General Description

The MAX3867 evaluation kit (EV kit) is an assembled

demonstration board that provides optical or electrical

evaluation of the MAX3867.

The EV kit is composed of two independent sections on

the PC board. The output of the electrical evaluation

section is interfaced to an SMA connector, which can

be connected to a 50

terminated oscilloscope. The

output of the optical evaluation section is configured for

attachment to a laser/monitor diode.

Features

o Fully Assembled and Tested

o +3.3V to +5.0V Operation

o Input Termination Provided On-Board

Evaluates: MAX3867

MAX3867 Evaluation Kit

________________________________________________________________ Maxim Integrated Products

1

19-1420; Rev 1; 6/00

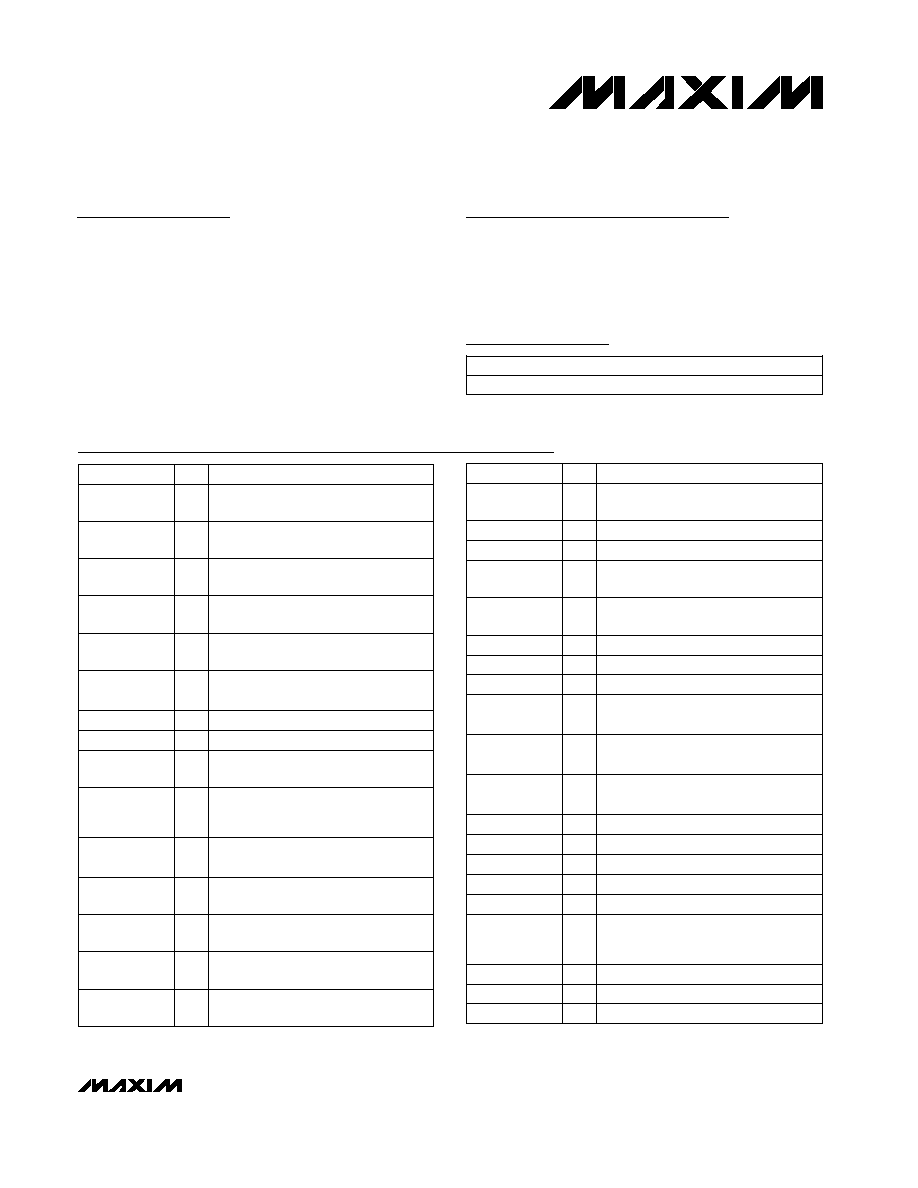

Electrical Component List

PART

MAX3867EVKIT

-40∞C to +85∞C

TEMP. RANGE

IC PACKAGE

48 TQFP

Ordering Information

1k

ferrite beads (0805)

