For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim's website at www.maxim-ic.com.

General Description

The MAX6901 evaluation system (EV system) consists

of a MAX6901 evaluation kit (EV kit) and a companion

Maxim SMBusTM interface board.

The MAX6901 EV kit is an assembled and tested PC

board that demonstrates the MAX6901 3-wire serial

real-time clock (RTC). This EV kit is intended to demon-

strate the functionality and features of the MAX6901

RTC. It is not designed to exercise the MAX6901 at its

maximum serial bus interface speed. A typical bus

interface speed is in the 90kHz range and depends

upon the operating system and computer used.

The Maxim SMBus interface board (MAXSMBus) allows

an IBM-compatible PC to use its parallel port to emulate

SPITM, 3-wire, and SMBus (2-wire) interfaces. Windows

Æ

95/98-compatible software provides a user-friendly

interface to exercise the features of the MAX6901.

(Note: Windows NT/2000 requires additional driver soft-

ware; contact the factory.) The program is menu driven

and offers a graphic interface with control buttons and

status display.

Order the complete EV system (MAX6901EVSYS) for

comprehensive evaluation of the MAX6901 using a PC.

Order the EV kit (MAX6901EVKIT) if the MAXSMBus

module has already been purchased with a previous

Maxim EV system, or for custom use in other µC-based

systems.

