| –≠–Ľ–Ķ–ļ—ā—Ä–ĺ–Ĺ–Ĺ—č–Ļ –ļ–ĺ–ľ–Ņ–ĺ–Ĺ–Ķ–Ĺ—ā: LTC3413 | –°–ļ–į—á–į—ā—Ć:  PDF PDF  ZIP ZIP |

1

LTC3413

sn3413 3413fs

FEATURES

DESCRIPTIO

U

APPLICATIO S

U

TYPICAL APPLICATIO

U

3A, 2MHz Monolithic

Synchronous Regulator for

DDR/QDR Memory Termination

s

High Efficiency: Up to 90%

s

Ī

3A Output Current

s

Symmetrical Source and Sink Output Current Limit

s

Low R

DS(ON)

Internal Switch: 85m

s

No Schottky Diode Required

s

2.25V to 5.5V Input Voltage Range

s

V

OUT

= V

REF

/2

s

Ī

1% Output Voltage Accuracy

s

Programmable Switching Frequency: Up to 2MHz

s

Power Good Output Voltage Monitor

s

Overtemperature Protected

s

Available in 16-Lead TSSOP Exposed Pad Package

The LTC

ģ

3413 is a high efficiency monolithic synchro-

nous step-down DC/DC converter utilizing a constant

frequency, current mode architecture. It operates from an

input voltage range of 2.25V to 5.5V and provides a

regulated output voltage equal to (0.5)V

REF

while sourcing

or sinking up to 3A of output current. An internal voltage

divider reduces component count and eliminates the need

for external resistors by dividing the reference voltage in

half. The internal synchronous power switch with 85m

on-resistance increases efficiency and eliminates the need

for an external Schottky diode. Switching frequencies up

to 2MHz are set by an external resistor.

Forced-continuous operation in the LTC3413 reduces

noise and RF interference. Fault protection is provided by

an overcurrent comparator that limits output current dur-

ing both sourcing and sinking operations. Adjustable

compensation allows the transient response to be opti-

mized over a wide range of loads and output capacitors.

s

Bus Termination: DDR and QDR

TM

Memory,

SSTL, HSTL, ...

s

Notebook Computers

s

Distributed Power Systems

, LTC and LT are registered trademarks of Linear Technology Corporation.

