| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: BUT11AF | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1

Motorola Bipolar Power Transistor Device Data

Full Pak

High Voltage NPN Power Transistor

For Isolated Package Applications

The BUT11AF was designed for use in line operated switching power supplies in a

wide range of end use applications. This device combines the latest state of the art

bipolar fabrication techniques to provide excellent switching, high voltage capability

and low saturation voltage.

∑

1000 Volt VCES Rating

∑

Low Base Drive Requirements

∑

Isolated Overmold Package

∑

Improved System Efficiency

∑

No Isolating Washers Required

∑

Reduced System Cost

∑

High Isolation Voltage Capability (4500 VRMS)

MAXIMUM RATINGS

Rating

Symbol

Value

Unit

Collector≠Emitter Sustaining Voltage

VCEO(sus)

450

Vdc

Collector≠Emitter Breakdown Voltage

VCES

1000

Vdc

Emitter≠Base Voltage

VEBO

9.0

Vdc

RMS Isolation Voltage (For 1 sec,

Per Figure 7

VISOL1

4500

TA = 25

∞

C, Rel. Humidity < 30%)

Per Figure 8

VISOL2

3500

V

Per Figure 9

VISOL3

2500

Collector Current -- Continuous

Collector Current

-- Pulsed (1)

IC

ICM

5.0

10

Adc

Base Current -- Continuous

Base Current

-- Pulsed (1)

IB

IBM

2.0

4.0

Adc

Total Power Dissipation @ TC = 25

∞

C*

Derated above 25

∞

C

PD

40

0.32

Watts

W/

∞

C

Operating and Storage Temperature Range

TJ, Tstg

≠ 65 to +150

∞

C

THERMAL CHARACTERISTICS

Thermal Resistance -- Junction to Case*

R

JC

3.125

∞

C/W

Maximum Lead Temperature for soldering purposes

1/8

from case for 5 sec.

TL

260

∞

C

(1) Pulse Test: Pulse Width = 5.0 ms, Duty Cycle

10%.

* Measurement made with thermocouple contacting the bottom insulated mounting surface of the package (in a location beneath the die),

the device mounted on a heatsink, thermal grease applied, and a mounting torque of 6 to 8 in . lbs.

Full Pak is a registered trademark of Motorola Inc.

MOTOROLA

SEMICONDUCTOR TECHNICAL DATA

Order this document

by BUT11AF/D

©

Motorola, Inc. 1995

BUT11AF

POWER TRANSISTOR

5.0 AMPERES

450 VOLTS

40 WATTS

CASE 221D≠02

TO≠220 TYPE

REV 2

BUT11AF

2

Motorola Bipolar Power Transistor Device Data

ELECTRICAL CHARACTERISTICS

(TC = 25

∞

C unless otherwise noted)

Characteristic

Symbol

Min

Typ

Max

Unit

OFF CHARACTERISTICS (1)

