| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: DSP56F802 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

DSP56F802/D

Rev. 0, 1/2002

© Motorola, Inc., 2002. All rights reserved.

DSP56F802

Preliminary Technical Data

DSP56F802 16-bit Digital Signal Processor

∑

Up to 40 MIPS operation at 80 MHz core

frequency

∑

DSP and MCU functionality in a unified,

C-efficient architecture

∑

MCU-friendly instruction set supports both

DSP and controller functions: MAC, bit

manipulation unit, 14 addressing modes

∑

8K

◊

16-bit words Program Flash

∑

1K

◊

16-bit words Program RAM

∑

2K

◊

16-bit words Data Flash

∑

1K

◊

16-bit words Data RAM

∑

2K

◊

16-bit words Boot Flash

∑

Hardware DO and REP loops

∑

6-channel PWM Module with fault input

∑

Two 12-bit ADCs (1 x 2 channel, 1 x 3 channel)

∑

Serial Communications Interface (SCI)

∑

Two General Purpose Quad Timers with 2

external outputs

∑

JTAG/OnCE

TM

port for debugging

∑

4 shared GPIO

∑

On-chip relaxation oscillator

∑

32-pin LQFP Package

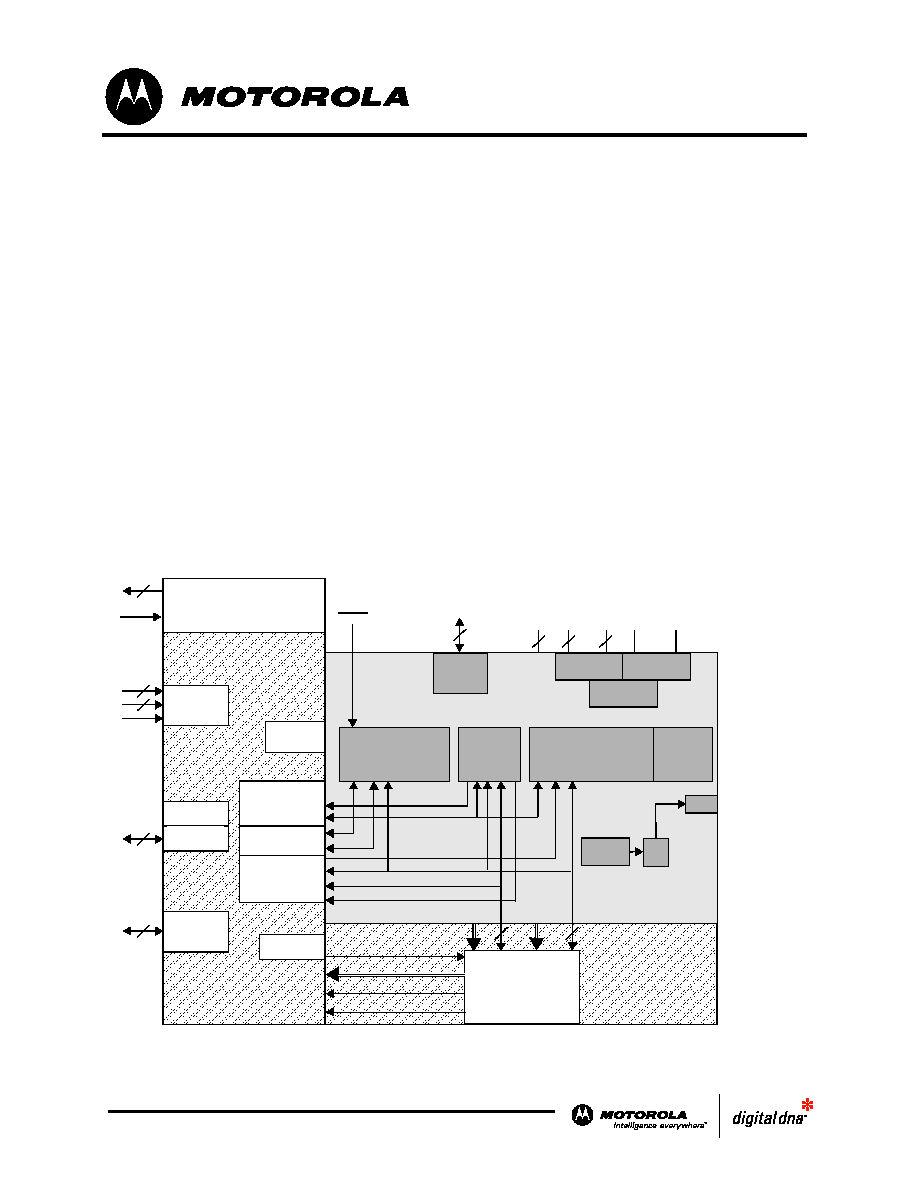

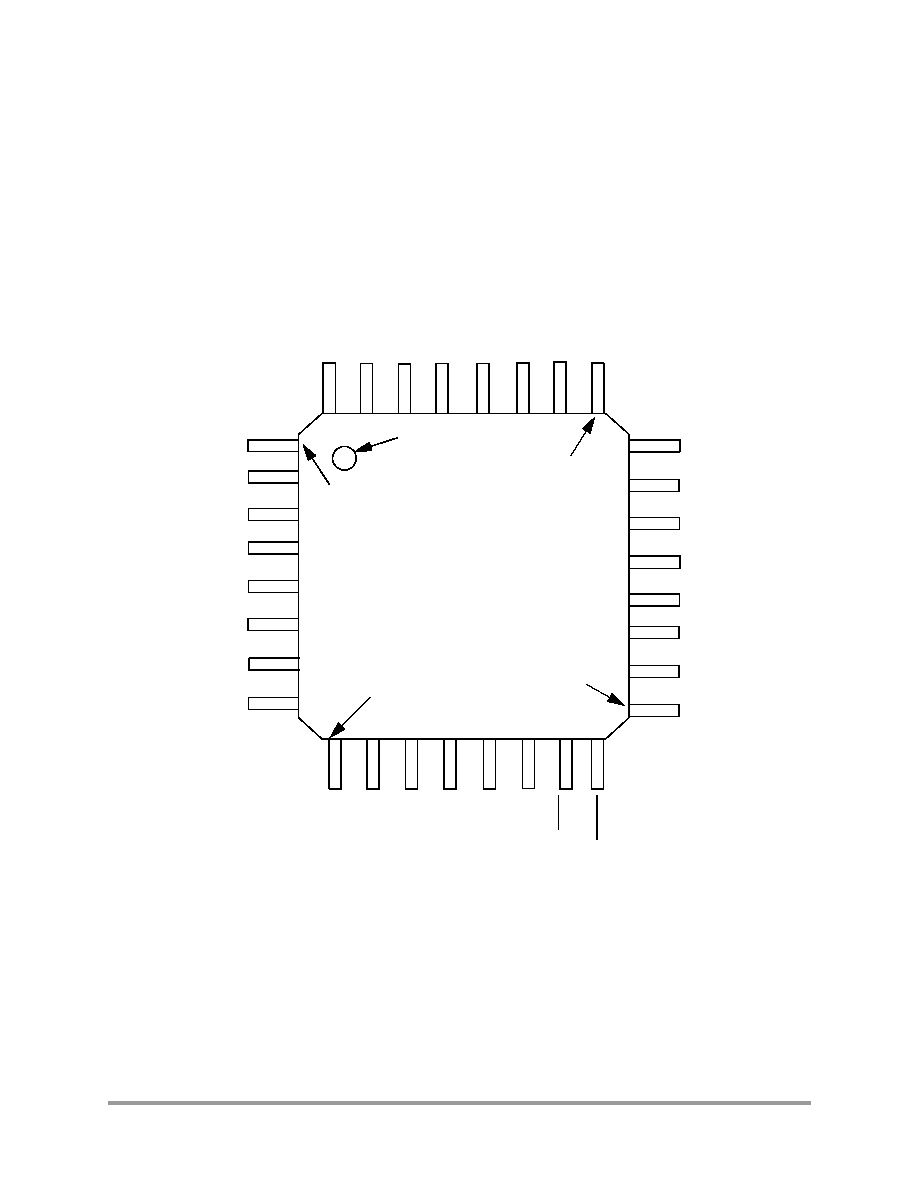

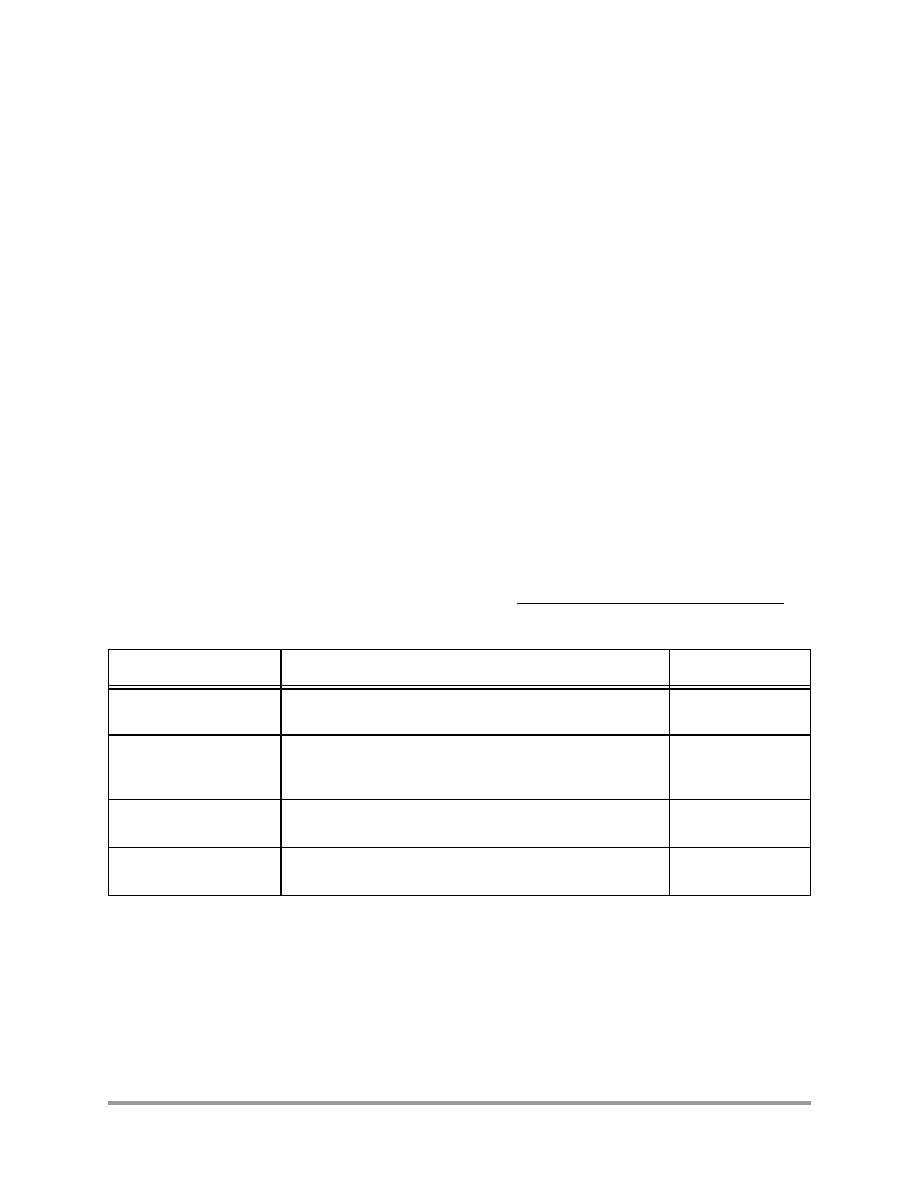

Figure 1. DSP56F802 Block Diagram

JTAG/

OnCE

Port

Digital Reg

Analog Reg

Low Voltage

Supervisor

Program Controller

and

Hardware Looping Unit

Data ALU

16 x 16 + 36

36-Bit MAC

Three 16-bit Input Registers

Two 36-bit Accumulators

Address

Generation

Unit

Bit

Manipulation

Unit

16-Bit

DSP56800

Core

PAB

PDB

XDB2

CGDB

XAB1

XAB2

INTERRUPT

CONTROLS

IPBB

CONTROLS

IPBus Bridge

(IPBB)

MODULE CONTROLS

ADDRESS BUS [8:0]

DATA BUS [15:0]

COP RESET

RESET

Application-

Specific

Memory &

Peripherals

Interrupt

Controller

Program Memory

8188 x 16 Flash

1024 x 16 SRAM

Boot Flash

2048x 16 Flash

Data Memory

2048 x 16 Flash

1024 x 16 SRAM

COP/

Watchdog

SCI0

or

GPIO

Quad Timer D

or GPIO

Quad Timer C

A/D1

A/D2

ADC

2

2

3

2

6

PWM Outputs

PWMA

16

16

VCAPC

V

DD

V

SS

* V

DDA

V

SSA

5

2

2

3

∑ ∑

∑

∑

∑

∑

∑

∑

VREF

PLL

Relaxation

Oscillator

.

*

includes TCS pin which is reserved for factory use and is tied to

VSS

Fault A0

2

DSP56F802 Preliminary Technical Data

MOTOROLA

Part 1 Overview

1.1 DSP56F802 Features

1.1.1

Digital Signal Processing Core

∑

Efficient 16-bit DSP56800 family DSP engine with dual Harvard architecture

∑

As many as 40 Million Instructions Per Second (MIPS) at 80 MHz core frequency

∑

Single-cycle 16

◊

16-bit parallel Multiplier-Accumulator (MAC)

∑

Two 36-bit accumulators including extension bits

∑

16-bit bidirectional barrel shifter

∑

Parallel instruction set with unique DSP addressing modes

∑

Hardware DO and REP loops

∑

Three internal address buses and one external address bus

∑

Four internal data buses and one external data bus

∑

Instruction set supports both DSP and controller functions

∑

Controller style addressing modes and instructions for compact code

∑

Efficient C compiler and local variable support

∑

Software subroutine and interrupt stack with depth limited only by memory

∑

JTAG/OnCE debug programming interface

1.1.2

Memory

∑

Harvard architecture permits as many as three simultaneous accesses to program and data memory

∑

On-chip memory including a low-cost, high-volume flash solution

-- 8K

◊

16 bit words of Program Flash

-- 1K

◊

16-bit words of Program RAM

-- 2K

◊

16-bit words of Data Flash

-- 1K

◊

16-bit words of Data RAM

-- 2K

◊

16-bit words of Boot Flash

∑

Programmable Boot Flash supports customized boot code and field upgrades of stored code through

a variety of interfaces (JTAG)

1.1.3

Peripheral Circuits for DSP56F802

∑

Pulse Width Modulator (PWM) with six PWM outputs with deadtime insertion and fault protection;

supports both center- and edge-aligned modes

∑

Two 12-bit, Analog-to-Digital Converters (ADCs), 1 x 2 channel and 1 x 3 channel, which support

two simultaneous conversions; ADC and PWM modules can be synchronized

∑

Two General Purpose Quad Timers with two external pins (or two GPIO)

∑