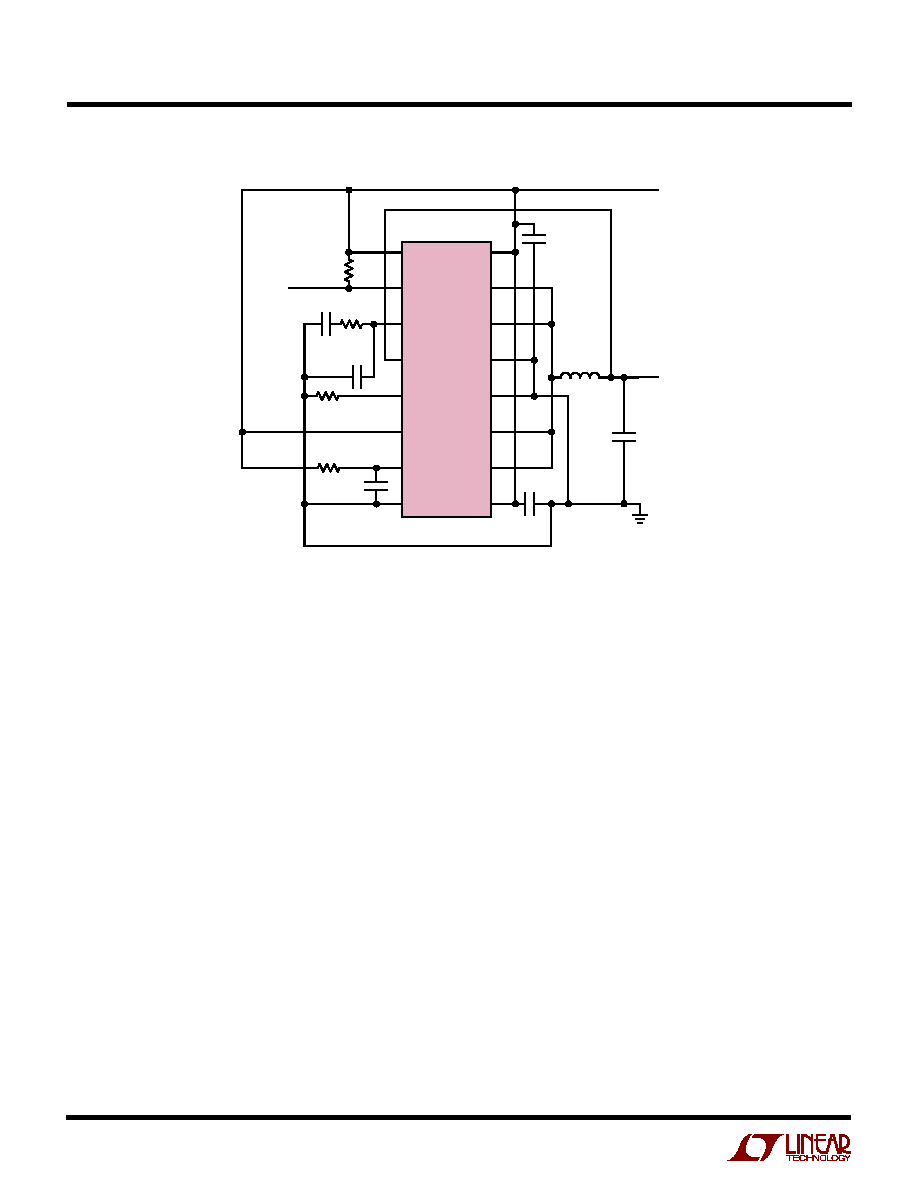

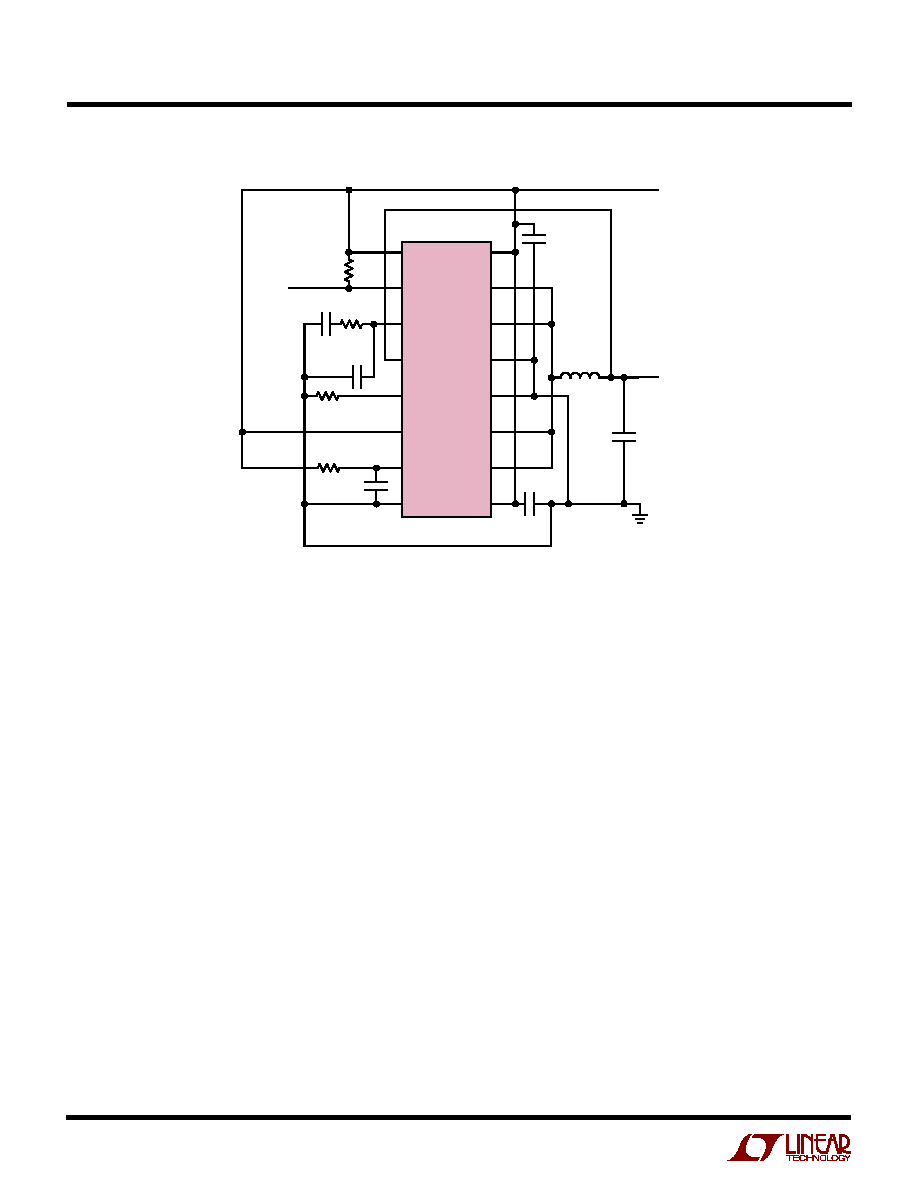

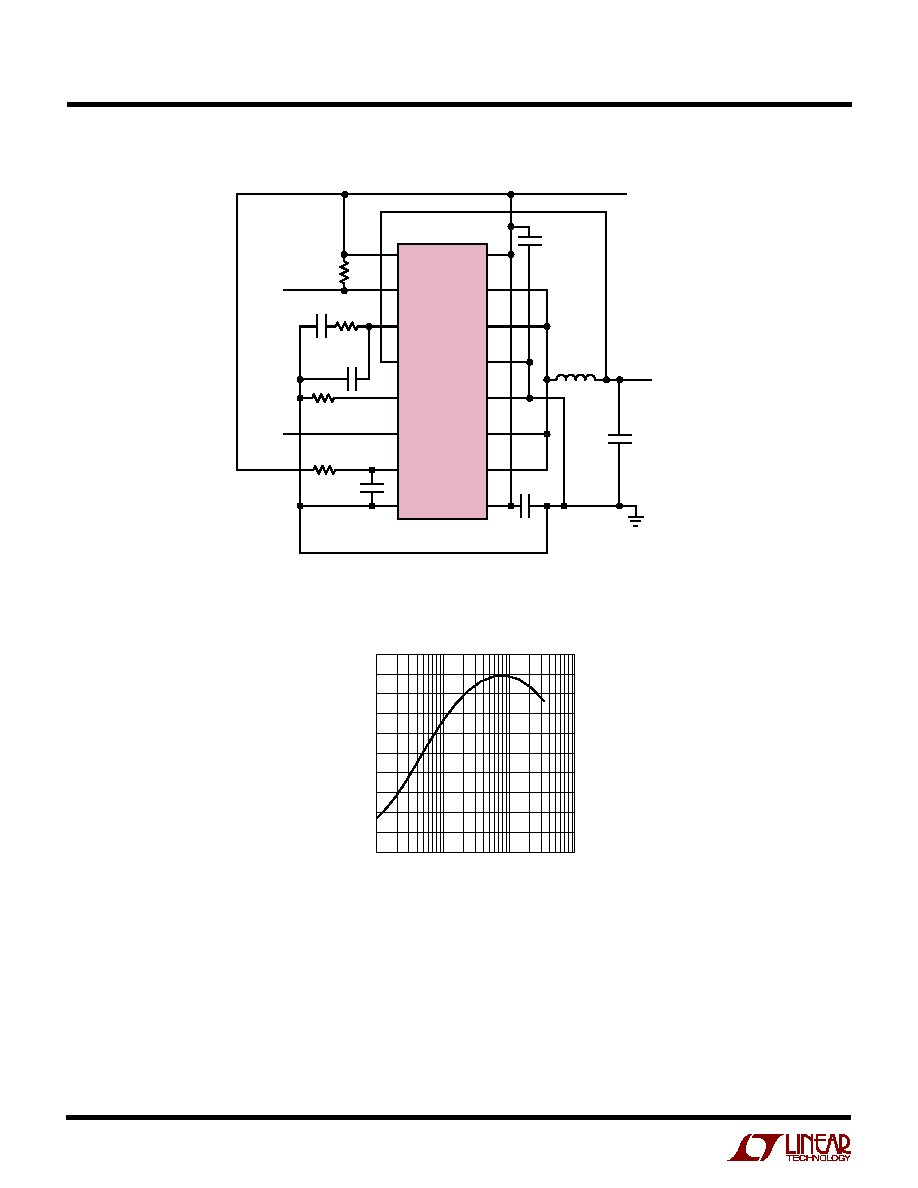

Figure 1a. High Efficiency Bus Termination Supply

Figure 1b. Efficiency vs Load Current

PV

IN

SV

IN

PGOOD

SW

V

REF

22

Ķ

F

4.7M

309k

L1: VISHAY DALE IHLP-2525CZ-01 0.47

C

OUT

: TDK C4532X5R0J107M

V

IN

2.5V

C

OUT

100

Ķ

F

◊

2

3413 F01a

V

OUT

1.25V

Ī

3A

L1

0.47

Ķ

H

LTC3413

PGND

RUN/SS

SGND

I

TH

R

T

V

FB

330pF

2200pF

5.11k

LOAD CURRENT (A)

0.01

40

EFFICIENCY (%)

50

60

70

80

0.1

1

10

3413 F01b

30

20

10

0

90

100

V

IN

= 2.5V

f = 1MHz

QDR RAMs and Quad Data Rate RAMs comprise a new family of products developed by Cypress

Semiconductor, Hitachi, IDT, Micron Technology, Inc. and Samsung.

2

LTC3413

sn3413 3413fs

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

V

IN

Input Voltage Range

2.25

5.5

V

V

FB

Feedback Voltage Accuracy

(Note 3)

q

Ī

1

%

I

FB

Voltage Feedback Leakage Current

0.4

Ķ

A

I

RUN

RUN/SS Leakage Current

1

Ķ

A

V

FB

Feedback Voltage Line Regulation

V

IN

= 2.7V to 5.5V (Note 3)

q

0.04

0.2

%/V

V

LOADREG

Feedback Voltage Load Regulation

Measured in Servo Loop, V

ITH

= 0.36V

q

0.02

0.2

%

Measured in Servo Loop, V

ITH

= 0.84V

q

≠ 0.02

≠ 0.2

%

V

PGOOD

Power Good Range

Ī

10

Ī

12

%

R

PGOOD

Power Good Pull-Down Resistance

120

200

I

Q

Input DC Bias Current

(Note 4)

Active Current

V

FB

= 1.5V, V

ITH

= 1.4V, V

REF

= 2.5V

250

330

Ķ

A

Shutdown

V

RUN

= 0V (Note 7)

0.02

1

Ķ

A

f

OSC

Switching Frequency

R

OSC

= 309k

0.88

1.00

1.12

MHz

Switching Frequency Range

(Note 6)

0.30

2.00

MHz

R

PFET

R

DS(ON)

of P-Channel FET

I

SW

= 300mA

85

110

m

R

NFET

R

DS(ON)

of N-Channel FET

I

SW

= 300mA

65

90

m

I

LIMIT

Peak Current Limit

3.8

5.4

A

V

UVLO

Undervoltage Lockout Threshold

1.75

2

2.25

V

I

LSW

SW Leakage Current

V

RUN

= 0V, V

IN

= 5.5V (Note 7)

0.1

1

Ķ

A

V

RUN

RUN Threshold

0.5

0.65

0.8

V

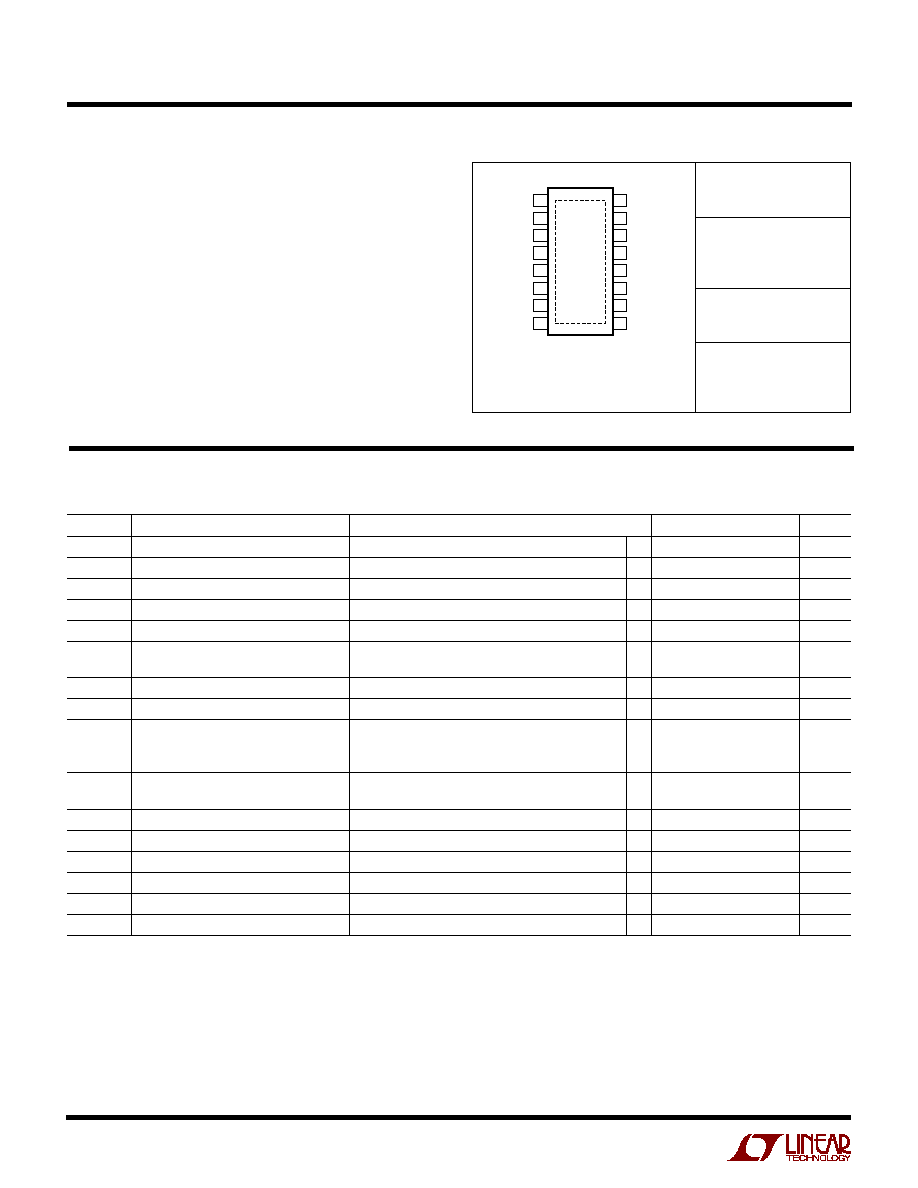

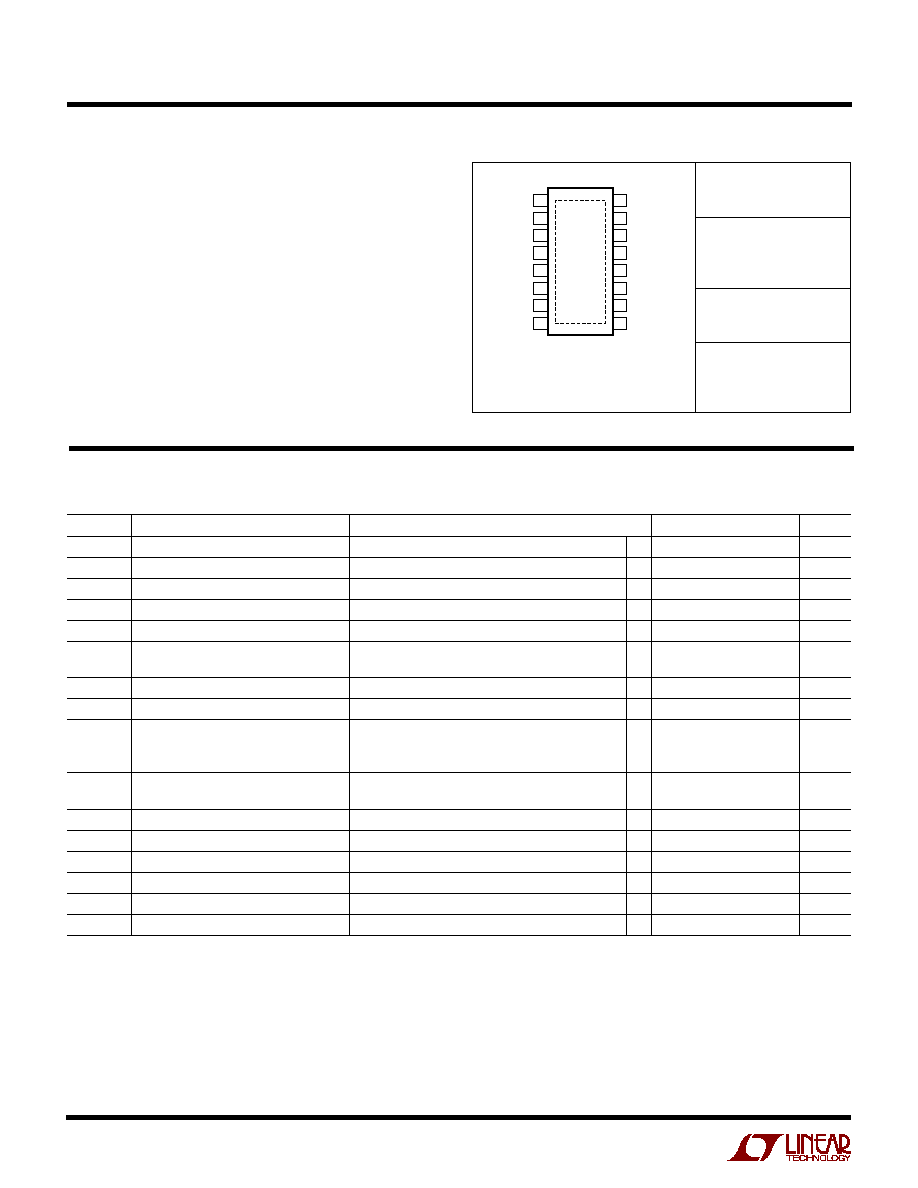

FE PACKAGE

16-LEAD PLASTIC TSSOP

EXPOSED PAD (PIN 17)

