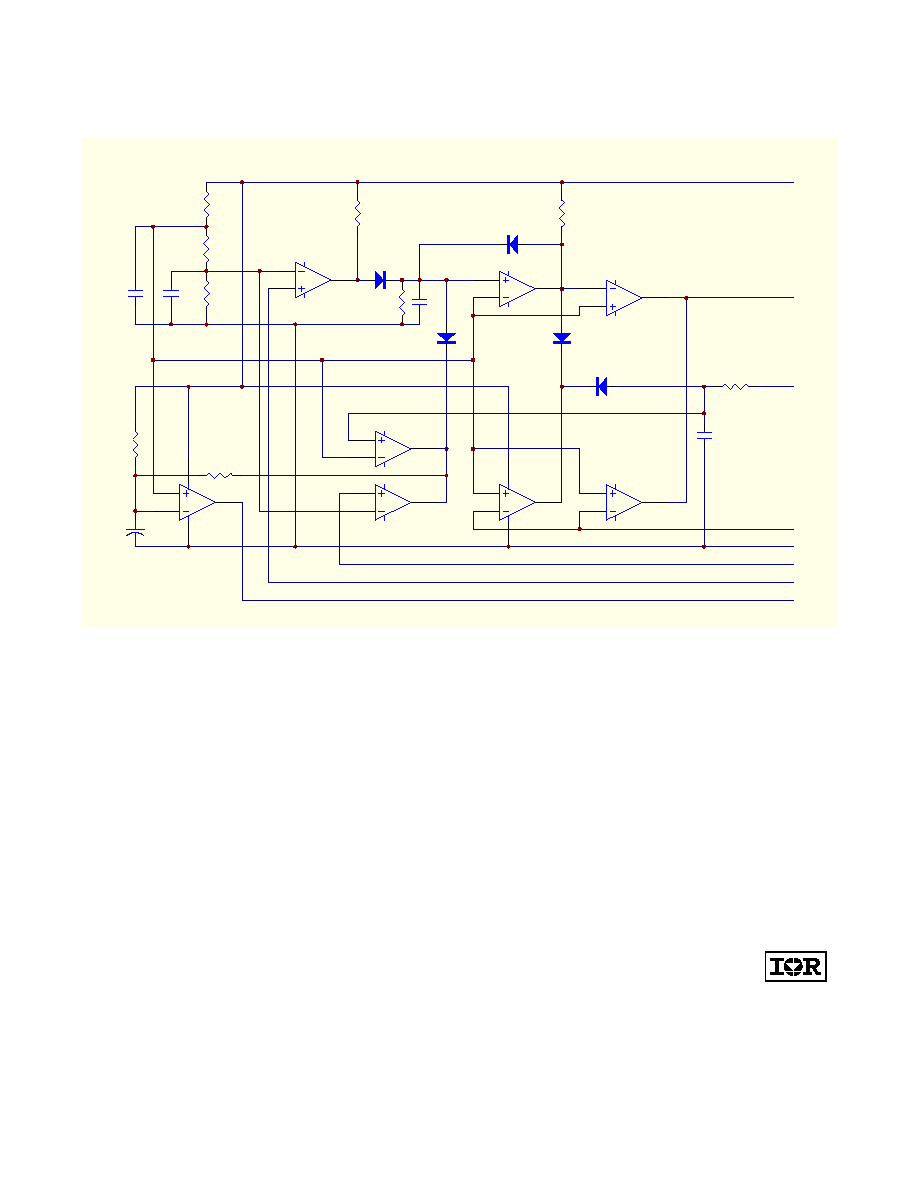

Ballast Control Logic

For corresponding signal waveforms, see

Timing Diagram.

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

7

5

4

2

3

12

IC2A

7

6

1

IC2B

9

8

14

IC2C

11

10

13

IC2D

5

4

2

3

12

IC4A

7

6

1

IC4B

9

8

14

IC4C

11

10

13

IC4D

R36

R15

R14

C26

C10

D6

R16

R19

C24

C15

D7

D8

D15

D20

R39

R35

R18

R45

+

C28

VCC

CT(IR2153)

RT(IR2153)

COM

LAMPOUT

OVER-CURRENT

PREHEAT

TBLANK

VTH1

VTH2

UNDERVOLTAGE

FREQSHIFT

RESET

LATCH

SHUTDOWN

(NON-LATCHED)

SHUTDOWN

(LATCHED)