Serial Communication Interface (SCI) with two pins (or two GPIO)

∑

Four multiplexed General Purpose I/O (GPIO) pins

DSP56F802 Description

MOTOROLA

DSP56F802 Preliminary Technical Data

3

∑

Computer-Operating Properly (COP) watchdog timer

∑

External interrupts via GPIO

∑

Trimmable on-chip relaxation oscillator

∑

External reset pin for hardware reset

∑

JTAG/On-Chip Emulation (OnCETM) for unobtrusive, processor speed-independent debugging

∑

Software-programmable, Phase Lock Loop-based frequency synthesizer for the DSP core clock

1.1.4

Energy Information

∑

Fabricated in high-density CMOS with 5V tolerant, TTL-compatible digital inputs

∑

Uses a single 3.3V power supply

∑

On-chip regulators for digital and analog circuitry to lower cost and reduce noise

∑

Wait and Stop modes available

∑

Integrated power supervisor

1.2 DSP56F802 Description

The DSP56F802 is a member of the DSP56800 core-based family of Digital Signal Processors (DSPs). It

combines, on a single chip, the processing power of a DSP and the functionality of a microcontroller with

a flexible set of peripherals to create an extremely cost-effective solution. Because of its low cost,

configuration flexibility, and compact program code, the DSP56F802 is well-suited for many applications.

The DSP56F802 includes many peripherals that are especially useful for applications such as motion

control, home appliances, encoders, tachometers, limit switches, power supply and control, engine

management, and industrial control for power, lighting, automation and HVAC.

The DSP56800 core is based on a Harvard-style architecture consisting of three execution units operating

in parallel, allowing as many as six operations per instruction cycle. The microprocessor-style programming

model and optimized instruction set allow straightforward generation of efficient, compact code for both

DSP and MCU applications. The instruction set is also highly efficient for C compilers to enable rapid

development of optimized control applications.

The DSP56F802 supports program execution from either internal or external memories. Two data operands

can be accessed from the on-chip data RAM per instruction cycle. The DSP56F802 also provides and up to

4 General Purpose Input/Output (GPIO) lines, depending on peripheral configuration.

The DSP56F802 DSP controller includes 8K words (16-bit) of program Flash and 2K words of Data Flash

(each programmable through the JTAG port) with 1K words of both program and data RAM. A total of 2K

words of Boot Flash is incorporated for easy customer-inclusion of field-programmable software routines

that can be used to program the main program and data flash memory areas. Both program and data flash

memories can be independently bulk erased or erased in page sizes of 256 words. The Boot Flash memory

can also be either bulk or page erased.

A key application-specific feature of the DSP56F802 is the inclusion of a Pulse Width Modulator (PWM)

module. This modules incorporates six complementary, individually programmable PWM signal outputs to

enhance motor control functionality. Complementary operation permits programmable dead-time insertion,

and separate top and bottom output polarity control. The up-counter value is programmable to support a

continuously variable PWM frequency. Both edge and center aligned synchronous pulse width control (0%

to 100% modulation) are supported. The device is capable of controlling most motor types: ACIM (AC

4

DSP56F802 Preliminary Technical Data

MOTOROLA

Induction Motors), both BDC and BLDC (Brush and Brushless DC motors), SRM and VRM (Switched and

Variable Reluctance Motors), and stepper motors. The PWMs incorporate fault protection with sufficient

output drive capability to directly drive standard opto-isolators. A "smoke-inhibit", write-once protection

feature for key parameters is also included. The PWM is double-buffered and includes interrupt control to

permit integral reload rates to be programmable from 1 to 16. The PWM modules provide a reference output

to synchronize the Analog-to-Digital Converters.