MUST BE SOLDERED TO SGND

1

2

3

4

5

6

7

8

TOP VIEW

16

15

14

13

12

11

10

9

SV

IN

PGOOD

I

TH

V

FB

R

T

V

REF

RUN/SS

SGND

PV

IN

SW

SW

PGND

PGND

SW

SW

PV

IN

17

(Note 1)

SV

IN

, PV

IN

Supply Voltages ........................ ≠ 0.3V to 6V

I

TH

, RUN/SS, V

FB

, PGOOD Voltages ........... ≠ 0.3V to V

IN

V

REF

Voltage .............................................. ≠ 0.3V to V

IN

SW Voltage .................................. ≠ 0.3V to (V

IN

+ 0.3V)

Peak SW Sink and Source Current ........................ 7.2A

Operating Ambient Temperature Range

(Note 2) .............................................. ≠ 40

į

C to 85

į

C

Junction Temperature (Notes 5, 8) ...................... 125

į

C

Storage Temperature Range ................ ≠ 65

į

C to 150

į

C

Lead Temperature (Soldering, 10 sec)................. 300

į

C

ORDER PART

NUMBER

LTC3413EFE

The

q

denotes specifications which apply over the full operating

temperature range, otherwise specifications are at T

A

= 25

į

C. V

IN

= 3.3V, unless otherwise noted.

T

JMAX

= 125

į

C,

JA

= 38

į

C/ W,

JC

= 10

į

C/ W

ABSOLUTE AXI U RATI GS

W

W

W

U

PACKAGE/ORDER I FOR ATIO

U

U

W

ELECTRICAL CHARACTERISTICS

Consult LTC Marketing for parts specified with wider operating temperature ranges.

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC3413E is guaranteed to meet performance specifications

from 0

į

C to 70

į

C. Specifications over the ≠40

į

C to 85

į

C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: The LTC3413E is tested in a feedback loop that adjusts V

FB

to

achieve a specified error amplifier output voltage (I

TH

).

Note 4: Dynamic supply current is higher due to the internal gate charge

being delivered at the switching frequency.

Note 5: T

J

is calculated from the ambient temperature T

A

and power

dissipation P

D

as follows: LTC3413E: T

J

= T

A

+ (P

D

∑ 38

į

C/W)

Note 6: 2MHz operation is guaranteed by design and not production tested.

Note 7: Shutdown current and SW leakage current are only tested during

wafer sort.

Note 8: This IC includes overtemperature protection that is intended to

protect the device during momentary overload conditions. Junction

temperature will exceed 125

į

C when overtemperature protection is active.

Continuous operation above the specified maximum operating junction

temperature may impair device reliability.

FE PART

MARKING

3413EFE

3

LTC3413

sn3413 3413fs

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

Switch On-Resistance

vs Temperature

Switch On-Resistance

vs Input Voltage

TEMPERATURE (

į

C)

≠40

0

ON-RESISTANCE (m

)

20

40

60

80

0

40

80

120

3413 G04

100

120

≠20

20

60

100

PFET

ON-RESISTANCE

NFET

ON-RESISTANCE

V

IN

= 3.3V

INPUT VOLTAGE (V)

2.5

0

ON-RESISTANCE (m

)

20

40

60

80

100

120

3

3.5

4

4.5

3413 G05

5

PFET ON-RESISTANCE

NFET ON-RESISTANCE

T

A

= 25

į

C

INPUT VOLTAGE (V)

2.5

0

LEAKAGE CURRENT (nA)

0.5

1.0

1.5

2.0

2.5

3

3.5

4

4.5

3413 G06

5

5.5

PFET

NFET

T

A

= 25

į

C

Switch Leakage vs Input Voltage

Frequency vs R

OSC

Frequency vs Input Voltage

Frequency vs Temperature

R

OSC

(k

)

54

0

FREQUENCY (kHz)

500

1500

2000

2500

654 754 854 954

4500

3413 G07

1000

154 254 354 454 554

3000

3500

4000

V

IN

= 3.3V

T

A

= 25

į

C

INPUT VOLTAGE (V)

2.5

990

FREQUENCY (kHz)

1000

1010

1020

1030

1050

3

3.5

4

4.5

3213 G08

5

5.5

1040

T

A

= 25

į

C

TEMPERATURE (

į

C)

≠40

990

FREQUENCY (kHz)

992

996

998

1000

1010

1004

0

40

60

3413 G09

994

1006

1008

1002

≠20

20

80

100 120

V

IN

= 3.3V

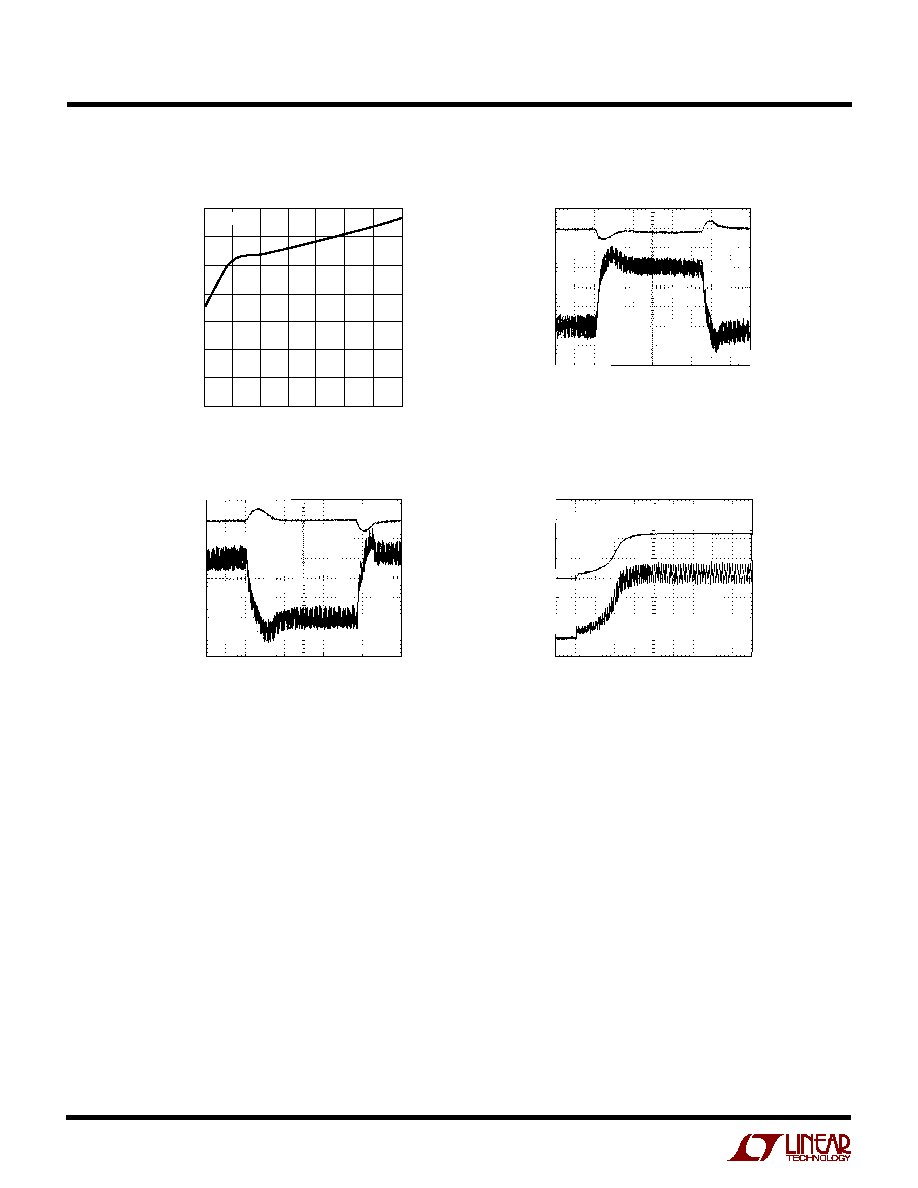

LOAD CURRENT (A)

0.01

40

EFFICIENCY (%)

50

60

70

80

0.1

1

10

3413 G01

30

20

10

0

90

100

V

IN

= 2.5V

V

OUT

= 1.25V

T

A

= 25

į

C

V

IN

= 3.3V

INPUT VOLTAGE (V)

2.5

EFFICIENCY (%)

50

60

70

4.0

5.0

3413 G02

40

30

20

3.0

3.5

4.5

80

90

100

5.5

LOAD = 1A

LOAD = 3A

LOAD = 100mA

V

OUT

= 1.25V

T

A

= 25

į

C

LOAD CURRENT (A)

0

≠0.30

V

OUT

/V

OUT

(%)