Features

o Proven PC Board Layout

o Low-Voltage Operation

o Supply-Current Monitoring

o Fully Assembled and Tested

o Easy-to-Use Menu-Driven Software

o Includes: Windows 95/98-Compatible Software

(3.5in Floppy Disk) Demo PC Board

Evaluates: MAX6901

MAX6901 Evaluation System/Evaluation Kit

________________________________________________________________ Maxim Integrated Products

1

19-2148; Rev 0; 8/01

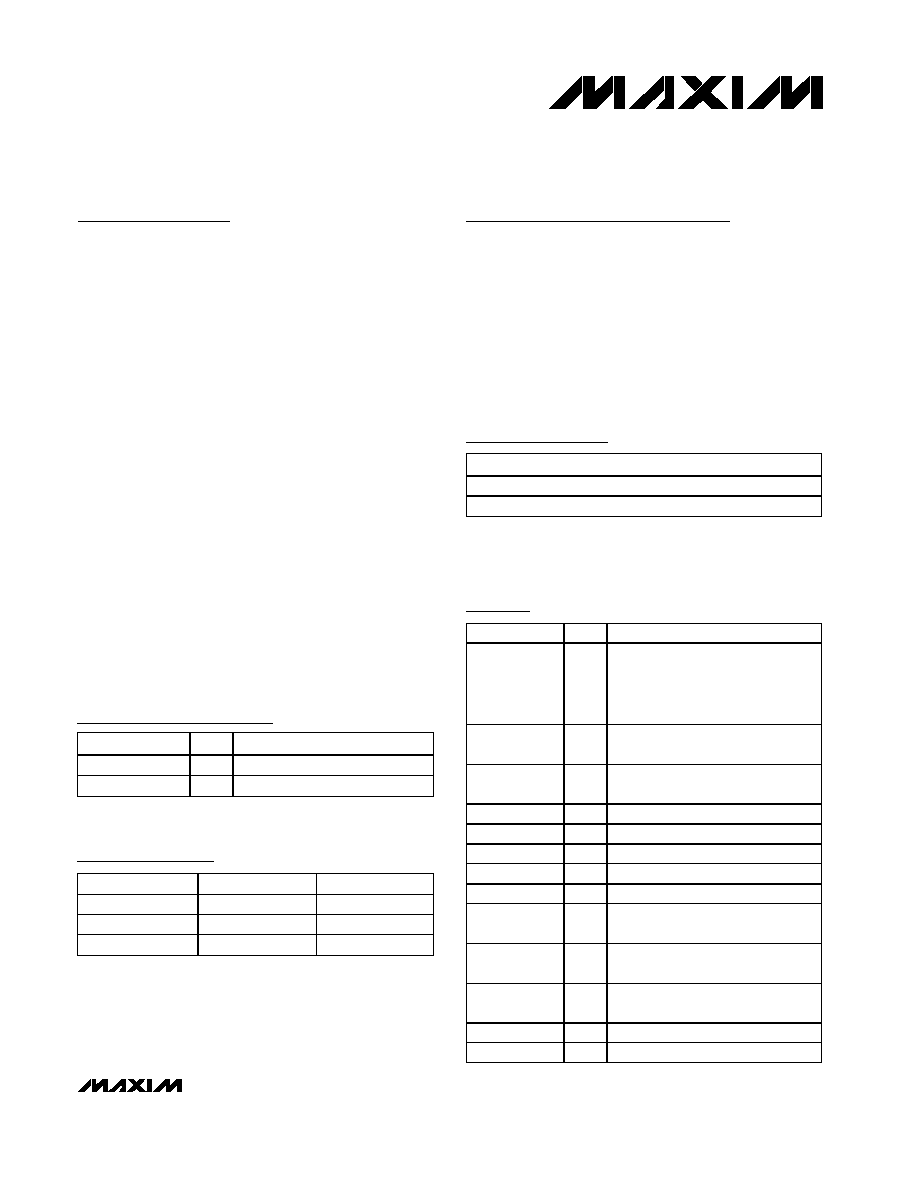

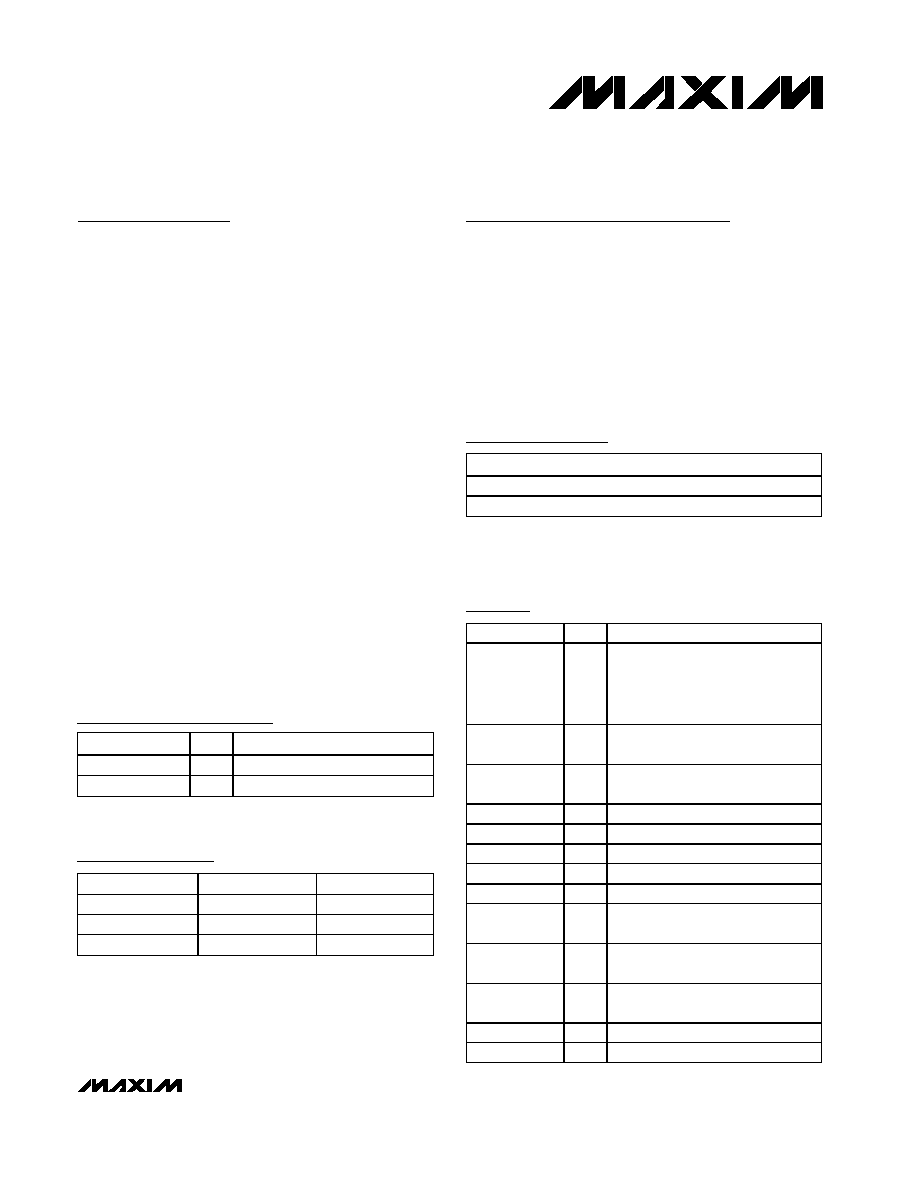

Component Suppliers

Ordering Information

SUPPLIER

PHONE

FAX

Murata

770-436-1300

770-436-3030

Taiyo Yuden

800-348-2496

847-925-0899

TDK

847-803-6100

847-390-4405

MAX6901EV Component List

DESIGNATION

QTY

DESCRIPTION

C1, C2, C3,

C6

4

0.1µF, 16V X7R ceramic

capacitors (0603)

Taiyo Yuden EMK107BJ104KA or

Murata GRM39X7R104K016 or

TDK C1608X7R1C104K

C4, C5

2

10µF, 35V capacitors

Al Electrolytic

J1

1

2

10 right-angle female

receptacle

JU1, JU2

2

2-pin headers

JU3≠JU6

0

Not installed

R1

1

49.9k

±1% resistor

R2

1

470k

±5% resistor

R3

1

100k

±5% resistor

U1

1

MAX6901EKA (8-pin SOT23)

real-time clock

U2

1

MAX1840EUB (10-pin µMAX)

level translator

U3

1

MAX1615EUK (5-pin SOT23)

linear voltage regulator

Y1

1

32.768kHz, 12.5pF quartz crystal

Y2

0

Not installed

PART

TEMP. RANGE

INTERFACE TYPE

MAX6901EVKIT

0∞C to +70∞C

User supplied

MAX6901EVSYS

0∞C to +70∞C

MAXSMBus

SMBus is a trademark of Intel Corp.

SPI is a trademark of Motorola, Inc.

Windows is a registered trademark of Microsoft Corp.

Note: The MAX6901 EV kit software is provided with the

MAX6901EVKIT. However, to use the software, the MAXSMBus