The DSP56F802 incorporates two 12-bit Analog-to-Digital Converters (ADCs) with a total of five channels.

A full set of standard programmable peripherals is provided that include a Serial Communications Interface

(SCI), and two Quad Timers. Any of these interfaces can be used as General-Purpose Input/Outputs (GPIO)

if that function is not required. An on-chip relaxation oscillator eliminates the need for an external crystal.

1.3 "Best in Class" Development Environment

The SDK (Software Development Kit) provides fully debugged peripheral drivers, libraries and interfaces

that allow programmers to create their unique C application code independent of component architecture.

The CodeWarrior Integrated Development Environment is a sophisticated tool for code navigation,

compiling, and debugging. A complete set of evaluation modules (EVMs) and development system cards

support concurrent engineering. Together, the SDK, CodeWarrior, and EVMs create a complete, scalable

tools solution for easy, fast, and efficient development.

1.4 Product Documentation

The four documents listed in

Table 1

are required for a complete description and proper design with the

DSP56F802. Documentation is available from local Motorola distributors, Motorola semiconductor sales

offices, Motorola Literature Distribution Centers, or online at www.motorola.com/semiconductors/dsp.

Table 1. DSP56F802 Chip Documentation

Topic

Description

Order Number

DSP56800

Family Manual

Detailed description of the DSP56800 family architecture, and

16-bit DSP core processor and the instruction set

DSP56800FM/D

DSP56F801/803/805/807

User's Manual

Detailed description of memory, peripherals, and interfaces of

the DSP56F801, DSP56F802, DSP56F803, DSP56F805, and

DSP56F807

DSP56F801-7UM/D

DSP56F802

Technical Data Sheet

Electrical and timing specifications, pin descriptions, and

package descriptions (this document)