≠0.25

≠0.20

≠0.15

≠0.10

0

0.5

1.0

1.5

2.0

3413 G03

2.5

3.0

≠0.05

T

A

= 25

į

C

Efficiency vs Load Current

Efficiency vs Input Voltage

Load Regulation

4

LTC3413

sn3413 3413fs

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

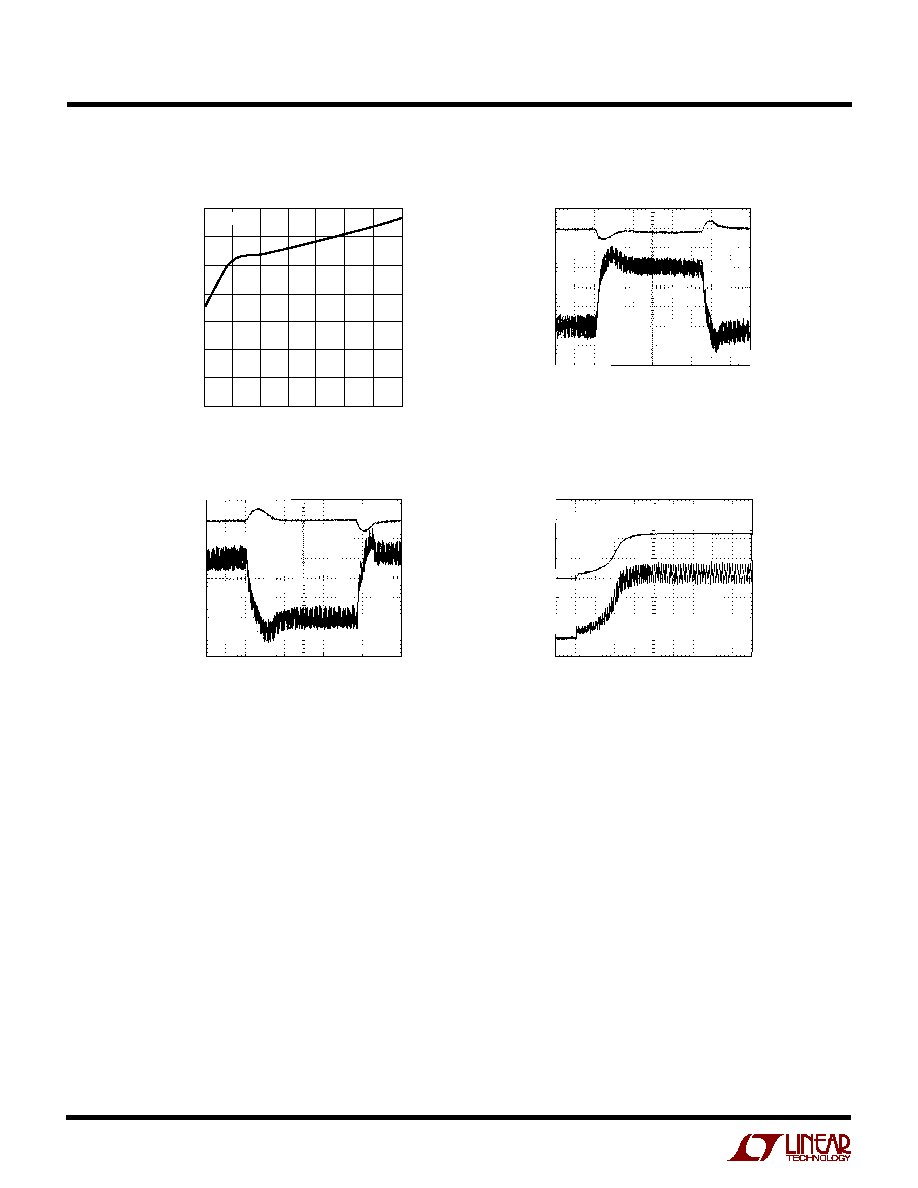

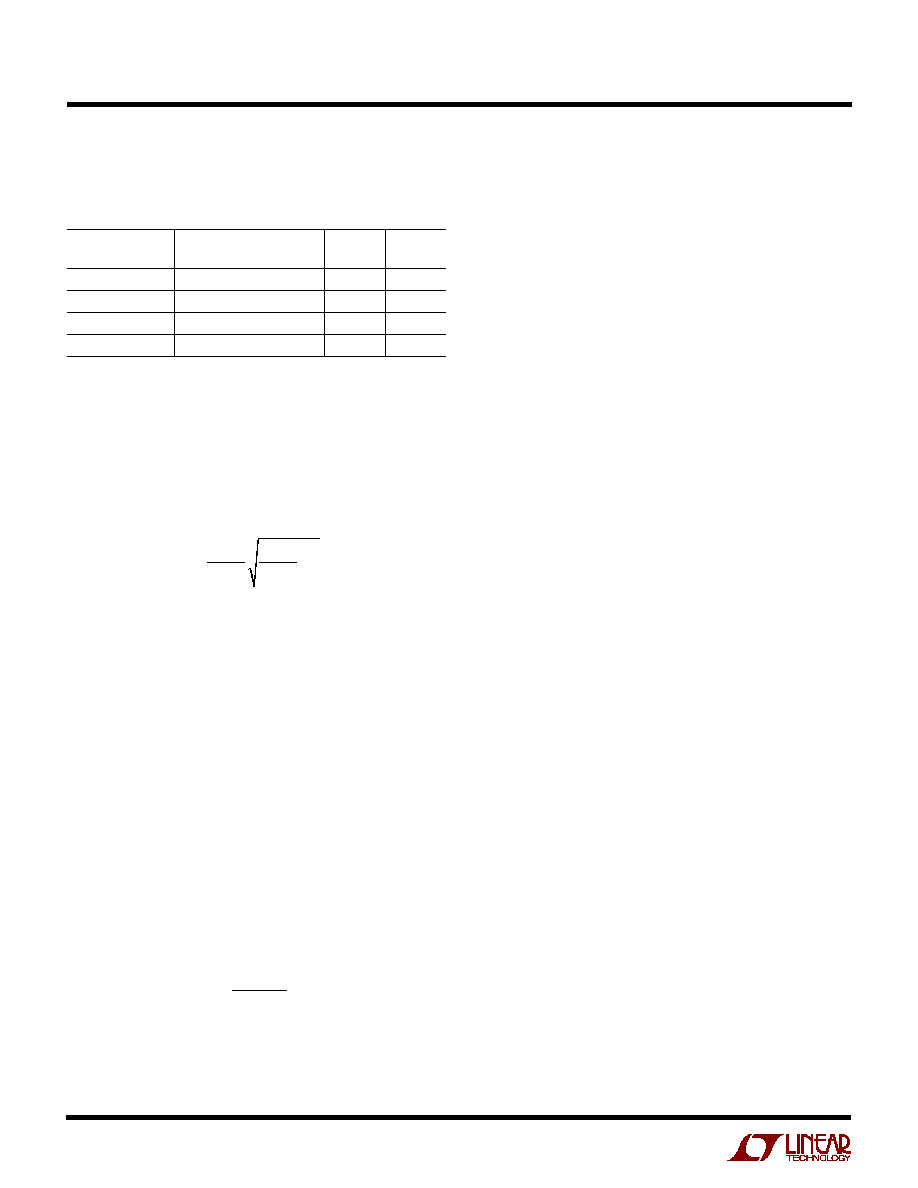

Quiescent Current vs Input Voltage

Load Step Transient

INPUT VOLTAGE (V)

2.0

200

250

350

3.5

4.5

3413 G10

150

100

2.5

3.0

4.0

5.0

5.5

50

0

300

QUIESCENT CURRENT (

Ķ

A)

T

A

= 25

į

C

OUTPUT

VOLTAGE

100mV/DIV

INDUCTOR

CURRENT

1A/DIV

V

IN

= 2.5V

20

Ķ

s/DIV

3413 G11

V

OUT

= 1.25V

LOAD STEP = 0A TO 3A

Load Step Transient

OUTPUT

VOLTAGE

100mV/DIV

INDUCTOR

CURRENT

1A/DIV

V

IN

= 2.5V

20

Ķ

s/DIV

3413 G12

V

OUT

= 1.25V

LOAD STEP = 0A TO ≠3A

Start-Up

INDUCTOR

CURRENT

1A/DIV

V

IN

= 2.5V

1ms/DIV

3413 G13

V

OUT

= 1.25V

LOAD = 0.4

OUTPUT

VOLTAGE

500mV/DIV

5

LTC3413

sn3413 3413fs

FU CTIO AL DIAGRA

U

U

W

≠

+

≠

+

≠

+

≠

+

≠

+

9

16

10

PV

IN

3

I

TH

6

V

REF

1

8

SV

IN

SGND

4

V

FB

PGOOD

SV

IN

PV

IN

SLOPE

COMPENSATION

RECOVERY

SLOPE

COMPENSATION

PMOS CURRENT

COMPARATOR

NMOS CURRENT

COMPARATOR

OSCILLATOR

ERROR

AMPLIFIER

LOGIC

RUN

RUN/SS

R

T

11

14

15

SW

SW

SW

SW

13

7

5

PGND

3413 BD

12 PGND

2

1.1V

REF

2

0.9V

REF

2

U

U

U

PI FU CTIO S

SV

IN

(Pin 1): Signal Input Supply. Decouple this pin to

SGND with a capacitor. SV

IN

must be greater or equal to

PV

IN

, however, the difference between SV

IN

and PV

IN

must

be less than 0.5V.

PGOOD (Pin 2): Power Good Output. Open-drain logic

output that is pulled to ground when the output voltage is

not within

Ī

10% of regulation point.

I

TH

(Pin 3): Error Amplifier Compensation Point. The

current comparator threshold increases with this control

voltage. Nominal voltage range for this pin is from 0.2V to

1.4V with 0.6V corresponding to the zero-sense voltage

(zero current).

V

FB

(Pin 4): Feedback Pin. Receives the feedback voltage

from the output.

R

T

(Pin 5): Oscillator Resistor Input. Connecting a resistor

to ground from this pin sets the switching frequency.

V

REF

(Pin 6): Reference Voltage Input. The positive input

of the internal error amplifier senses one-half of the

voltage at this pin through a resistor divider.

RUN/SS (Pin 7): Run Control and Soft-Start Input. Forcing

this pin below 0.5V shuts down the LTC3413. In shutdown

all functions are disabled drawing < 1

Ķ

A of supply current.

A capacitor to ground from this pin sets the ramp time to

full output current.

SGND (Pin 8): Signal Ground. All small-signal compo-

nents and compensation components should connect to

this ground, which in turn connects to PGND at one point.

PV

IN

(Pins 9, 16): Power Input Supply. Decouple this pin

to PGND with a capacitor.

SW (Pins 10, 11, 14, 15): Switch Node Connection to

Inductor. This pin connects to the drains of the internal

main and synchronous power MOSFET switches.

PGND (Pins 12, 13): Power Ground. Connect this pin

closely to the (≠) terminal of C

IN

and C

OUT

.

EXPOSED PAD (Pin 17): Should be connected to SGND.

6

LTC3413

sn3413 3413fs

OPERATIO

U

Main Control Loop

The LTC3413 is a monolithic, constant frequency, current

mode step-down DC/DC converter that is capable of sourc-

ing and sinking current at the output. During normal op-

eration, the internal top power switch (P-channel MOSFET)

is turned on at the beginning of each clock cycle. Current

in the inductor increases until the current comparator trips

and turns off the top power MOSFET. The peak inductor

current at which the current comparator shuts off the top

power switch is controlled by the voltage on the I

TH

pin.