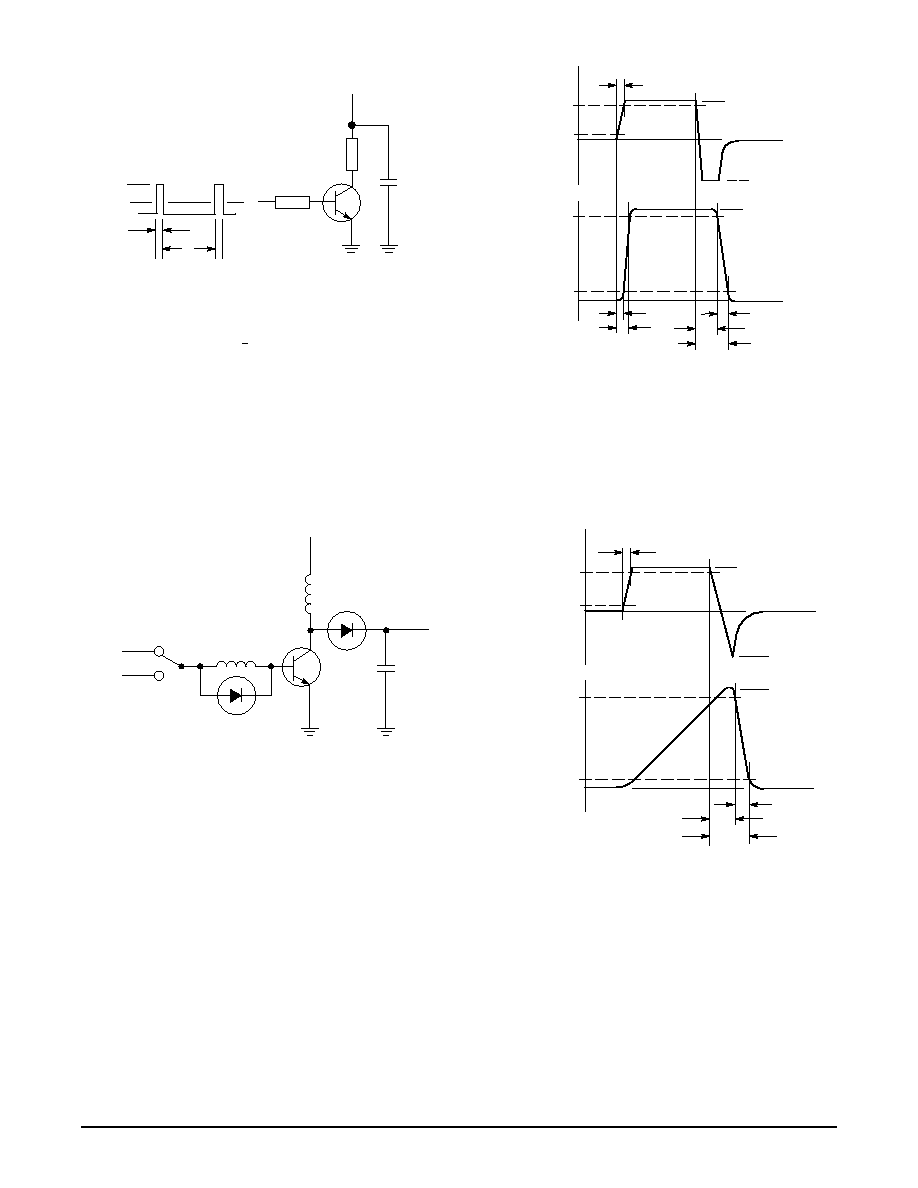

Collector-Emitter Sustaining Voltage (Figures 1 & 2)

(IC = 100 mAdc, IB = 0, L = 25

µ

H)

VCEO(sus)

450

≠

≠

Vdc

Collector Cutoff Current

(VCE = 1000 Vdc, VBE = 0)

(VCE = 1000 Vdc, VBE = 0, TJ = 125

∞

C)

ICES

≠

≠

≠

≠

1.0

2.0

mAdc

Emitter-Base Leakage

(VEB = 9.0 Vdc, IC = 0)

IEBO

≠

≠

10

mAdc

ON CHARACTERISTICS (1)

Collector-Emitter Saturation Voltage

(IC = 2.5 Adc, IB = 0.5 Adc)

VCE(sat)

≠

≠

1.5

Vdc

Base-Emitter Saturation Voltage

(IC = 2.5 Adc, IB = 0.5 Adc)

VBE(sat)

≠

≠

1.5

Vdc

DC Current Gain

(IC = 5.0 mAdc, VCE = 5.0 Vdc)

hFE

10

≠

≠

≠

≠

≠

DYNAMIC CHARACTERISTICS

Insulation Capacitance (Collector to External Heatsink)