DSP56F802/D

DSP56F802

Product Brief

Summary description and block diagram of the DSP56F802

core, memory, peripherals and interfaces

DSP56F802PB/D

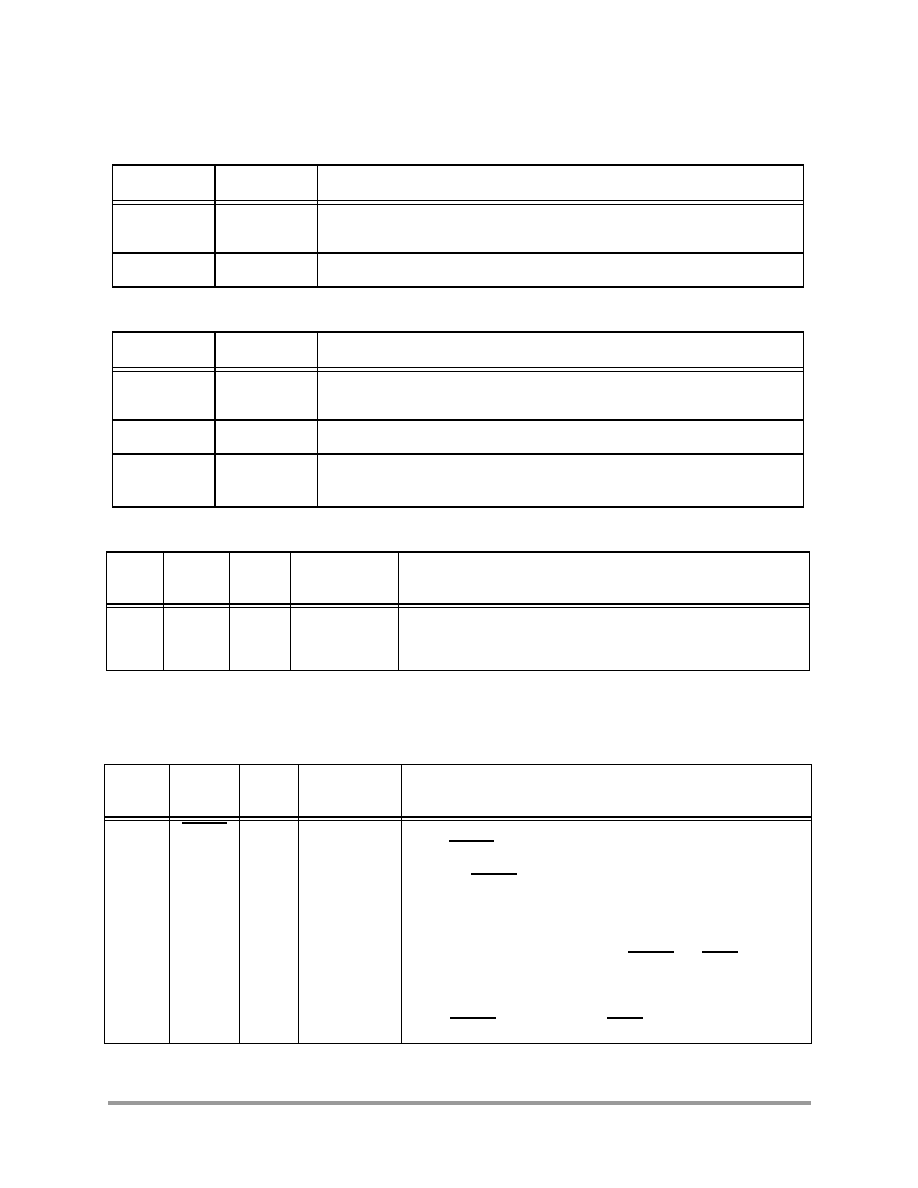

Data Sheet Conventions

MOTOROLA

DSP56F802 Preliminary Technical Data

5

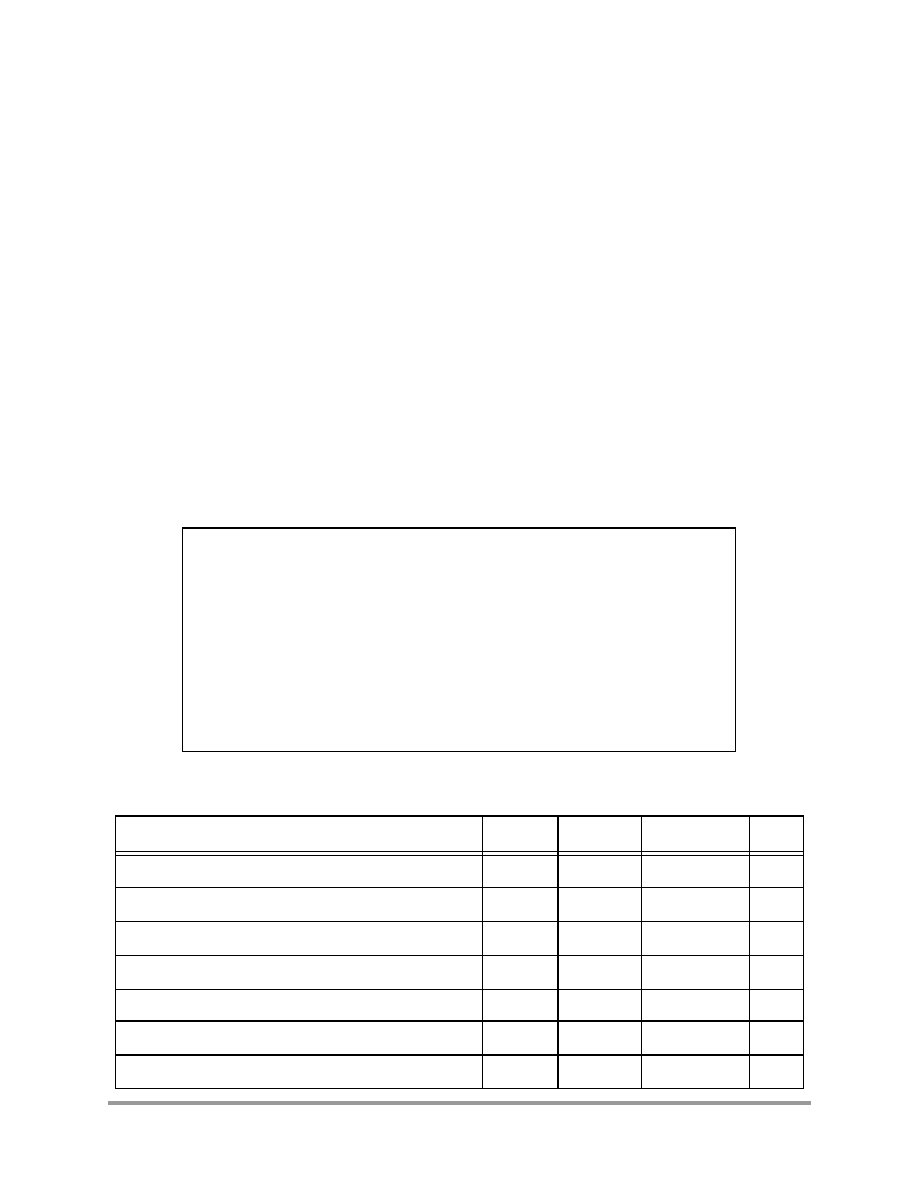

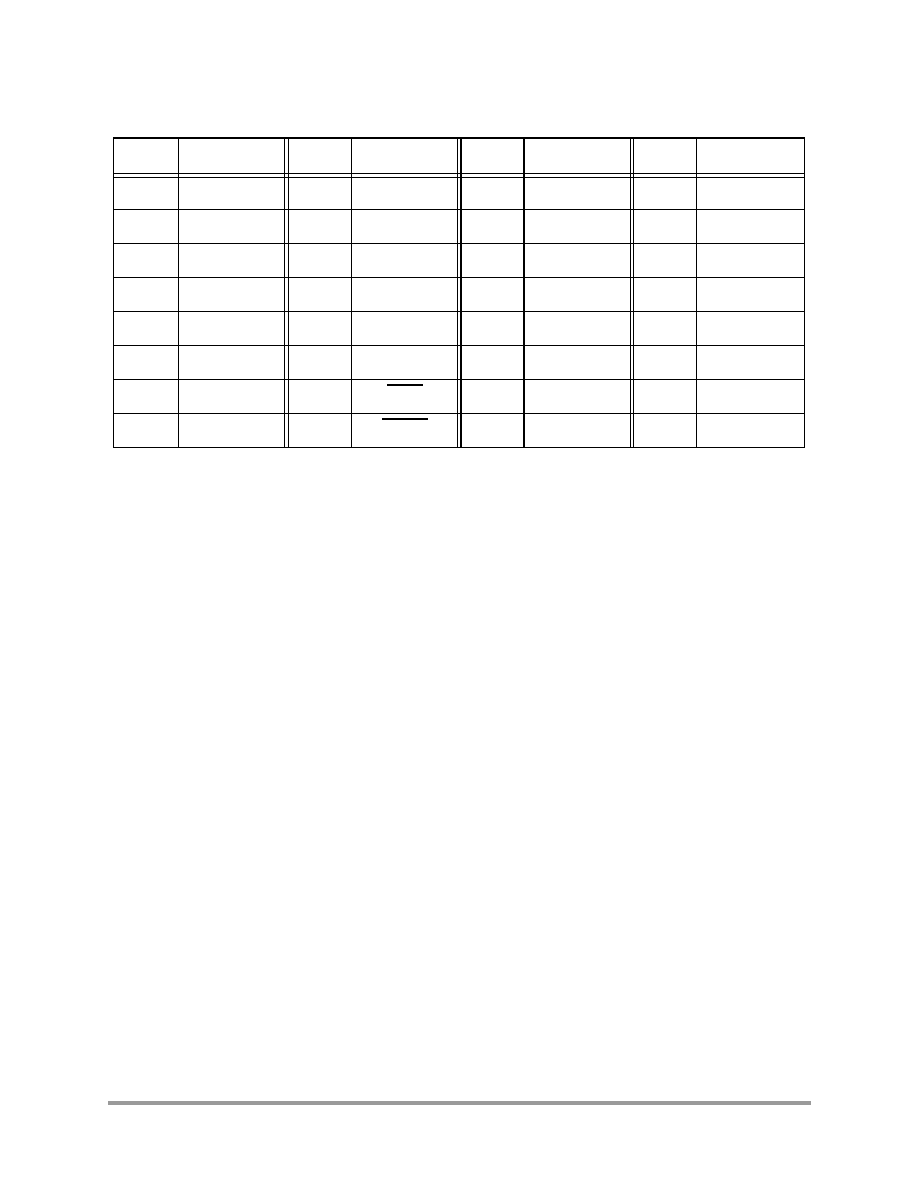

1.5 Data Sheet Conventions

This data sheet uses the following conventions:

OVERBAR

This is used to indicate a signal that is active when pulled low. For example, the RESET pin is

active when low.

"asserted"

A high true (active high) signal is high or a low true (active low) signal is low.

"deasserted"

A high true (active high) signal is low or a low true (active low) signal is high.

Examples:

Signal/Symbol

Logic State

Signal State

Voltage

1

1.

Values for VIL, VOL, VIH, and VOH are defined by individual product specifications.