The error amplifier adjusts the voltage on the I

TH

pin by

comparing the feedback signal on the V

FB

pin with a refer-

ence voltage that is equal to one-half of the voltage on the

V

REF

pin. When the load current increases, it causes a

reduction in the feedback voltage relative to the reference.

The error amplifier raises the I

TH

voltage until the average

inductor current matches the new load current. When the

top power MOSFET shuts off, the synchronous power

switch (N-channel MOSFET) turns on until either the bot-

tom current limit is reached or the beginning of the next

clock cycle. The bottom current limit is set at ≠ 7A.

The operating frequency is set by an external resistor

connected between the R

T

pin and ground. The switching

frequency can range from 300kHz to 2MHz.

Overvoltage and undervoltage comparators will pull the

PGOOD output low if the output voltage comes out of

regulation by

Ī

10%. In an overvoltage condition, the top

power MOSFET is turned off and the bottom power MOSFET

is switched on until either the overvoltage condition clears

or the bottom MOSFET's current limit is reached.

Dropout Operation

When the input supply voltage decreases toward the

output voltage, the duty cycle increases toward the maxi-

mum on-time. Further reduction of the supply voltage

forces the main switch to remain on for more than one

cycle until it reaches 100% duty cycle. The output voltage

will then be determined by the input voltage minus the

voltage drop across the internal P-channel MOSFET and

the inductor.

Low Supply Operation

The LTC3413 is designed to operate down to an SV

IN

input

supply voltage of 2.25V. One important consideration at

low input supply voltages is that the R

DS(ON)

of the P-

channel and N-channel power switches increases. The

user should calculate the power dissipation when the

LTC3413 is used at 100% duty cycle with low input

voltages to ensure that thermal limits are not exceeded.

Slope Compensation and Inductor Peak Current

Slope compensation provides stability in constant fre-

quency architectures by preventing subharmonic oscilla-

tions at duty cycles greater than 50%. It is accomplished

internally by adding a compensating ramp to the inductor

current signal at duty cycles in excess of 40%. Normally,

the maximum inductor peak current is reduced when slope

compensation is added. In the LTC3413, however, slope

compensation recovery is implemented to keep the maxi-

mum inductor peak current constant throughout the range

of duty cycles.

Short-Circuit Protection

When the output is shorted to ground, the inductor current

decays very slowly during a single switching cycle. To

prevent current runaway from occurring, a secondary

current limit is imposed on the inductor current. If the

inductor valley current increases greater than 5A, the top

power MOSFET will be held off and switching cycles will be

skipped until the inductor current is reduced.

7

LTC3413

sn3413 3413fs

APPLICATIO S I FOR ATIO

W

U

U

U

The basic LTC3413 application circuit is shown in Figure

1a. External component selection is determined by the

maximum load current and begins with the selection of the

inductor value and operating frequency followed by C

IN

and C

OUT

.

Operating Frequency

Selection of the operating frequency is a tradeoff between

efficiency and component size. High frequency operation

allows the use of smaller inductor and capacitor values.

Operation at lower frequencies improves efficiency by

reducing internal gate charge losses but requires larger

inductance values and/or capacitance to maintain low

output ripple voltage.

The operating frequency of the LTC3413 is determined by

an external resistor that is connected between pin R

T

and

ground. The value of the resistor sets the ramp current that

is used to charge and discharge an internal timing capaci-

tor within the oscillator and can be calculated by using the

following equation.

R

f

k

OSC

=

( )

3 23 10

10

11

.

∑

≠

Although frequencies as high as 2MHz are possible, the

minimum on-time of the LTC3413 imposes a minimum

limit on the operating duty cycle. The minimum on-time is

typically 110ns. Therefore, the minimum duty cycle is

equal to 100 ∑ 110ns ∑ f (Hz).

Inductor Selection

For a given input and output voltage, the inductor value

and operating frequency determine the ripple current. The

ripple current

I

L

increases with higher V

IN

or V

OUT

and

decreases with higher inductance.

=

I

V

f

V

V

L

OUT

L

OUT

IN

1≠

Having a lower ripple current reduces the core losses in

the inductor, the ESR losses in the output capacitors and

the output voltage ripple. Highest efficiency operation is

achieved at low frequency with small ripple current. This,

however, requires a large inductor.

A reasonable starting point for selecting the ripple current

is

I

L

= 0.4(I

MAX

). The largest ripple current occurs at the

highest V

IN

. To guarantee that the ripple current stays

below a specified maximum, the inductor value should be

chosen according to the following equation:

L

V

f I

V

V

OUT

L MAX

OUT

IN MAX

=

(

)

(

)

≠

1

Inductor Core Selection

Once the value for L is known, the type of inductor must be

selected. Actual core loss is independent of core size for

a fixed inductor value, but it is very dependent on the

inductance selected. As the inductance increases, core

losses decrease. Unfortunately, increased inductance re-

quires more turns of wire and therefore copper losses will

increase.

Ferrite designs have very low core losses and are used

often at high switching frequencies, so design goals can

concentrate on copper loss and preventing saturation.

Ferrite core material saturates "hard," which means that

inductance collapses abruptly when the peak design cur-

rent is exceeded. This results in an abrupt increase in

inductor ripple current and consequent output voltage

ripple. Do not allow the core to saturate!

Different core materials and shapes will change the size/

current and price/current relationship of an inductor.

Toroid or shielded pot cores in ferrite or permalloy

materials are small and don't radiate much energy, but

generally cost more than powdered iron core inductors

with similar characteristics. The choice of which style

inductor to use mainly depends on the price versus size

requirements and any radiated field/EMI requirements.

8

LTC3413

sn3413 3413fs

APPLICATIO S I FOR ATIO

W

U

U

U

The output ripple is highest at maximum input voltage

since

I

L

increases with input voltage. Multiple capacitors

placed in parallel may be needed to meet the ESR and RMS

current handling requirements. Dry tantalum, special poly-

mer, aluminum electrolytic and ceramic capacitors are all

available in surface mount packages. Special polymer

capacitors offer very low ESR but have lower capacitance

density than other types. Tantalum capacitors have the

highest capacitance density but it is important to only use

types that have been surge tested for use in switching

power supplies.

Aluminum electrolytic capacitors have significantly higher

ESR, but can be used in cost-sensitive applications pro-

vided that consideration is given to ripple current ratings

and long term reliability. Ceramic capacitors have excel-

lent low ESR characteristics but can have a high voltage

coefficient and audible piezoelectric effects. The high Q of

ceramic capacitors with trace inductance can also lead to

significant ringing.

Using Ceramic Input and Output Capacitors

Higher values, lower cost ceramic capacitors are now

becoming available in smaller case sizes. Their high ripple

current, high voltage rating and low ESR make them ideal

for switching regulator applications. However, care must

be taken when these capacitors are used at the input and

output. When a ceramic capacitor is used at the input and

the power is supplied by a wall adapter through long wires,

a load step at the output can induce ringing at the input,

V

IN

. At best, this ringing can couple to the output and be

mistaken as loop instability. At worst, a sudden inrush of

current through the long wires can potentially cause a

voltage spike at V

IN

large enough to damage the part.

When choosing the input and output ceramic capacitors,

choose the X5R or X7R dielectric formulations. These

Table 1 shows some recommended surface mount

inductors for LTC3413 applications.

Table 1. Recommended Surface Mount Inductors

Value

DCR

Manufacturer

Part Number

(

Ķ

H)

(m

)

Murata

LQH55DNR47M01

0.47

13.0

Vishay/Dale

IHLP2525CZPJR47M01

0.47

4.2

Pulse

P1166.681T

0.44

6.0

Cooper

SD20-R47

0.47

20.0

C

IN

and C

OUT

Selection

The input capacitance, C

IN

, is needed to filter the trapezoi-

dal wave current at the source of the top MOSFET. To

prevent large voltage transients from occurring, a low ESR

input capacitor sized for the maximum RMS current

should be used. The maximum RMS current is given by:

I

I

V

V

V

V

RMS

OUT MAX

OUT

IN

IN

OUT

=

(

)

≠ 1

This formula has a maximum at V

IN

= 2V

OUT

, where I

RMS

= I

OUT

/2. This simple worst-case condition is commonly

used for design because even significant deviations do not

offer much relief. Note that ripple current ratings from

capacitor manufacturers are often based on only 2000

hours of life which makes it advisable to further derate the

capacitor, or choose a capacitor rated at a higher tempera-

ture than required. Several capacitors may also be paral-

leled to meet size or height requirements in the design.

The selection of C

OUT

is determined by the effective series

resistance (ESR) that is required to minimize voltage

ripple and load step transients as well as the amount of

bulk capacitance that is necessary to ensure that the

control loop is stable. Loop stability can be checked by

viewing the load transient response as described in a later

section. The output ripple,

V

OUT

, is determined by:

+

V

I ESR

fC

OUT

L

OUT

1

8

9

LTC3413

sn3413 3413fs

dielectrics have the best temperature and voltage charac-

teristics of all the ceramics for a given value and size.