Murata BLM21A102S

2

L7, L13

2-pin headers (0.1in center)

Digi-Key S1012-36-ND

2

JU4, JU5

Shunts

Digi-Key S9000-ND

2

JU4, JU5

SMA edge-mount connectors

EFJohnson 142-0701-801 or

Digi-Key J502-ND

5

J5≠J9

LED

Digi-Key P363-ND

1

D3

1000pF ±10% ceramic capacitor (0402)

1

C43

0.01µF ±10% ceramic capacitors

(0603)

2

C41, C45

10µF ±20% tantalum (16V) capacitor

AVX TAJC106M016

1

C40

DESIGNATION

0.056µF ±10% ceramic capacitors

(0603)

2

C37, C39

0.1µF ±10% ceramic capacitors (0603)

5

C26, C27, C29,

C30, C34

Do not install.

5

C14, C21, C31,

C33, C44

DESCRIPTION

QTY

0.22µF ±10% ceramic capacitor (0603)

1

C42

Do not install.

1

R37

110

±1% resistor (0603)

1

R34

124

±1% resistors (0402)

4

R28, R29, R32,

R33

84.5

±1% resistors (0402)

4

R25, R26, R30,

R31

1k

±1% resistor (0603)

1

R23

1.5k

±1% resistors (0603)

3

R5, R22, R47

DESIGNATION

DESCRIPTION

QTY

1.2µH inductor

Coilcraft 1008LS-122XKBC

1

L9

R38, R49

2

49.9

±1% resistors (0402)

R40

1

100k

variable resistor

Bournes or Digi-Key 3296W-104-ND

R41

1

50k

variable resistor

Bournes or Digi-Key 3296W-503-ND

R42

1

200k

variable resistor

Bournes or Digi-Key 3296W-204-ND

R43, R45

2

0

resistors (0603)

R46

1

15

±1% resistor (0603)

U2

1

MAX3867ECM (48-pin TQFP)

U3

1

MAX495ESA

600

ferrite beads (0603)

Murata BLM11A601SPT

2

L10, L11

TP2, TP3, TP8,

TP10≠TP13,

VCC1, GND1

9

Test points

Digi-Key 5000K-ND

TP17, TP18

2

Do not install.

None

1

MAX3867 EV kit circuit board (Rev D)

0.01µF ±10% ceramic capacitors

(0402)

4

C24, C25, C28,

C32

R44

1

24.9

±1% resistor (0402)

None

1

MAX3867 data sheet

For free samples and the latest literature, visit www.maxim-ic.com or phone 1-800-998-8800.

For small orders, phone 1-800-835-8769.

Q2

PNP transistor (SOT23)

Zetex FMMT591A ("91A" marking)

1

Quick Start

Electrical Evaluation

In the electrical configuration, an automatic power con-

trol (APC) test circuit is included to emulate a semicon-

ductor laser with a monitor photodiode. Monitor diode

(MD) current is provided by Q2, which is controlled by

an operational amplifier (U3). The APC test circuit, con-

sisting of U3 and Q2, applies the simulated MD current

(the laser bias current divided by 100) to the MD pin of

the MAX3867. To ensure proper operation in the electri-

cal configuration, set up the evaluation board as fol-

lows:

1) If data is to be latched, remove the shunt from JU4

to enable the input clock; otherwise, leave the shunt

in place.