Cc-hs

≠

15

≠

pF

SWITCHING CHARACTERISTICS

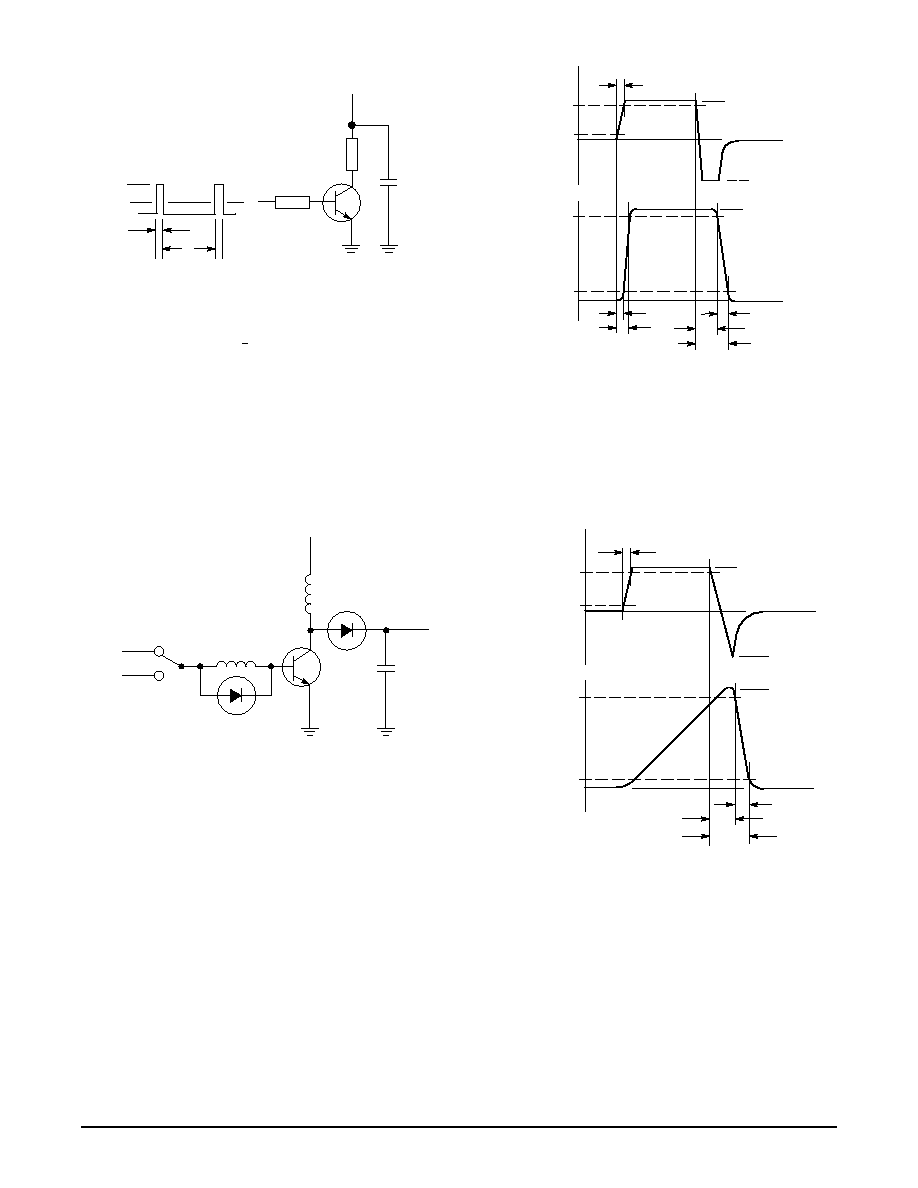

Inductive Load (Figures 3 & 4)

Storage

IC = 2.5 Adc, IB1 = 0.5 Adc

TJ = 25

∞

C

ts

≠

1100

1400

ns

Fall Time

IC = 2.5 Adc, IB1 = 0.5 Adc

TJ = 25

∞

C

tfi

≠

80

150

Storage

IC = 2.5 Adc, IB1 = 0.5 Adc

TJ = 100

∞

C

ts

≠

1200

1500

Fall Time

TJ = 100

∞

C

tfi

≠

140

300

Resistive Load (Figures 5 & 6)