board is required to interface the EV kit to the computer.

Note: Please indicate you are using the MAX6901 when contact-

ing these manufacturers.

MAX6901EVSYS

Component List

PART

QTY

DESCRIPTION

MAX6901EVKIT

1

MAX6901 EV kit

MAXSMBUS

1

Interface board

Evaluates: MAX6901

MAX6901 Evaluation System/Evaluation Kit

2

_______________________________________________________________________________________

Quick Start

Required Equipment

Before you begin, the following equipment is needed:

∑

Maxim MAX6901EVKIT and MAXSMBus interface

board

∑

12VDC power supply (Any supply voltage between

+9V and +15V is acceptable.)

∑

Computer running Windows 95 or 98

∑

Spare parallel port

∑

25-pin I/O extension cable

Procedure

1) Carefully connect the boards by aligning the 20-pin

connector of the MAX6901 EV kit with the 20-pin

header of the MAXSMBus interface board. Gently

press them together. The two boards should be flush

against each other.

Do not turn on the power until all connections are

made.

2) Connect the 25-pin I/O extension cable from the

computer's parallel port to the MAXSMBus board.

The EV kit software uses a loopback connection to

confirm that the correct port has been selected.

3) Install the EV system software on your computer by

running the INSTALL.EXE program on the floppy

disk. The program files are copied and icons are

created for them in the Windows Start menu.

4) Ensure that the jumper settings are in the default

position (Table 1).

5) Connect the 12VDC power supply to the

MAXSMBus board between POS9 and GND.

Voltage for the MAX6901 ICs comes from the

MAXSMBus board.

6) Start the program by opening its icon in the Start

menu.