EFJohnson

Evaluates: MAX3867

MAX3867 Evaluation Kit

2

_______________________________________________________________________________________

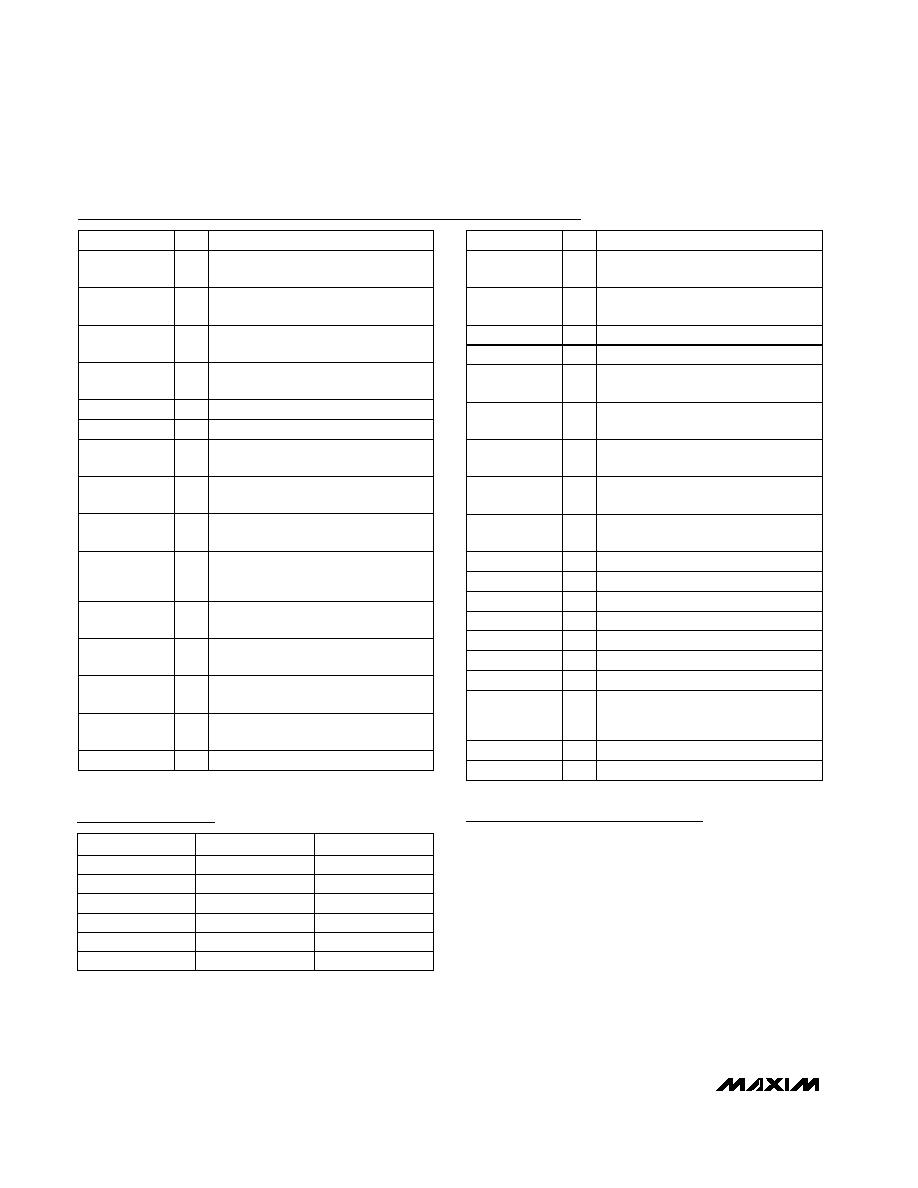

600

ferrite bead (0603)

Murata BLM11HA601SPT

1

L2

0

resistor (0603)

1

L3

1k

ferrite bead (0805)

Murata BLM21A102S

1

L1

Shunts

Digi-Key S9000-ND

2

JU1, JU2

2-pin headers (0.1in center)

