Series Number

3003 9th Avenue SW

DU6629

PO Box 50

DU1330

Watertown, SD 57201

DU1352

Toll free: 888-978-2638

DU1311

Ph: 605-886-3326

DU1971

Fax: 605-886-8995

SMD Unshielded Power Inductor Series; Part Numbering Sequence: ( Series Number ) - ( Suffix Code )(Tolerance), example DU1330-220M

Bulk Packaging add (-B) to end of Part Numbering Sequence. example DU1330-220M-B

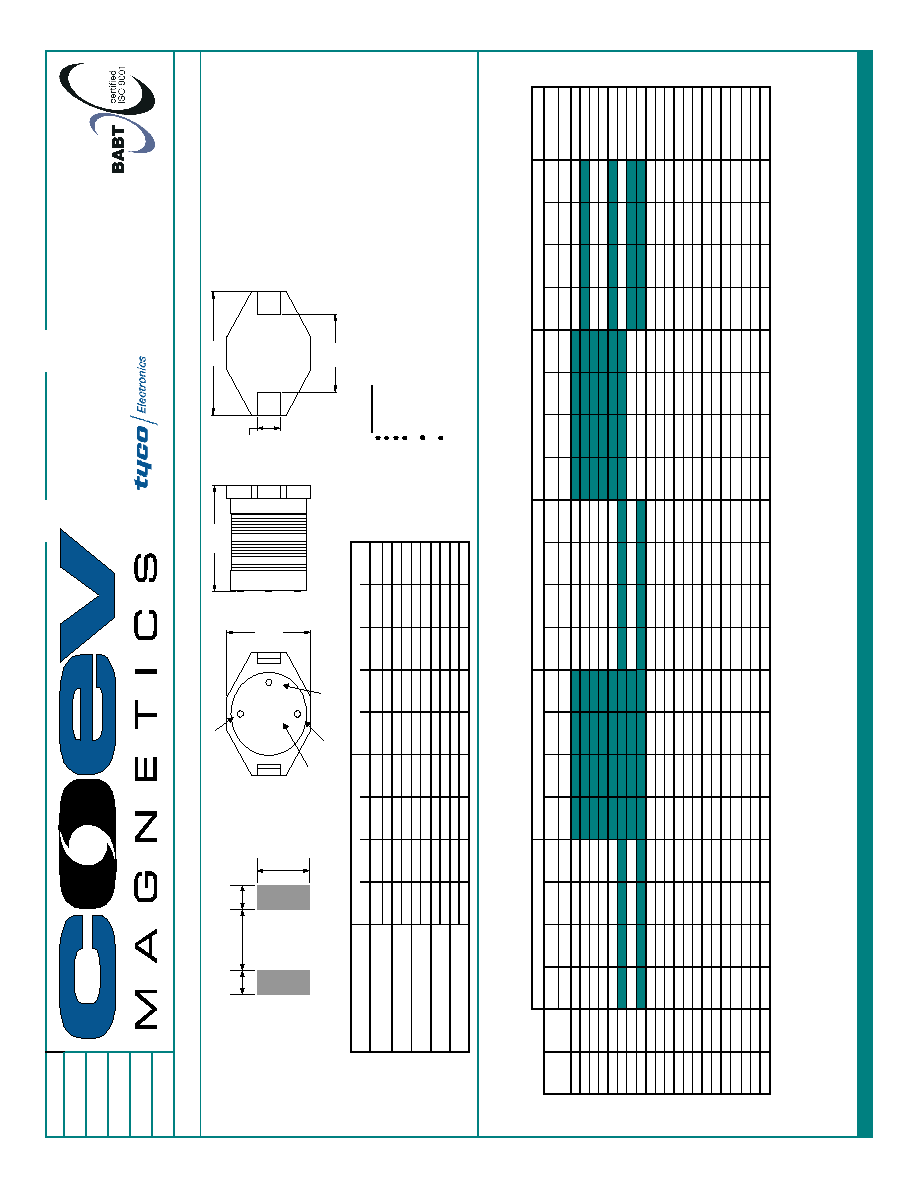

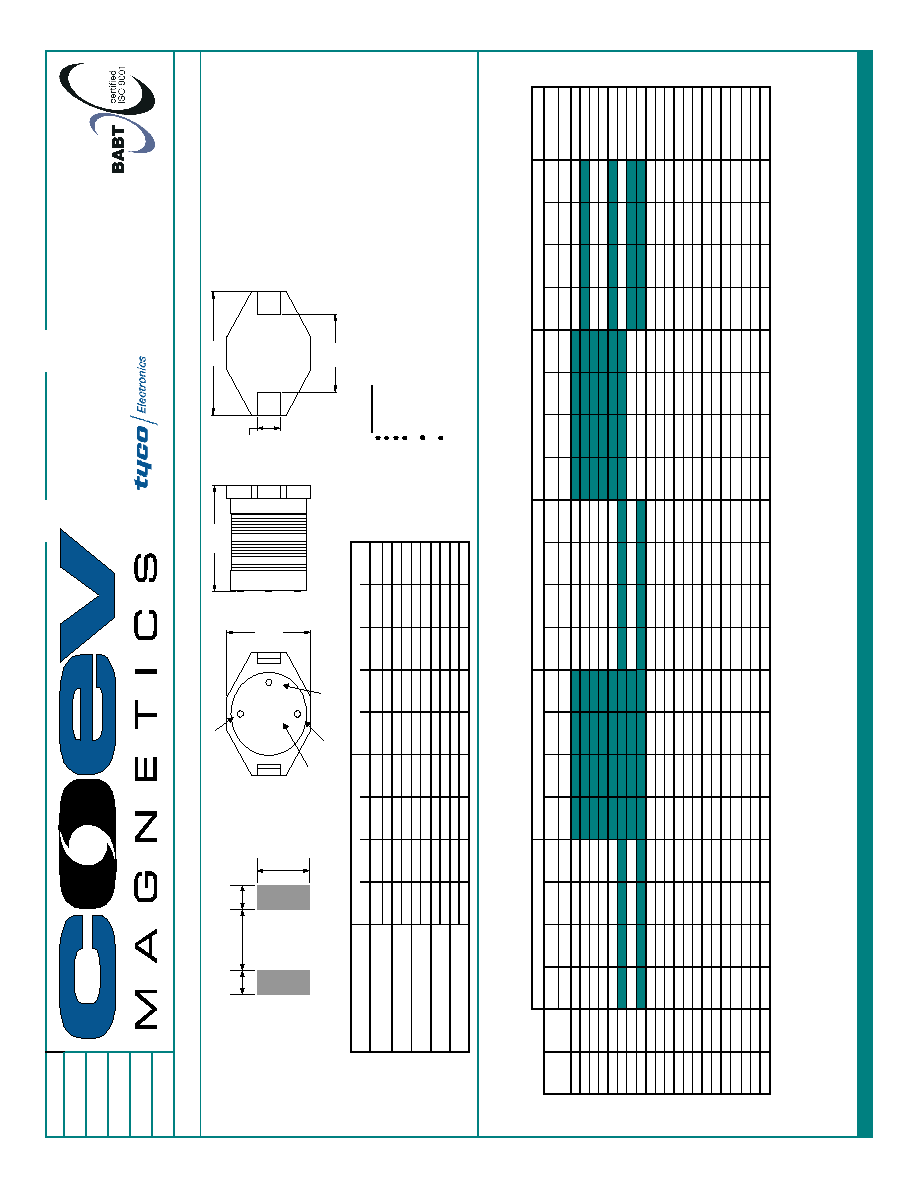

Series

Number

Units

L

W

H

Y

Z

A

B

C

inches

0.260"

0.177"

0.115"

0.190"

0.050"

0.140"

0.055"

0.160"

[ mm ]

[ 6.60 ]

[ 4.50 ]

[ 2.92 ]

[ 4.83 ]

[ 1.27 ]

[ 3.56 ]

[ 1.40 ]

[ 4.06 ]

inches

0.510"

0.370"

0.130"

0.300"

0.100"

0.110"

0.115"

0.290"

[ mm ]

[ 12.95 ]

[ 9.40 ]

[ 3.30 ]

[ 7.62 ]

[ 2.54 ]

[ 2.79 ]

[ 2.92 ]

[ 7.37 ]

inches

0.510"

0.370"

0.205"

0.300"

0.100"

0.110"

0.115"

0.290"

[ mm ]

[ 12.95 ]

[ 9.40 ]

[ 5.21 ]

[ 7.62 ]

[ 2.54 ]

[ 2.79 ]

[ 2.92 ]

[ 7.37 ]

inches

0.510"

0.370"

0.450"

0.300"

0.100"

0.110"

0.115"

0.290"

[ mm ]

[ 12.95 ]

[ 9.40 ]

[ 11.43 ]

[ 7.62 ]

[ 2.54 ]

[ 2.79 ]