Turn-On Time

IC = 2.5 Adc, IB1 = IB2 = 0.5 Adc

ton

≠

≠

1000

ns

Storage Time

IC = 2.5 Adc, IB1 = IB2 = 0.5 Adc

ts

≠

≠

4000

Fall Time

tf

≠

≠

800

(1) Pulse Test: Pulse Width = 300

µ

s

, Duty Cycle

2.0%.

0

200

250

100

MIN

VCEO(sus)

VCE (V)

Figure 1. Oscilloscope Display for Sustaining Voltage

IC

(mA)

HOR.

OSCILLOSCOPE

VERT.

OSCILLOSCOPE

+50 V

L

VIN

0

tp

T

100 ≠ 200

1

Figure 2. Test Circuit for VCEO(sus)

BUT11AF

3

Motorola Bipolar Power Transistor Device Data

VIN

0

tp

T

RB

RL

T.U.T.

VCC

Figure 3. Test Circuit Resistive Load

VCC

VIN

tp

tp

T

= 250 V

= ≠ 6 to +8 V

= 20

µ

s

= 0.01

90%

10%

90%

10%

IB

IC

IB on

IB off

IC on

tr

t

td

ton

toff

ts

tf

t

Figure 4. Switching Times Waveforms with

Resistive Load

Figure 5. Test Circuit Inductive Load

+IB1

≠VBE

LB

VCC

LC

VCL

T.U.T.