Digi-Key S1012-36-ND

2

JU1, JU2

0.1µF ±10% ceramic capacitors (0603)

5

C10≠C13, C23

SMA edge-mount connectors

EFJohnson 142-0701-801 or

Digi-Key J502-ND

4

J1≠J4

LED

Digi-Key P363-ND

1

D1

0.01µF ±10% ceramic capacitors

(0603)

3

C20, C22, C36

10µF ±20% tantalum (16V) capacitor

AVX TAJC106M016

1

C19

0.056µF ±10% ceramic capacitor

(0603)

1

C7

DESIGNATION

1000pF ±10% ceramic capacitor

(0402)

1

C6

Do not install.

6

C5, C8, C9,

C15, C18, C35

0.01µF ±10% ceramic capacitors

(0402)

6

C1≠C4, C17,

C38

DESCRIPTION

QTY

R16

1

100k

variable resistor

Bournes or Digi-Key 3296W-104-ND

200k

variable resistor

Bournes or Digi-Key 3296W-204-ND

1

R15

R18

1

110

±1% resistor (0603)

R19

1

Do not install.

R20

1

27.4

±1% resistor (0402)

R21

1

49.9

±1% resistor (0402)

R27

1

24.9

±1% resistor (0402)

R35, R48

2

0

resistors (0603)

50k

variable resistor

Bournes or Digi-Key 3296W-503-ND

1

R14

124

±1% resistors (0402)

4

R8, R9, R12,

R13

84.5

±1% resistors (0402)

4

R6, R7, R10,

R11

1.0k

±1% resistor (0603)

1

R3

1.5k

±1% resistors (0603)

2

R1, R2

1.2µH Inductor

Coilcraft 1008LS-122XKBC

1

L4

TP15, TP16

2

Do not install.

TP1, TP4, TP5,

TP6, TP14,

VCC, GND

7

Test points

Digi-Key 5000K-ND

DESIGNATION

DESCRIPTION

QTY

Optical Component List

SUPPLIER

PHONE

FAX

AVX

803-946-0690

803-626-3123

Coilcraft

847-639-6400

847-639-1469

402-474-4800

402-474-4858

Zetex

516-543-7100

516-864-7630

Component Suppliers

Digi-Key

218-681-6674

218-681-3380

Murata

814-237-1431

814-238-0490

600

ferrite beads (0603)

Murata BLM11A601SPT

2

L5, L6

U1

1

MAX3867ECM (48-pin TQFP)

R36

1

43.2

±1% resistor (0402)

0.22µF ±10% ceramic capacitor (0805)

1

C16

2) Remove the shunt from JU5 to enable the outputs.

Note: When performing the following resistance checks,

manually set the ohmmeter to a high range to avoid for-

ward biasing the on-chip ESD protection diodes.

3) Adjust R41, the MOD potentiometer, for 10k

resis-

tance between pins 1 and 3 (test point 3 and

ground).

4) Adjust R42, the BIAS potentiometer, for 10k

resis-

tance between pins 1 and 3 (test point 2 and

ground).

5) Adjust R40, the APC potentiometer, for 10k

resis-

tance between pins 1 and 3 (test point 8 and ground).

6) Apply a differential input signal (max amplitude

800mV per side) to J7 and J8 (DATA+ and DATA-).

7) If the latch is enabled, apply a differential clock sig-

nal (max amplitude

800mV per side) to J5 and J6

(CLK+ and CLK-).

8) Attach a high-speed oscilloscope with 50

inputs

to J9.

9) Power up the board with a +3.3V supply.