[ 2.92 ]

[ 7.37 ]

inches

0.730"

0.600"

0.291"

0.500"

0.100"

0.110"

0.115"

0.490"

[ mm ]

[ 18.54 ]

[ 15.24 ]

[ 7.40 ]

[ 12.70 ]

[ 2.54 ]

[ 2.79 ]

[ 2.92 ]

[ 12.45 ]

DU6629

DU1330

DU1352

DU1311

DU1971

L

1

Suffix

DCR

2

I

SAT

3

I

RMS

5

Tolerance

DCR

2

I

SAT

3

I

RMS

5

Tolerance

DCR

2

I

SAT

3

I

RMS

6

Tolerance

DCR

2

I

SAT

3

I

RMS

7

Tolerance

DCR

2

I

SAT

3

I

RMS

7

Tolerance

µH

Codes

A

A

Suffix

4

A

A

Suffix

4

A

A

Suffix

4

A

A

Suffix

4

A

A

Suffix

4

1.0

1R0

0.050

2.90

2.90

M

0.0092

9.00

6.80

M

0.009

20.00

8.60

M

1.5

1R5

0.050

2.60

2.80

M

0.0104

8.00

6.40

M

BRN GRN RED

2.2

2R2

0.070

2.30

2.40

M

0.0120

7.00

6.10

M

0.014

16.00

7.10

M

RED RED RED

3.3

3R3

0.080

2.00

2.00

M

0.0150

6.40

5.40

M

0.018

14.00

6.20

M

ORG ORG RED

4.7

4R7

0.090

1.50

1.50

M

0.0184

5.40

4.80

M

YEL VIO RED

5.6

5R6

0.020

12.00

5.30

M

GRN BLU RED

6.8

6R8

0.130

1.20

1.40

M

0.0270

4.60

4.40

M

0.015

10.00

5.00

M

BLU GRY RED

8.0

8R0

0.022

9.50

4.00

M

GRY BLK RED

10

100

0.160

1.10

1.30

M

0.110

2.40

2.00

M

0.0380

3.80

3.90

M

0.040

8.00

3.50

M

0.031

10.00

4.30

M

BRN BLK ORG

15

150

0.230

0.90

1.20

M

0.150

2.00

1.50

M

0.0460

3.00

3.10

M

0.050

7.00

3.00

M

0.036

8.00

4.00

M

BRN GRN ORG

22

220

0.370

0.70

0.80

M

0.230

1.60

1.30

M

0.0850

2.60

2.70

M

0.070

5.50

2.50

M

0.047

7.00

3.50

M

RED RED ORG

33

330

0.510

0.58

0.60

M

0.300

1.40

1.10

M

0.1012

2.00

2.10

M

0.080

4.00

2.00

M

0.066

5.50

3.00

M

ORG ORG ORG

47

470

0.640

0.50

0.50

M

0.390

1.00

0.80

M

0.1400

1.60

1.80

M

0.110

3.80

1.60

M

0.086

4.50

2.60

M

YEL VIO ORG

68

680

0.860

0.40

0.40

M

0.660

0.90

0.70

M

0.2000

1.40

1.50

M

0.170

3.00

1.20

M

0.130

3.50

2.30

M

BLU GRY ORG

100

101

1.270

0.31

0.30

M

0.840

0.70

0.60

M

0.2800

1.20

1.30

M

0.220

2.50

1.20

M

0.190

3.00

1.80

M

BRN BLK YEL

150

151

2.000

0.27

0.25

M

1.200

0.60

0.50

M

0.4000

1.00

1.00

M

0.340

2.00

0.90

M

0.250

2.60

1.50

M

BRN GRN YEL

220

221

3.110

0.22

0.20

M

1.900

0.50

0.40

M

0.6100

0.80

0.80

M

0.440

1.60

0.70

M

0.380

2.40

1.20

M

RED RED YEL

330

331

4.800

0.18

0.16

M

2.700

0.40

0.30

M

1.0200

0.60

0.60

M

0.700

1.20

0.60

M

0.560

1.90

1.00

M

ORG ORG YEL

470

471

6.600

0.16

0.15

M

4.000

0.30

0.20

M

1.2700

0.50

0.50

M

0.950

1.00

0.30

M

0.850

1.40

0.82

M

YEL VIO YEL

680

681

9.200

0.10

0.12

M

5.300

0.20

0.10

M

2.0200

0.40

0.40

M

1.200

1.00

0.20

M

1.100

1.20

0.72

M

BLU GRY YEL

1000

102

13.800

0.10

0.07

M

8.400

0.10

0.05

M

3.0000

0.30

0.30

M

2.000

0.80

0.10

M

1.800

1.00

0.56

M

BRN BLK GRN

1) Tested at 100kHz, 100mVrms @20∞C

6) Current applied to produce a typical 15∞C temperature rise from nominal inductance.