7Z89211.2

VCL

VCC

VEB

LB

VCL

= 300 V

= 30 V

= 5 V

= 1

µ

H

= 200

µ

H

Figure 6. Switching Times Waveforms

with Inductive Load

90%

10%

90%

10%

IB

IC

IB1

IB2

IC on

tr

tf

ts

toff

t

BUT11AF

4

Motorola Bipolar Power Transistor Device Data

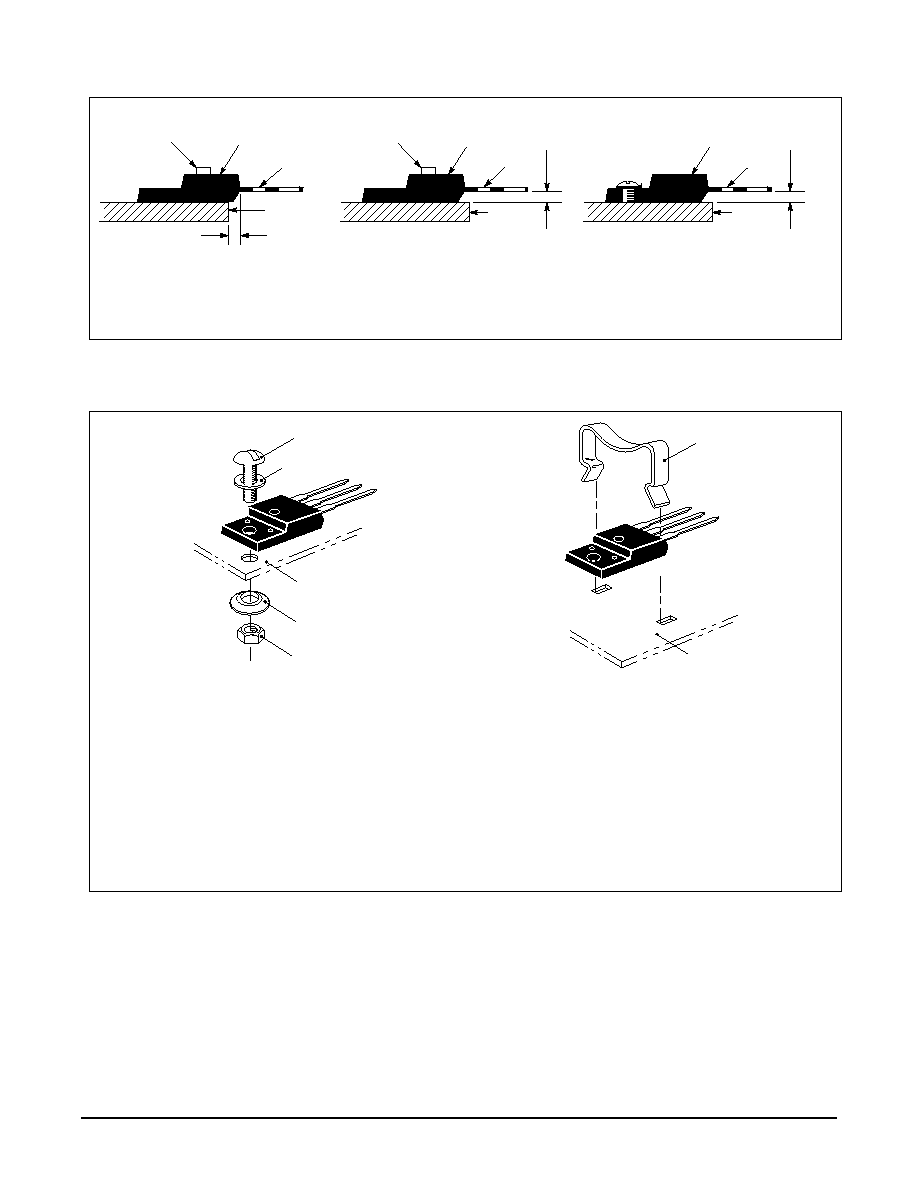

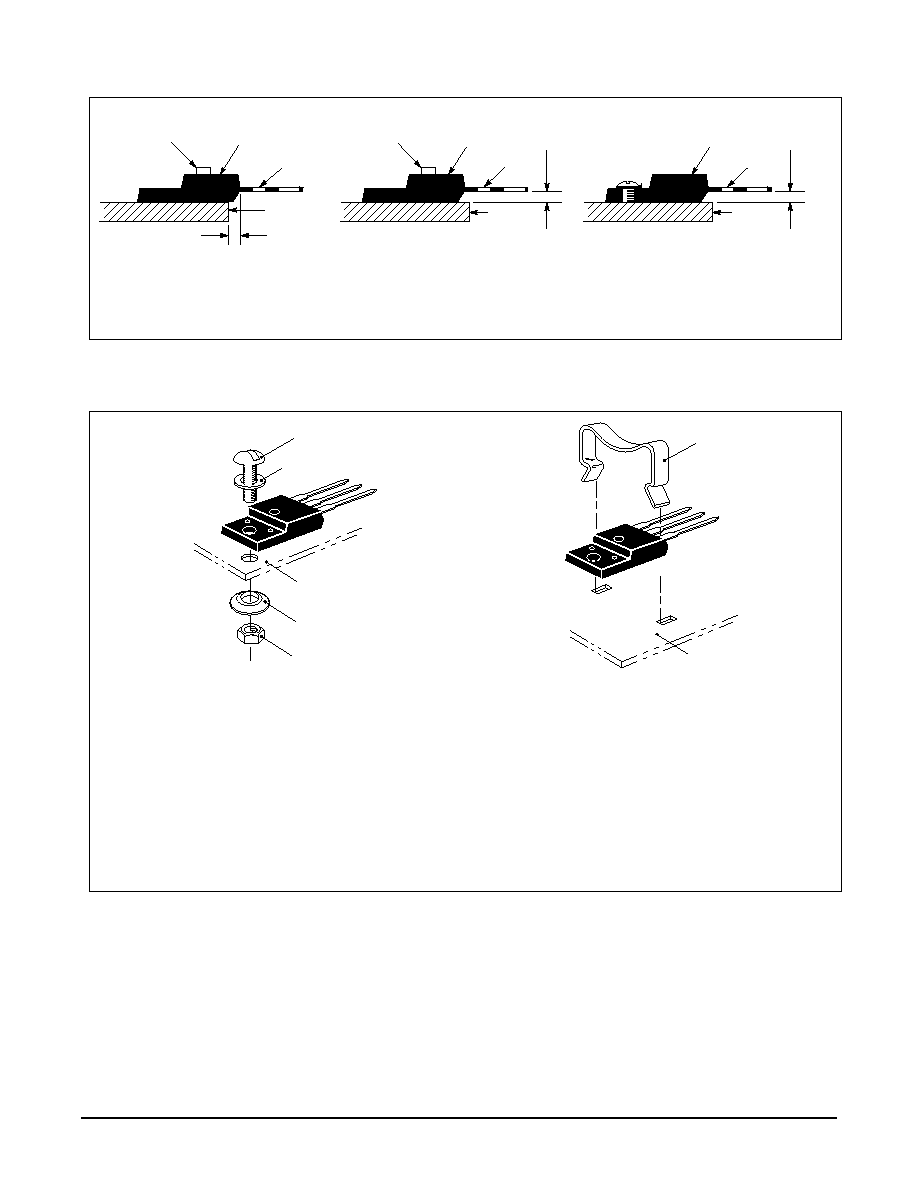

TEST CONDITIONS FOR ISOLATION TESTS*

MOUNTED

FULLY ISOLATED

PACKAGE

LEADS

HEATSINK

0.110

MIN

Figure 7. Screw or Clip Mounting Position

for Isolation Test Number 1

* Measurement made between leads and heatsink with all leads shorted together.

CLIP

MOUNTED

FULLY ISOLATED

PACKAGE

LEADS

HEATSINK

CLIP

0.107

MIN

MOUNTED

FULLY ISOLATED

PACKAGE

LEADS

HEATSINK

0.107

MIN

Figure 8. Clip Mounting Position

for Isolation Test Number 2

Figure 9. Screw Mounting Position

for Isolation Test Number 3

MOUNTING INFORMATION

4≠40 SCREW

PLAIN WASHER

HEATSINK

COMPRESSION WASHER

NUT

CLIP

HEATSINK

Laboratory tests on a limited number of samples indicate, when using the screw and compression washer mounting technique, a screw

torque of 6 to 8 in . lbs is sufficient to provide maximum power dissipation capability. The compression washer helps to maintain a constant

pressure on the package over time and during large temperature excursions.

Destructive laboratory tests show that using a hex head 4≠40 screw, without washers, and applying a torque in excess of 20 in . lbs will

cause the plastic to crack around the mounting hole, resulting in a loss of isolation capability.

Additional tests on slotted 4≠40 screws indicate that the screw slot fails between 15 to 20 in . lbs without adversely affecting the package.

However, in order to positively ensure the package integrity of the fully isolated device, Motorola does not recommend exceeding 10 in . lbs

of mounting torque under any mounting conditions.