10) Adjust R42 until the desired laser bias current is

achieved:

11) Adjust R41 until the desired laser modulation cur-

rent is achieved:

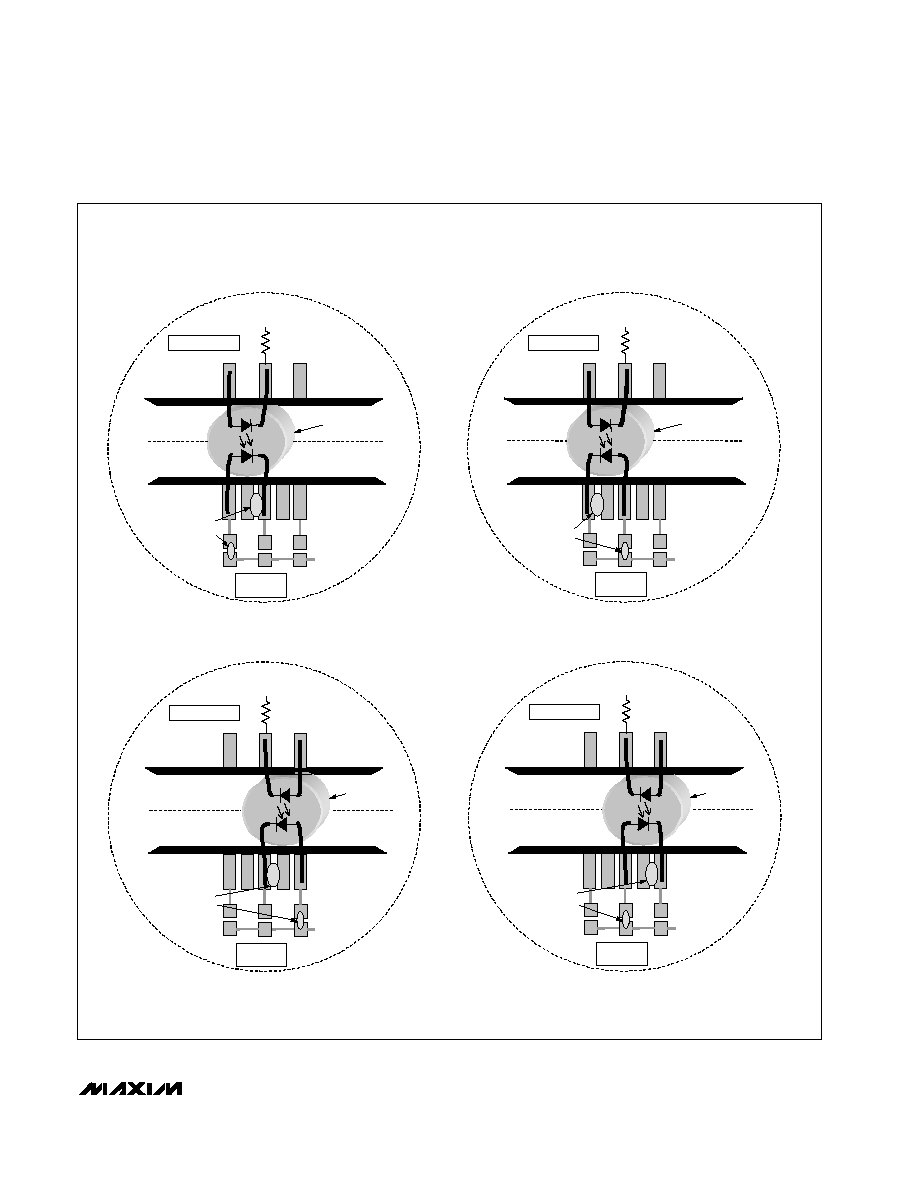

Optical Evaluation

For optical evaluation of the MAX3867, configure the EV

kit as follows:

1) If data is to be latched, remove the shunt from JU1

to enable the input clock; otherwise, leave the shunt

in place.

2) Remove the shunt from JU2 to enable the outputs.

3) The EV kit is designed to allow connection of a vari-

ety of possible laser/monitor diode pin configura-

tions. Connect a TO-header-style laser with MD

(Figure 1) as follows:

∑

Keeping its leads as short as possible, connect

the laser diode to two of the three pads in the

cutout portion on the top (component) side of

the PC board. Solder the laser diode cathode to

the center pad, and solder the anode to either

of the other two pads (they are both connected

to V

CC

).