ENABLE

TPHEAT

IRPLLNR1

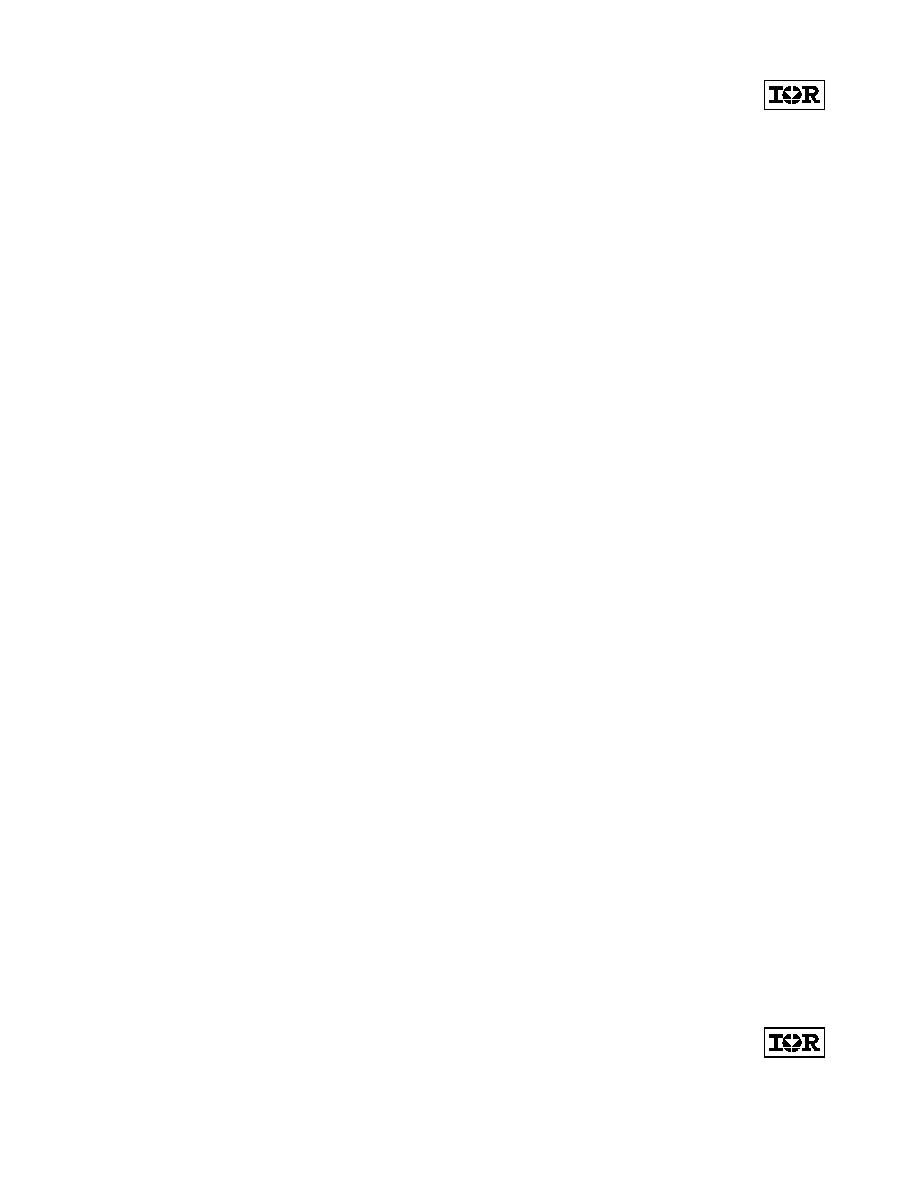

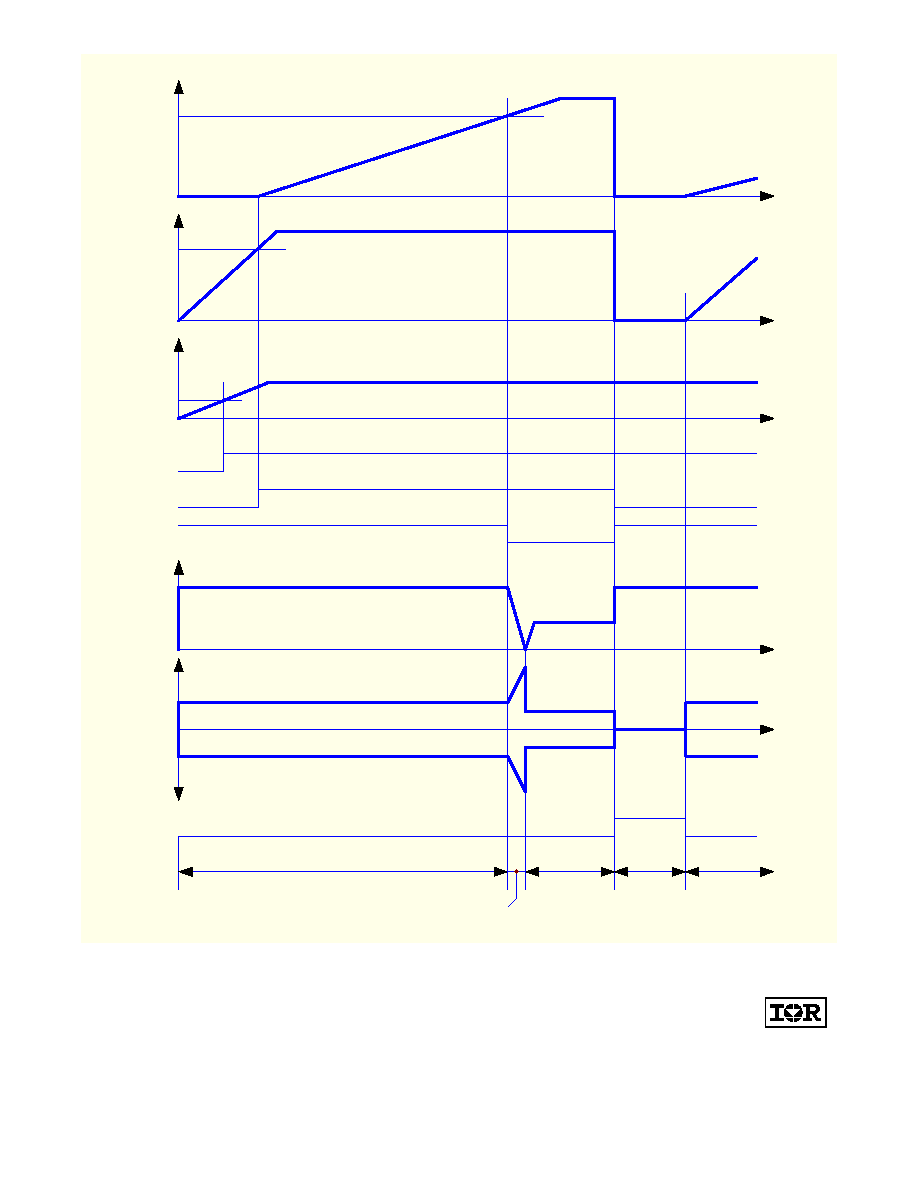

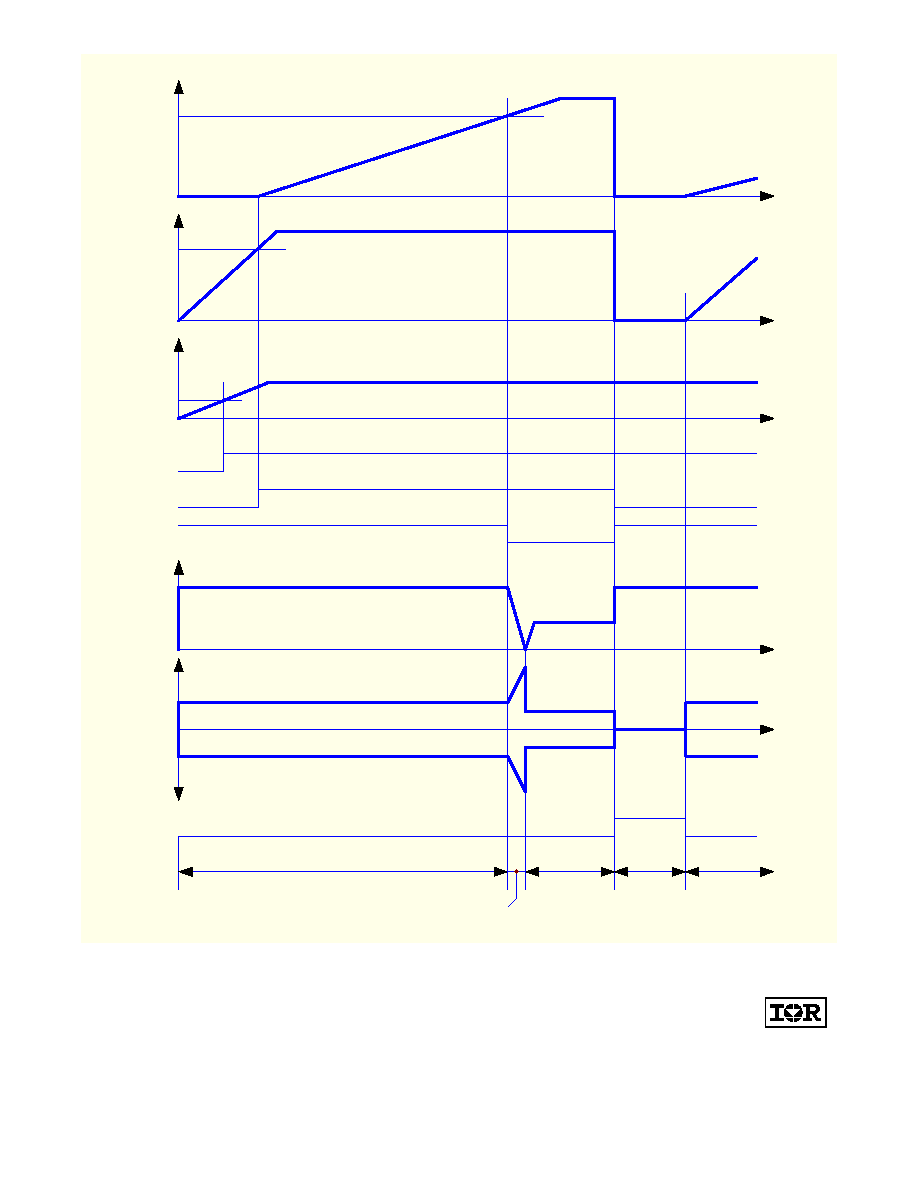

Timing Diagram (Normal operation, lamp removal/re-insertion during running)

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

8

VTH1

VTH1

TPHEAT

TBLANK

ENABLE

PREHEAT

V(R41)

I(L4)