Figure 10. Typical Mounting Techniques

for Isolated Package

BUT11AF

5

Motorola Bipolar Power Transistor Device Data

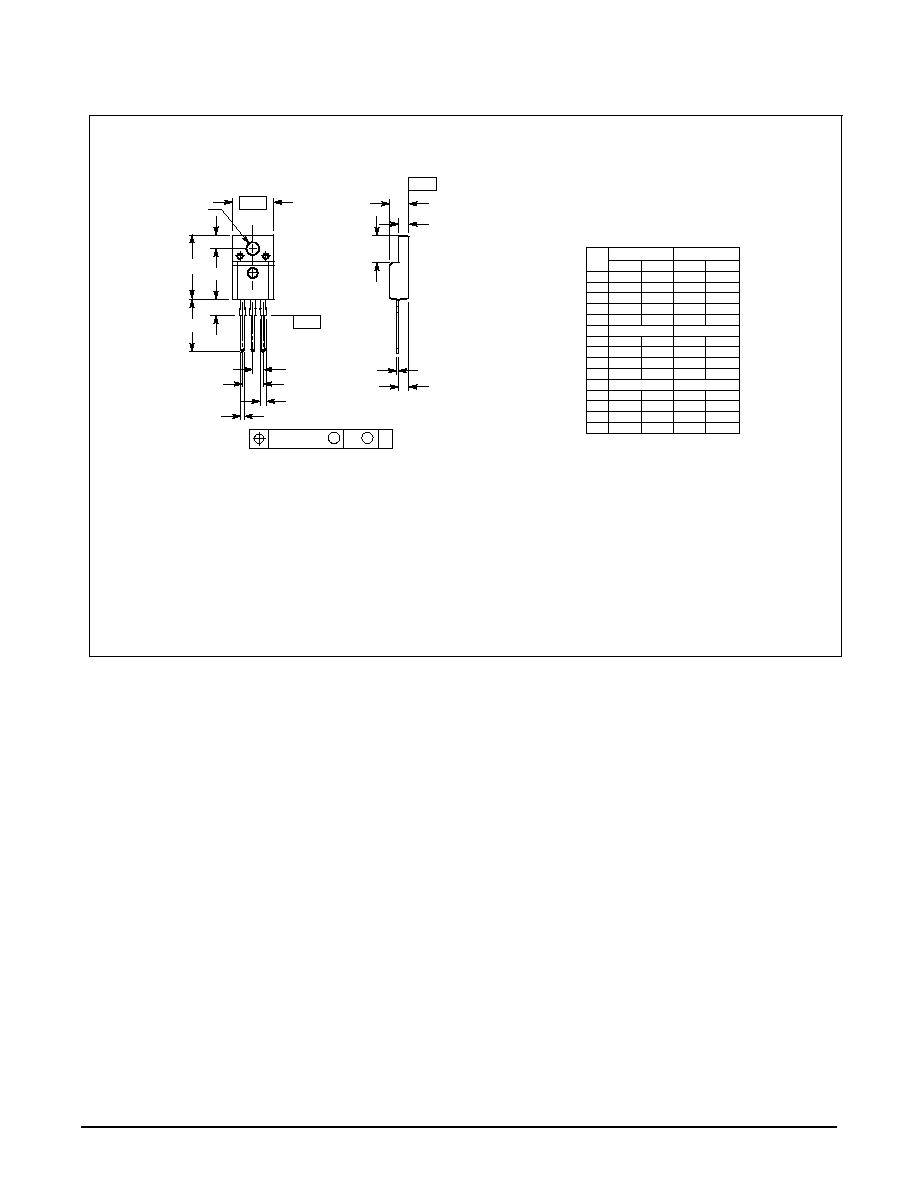

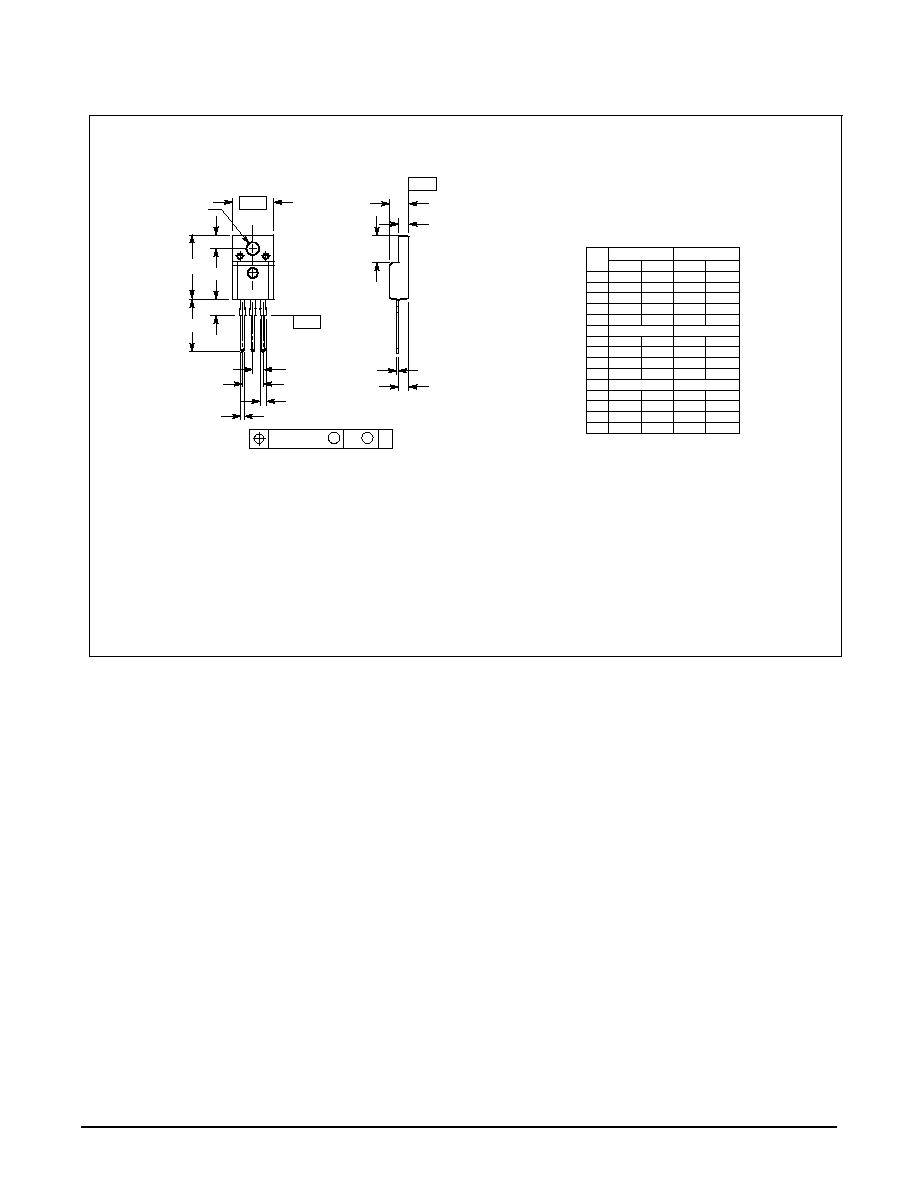

PACKAGE DIMENSIONS

CASE 221D≠02

TO≠220 TYPE

ISSUE D

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

STYLE 2:

PIN 1. BASE

2. COLLECTOR

3. EMITTER

DIM

A

MIN

MAX

MIN

MAX

MILLIMETERS

0.621

0.629

15.78

15.97

INCHES

B

0.394

0.402

10.01

10.21

C

0.181

0.189

4.60

4.80

D

0.026

0.034

0.67

0.86

F

0.121

0.129

3.08

3.27

G

0.100 BSC

2.54 BSC

H

0.123

0.129

3.13

3.27

J

0.018

0.025

0.46

0.64

K

0.500

0.562

12.70

14.27

L

0.045

0.060

1.14

1.52

N

0.200 BSC

5.08 BSC

Q

0.126

0.134

3.21

3.40

R

0.107

0.111

2.72

2.81

S

0.096

0.104

2.44

2.64

U

0.259

0.267

6.58

6.78

≠B≠

≠Y≠

G

N

D

L

K

H

A

F

Q

3 PL

1 2 3

M

B

M

0.25 (0.010)

Y

SEATING

PLANE

≠T≠

U

C

S

J

R