7) Click on the Set from Computer's Clock button to

write the current time of day into the MAX6901.

8) Observe the difference between the computer's time

and the MAX6901 time. The offset is calculated by

Offset = RTC time - PC time. In general, the RTC

keeps more accurate time than the PC. To determine

long-term accuracy of the RTC, it must be set by and

checked against an accurate time source. The easi-

est way to do this using the MAX6901 EV software is

to use an Internet time service to set the PC clock and

then set the RTC from the PC clock. This Internet time

service can then be used to accurately update the PC

clock regularly for an accurate comparison of the

RTC against a known time standard. The National

Institute of Standards and Technology (NIST) offers

such an Internet time service without charge

(http://www.boulder.nist.gov/timefreq/service/its.htm).

Note: The MAX6901EVSYS may be unplugged from the

parallel port for long-term drift testing.

Detailed Description of

Hardware

The MAX6901 (U1) is a real-time clock with RAM. The

MAX1840 level translator (U2) is not required for normal

operation of the MAX6901, but allows operation at supply

voltages down to +2V, while still communicating with the

MAXSMBus board, which is using +5V logic levels. See

Figure 7 and refer to the MAX6901 data sheet.

Measuring Timekeeping Supply Current

The MAX6901 is in standby mode whenever no com-

mands are being sent. To measure the timekeeping

supply current drawn in standby mode, first ensure that

the main screen's Cyclic Burst Read checkbox is not

checked, disable the 32kHz output by checking the

32kHz Disable checkbox, remove the shunt from JU2,

and measure the voltage across R1. A voltage drop of

10mV represents 200nA of timekeeping supply current.

For active bus operation (serial bus activity), replace

shunt JU2 to prevent excessive voltage drop across

resistor R1.

Surface-Mount Crystal

The EV kit comes with a 1.1mm cylindrical tuning fork

crystal; however, the PC board layout accommodates an

optional surface-mount crystal. Only one crystal may be

used.