2) DCRs (DC resistances) are maximums @20∞C.

7) Current applied to produce a typical 40∞C temperature rise from nominal inductance.

3) DC (Direct Current) current applied to produce a typical 10% drop in inductance.

4) Suffix of M=20%

5) Current applied to produce a typical 30∞C temperature rise from nominal inductance.

Call Toll Free: 888-978-2638 Website: www.tycopowercomponents.com

Maximum Dimensions

Nominal Dimensions

DU6629

DU1330

Dot Code

1st 2nd 3rd

BRN BLK RED

DU1352

DU1311

DU1971

Significant Digit

H

Y

W

L

Z

Suffix Code

XXX

1st significant digit

3rd significant digit

2nd significant digit

Parts will be marked with Significant Digit Dots OR Suffix code

B

A

C

B

Suggested Land Pattern

Features:

High enerty storage and low resistance

Ideal for DC-DC step-up or step-down conversion

Reliable surface mounting, flat top for pick and place

Robust temperature deflection to provent damage

during solder reflow

Drop in replacements for industry prevalent

competitor series

Operating temperature -40∞C to +85∞C

Specifications subject to change without notice.

Item

Specification

Test Method/Condition

Environmental

Static Humidity

After exposure part remains within

specified electrical parameters for

L, Q and DCR.

Storage Life

After exposure part remains within

specified electrical parameters for

L, Q and DCR.

Moisture Resistance

After exposure, part shall not

Per MIL-STD 202 Method 106, ten 24 hour cycles at +25∞C to

have a shorted or open winding.

+65∞C at 80 to 95% R.H. During any of the first 9 cycles, inductors

are revolved from the chamber and exposed to -10∞C for 3 hours.

Allow parts to dry for 2 hours before measurements are taken.

Temperature Cycle

After exposure part remains

10 cycles (Air to Air) 1 cycle shall consist of:

within specified electrical

30 minutes exposure to +85∞C

parameters for L, Q and DCR.

30 minutes exposure to -40∞C

Allow 20 minutes transition between extremes.

Temperature Shock

After exposure part remains

10 cycles (Air to Air) 1 cycle shall consist of:

within specified electrical

30 minutes exposure to -45∞C

parameters for L, Q and DCR.

30 minutes exposure to +125∞C

15 seconds maximum transition between temperatures

General

Storage Temperature

Range

-40∞C to +85∞C

Operating Temperature

Range

-40∞C to +85∞C

Flammability

IEC 695-2-2

Withstands needle-flame test

Other

Vibration

After exposure part remains

Inductors shall be randomly vibrated per NAVMAT P9492

within specified electrical

profile. Samples shall be subjected to 0.04G/Hz for a

parameters for L, Q and DCR.

minimum of 15 minutes per axis, for each of the three axes.

Mechanical Shock

After exposure part remains

Test per MIL-STD 202 method 213 test condition A, test

within specified electrical

mounted samples 3 axes, 6 times, totaling 18 shocks.

parameters for L, Q and DCR.

(50Gs, 11ms, half-sine).

Solderability

Wetting shall cover 90% minimum

of each termination

Component Adhesion

(Push Test)

4 pounds

Apply and measure force with a digital force gauge set.

Resistance to Solvent

No sign of degradation in

Withstands 6 minutes of alcohol.

appearance or marking detail.

Withstands 3 minutes forced spray Freon TMS

Load Life

After exposure, part shall not

Parts to be stored at 110∞C for 1000 hours with rated current

have a shorted or open winding.

applied. Parts to be tested at: start, 500 and 1000 hours. Allow

2 hours at room temperature before testing.

Series

Revision

Sheet 3 of 3

Subject parts to an environment of +50∞C 90 to 100% R.H. for 46 to 50

hours. After exposure, allow parts to dry for 2 hours before measurements

are taken.

Expose parts to an environment of +50∞C with 90 to 95% R.H. for 100

hours. After exposure, allow parts to dry for 2 hours before measurements

are taken.

DU SERIES

C

For Print Distribution to Customers

Dip pads in RMA flux, 63/37 solder (Sn/Pb) at 232∞C for 5 seconds ±2

seconds.