PIN

True

Asserted

V

IL

/V

OL

PIN

False

Deasserted

V

IH

/V

OH

PIN

True

Asserted

V

IH

/V

OH

PIN

False

Deasserted

V

IL

/V

OL

6

DSP56F802 Preliminary Technical Data

MOTOROLA

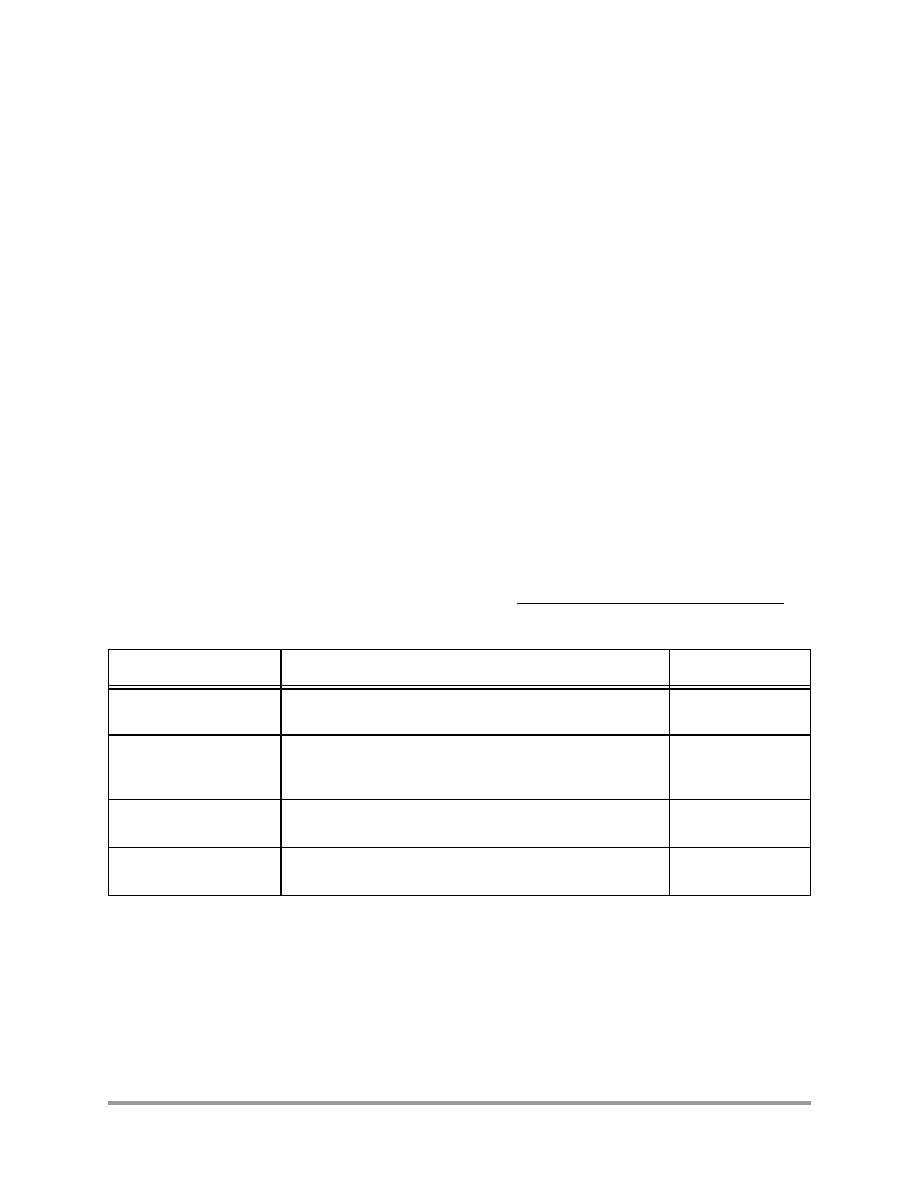

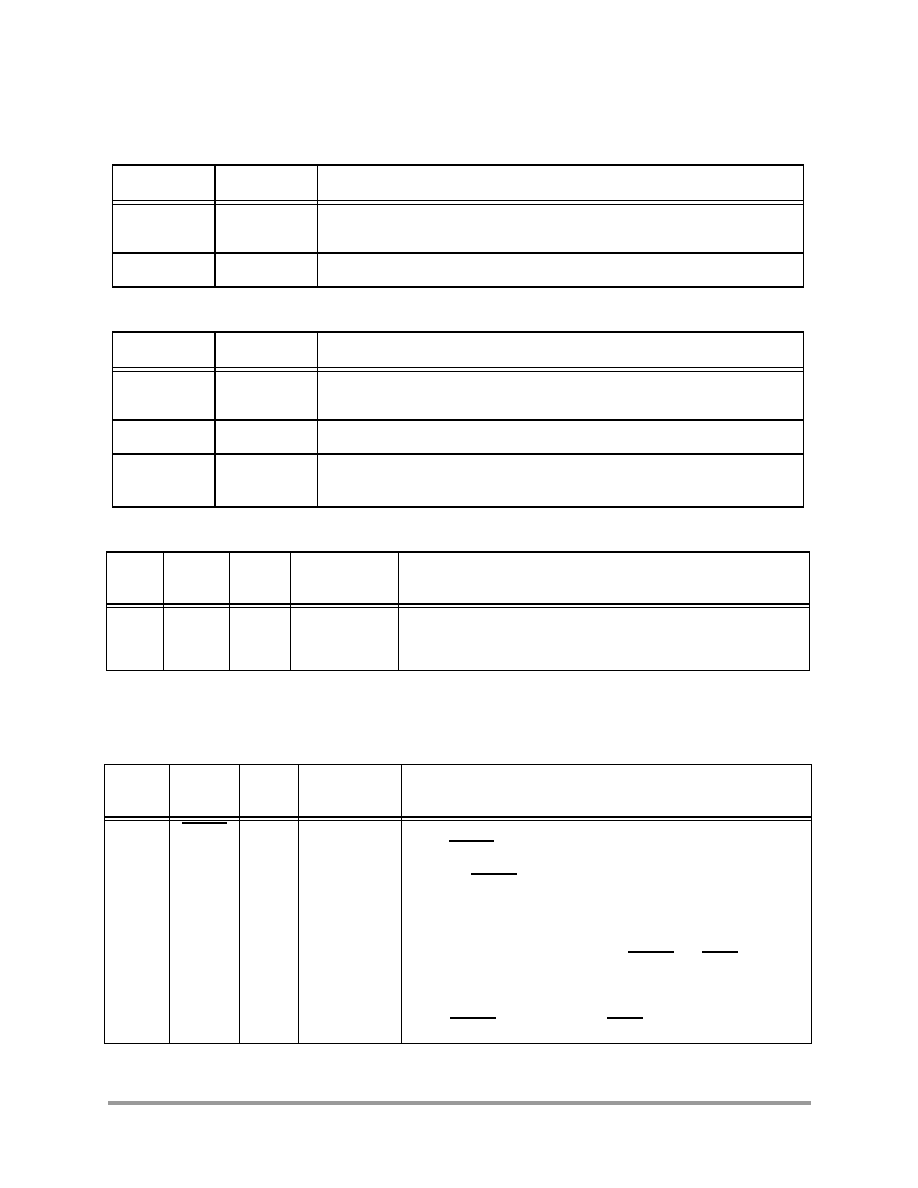

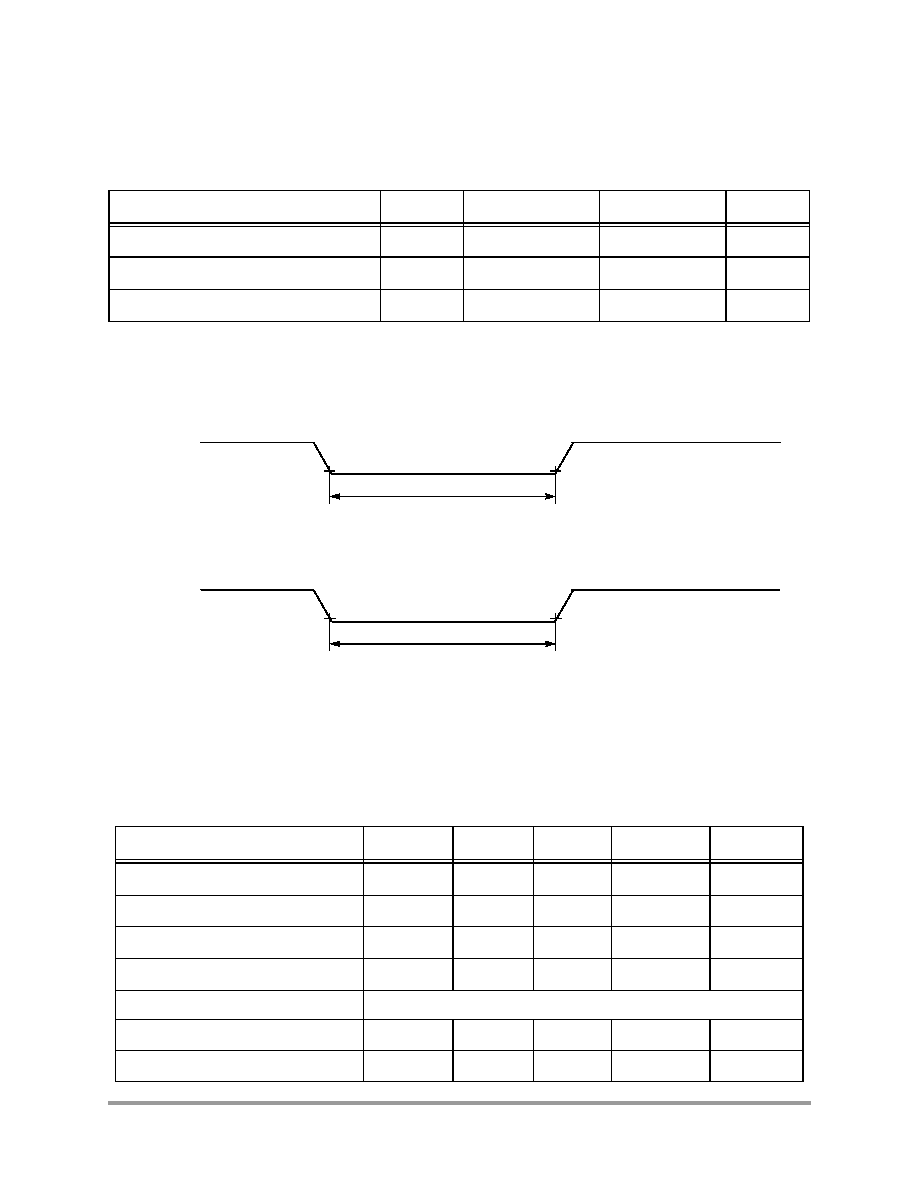

Part 2 Signal/Connection Descriptions

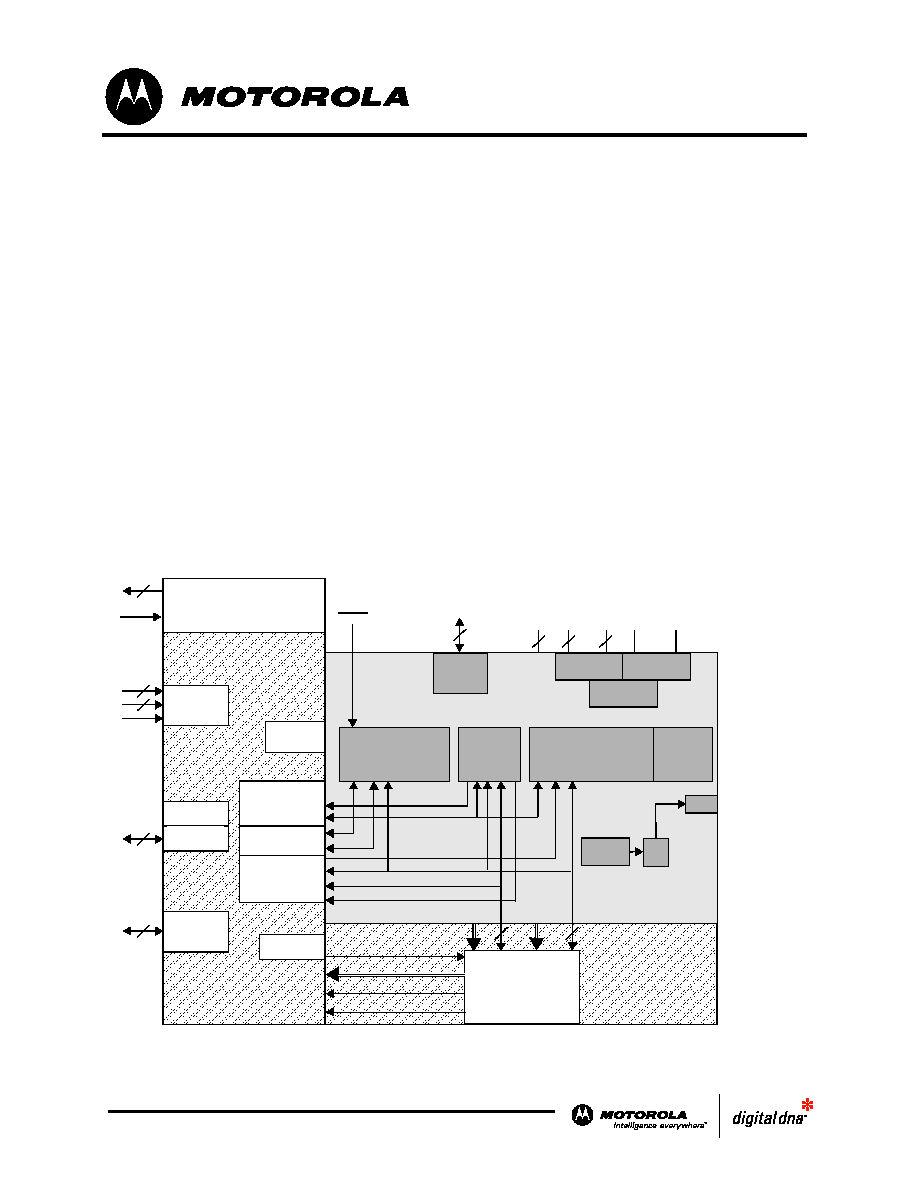

2.1 Introduction

The input and output signals of the DSP56F802 are organized into functional groups, as shown in

Table 2

and as illustrated in

Figure 2

. In

Table 3

through

Table 11

, each table row describes the signal or signals

present on a pin.