LAMPOUT

t

t

t

t

PREHEAT

RUN

SHUTDOWN

PREHEAT

IGN

VTH2

UNDER-

t

FREQSHIFT

VOLTAGE

IRPLLNR1

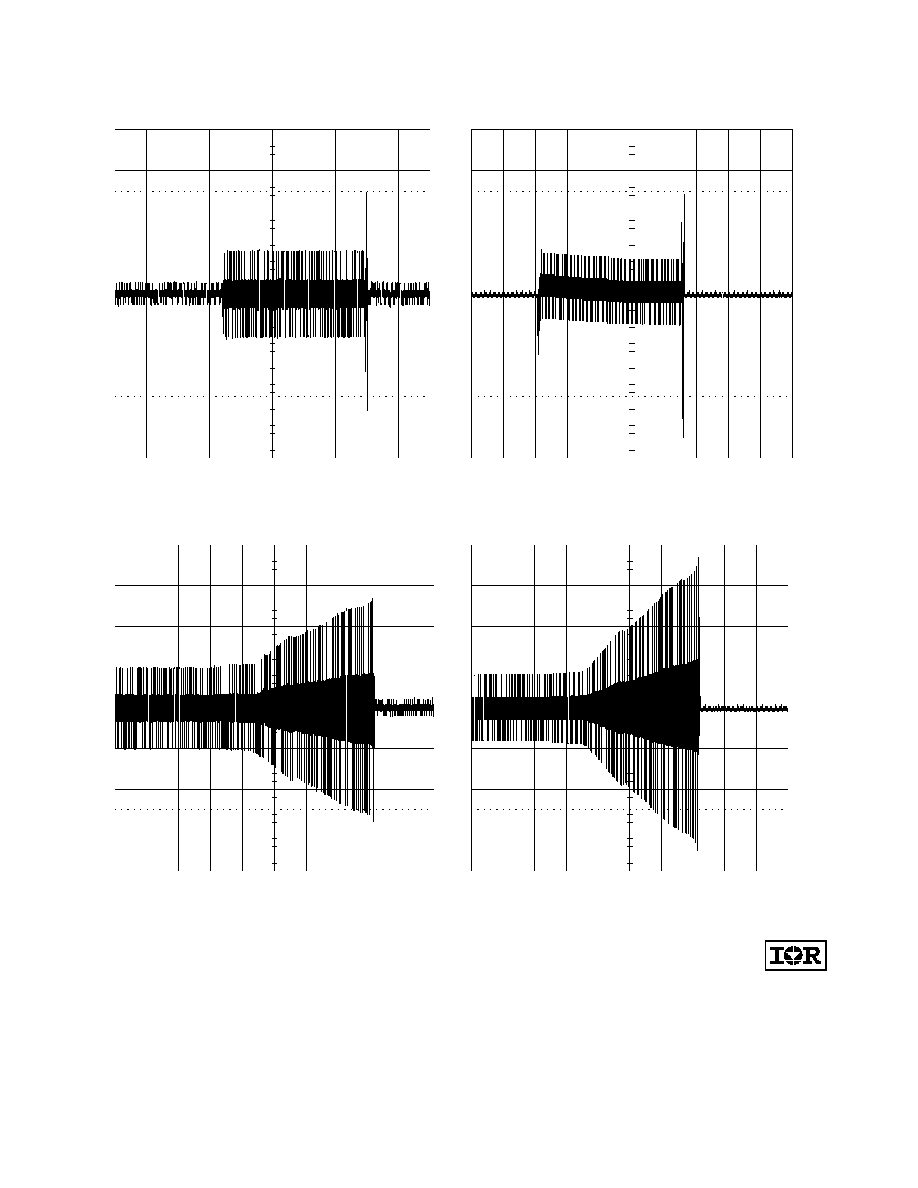

Measurements

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

9

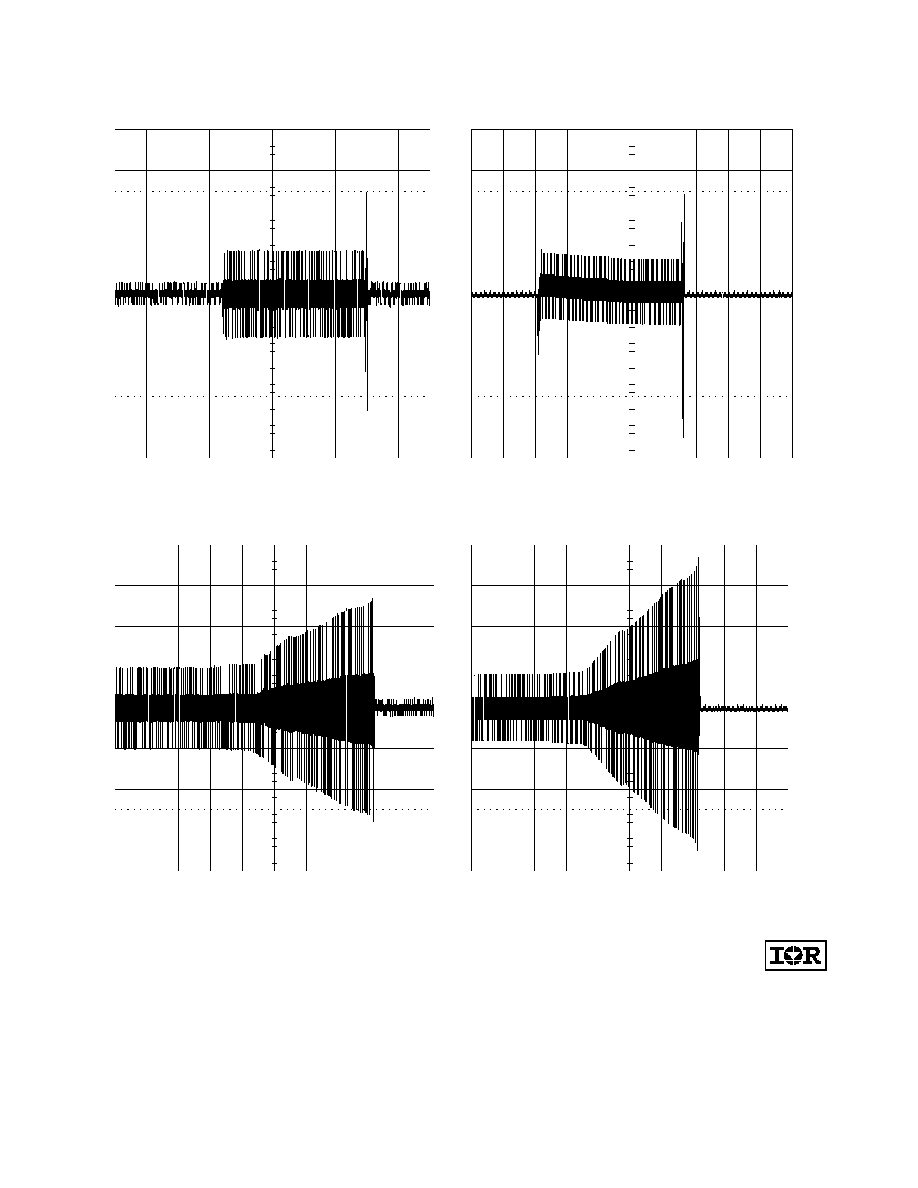

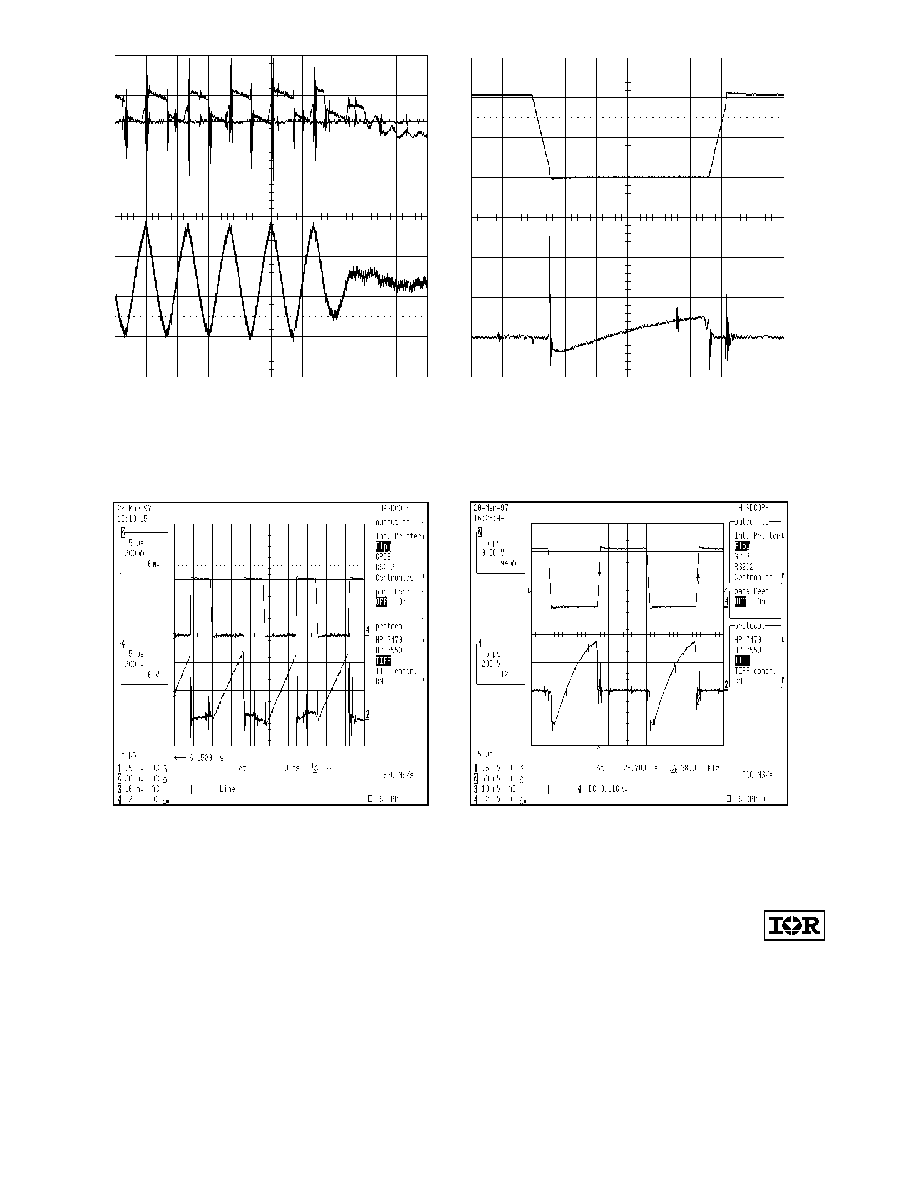

The following waveforms (see Figures 1 and 2) are from a dual 40W/T12 ballast (see Bill of

Materials) and include ballast input, ouput and control measurements during all modes of

operation.

Figure 1 : Line input voltage (upper trace, 200V/div) and

Figure 2 : Drain-to-source voltage (upper trace, 200V/div)

current (lower trace, 0.5A/div) during 120VAC normal

current (lower trace, 0.5A/div) during 230VAC normal

operation. Timescale = 5ms/div.

operation. Timescale = 5ms/div.

Figure 3 : Line input current (200V/div) during preheat,

Figure 4 : Rectifier output voltage (upper trace, 200V/div),

ignition and running operating conditions.

VCC IR2153 (middle trace, 10V/div) and VDD LX1562

Timescale = 0.5s/div.

(lower trace, 10V/div) during start-up. Timescale = 5ms/div.

IRPLLNR1

Measurements (cont.)