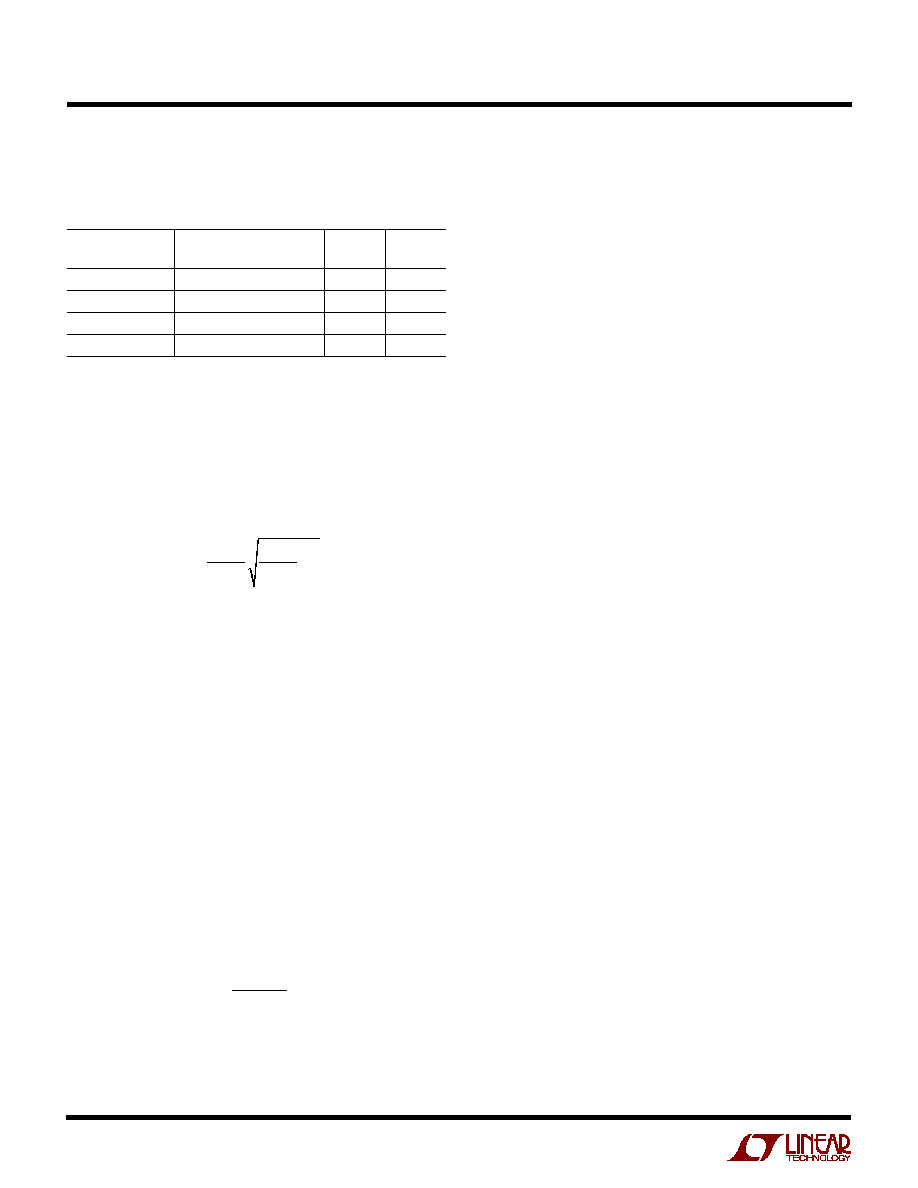

Output Voltage Programming

In most applications, V

OUT

is connected directly to V

FB

.

The output voltage will be equal to one-half of the voltage

on the V

REF

pin for this case.

V

V

OUT

REF

=

2

If a different output voltage relationship is desired, an

external resistor divider from V

OUT

to V

FB

can be used. The

output voltage will then be set according to the following

equation:

pulled above 2V. The full current range becomes available

on I

TH

after 1024 switching cycles. If a longer soft-start

period is desired, the clamp on I

TH

can be set externally

with a resistor and capacitor on the RUN/SS pin as shown

in Figure 1a. The soft-start duration can be calculated by

using the following formula:

t

R

V

V

SS

SS

IN

=

∑ C

ln

V

(Seconds)

SS

IN

≠ .

1 8

Efficiency Considerations

The efficiency of a switching regulator is equal to the

output power divided by the input power times 100%. It is

often useful to analyze individual losses to determine what

is limiting the efficiency and which change would produce

the most improvement. Efficiency can be expressed as:

Efficiency = 100% - (L1 + L2 + L3 + ...)

where L1, L2, etc. are the individual losses as a percentage

of input power.

Although all dissipative elements in the circuit produce

losses, two main sources usually account for most of the

losses: V

IN

quiescent current and I

2

R losses.

The V

IN

quiescent current loss dominates the efficiency

loss at very low load currents whereas the I

2

R loss

dominates the efficiency loss at medium to high load

currents. In a typical efficiency plot, the efficiency curve at

very low load currents can be misleading since the actual

power lost is of no consequence.

1. The V

IN

quiescent current is due to two components:

the DC bias current as given in the Electrical Characteris-

tics and the internal main switch and synchronous switch

gate charge currents. The gate charge current results from

switching the gate capacitance of the internal power

MOSFET switches. Each time the gate is switched from

APPLICATIO S I FOR ATIO

W

U

U

U

R2

V

OUT

R1

3413 F02

V

FB

SGND

LTC3413

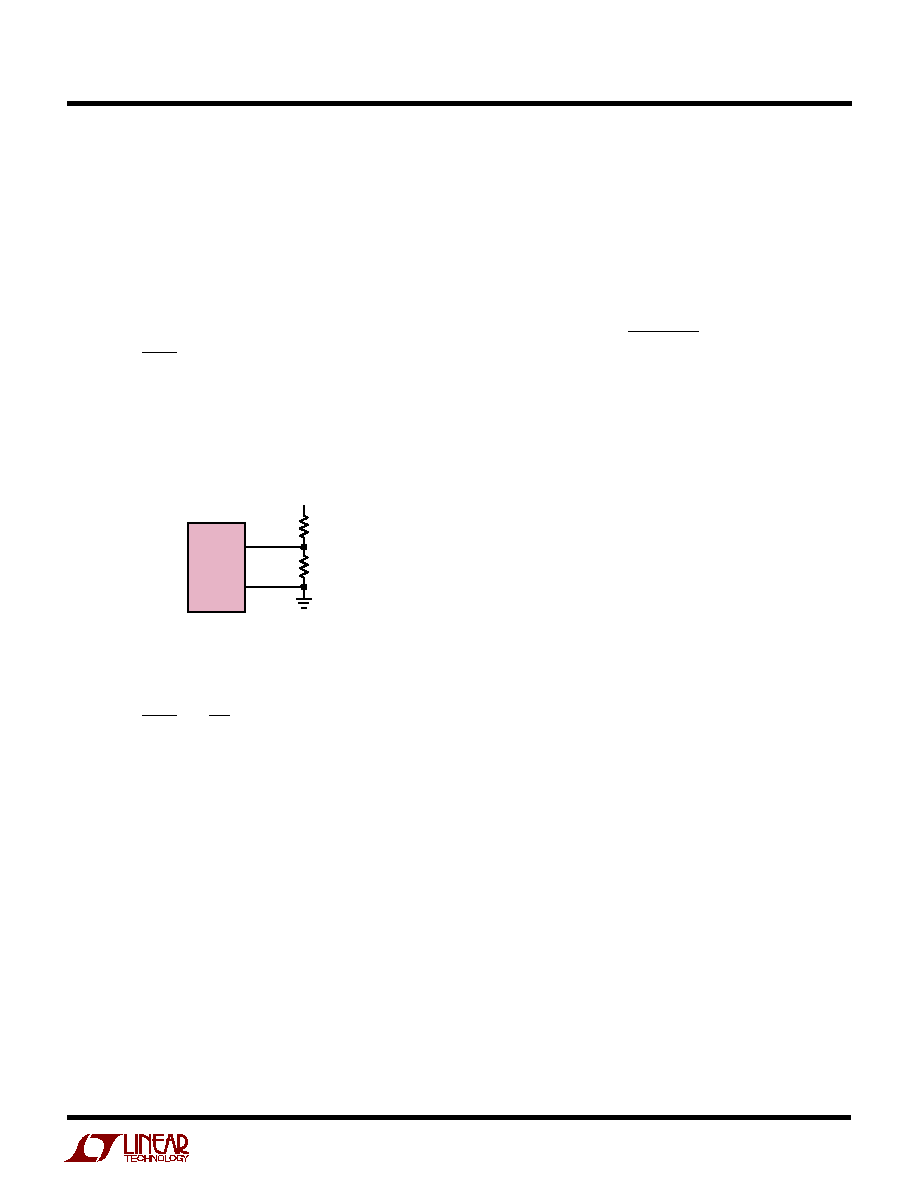

Figure 2. Setting the Output Voltage

V

V

R

R

OUT

REF

=

+

2

1

2

1

Soft-Start

The RUN/SS pin provides a means to shut down the

LTC3413 as well as a timer for soft-start. Pulling the

RUN/SS pin below 0.5V places the LTC3413 in a low

quiescent current shutdown state (I

Q

< 1

Ķ

A).

The LTC3413 contains an internal soft-start clamp that

gradually raises the clamp on I

TH

after the RUN/SS pin is

10

LTC3413

sn3413 3413fs

high to low to high again, a packet of charge dQ moves

from V

IN

to ground. The resulting dQ/dt is the current out

of V

IN

that is typically larger than the DC bias current. In

continuous mode, I

GATECHG

= f(Q

T

+ Q

B

) where Q

T

and Q

B

are the gate charges of the internal top and bottom

switches. Both the DC bias and gate charge losses are

proportional to V

IN

and thus their effects will be more

pronounced at higher supply voltages.

2. I

2

R losses are calculated from the resistances of the

internal switches, R

SW

, and external inductor R

L

. In con-

tinuous mode the average output current flowing through

inductor L is "chopped" between the main switch and the

synchronous switch. Thus, the series resistance looking

into the SW pin is a function of both top and bottom

MOSFET R

DS(ON)

and the duty cycle (DC) as follows:

R

SW

= (R

DS(ON)TOP

)(DC) + (R

DS(ON)BOT

)(1 ≠ DC)

The R

DS(ON)

for both the top and bottom MOSFETs can be

obtained from the Typical Performance Characteristics

curves. Thus, to obtain I

2

R losses, simply add R

SW

to R

L

and multiply the result by the square of the average output

current.

Other losses including C

IN

and C

OUT

ESR dissipative

losses and inductor core losses generally account for less

than 2% of the total loss.

Thermal Considerations

In most applications, the LTC3413 does not dissipate

much heat due to its high efficiency.

But, in applications where the LTC3413 is running at high

ambient temperature with low supply voltage and high

duty cycles, such as in dropout, the heat dissipated may

exceed the maximum junction temperature of the part. If

the junction temperature reaches approximately 150

į

C,

both power switches will be turned off and the SW node

will become high impedance.

To avoid the LTC3413 from exceeding the maximum

junction temperature, the user will need to do some

thermal analysis. The goal of the thermal analysis is to

determine whether the power dissipated exceeds the

maximum junction temperature of the part. The tempera-

ture rise is given by:

T

R

= (P

D

)(

JA

)

where P

D

is the power dissipated by the regulator and

JA

is the thermal resistance from the junction of the die to the

ambient temperature.

The junction temperature, T

J

, is given by:

T

J

= T

A

+ T

R

where T

A

is the ambient temperature.

As an example, consider the LTC3413 in dropout at an

input voltage of 3.3V, a load current of 3A and an ambient

temperature of 70

į

C. From the Typical Performance graph

of switch resistance, the R

DS(ON)

of the P-channel switch

at 70

į

C is approximately 97m

. Therefore, power dissi-

pated by the part is:

P

D

= (I

LOAD

2

)(R

DS(ON)

) = (3A)

2

(97m

) = 0.87W

For the TSSOP package, the

JA

is 38

į

C/W. Thus the

junction temperature of the regulator is:

T

J

= 70

į

C + (0.87W)(38

į

C/W) = 103

į

C

which is below the maximum junction temperature of

APPLICATIO S I FOR ATIO

W

U

U

U

11

LTC3413

sn3413 3413fs

APPLICATIO S I FOR ATIO

W

U

U

U

125

į

C.

Note that at higher supply voltages, the junction tempera-

ture is lower due to reduced switch resistance (R

DS(ON)

).