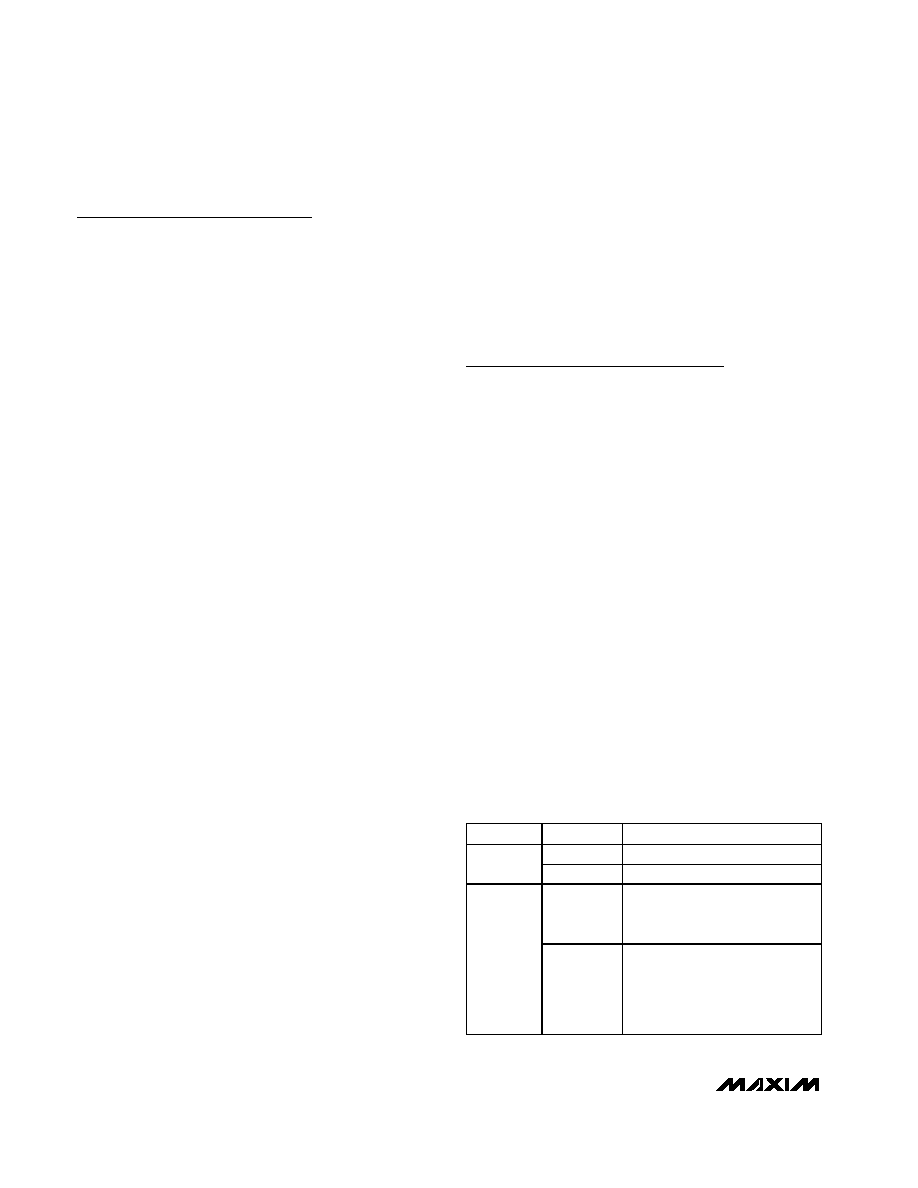

Table 1. Jumper Functions

JUMPER

POSITION

FUNCTION

*Closed

V

L

= +5V

JU1

Open

User-supplied V

L

+5V

*Closed

Supply current-sensing resistor

R1 is shorted, enabling

communication with the RTC.

JU2

Open

Timekeeping supply current can

be estimated by measuring

voltage across R1.

Communication is not possible in

this state.

*Asterisk indicates default configuration.

MAXSMBus Connector

The MAXSMBus board connects to the MAX6901 EV kit

in accordance with Table 2.

Evaluation of the MAX6901 at

a Lower Voltage

To evaluate the MAX6901 at a lower voltage, remove

the shunt from jumper JU1 and apply the desired volt-

age (+2V to +5V) to the VL pad.

EV Kit Stand-Alone

The MAX6901 EV kit can be connected to a different 3-

wire interface with or without level translation.

To connect with level translation, use the pads labeled

X_I/O, X_SCLK, and X_CS. Cut the trace-shorting jumper

JU6 and connect the 3-wire interface logic voltage to the

VCC pad. Remove the shunt from JU1 and apply the

desired voltage for the MAX6901 to the VL pad.

To connect without level translation, cut the traces short-

ing JU3, JU4, and JU5 and use the pads labeled I/O,

SCLK, and CS. Remove the shunt from JU1 and connect

the 3-wire interface logic-voltage to the VL pad.

Troubleshooting

Problem: Unable to communicate while measuring

supply current.

JU2 must be closed to enable communication.

Problem: Initial date POR value of RTC is 01-JAN-2070.

RTC evaluation software was started. RTC time was set

from computer clock. RTC was powered down. RTC

evaluation software remained running and then RTC

was powered back up. RTC evaluation software only

reads the Century register when time is set from the

computer clock or when the software is initially

launched. Stop Cyclic Burst Read. Do a single read of

the Century register. Continue by starting the Cyclic

Burst Read.

Detailed Description

of Software

The evaluation software provides access to all regis-

ters. The main timekeeping registers appear in the

main screen, with other screens accessible from the

View menu. To write to a single register, click on the

appropriate register select button, set the desired

value, and then click the Write button. To read a regis-

ter, click on the appropriate register select button, and

then click the Read button. Cyclic Burst Read should

be disabled before a read or write to a single register.