Table 2. Functional Group Pin Allocations

Functional Group

Number of

Pins

Detailed

Description

Power (V

DD

or V

DDA

)

3

Table 3

Ground (V

SS,

V

SSA,

TCS)

4

Table 4

Supply Capacitors

2

Table 5

Program Control

1

Table 6

Pulse Width Modulator (PWM) Port and Fault Input

7

Table 7

Serial Communications Interface (SCI) Port

1

1.

Alternately, GPIO pins

2

Table 8

Analog-to-Digital Converter (ADC) Port (including V

REF)

6

Table 9

Quad Timer Module Port

2

Table 10

JTAG/On-Chip Emulation (OnCE)

5

Table 11

Introduction

MOTOROLA

DSP56F802 Preliminary Technical Data

7

Figure 2. DSP56F802 Signals Identified by Functional Group

1

1. Alternate pin functionality is shown in parenthesis.

DSP56F802

Power Port

Ground Port

Power Port

Ground Port

SCI0 Port or

GPIO

V

DD

V

SS

V

DDA

V

SSA

VCAPC

TCK

TMS

TDI

TDO

TRST

JTAG/

OnCE

TM

Port

PWMA0-5

Fault A0

TXD0 (GPIOB0)

RXD0 (GPIOB1)

ANA2-4, ANA6-7

VREF

TD1-2 (GPIOA1-2)

RESET

Quad

Timer D or

GPIO

ADCA Port

Other

Supply Port

2

3*

1

1

2

1

1

1

1

1

Program

Control

6

1

1

1

5

1

2

1

*

includes TCS pin which is reserved for factory use and is tied to

VSS

8

DSP56F802 Preliminary Technical Data

MOTOROLA

2.2 Power and Ground Signals

2.3 Interrupt and Program Control Signals

Table 3. Power Inputs

No. of Pins

Signal Name

Signal Description

2

V

DD

Power--These pins provide power to the internal structures of the chip, and

should all be attached to V

DD.

1

V

DDA

Analog Power--This pin supplies an analog power source.

Table 4. Grounds

No. of Pins

Signal Name

Signal Description

2

V

SS

GND--These pins provide grounding for the internal structures of the chip, and

should all be attached to V

SS.

1

V

SSA

Analog Ground--This pin supplies an analog ground.

1

TCS

TCS--This pin is reserved for factory use and must be tied to V

SS

for normal

use. In block diagrams, this pin is considered an additional V

SS.

Table 5. Supply Capacitors and VPP

No. of

Pins

Signal

Name

Signal

Type

State During

Reset

Signal Description

2

VCAPC Supply

Supply

VCAPC - Connect each pin to a 2.2

µ

F bypass capacitor in order

to bypass the core logic voltage regulator (required for proper chip

operation). For more information, refer to

Section 5.2

Table 6. Program Control Signals

No. of

Pins

Signal

Name

Signal

Type

State During

Reset

Signal Description

1

RESET

Input

Input

Reset--This input is a direct hardware reset on the processor.

When RESET is asserted low, the DSP is initialized and placed in

the Reset state. A Schmitt trigger input is used for noise immunity.

When the RESET pin is deasserted, the initial chip operating

mode is latched from the EXTBOOT pin. The internal reset signal

will be deasserted synchronous with the internal clocks, after a

fixed number of internal clocks.

To ensure complete hardware reset, RESET and TRST should be

asserted together. The only exception occurs in a debugging

environment when a hardware DSP reset is required and it is

necessary not to reset the OnCE/JTAG module. In this case,

assert RESET, but do not assert TRST.

Pulse Width Modulator (PWM) Signals

MOTOROLA

DSP56F802 Preliminary Technical Data

9

2.4 Pulse Width Modulator (PWM) Signals

2.5 Serial Communications Interface (SCI) Signals

2.6 Analog-to-Digital Converter (ADC) Signals

Table 7. Pulse Width Modulator (PWMA) Signals

No. of

Pins

Signal

Name

Signal

Type

State During

Reset

Signal Description

6

PWMA0-5

Output

Tri-stated

PWMA0-5-- These are six PWMA output pins.

1

FAULTA0

Input

Input

FAULTA0 --This fault input is used for disabling selected

PWMA outputs in cases where fault conditions originate off

chip.

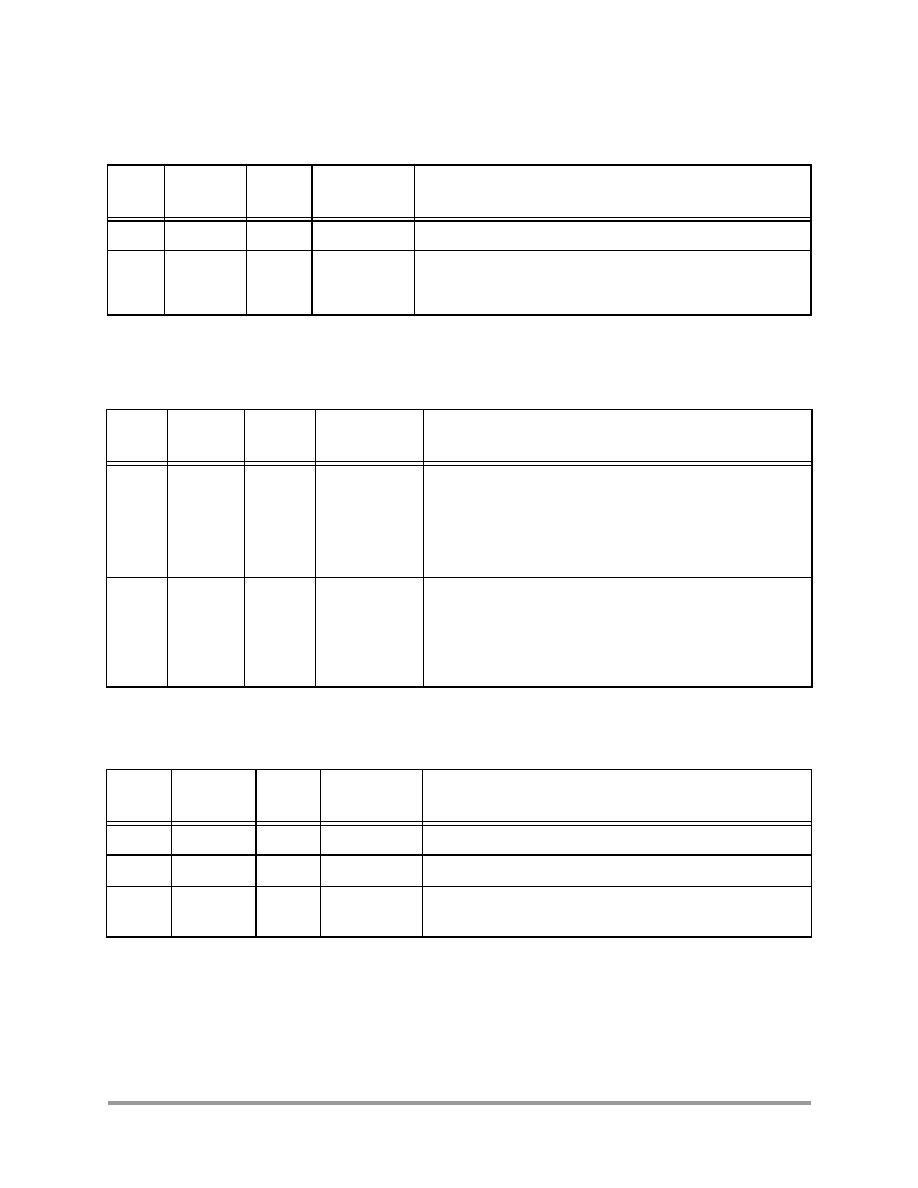

Table 8. Serial Communications Interface (SCI0) Signals

No. of

Pins

Signal

Name

Signal

Type

State During

Reset

Signal Description

1

TXD0

GPIOB0

Output

Input/

Output

Input

Input

Transmit Data (TXD0)--transmit data output

Port B GPIO--This pin is a General Purpose I/O (GPIO) pin

that can individually be programmed as input or output pin.

After reset, the default state is SCI output.

1

RXD0

GPIOB1

Input

Input/

Output

Input

Input

Receive Data (RXD0)--receive data input

Port B GPIO--This pin is a General Purpose I/O (GPIO) pin

that can individually be programmed as input or output pin.

After reset, the default state is SCI input.

Table 9. Analog to Digital Converter Signals

No. of

Pins

Signal

Name

Signal

Type

State During

Reset

Signal Description

3

ANA2-4

Input

Input

ANA2-4--Analog inputs to ADC channel 1

2

ANA6-7

Input

Input

ANA6-7--Analog inputs to ADC channel 2

1

VREF

Input

Input

VREF--Analog reference voltage. Must be set to V

DDA

- 0.3V

= 3.0V for optimal performance.