∑

Connect the monitor photodiode to two of the

five pads on the bottom (solder) side of the PC

board, directly below the laser diode pads.

Three of these pads (the middle and outside

positions) are initially not connected. The other

two pads are connected to V

CC

. Solder the

anode and cathode of the monitor photodiode

to any two of the three pads that are not con-

nected. Then connect the anode to the MD pin

by shorting the corresponding solder jumper

(Figure 1). Connect the cathode to V

CC

by using

solder to bridge to an adjacent V

CC

pad.

Note: When performing resistance checks, manually

set the ohmmeter to a high range to avoid for-

ward biasing the on-chip ESD protection diodes.

4) Adjust R14, the MOD potentiometer, for maximum

resistance between pins 1 and 3 (test point 5 and

ground).

5) Adjust R15, the BIAS potentiometer, for maximum

resistance between pins 1 and 3 (test point 4 and

ground).

6) Adjust R16, the APC potentiometer, for desired opti-

cal power. (Refer to the Design Procedure section

of the MAX3867 data sheet.)

7) Apply a differential input signal (

800mV per side)

to J1 and J2 (DATA+ and DATA-).

8) Apply a differential clock signal (

800mV per side)

to J3 and J4 (CLK+ and CLK-).

9) Attach the laser diode fiber connector to an opti-

cal/electrical converter.

10) Power up the board with a +3.3V supply.

11) Adjust R15 until the LED (D1) is no longer illuminat-

ed. Optical power can be observed on an oscillo-

scope connected to an optical/electrical converter.

12) Adjust R14 until the desired optical amplitude is

achieved. Optical amplitude can be observed on

an oscilloscope connected to an optical/electrical

converter.

I

MOD

=

Signal Amplitude (Volts)