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

10

Figure 5: Inductor (L4 or L5) current (0.5A/div) during

Figure 6: Lamp voltage (200V/div) during preheat and

preheat and ignition operating conditions.

ignition operating conditions. Timescale = 0.5A/div.

Timescale = 0.5A/div.

Figure 7: Inductor current (L4 or L5) (0.5A/div) ramping up

Figure 8: Lamp voltage (200V/div) ramping up after

after preheat to ignite the lamp. Timescale = 5ms/div.

preheat to ignite the lamp. Timescale = 5ms/div. Dummy

Dummy filaments inserted to simulate non-strike condition.

filaments inserted to simulate non-strike condition.

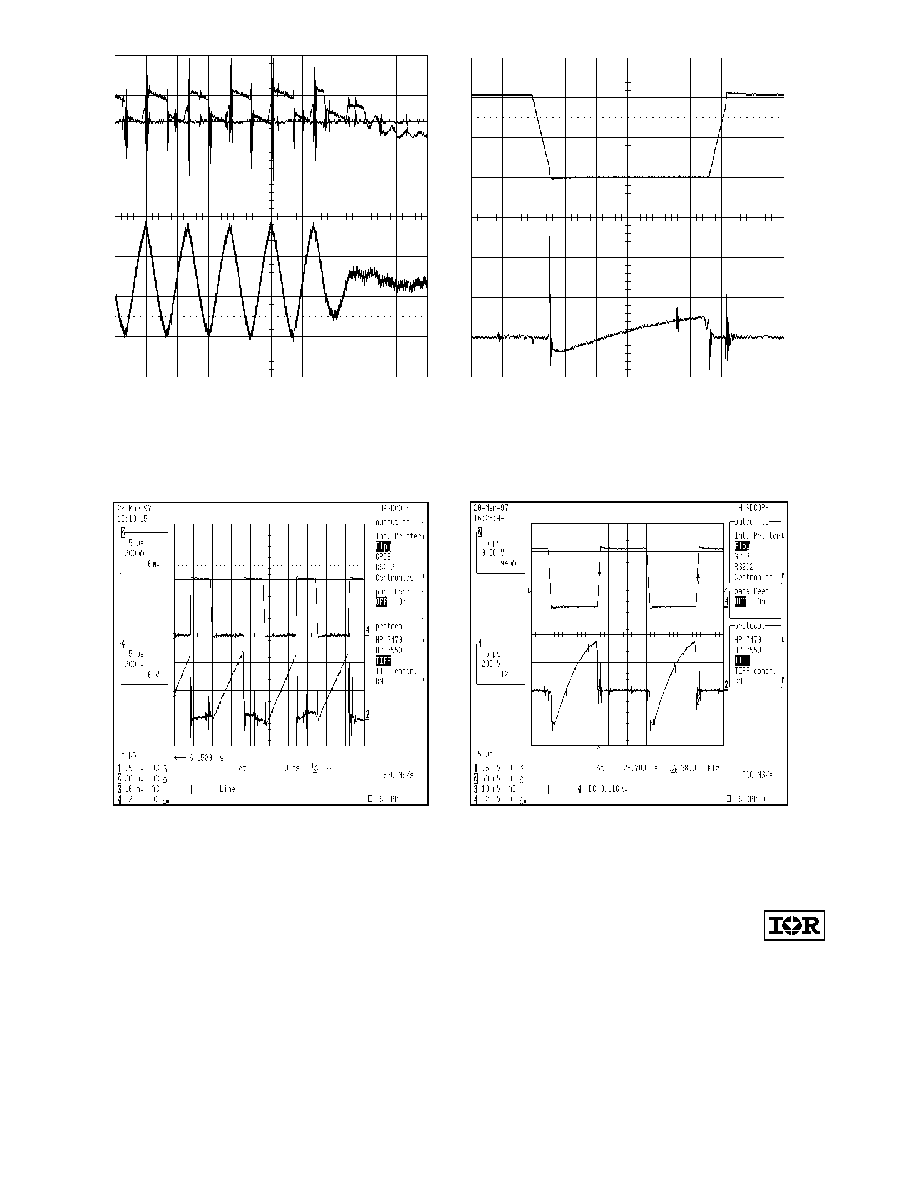

IRPLLNR1

Measurements (cont.)

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

11

Figure 9: Filament current (upper trace, 0.5A/div) and

Figure 10: VCO voltage (5V/div) showing control sequence

voltage (lower trace, 10V/div) during preheat.

during preheat, ignition and running conditions.

Timescale = 0.5A/div.

Timescale = 0.5A/div.

Figure 11: Half-bridge voltage (upper trace, 200V/div),

Figure 12: Half-bridge voltage (upper trace, 200V/div)

half-bridge current (middle/upper trace, 1A/div), Vth2

and lampout signal V:D16 (lower trace, 5V/div) during

threshold voltage (middle/lower trace, 1V/div) and current

lamp removal/re-insertion condition. Timescale = 10ms/div.

detection voltage (lower trace, 1V/div) During normal

running condtions. Timescale = 5us/div.

IRPLLNR1

Measurements (cont.)

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

12

Figure 13: Vth2 threshold voltage (upper middle trace,

Figure 14: Half-bridge voltage (upper trace, 200V/div) and

1V/div), current detection signal V:C16 (upper trace, 1V/div)

lower half-bridge MOSFET source current (1A/div) during

and inductor current (lower trace, 0.5A/div) during non-strike/

hard-switching fault condition. Timescale = 1us/div. Upper

shutdown condition. Timescale = 20us/div. V:C16 exceeds

filament of 1 lamp removed, other lamp remains running.