10

DSP56F802 Preliminary Technical Data

MOTOROLA

2.7 Quad Timer Module Signals

2.8 JTAG/OnCE

Table 10. Quad Timer Module Signals

No. of

Pins

Signal

Name

Signal

Type

State During

Reset

Signal Description

2

TD1-2

GPIOA1-2

Input/

Output

Input/

Output

Input

Input

TD1-2--Timer D Channel 1-2

Port A GPIO--These pins are General Purpose I/O (GPIO)

pins that can individually be programmed as input or output

pins.

After reset, the default state is the quad timer input.

Table 11. JTAG/On-Chip Emulation (OnCE) Signals

No. of

Pins

Signal

Name

Signal

Type

State During

Reset

Signal Description

1

TCK

Input

Input, pulled

low internally

Test Clock Input--This input pin provides a gated clock to

synchronize the test logic and shift serial data to the JTAG/OnCE port.

The pin is connected internally to a pull-down resistor.

1

TMS

Input

Input, pulled

high internally

Test Mode Select Input--This input pin is used to sequence the JTAG

TAP controller's state machine. It is sampled on the rising edge of TCK

and has an on-chip pull-up resistor.

1

TDI

Input

Input, pulled

high internally

Test Data Input--This input pin provides a serial input data stream to

the JTAG/OnCE port. It is sampled on the rising edge of TCK and has

an on-chip pull-up resistor.

1

TDO

Output

Tri-stated

Test Data Output--This tri-statable output pin provides a serial output

data stream from the JTAG/OnCE port. It is driven in the Shift-IR and

Shift-DR controller states, and changes on the falling edge of TCK.

1

TRST

Input

Input, pulled

high internally

Test Reset--As an input, a low signal on this pin provides a reset

signal to the JTAG TAP controller. To ensure complete hardware reset,

TRST should be asserted whenever RESET is asserted. The only

exception occurs in a debugging environment, since the OnCE/JTAG

module is under the control of the debugger. In this case it is not

necessary to assert TRST when asserting RESET. Outside of a

debugging environment RESET should be permanently asserted by

grounding the signal, thus disabling the OnCE/JTAG module on the

DSP.

General Characteristics

MOTOROLA

DSP56F802 Preliminary Technical Data

11

Part 3 Specifications

3.1 General Characteristics

The DSP56F802 is fabricated in high-density CMOS with 5-volt tolerant TTL-compatible digital inputs.

The term "5-volt tolerant" refers to the capability of an I/O pin, built on a 3.3V compatible process

technology, to withstand a voltage up to 5.5V without damaging the device. Many systems have a mixture

of devices designed for 3.3V and 5V power supplies. In such systems, a bus may carry both 3.3V and 5V-

compatible I/O voltage levels (a standard 3.3V I/O is designed to receive a maximum voltage of 3.3V

±

10%

during normal operation without causing damage). This 5V tolerant capability therefore offers the power

savings of 3.3V I/O levels while being able to receive 5V levels without being damaged.

Absolute maximum ratings given in

Table 12

are stress ratings only, and functional operation at the

maximum is not guaranteed. Stress beyond these ratings may affect device reliability or cause permanent

damage to the device.

The DSP56F802 DC and AC electrical specifications are preliminary and are from design simulations.

These specifications may not be fully tested or guaranteed at this early stage of the product life cycle.

Finalized specifications will be published after complete characterization and device qualifications have

been completed.

CAUTION

This device contains protective circuitry to guard against

damage due to high static voltage or electrical fields.

However, normal precautions are advised to avoid

application of any voltages higher than maximum rated

voltages to this high-impedance circuit. Reliability of

operation is enhanced if unused inputs are tied to an

appropriate voltage level.

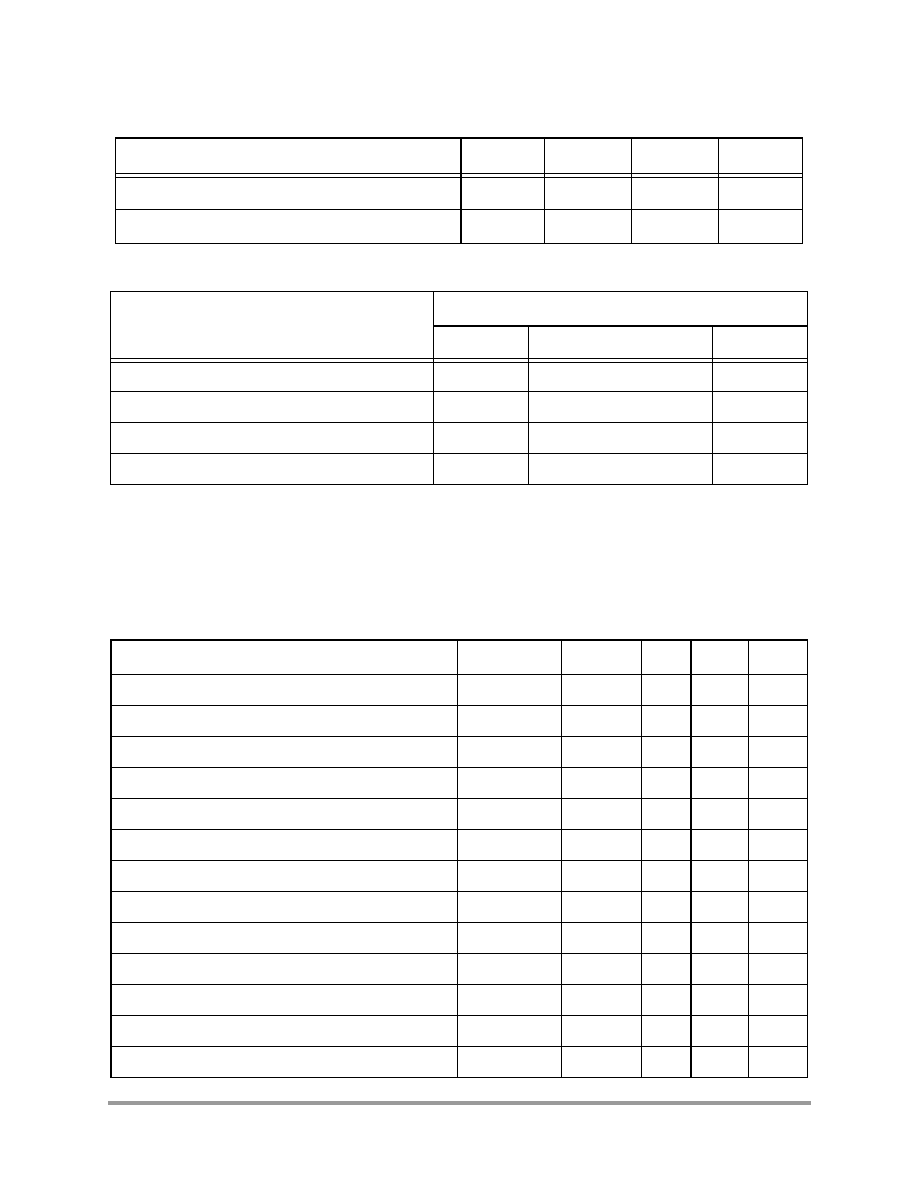

Table 12. Absolute Maximum Ratings

Characteristic

Symbol

Min

Max

Unit

Supply voltage

V

DD

V

SS

≠ 0.3

V

SS

+ 4.0

V

All other input voltages, excluding Analog inputs

V

IN

V

SS

≠ 0.3

V

SS

+ 5.5V

V

Analog Inputs ANAx, V

REF

V

IN

V

SS

≠ 0.3

V

DDA

+ 0.3V

V

Current drain per pin excluding V

DD

, V

SS

, & PWM ouputs

I

--

10

mA

Current drain per pin for PWM outputs

I

--

20

mA

Junction temperature

T

J

--

150

∞C

Storage temperature range

T

STG

-55

150

∞C

12

DSP56F802 Preliminary Technical Data

MOTOROLA

3.2 DC Electrical Characteristics

Table 13. Recommended Operating Conditions

Characteristic

Symbol

Min

Max

Unit

Supply voltage

V

DD

3.0

3.6

V

Ambient operating temperature

T

A

-40

85

∞C

Table 14. Thermal Characteristics

1

1.

See

Section 5.1

for more detail.