Checking Transient Response

The regulator loop response can be checked by looking at

the load transient response. Switching regulators take

several cycles to respond to a step in load current. When

a load step occurs, V

OUT

immediately shifts by an amount

equal to

I

LOAD

(ESR), where ESR is the effective series

resistance of C

OUT

.

I

LOAD

also begins to charge or

discharge C

OUT

generating a feedback error signal used by

the regulator to return V

OUT

to its steady-state value.

During this recovery time, V

OUT

can be monitored for

overshoot or ringing that would indicate a stability prob-

lem. The I

TH

pin external components and output capaci-

tor shown in Figure 1a will provide adequate compensa-

tion for most applications.

Output Voltage Tracking of V

REF

For applications in which the V

REF

pin is connected to the

V

IN

pin, the output voltage will be equal to one-half of the

voltage on the V

IN

pin. Because the output voltage will

track the input voltage, any disturbance on V

IN

will appear

on V

OUT

. For example, a load step transient could cause

the input voltage to drop if there is insufficient bulk

capacitance at the V

IN

pin. The corresponding drop in the

output voltage during the load step transient is caused by

the V

OUT

tracking of V

IN

and should not be confused with

poor load regulation.

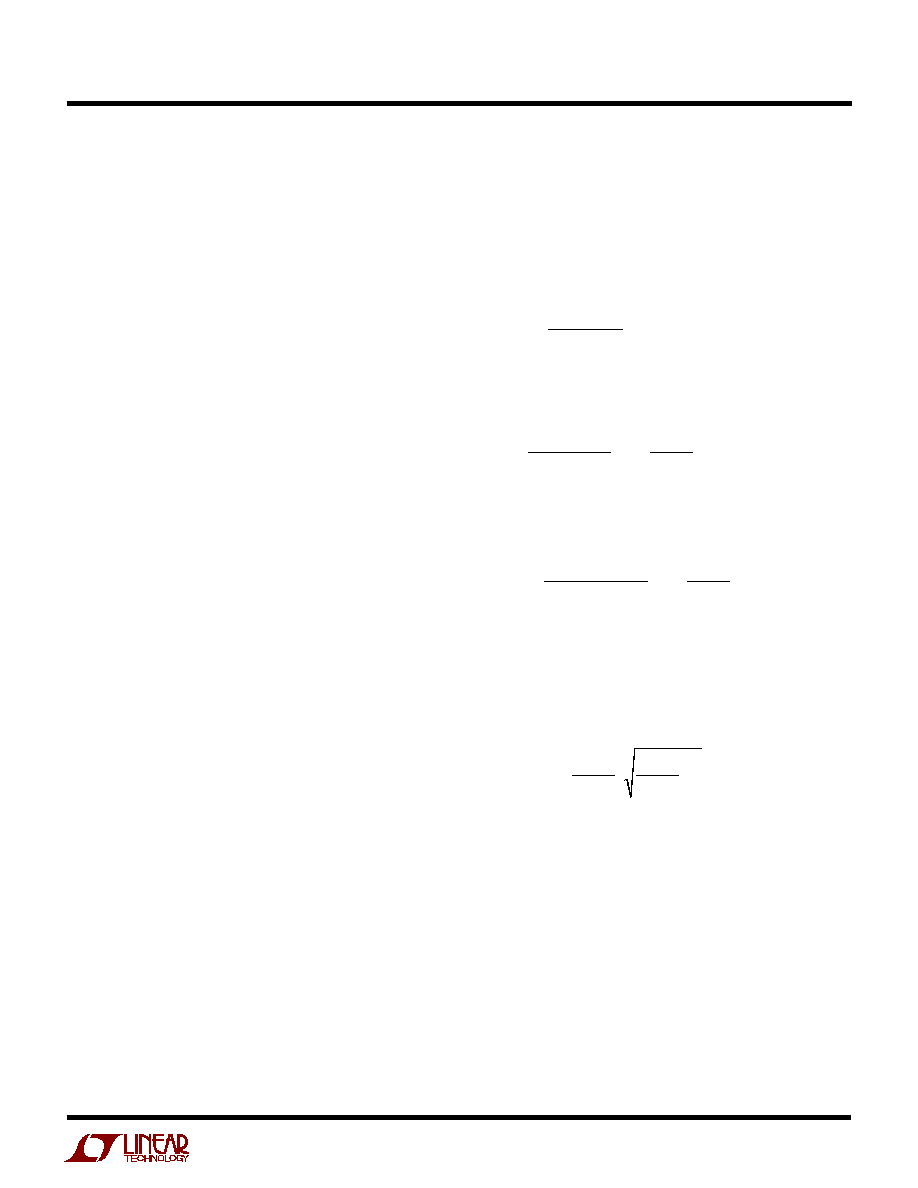

Design Example

As a design example, consider using the LTC3413 in an

application with the following specifications: V

IN

= 2.5V,

V

OUT

= 1.25V, I

OUT(MAX)

=

Ī

3A, f = 1MHz.

First, calculate the timing resistor:

R

k

k

OSC

=

=

3 23 10

1 10

10

313

11

6

.

∑

∑

≠

Use a standard value of 309k. Next, calculate the inductor

value for about 40% ripple current:

L

V

MHz

A

V

V

H

=

=

Ķ

1 25

1

1 2

1

1 25

2 5

0 47

.

∑ .

≠

.

.

.

Using a 0.47

Ķ

H inductor results in a maximum ripple

current of:

=

Ķ

=

I

V

MHz

H

V

V

A

L

1 25

1

0 47

1

1 25

2 5

1 33

.

∑ .

≠

.

.

.

C

OUT

will be selected based on the ESR that is required to

satisfy the output voltage ripple requirement and the bulk

capacitance needed for loop stability. For this design, two

100

Ķ

F ceramic capacitors will be used. C

IN

should be sized

for a maximum current rating of:

I

A

V

V

V

V

A

RMS

RMS

=

=

3

1 25

2 5

2 5

1 25

1 1 5

.

.

.

.

≠

.