Vth2 as current ramps up and ballast is shutdown. Dummy

Condition continues until V:C16 exceeds Vth2 (V:C26).

filaments inserted to simulate non-strke condtion.

Figure 15: Voltage (upper trace, 200V/div) and current

Figure 16: Drain-to-source voltage (upper trace, 200V/div)

(lower trace, 0.5A/div) waveforms of PFC MOSFET (M1)

and source current (lower trace, 0.7A/div) of MOSFET (M5)

during lowest line (100VAC) condition.

during maximum running lamp power.

IRPLLNR1

Measurements (cont.)

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

13

Figure 17: Typical Conducted EMI frequency response for phase against

neutral (upper trace: Quasi Peak, lower trace: Average). EN55015 limit

lines also shown.

Figure 18: Typical Conducted EMI frequency response for neutral against

neutral (upper trace: Quasi Peak, lower trace: Average). EN55015 limit

lines also shown.

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

14

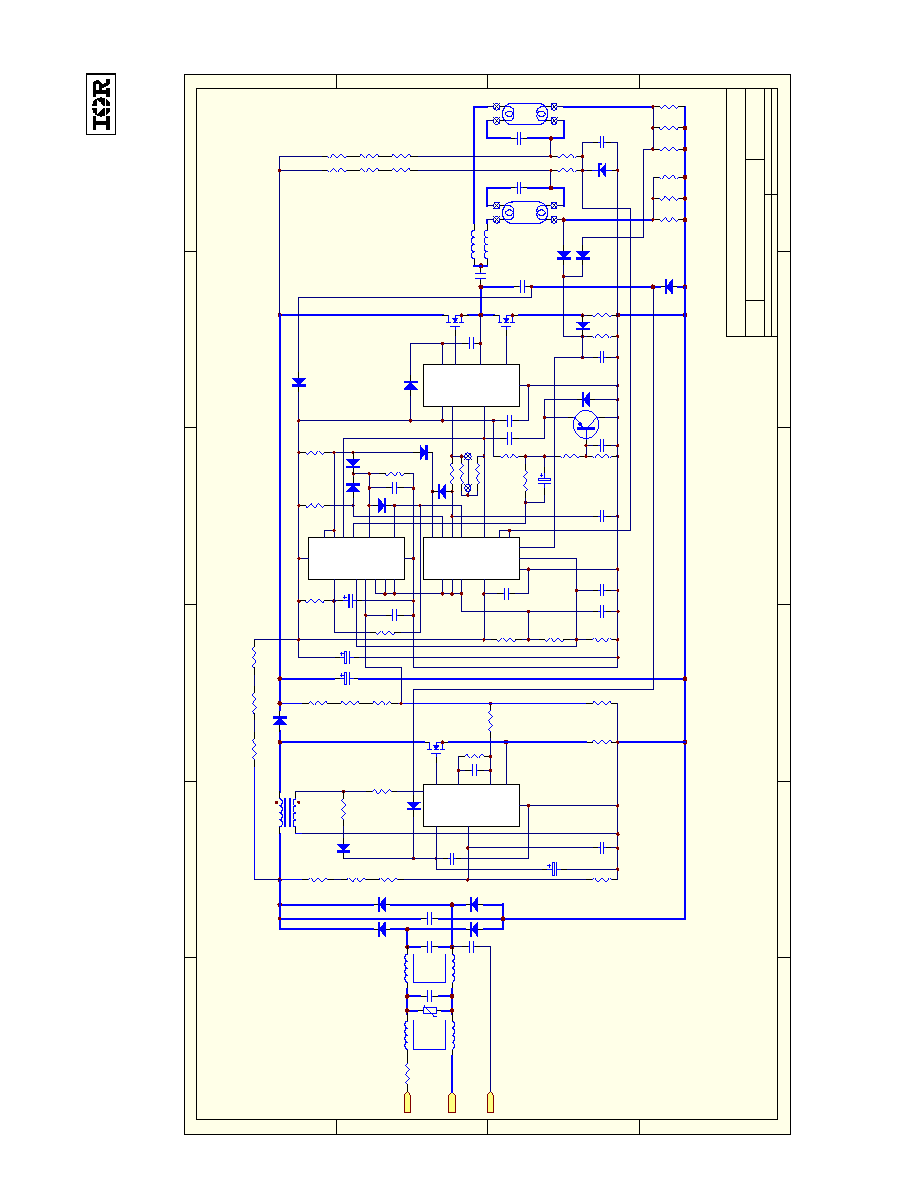

IRPLLNR1

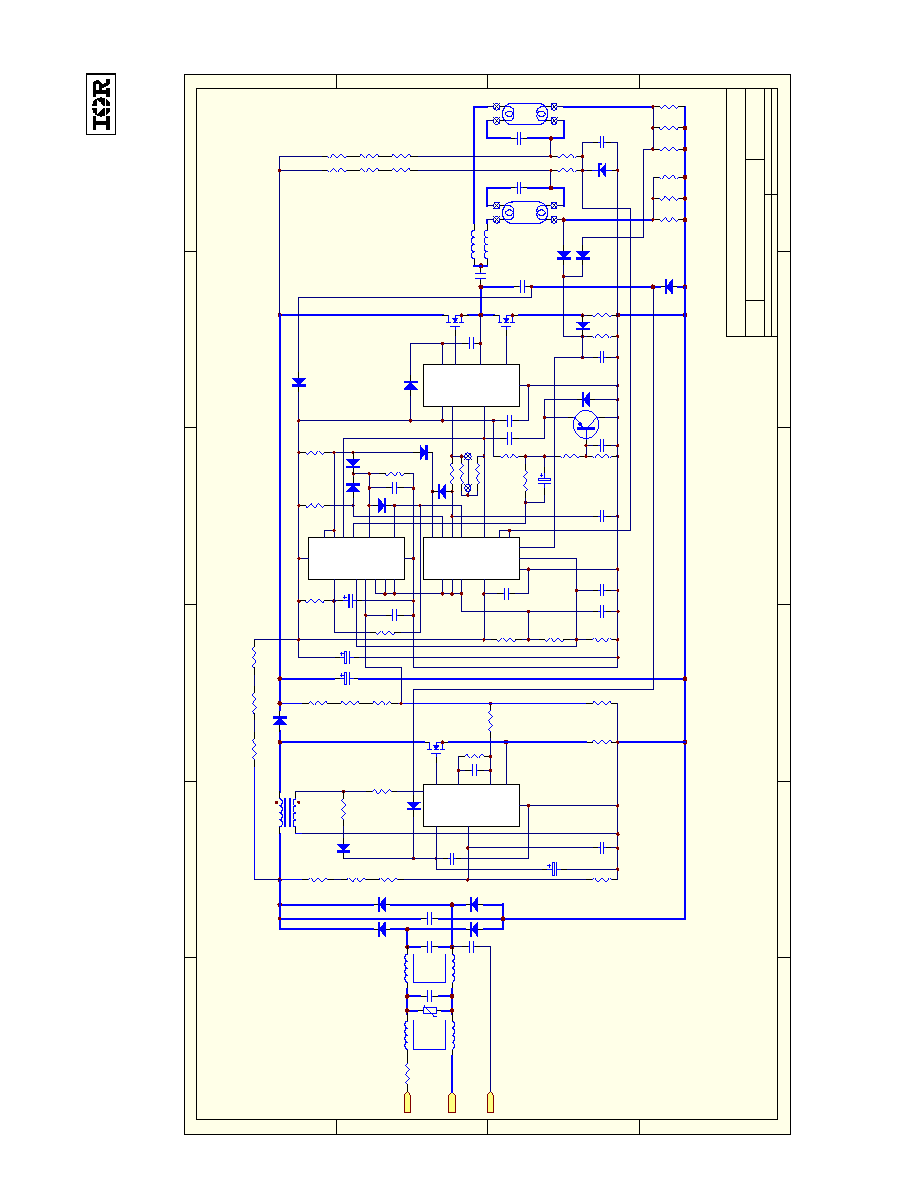

Circuit Schematic

1

2

3

4

5

6

A

B

C

D

6

5

4

3

2

1

D

C

B

A

Title

Number

Revision

Size

B

Date:

8-Jan-1998

Sheet of

File:

C:\PROTEL\SCH\IRPLLNR1\IRPLLNR1.SCH Drawn By:

N

L

R1

R5

5

8

C6

6

3

7

2

R6

1

4

LX1562M

R8

D5

R9

R13

D11

C14

C18

C17

D13

M4

M5

D1

D2

D3

D4

C2

C3

C1

L2

RV1

C19

L4

L5

C23

C21