25

I

BIAS

TP13

TP12

=

V

- V

15

Evaluates: MAX3867

MAX3867 Evaluation Kit

_______________________________________________________________________________________

3

Evaluates: MAX3867

MAX3867 Evaluation Kit

4

_______________________________________________________________________________________

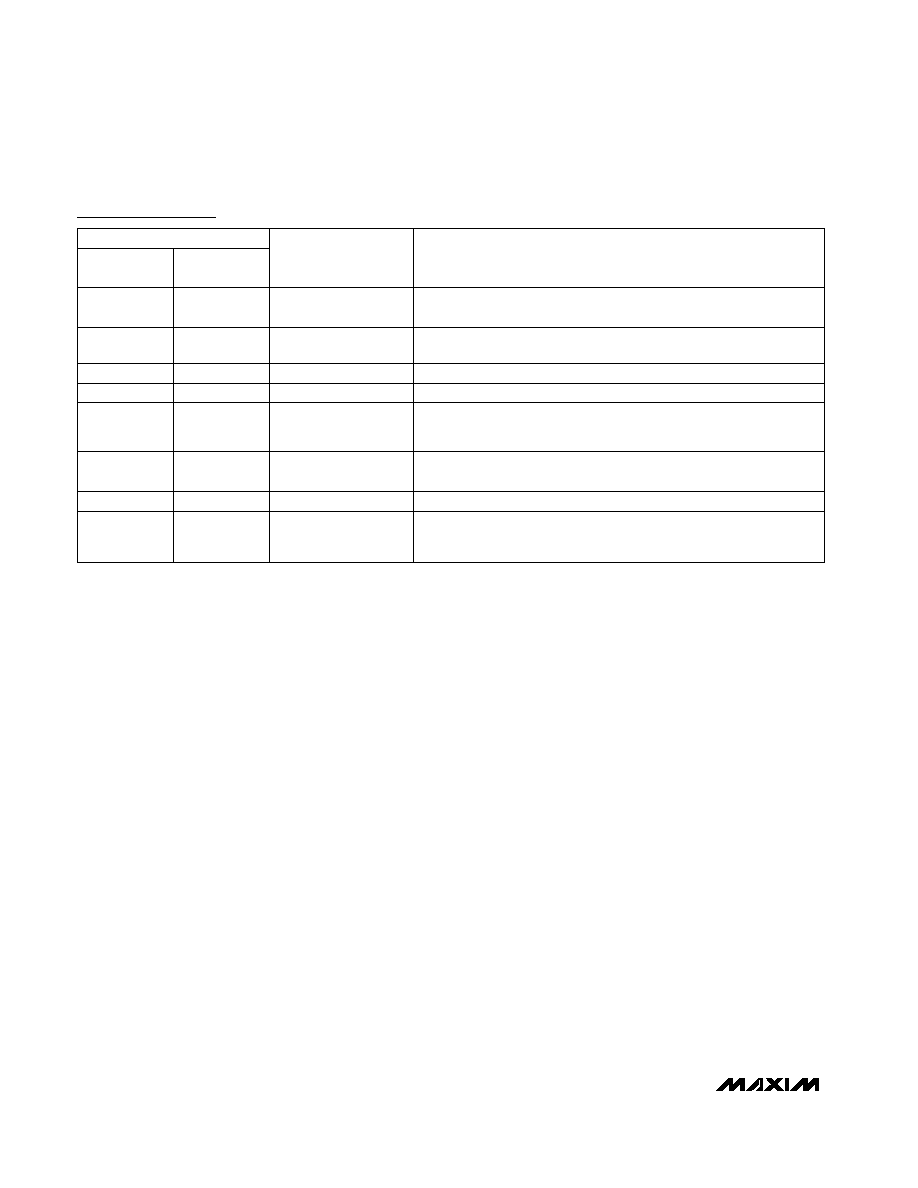

Adjustment and Control Descriptions (see Quick Start first)

Electrical Output

Electrical Output SMA

--

OPTICAL

FUNCTION

NAME

Refer to the Design section of the MAX3867 data sheet. Set APC cur-

rent, then increase bias current until LED goes off (LED is illuminated

when the APC loop is open, and off when the APC loop is closed).

Fail Indicator

D1

TTL low level indicates a failure in the APC loop.

Fail Indicator

TP1

ELECTRICAL

JU4

JU5

J8

R41

R42

R40

TP10

D3

For closed-loop operation, R16 or R40 adjusts the MD current level.

APC

R16

Adjusts the laser bias current. In open-loop mode, R15 or R42 adjusts

the laser bias current. In closed-loop operation, R15 or R42 adjusts the

maximum laser bias current.

BIAS

R15

Adjusts the laser modulation current.

MOD

R14

Enables/disables the output currents. Shunt to disable the part.

Remove shunt for normal operation.

OUTPUT DISABLE

JU2

Enables/disables the clock input. Shunt for direct data transmission.

Remove shunt to enable clock input.