Main Screen

The Read button reads the most recently selected time-

keeping register. The Write button writes the most

recently selected timekeeping register. The Burst Read

button performs a Burst Read from the timekeeping

registers (except Century). The Burst Write button per-

forms a Burst Write to the timekeeping registers (except

Century). The Set from Computer's Clock button writes

the PC's time into the MAX6901. The Cyclic Burst Read

checkbox tells the software to perform a Burst Read

from the timekeeping registers, at a rate of approxi-

mately four times per second. Updates are shown in

the register display, along with the difference between

MAX6901 time and the host PC's time. Note: Cyclic

Burst Read should be disabled before a read or write to

a single register. Figure 1 shows the main screen.

The Hour register setting can be switched from 12hr

format to 24hr format by clicking the -->24 button.

Checking the 32kHz Disable checkbox disables the

32kHz output (pin 5) on the MAX6901. A checkmark cor-

responds to a logic 1 for bit 7 of the Seconds register.

Evaluates: MAX6901

MAX6901 Evaluation System/Evaluation Kit

_______________________________________________________________________________________

3

Table 2. MAXSMBus Connector Signals

PIN

CONNECTOR P1 ON

MAXSMBus BOARD

CONNECTOR J1 ON

MAX6901 EV KIT

1

+5V

No connection

2

GND

Ground

3

SDA

X_I/O

4

GND

Ground

5

GND

Ground

6

GND

Ground

7

SCL

X_SCLK

8

GND

Ground

9

SMBSUS

X_CS

10

GND

Ground

11

ALERT

No connection

12

GND

Ground

13

ALERT2

No connection

14

GND

Ground

15

OUTA

No connection

16

GND

Ground

17

OUTB

No connection

18

GND

Ground

19

GND

Ground

20

RAW PWR

+9V

Note: Odd-numbered pins are on the outer row. Even-num-

bered pins are on the inner row.

Evaluates: MAX6901

RAM Screen

The Single Read button reads the most recently select-

ed RAM location. The Single Write button writes the

most recently selected RAM location. The Burst Read

button performs a Burst Read from the entire RAM. The

Burst Write button performs a Burst Write to the RAM.

Normally, all 31 locations are read, but the Burst Write

length can be reduced. The Burst Write always begins

with RAM location 0. The Preset Data button performs a

Burst Write to the RAM, setting all data to the same

value. Note: Cyclic Burst Read should be disabled

before reading or writing to RAM. Figure 2 is the RAM

screen.