LP1

LP2

VCC

RT

CT

VB

HO

VS

LO

VSS

IR2153

1 of 1

WARM-START UNIVERSAL INPUT FLUORESCENT BALLAST

R50

R14

R15

R4

R12

R7

M1

C7

C13

C12

C8

R23

R27

R26

R30

D19

D14

D16

L1

L3

C5

C9

C10

R22

R21

C16

R17

F1

400VDC

90..275VAC

Note: Thick traces represent high-frequency, high-current paths. Lead lengths should be minimized to avoid high-frequency noise problems.

C11

R10

R11

R2

R3

R25

R24

R28

R29

C4

50/60Hz

IC1

IC3

3

11

12

TLC339

IC2

1

8

13

4

6

D18

C22

R40

R37

R36

154..254VDC

X2:1

X2:2

X2:3

X2:4

X3:1

X3:3

X3:2

X3:4

D10

R46

R43

R44

R47

R48

R49

3

12

14

1

D8

2

R18

C15

C24

R16

R35

D9

Q1

C20

R42

R41

R19

R39

11

5

7

10

6

5

9

10

R45

2

8

13

C26

TLC339

IC4

9

4

14

X1:1

X1:2

X1:3

E

C27

7

C25

D7

D6

D12

D20

D15

R34

D17

R20

JP1

C28

R51

Reference Design Data Sheet intended for design information only.

Subjected to changes without prior notice.

15

WORLD HEADQUARTERS: 233 KANSAS ST., EL SEGUNDO, CA 90245 USA ∑ (310)322-3331 ∑ FAX (310)322-3332 ∑ TELEX 472-0403

EUROPEAN HEADQUARTERS: HURST GREEN, OXTED, SURREY RH8 9BB, UK ∑ (44)0883 713215 ∑ FAX (944)0883 714234 ∑ TELEX 95219

Sales Offices, Agents and Distributors in Major Cities Throughout the World.

Data and specifications subject to change without notice.

© 1997 International Rectifier Printed in U.S.A. 4-97