Decoupling the PV

IN

pins with two 100

Ķ

F capacitors is

12

LTC3413

sn3413 3413fs

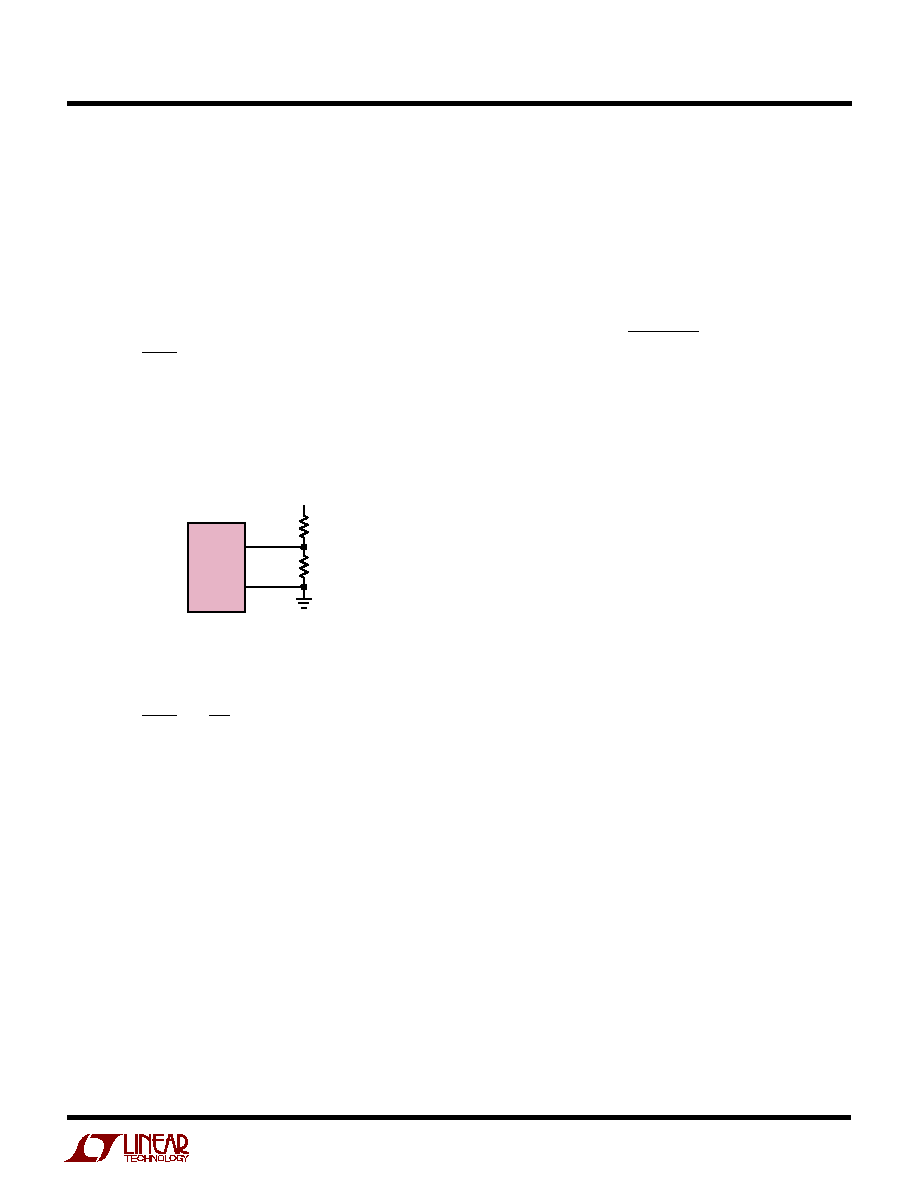

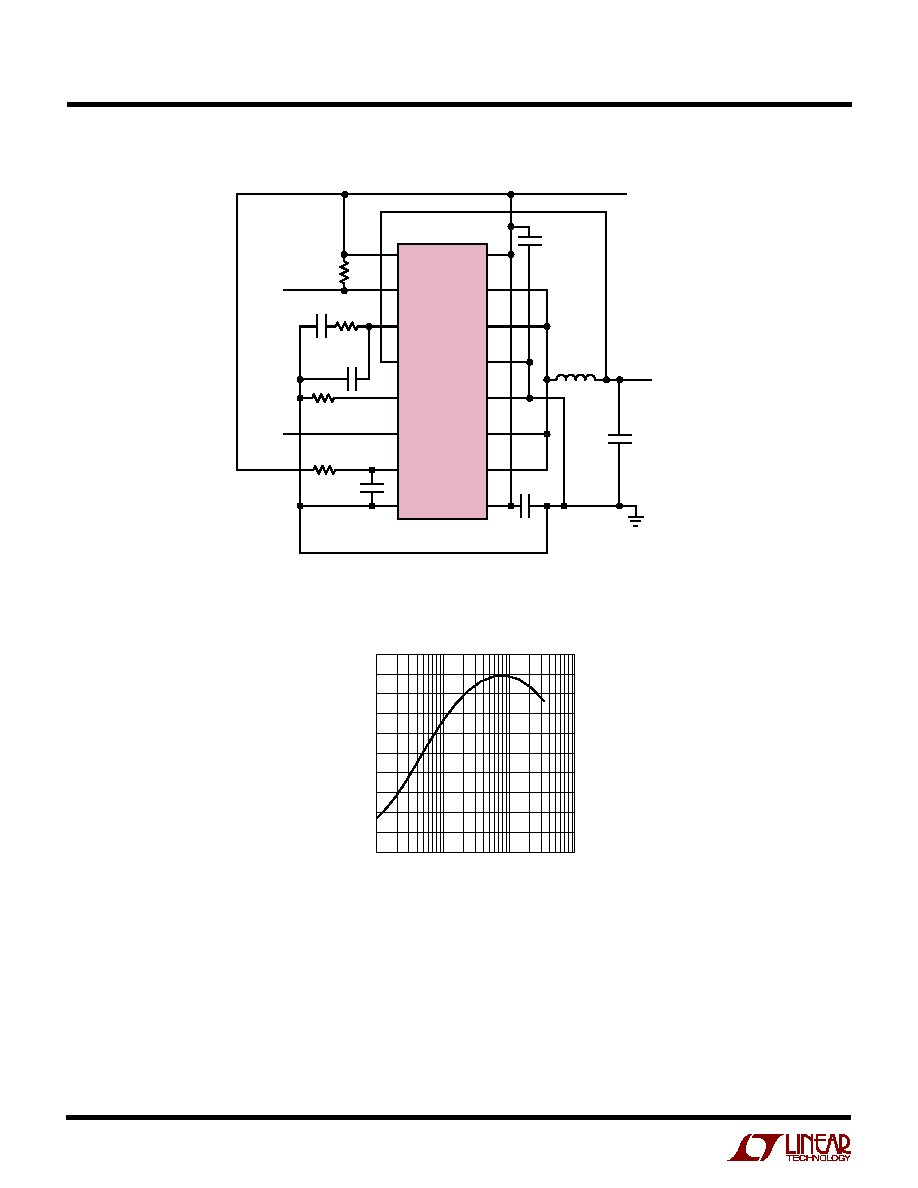

Figure 3. One-Half V

REF

,

Ī

3A DDR Memory Termination Supply at 1MHz

(Efficiency Curve is Shown in Figure 1b)

R

PG

100k

R

ITH

5.11k

R

OSC

309k

*VISHAY DALE IHLP-2525CZ-01 0.47

Ķ

H

**TDK C4532X5R0J107M

R

SS

4.7M

C

SS

330pF X7R

C

ITH

2200pF

X7R

C

C

100pF

PGOOD

SV

IN

PGOOD

I

TH

V

FB

R

T

V

REF

RUN/SS

SGND

PV

IN

SW

SWV

FB

PGND

PGND

SW

SW

PV

IN

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

LTC3413

L1*

0.47

Ķ

H

C

IN1

**

100

Ķ

F

C

IN2

**

100

Ķ

F

C

OUT

**

100

Ķ

F

◊

2

GND

3413 F03

V

OUT

1.25V

Ī

3A

V

IN

2.5V

adequate for most applications. Connect the V

REF

pin

directly to SV

IN

. Connecting the V

FB

pin directly to V

OUT

will set the output voltage equal to one-half of the voltage

on the V

REF

pin. The complete circuit for this design

example is illustrated in Figure 3.

PC Board Layout Checklist

When laying out the printed circuit board, the following

checklist should be used to ensure proper operation of the

LTC3413. Check the following in your layout.

1. A ground plane is recommended. If a ground plane layer

is not used, the signal and power grounds should be

segregated with all small-signal components returning to

the SGND pin at one point which is then connected to the

PGND pin close to the LTC3413.

2. Connect the (+) terminal of the input capacitor(s), C

IN

,

as close as possible to the PV

IN

pin. This capacitor

provides the AC current into the internal power MOSFETs.

3. Keep the switching node, SW, away from all sensitive

small-signal nodes.

4. Flood all unused areas on all layers with copper. Flood-

ing with copper will reduce the temperature rise of power

components. You can connect the copper areas to any DC

net (PV

IN

, SV

IN

, V

OUT

, PGND, SGND or any other DC rail in

your system).

5. Connect the V

FB

pin directly to the V

OUT

pin.

APPLICATIO S I FOR ATIO

W

U

U

U

13

LTC3413

sn3413 3413fs

Figure 4. LTC3413 Layout Diagram

APPLICATIO S I FOR ATIO

W

U

U

U

(4c) PCB Photo

(4a) Top Layer

(4b) Bottom Layer

14

LTC3413

sn3413 3413fs

TYPICAL APPLICATIO

U

1.25V,

Ī

3A DDR Memory Termination Supply at 1MHz

R

PG

100k

R

ITH

5.11k

R

OSC

309k

*VISHAY DALE IHLP-2525CZ-01 0.47

Ķ

H

**TDK C4532X5R0J107M

R

SS

4.7M

C

SS

330pF X7R

C

ITH

2200pF

X7R

C

C

100pF

PGOOD

2.5V

SV

IN

PGOOD

I

TH

V

FB

R

T

V

REF

RUN/SS

SGND

PV

IN

SW

SWV

FB

PGND

PGND

SW

SW

PV

IN

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

LTC3413

L1*

0.47

Ķ

H

C

IN1

**

100

Ķ

F

C

IN2

**

100

Ķ

F

C

OUT

**

100

Ķ

F

◊

2

GND

3413 TA01

V

OUT

1.25V

Ī

3A

V

IN

3.3V

LOAD CURRENT (A)

0.01

EFFICIENCY (%)

100

90

80

70

60

50

40

30

20

10

0

0.1

1

10

3413 TA01b

Efficiency vs Load Current,

V

IN

= 3.3V, V

OUT

= 1.25V, f = 1MHz

15

LTC3413

sn3413 3413fs

U

PACKAGE DESCRIPTIO

FE Package

16-Lead Plastic TSSOP (4.4mm)

(Reference LTC DWG # 05-08-1663,

Exposed Pad Variation BA)

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no represen-

tation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

FE16 (BA) TSSOP 0203

0.09 ≠ 0.20

(.0036 ≠ .0079)

0

į

≠ 8

į

0.45 ≠ 0.75

(.018 ≠ .030)

4.30 ≠ 4.50*

(.169 ≠ .177)

6.40

BSC

1

3

4

5

6 7 8

10

9

4.90 ≠ 5.10*

(.193 ≠ .201)

16 1514 13 12 11

1.10

(.0433)

MAX

0.05 ≠ 0.15

(.002 ≠ .006)

0.65

(.0256)

BSC

2.74

(.108)

2.74

(.108)

0.195 ≠ 0.30

(.0077 ≠ .0118)

2

MILLIMETERS

(INCHES)

*DIMENSIONS DO NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.150mm (.006") PER SIDE

NOTE:

1. CONTROLLING DIMENSION: MILLIMETERS

2. DIMENSIONS ARE IN

RECOMMENDED SOLDER PAD LAYOUT

3. DRAWING NOT TO SCALE

0.45

Ī

0.05

0.65 BSC

4.50

Ī

0.10

6.60

Ī

0.10

1.05

Ī

0.10

2.74

(.108)

2.74

(.108)

SEE NOTE 4

4. RECOMMENDED MINIMUM PCB METAL SIZE

FOR EXPOSED PAD ATTACHMENT

16

LTC3413

sn3413 3413fs

LT/TP 0703 1K ∑ PRINTED IN USA

©

LINEAR TECHNOLOGY CORPORATION 2002

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

q

FAX: (408) 434-0507

q

www.linear.com

RELATED PARTS

PART NUMBER

DESCRIPTION

COMMENTS

LTC3406

600mA, (I

OUT

) 1.5MHz Synchronous Step-Down Regulator

V

IN

: 2.5V to 5.5V, V

OUT(MIN)

: 0.6V, I

Q

: 20

Ķ

A, ThinSOT

LTC3407

Dual 600mA, (I

OUT

) 1.5MHz, Synchronous Step-Down Regulator

V

IN

: 2.5V to 5.5V, V

OUT(MIN)

: 0.6V, I

Q

: 40

Ķ

A, MS10E

LTC3411

1.25A, (I

OUT

) 4MHz, Monolithic Synchronous Step-Down Regulator

V

IN

: 2.5V to 5.5V, V

OUT(MIN)

: 0.8V, I

Q

: 60

Ķ

A, MS, DFN-10

LTC3412

2.5A, (I

OUT

) 4MHz, Monolithic Synchronous Step-Down Regulator

V

IN

: 2.5V to 5.5V, V

OUT(MIN)

: 0.8V, I

Q

: 60

Ķ

A, TSSOP-16

LTC3414

4A, (I

OUT

) 4MHz, Monolithic Synchronous Step-Down Regulator

V

IN

: 2.25V to 5.5V, V

OUT(MIN)

: 0.8V, I

Q

: 64

Ķ

A, TSSOP-20E

LTC3713

Low Input Voltage, No R

SENSE

TM

Synchronous Controller

V

IN

: 1.5V to 10V, V

OUT(MIN)

: 0.8V, SSOP-24

LTC3717

No R

SENSE

Controller for DDR Memory Termination

V

IN

: 5V to 36V, V

OUT(MIN)

: 0.8V, SSOP-24

LTC3718

Low Input Voltage, No R

SENSE

Controller for DDR Memory Termination

V

IN

: 1.5V to 10V,V

OUT(MIN)

: 0.8V, SSOP-24

No R

SENSE

is a trademark of Linear Technology Corporation.

3.3V to 0.75V,

Ī

3A HSTL Application

R

PG

100k

R

ITH

10k

R

OSC

309k

*VISHAY DALE IHLP-2525CZ-01 0.47

Ķ

H

**TDK C4532X5R0J107M

TAIYO YUDEN JMK325BJ226MM

SANYO POSCAP 4TPD470M

R

SS

4.7M

C

SS

330pF X7R

C

ITH

2200pF

X7R

C

C

100pF

PGOOD

1.5V

SV

IN

PGOOD

I

TH

V

FB

R

T

V

REF

RUN/SS

SGND

PV

IN

SW

SWV

FB

PGND

PGND

SW

SW

PV

IN

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

LTC3413

L1*

0.47

Ķ

H

C

IN1

**

100

Ķ

F

C

IN2

**

100

Ķ

F

C

OUT1

22

Ķ

F

C

OUT2

470

Ķ

F

GND

3413 TA02

V

OUT

0.75V

Ī

3A

V

IN

3.3V

+

TYPICAL APPLICATIO

U