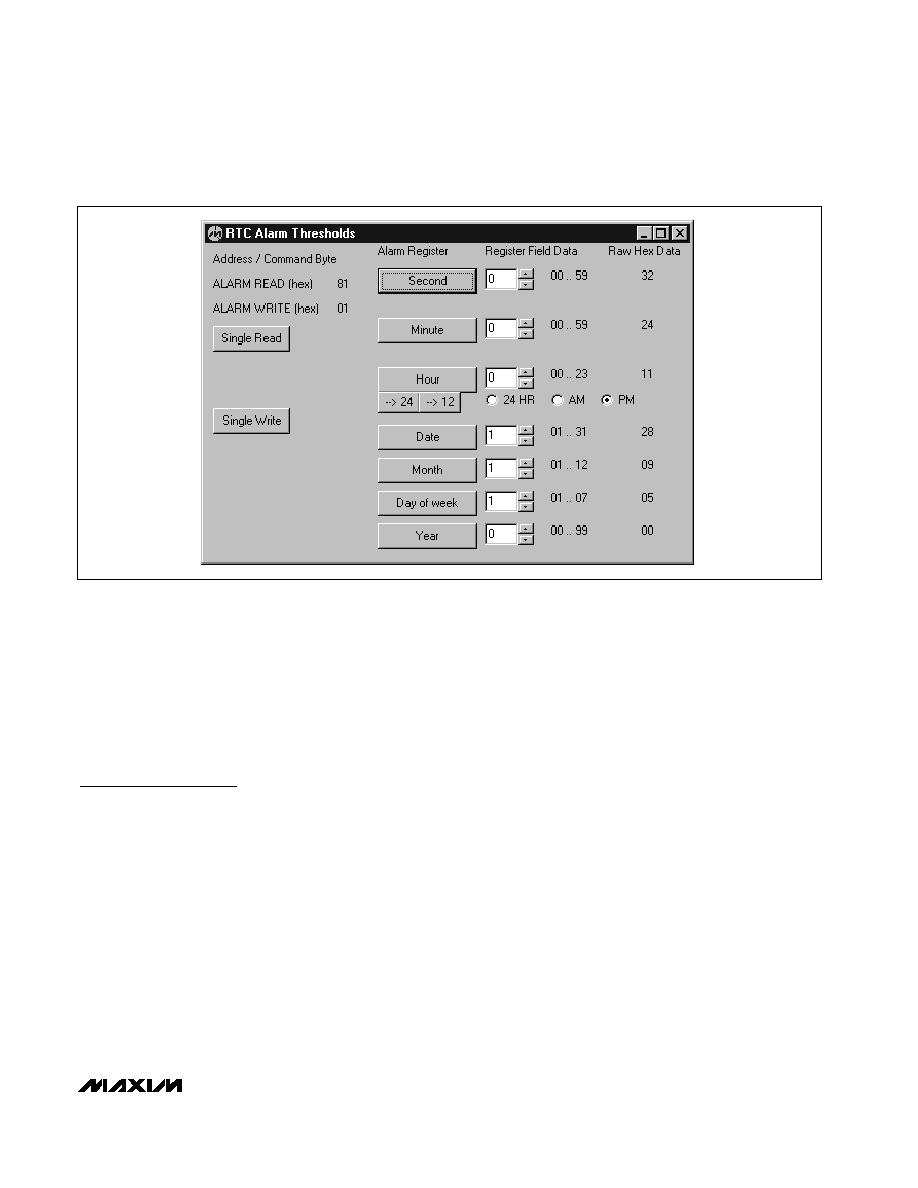

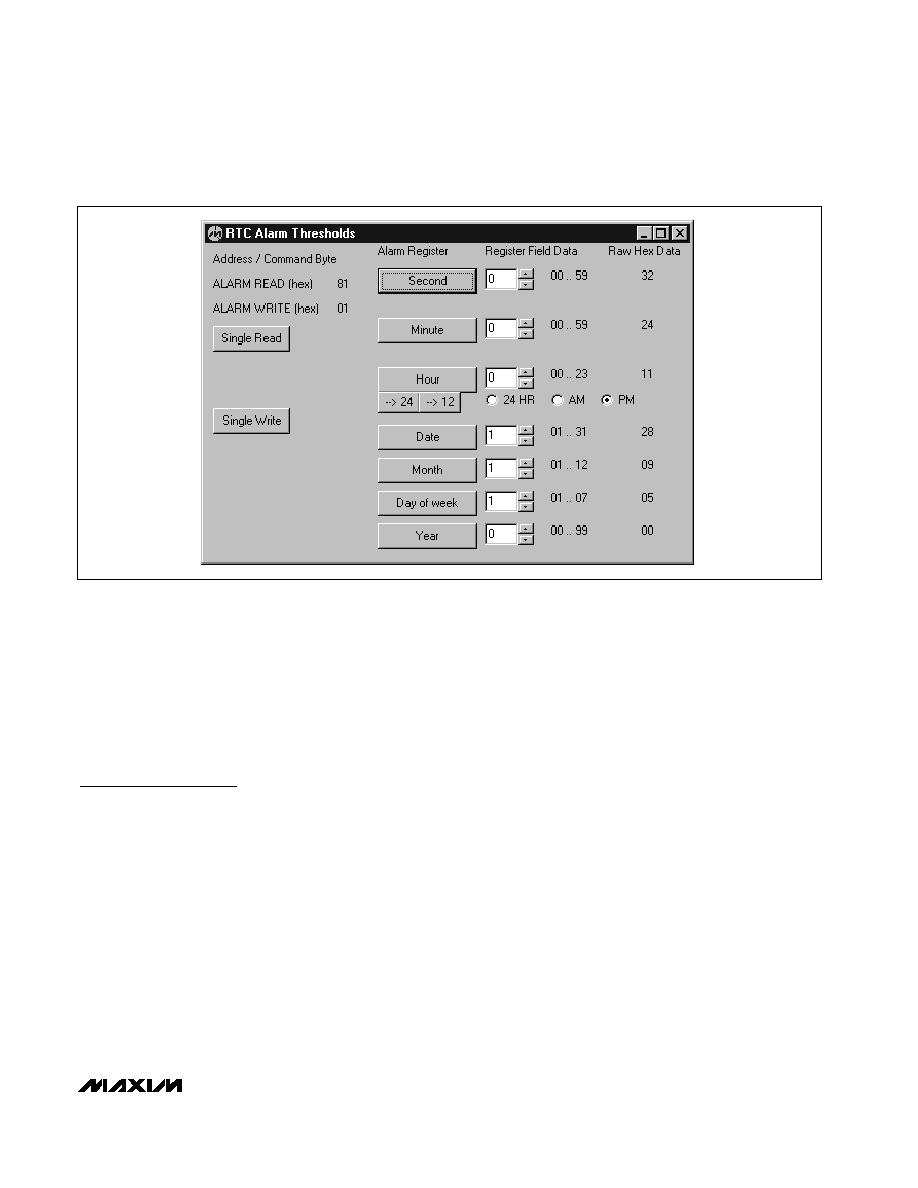

Alarm Thresholds Screen

The Read button reads the most recently selected

alarm threshold register. The Write button writes the

most recently selected alarm threshold register.

The Hour register setting can be switched from 12hr

format to 24hr format by clicking the -->24 button.

Note: Cyclic Burst Read should be disabled before a

read or write to a single register. Figure 3 is the Alarm

Thresholds screen.

MAX6901 Evaluation System/Evaluation Kit

4

_______________________________________________________________________________________

Figure 2. RAM Screen

Figure 1. Main Screen

Setup Screen

Each setup register is represented by a group of eight

checkboxes, one for each bit. A checkmark indicates

that the corresponding bit is a logic 1. The Read button

updates the most recently selected setup register's

checkboxes. The Write button writes the most recently

selected setup register. Note: Cyclic Burst Read

should be disabled before a read or write to a single

register. Figure 4 is the Setup screen.

Auxiliary Functions

SPI/3-Wire Diagnostic

The transition from evaluation to custom software devel-

opment requires access to the low-level interface.

Access the SPI/3-wire diagnostic from the main

screen's View menu. The SPI/3-Wire Diagnostic screen

allows you to send SPI or 3-wire commands, or manipu-

late the parallel port pins directly. Each of the 25 paral-

lel port pins is represented by a checkbox. A check-