CLOCK DISABLE

JU1

COMPONENT

Evaluates: MAX3867

MAX3867 Evaluation Kit

_______________________________________________________________________________________

5

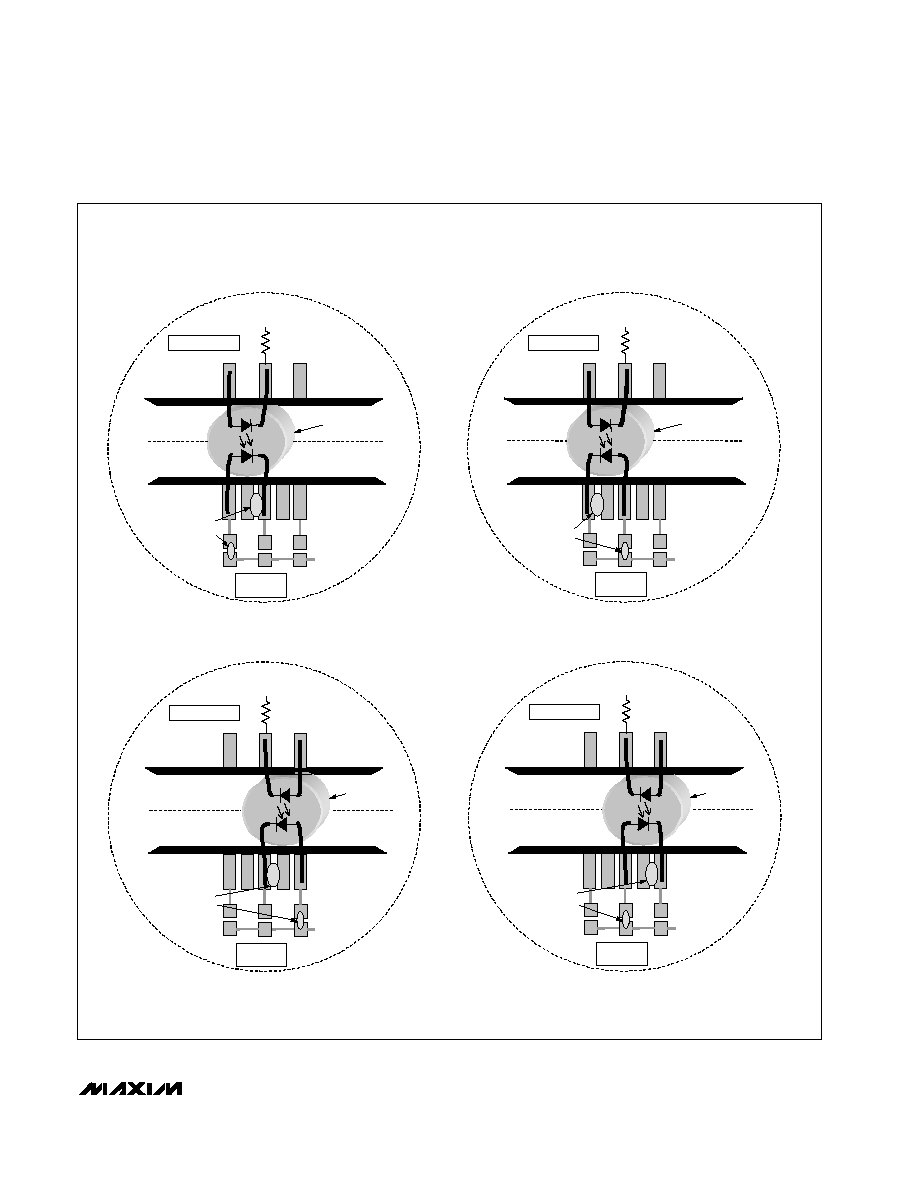

Figure 1. Attachment of Laser Diode/Monitor Diode to MAX3867 EV Kit

TOP OF PC BOARD

R20

V

CC

V

CC

TO-46 CAN

LASER/PHOTODIODE

PAIR

LD

PD

TO MD

V

CC

V

CC

SOLDER

BRIDGES

BOTTOM OF

PC BOARD

CONFIGURATION 1

TOP OF PC BOARD

R20

V

CC

V

CC

TO-46 CAN

LASER/PHOTODIODE

PAIR

LD

PD

V

CC

V

CC

TO MD

BOTTOM OF

PC BOARD

SOLDER

BRIDGES

CONFIGURATION 2

TOP OF PC BOARD

R20

V

CC

V

CC

TO-46 CAN

LASER/PHOTODIODE

PAIR

LD

PD

V

CC

V

CC

TO MD

BOTTOM OF

PC BOARD

SOLDER

BRIDGES

CONFIGURATION 3

R20

V

CC

V

CC

TOP OF PC BOARD

LD

TO-46 CAN

LASER/PHOTODIODE

PAIR

PD

V

CC

V

CC

TO MD

BOTTOM OF

PC BOARD

SOLDER

BRIDGES

CONFIGURATION 4