mark means that the corresponding pin is at a logic

high level. Pins that are inputs to the PC are grayed.

The Bit Banging SPI Diagnostic transmits data using

synchronous serial format (similar to Motorola's

68HC11 SPI interface). The SPI interface sends and

receives data simultaneously on separate pins. Parallel

port pin 2 drives the SCLK, pin 1 drives DIN, pin 4 dri-

ves CS, and pin 11 senses DOUT.

When the software is communicating through the

MAXSMBus board DOUT, CS, and SCLK are inverted.

DIN is not inverted.

The signals come out of the MAXSMBus at connector

P1; DOUT is pin 3, CS is pin 9, SCLK is pin 7, and DIN

is pin 15.

The 3-wire interface uses a bidirectional data pin. The

least-significant bit (LSB) is transmitted first, and (CPOL

= 1, CPHA = 0) mode is used. Parallel port pin 2 drives

SCLK, pin 11 drives I/O, and pin 4 drives CS.

When the software is communicating through the

MAXSMBus board SCLK, I/O and CS are inverted.

The signals come out of the MAXSMBus at connector

P1; SCLK is pin 7, CS is pin 9, and I/O is pin 3.

When using this software, the data is relative to the par-

allel port. However, there are checkboxes that allow the

signals to be inverted to accommodate the

MAXSMBus board. Note: Disable Cyclic Burst Read

when using the SPI/3-wire diagnostic utility. Figure 5 is

the SPI/3-Wire Diagnostic screen.

Evaluates: MAX6901

MAX6901 Evaluation System/Evaluation Kit

_______________________________________________________________________________________

5

Figure 3. Alarm Thresholds Screen