Characteristic

32-pin LQFP

Symbol

Value

Unit

Junction-to-ambient (estimated)

R

JA

53.2

∞C/W

I/O pin power dissipation

P

I/O

User Determined

W

Power dissipation

P

D

P

D

= (I

DD

x V

DD

) + P

I/O

W

Maximum allowed P

D

P

DMAX

(T

J

- T

A

) /

JA

∞

C

Table 15. DC Electrical Characteristics

Operating Conditions:

V

SS

= V

SSA

= 0 V, V

DD

= V

DDA

= 3.0≠3.6 V, T

A

= ≠40

∞

to +85

∞

C, C

L

50 pF, f

op

= 80 MHz

Characteristic

Symbol

Min

Typ

Max

Unit

Input high voltage

V

IH

2.0

--

5.5

V

Input low voltage

V

IL

-0.3

--

0.8

V

Input current low (pullups/pulldowns disabled)

I

IL

-1

--

1

µ

A

Input current high (pullups/pulldowns disabled)

I

IH

-1

--

1

µ

A

Typical pullup or pulldown resistance

R

PU

, R

PD

--

30

--

K

Input/output tri-state current low

I

OZL

-10

--

10

µ

A

Input/output tri-state current low

I

OZH

-10

--

10

µ

A

Output High Voltage (at IOH)

V

OH

V

DD

≠ 0.7

--

--

V

Output Low Voltage (at IOL)

V

OL

--

--

0.4

V

Output High Current

I

OH

--

--

-4

mA

Output Low Current

I

OL

--

--

4

mA

Input capacitance

C

IN

--

8

--

pF

Output capacitance

C

OUT

--

12

--

pF

DC Electrical Characteristics

MOTOROLA

DSP56F802 Preliminary Technical Data

13

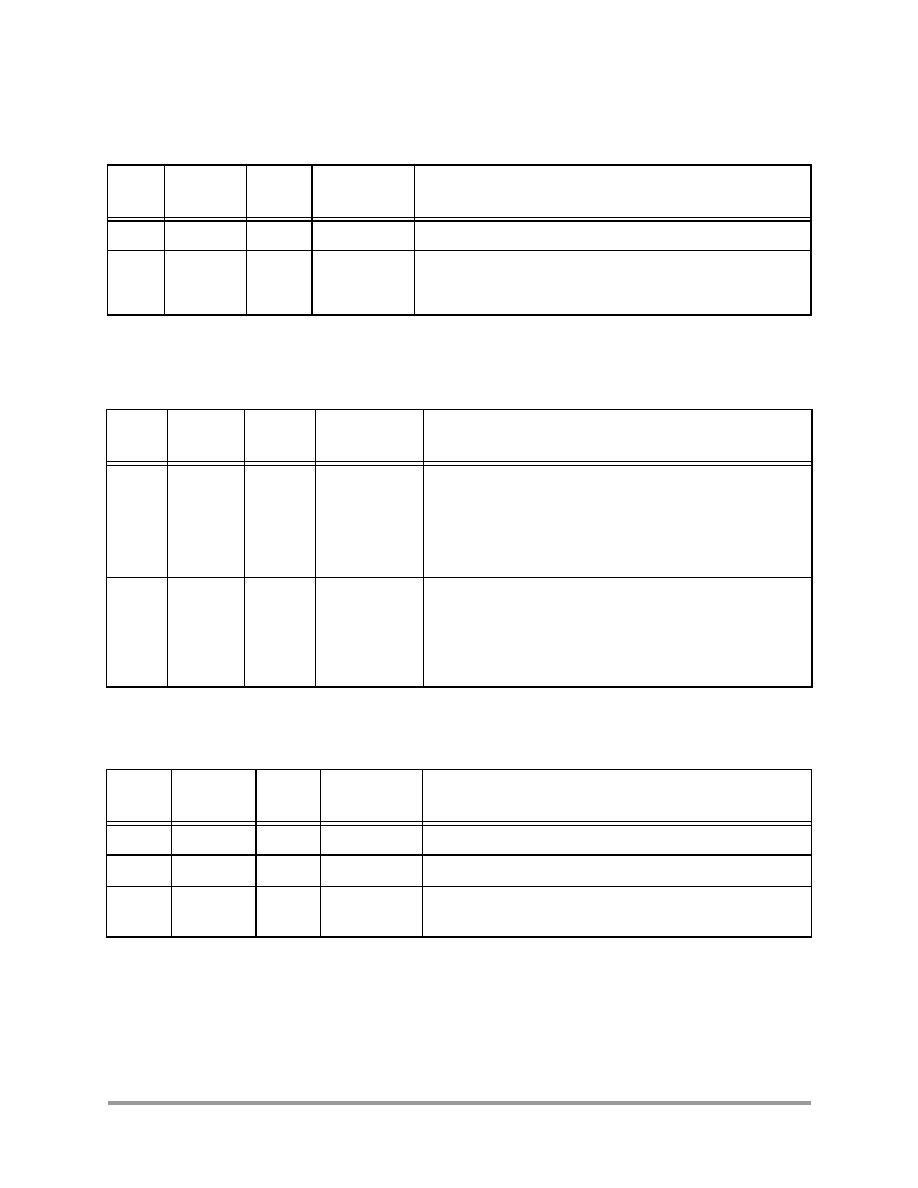

Figure 3. Maximum Run Idd vs. Frequency (see Note 4 above)

PWM pin output source current

1

I

OHP

--

--

-10

mA

PWM pin output sink current

2

I

OLP

--

--

16

mA

V

DD

supply current

I

DDT

3

Run

4

--

103

138

mA

Wait

5

--

72

98

mA

Stop

--

60

84

mA

Low Voltage Interrupt

6

Core Voltage Interrupt

V

EI

2.4

--

2.7

2.2

2.9

--

V

Power on Reset

7

POR

--

1.7

2.0

V

1.

PWM pin output source current measured with 50% duty cycle.

2.

PWM pin output sink current measured with 50% duty cycle.

3.

I

DDT

= I

DD

+ I

DDA

(Total supply current for VDD + VDDA)

4.

Run (operating) I

DD

measured using 8MHz clock source. All inputs 0.2V from rail; outputs unloaded. All ports

configured as inputs; measured with all modules enabled.

5.

Wait I

DD

measured using internal relaxation oscillator set to 8 MHz; all inputs 0.2V from rail; no DC loads; less

than 50 pF on all outputs. C

L

= 20 pF on EXTAL; all ports configured as inputs; measured with PLL enabled.

6.

Low voltage interrupt monitors the V

DD

supply. When V

DD

drops below V

EI

value, an interrupt is generated.

Functionality of the device is guaranteed under transient conditions when V

DDA

>V

EI

.

7.

Power-on reset occurs whenever the internally regulated 2.5V digital supply drops below V

POR

. While power is

ramping up, this signal remains active for as long as the internal 2.5V supply is below 1.5V no matter how long the ramp

up rate is. The internally regulated voltage is typically 100 mV less than V

DD

during ramp up until 2.5V is reached, at

which time it self regulates.

Table 15. DC Electrical Characteristics

Operating Conditions:

V

SS

= V

SSA

= 0 V, V

DD

= V

DDA

= 3.0≠3.6 V, T

A

= ≠40

∞

to +85

∞

C, C

L

50 pF, f

op

= 80 MHz

Characteristic

Symbol

Min

Typ

Max

Unit

180

150

120

90

60

30

0

I

dd (

m

A)

Digital (VDD=3.6V)

Analog (VDDA=3.6V)

Total

Freq. (MHz)

0

40

60

80

20

I

dd (

m

A)

40

180

150

120

90

60

30

0

14

DSP56F802 Preliminary Technical Data

MOTOROLA

3.3 AC Electrical Characteristics

Timing waveforms in

Section 3.3

are tested with a V

IL

maximum of 0.8 V and a V

IH

minimum of 2.0 V for

all pins except XTAL, which is tested using the input levels in

Section 3.2

In

Figure 4

the levels of V

IH

and

V

IL

for an input signal are shown.

Figure 4. Input Signal Measurement References

Figure 5

shows the definitions of the following signal states:

∑

Active state, when a bus or signal is driven, and enters a low impedance state.

∑

Tri-stated, when a bus or signal is placed in a high impedance state.

∑

Data Valid state, when a signal level has reached V

OL

or V

OH.

∑

Data Invalid state, when a signal level is in transition between V

OL

and V

OH.

Figure 5. Signal States

V

IH

V

IL

Fall Time

Input Signal

Note: The midpoint is V

IL

+ (V

IH

≠ V

IL

)/2.

Midpoint1

Low

High

90%

50%

10%

Rise Time

Data Invalid State

Data1

Data2 Valid

Data

Tri-stated

Data3 Valid

Data2

Data3

Data1 Valid

Data Active

Data Active

Flash Memory Characteristics

MOTOROLA

DSP56F802 Preliminary Technical Data

15

3.4 Flash Memory Characteristics

Table 16. Flash Memory Truth Table

Mode

XE

1

1.

X address enable, all rows are disabled when XE = 0

YE

2

2.

Y address enable, YMUX is disabled when YE = 0

SE

3

3.

Sense amplifier enable

OE

4

4.

Output enable, tri-state flash data out bus when OE = 0

PROG

5

5.

Defines program cycle

ERASE

6

6.

Defines erase cycle

MAS1

7

7.

Defines mass erase cycle, erase whole block

NVSTR

8

8.

Defines non-volatile store cycle

Standby

L

L

L

L

L

L

L

L

Read

H

H

H

H

L

L

L

L

Word Program

H

H

L

L

H

L

L

H

Page Erase

H

L

L

L

L

H

L

H

Mass Erase

H

L

L

L

L

H

H

H

Table 17. IFREN Truth Table

Mode

IFREN = 1

IFREN = 0

Read

Read information block

Read main memory block

Word program

Program information block

Program main memory block

Page erase

Erase information block

Erase main memory block

Mass erase

Erase both blocks

Erase main memory block

16

DSP56F802 Preliminary Technical Data

MOTOROLA

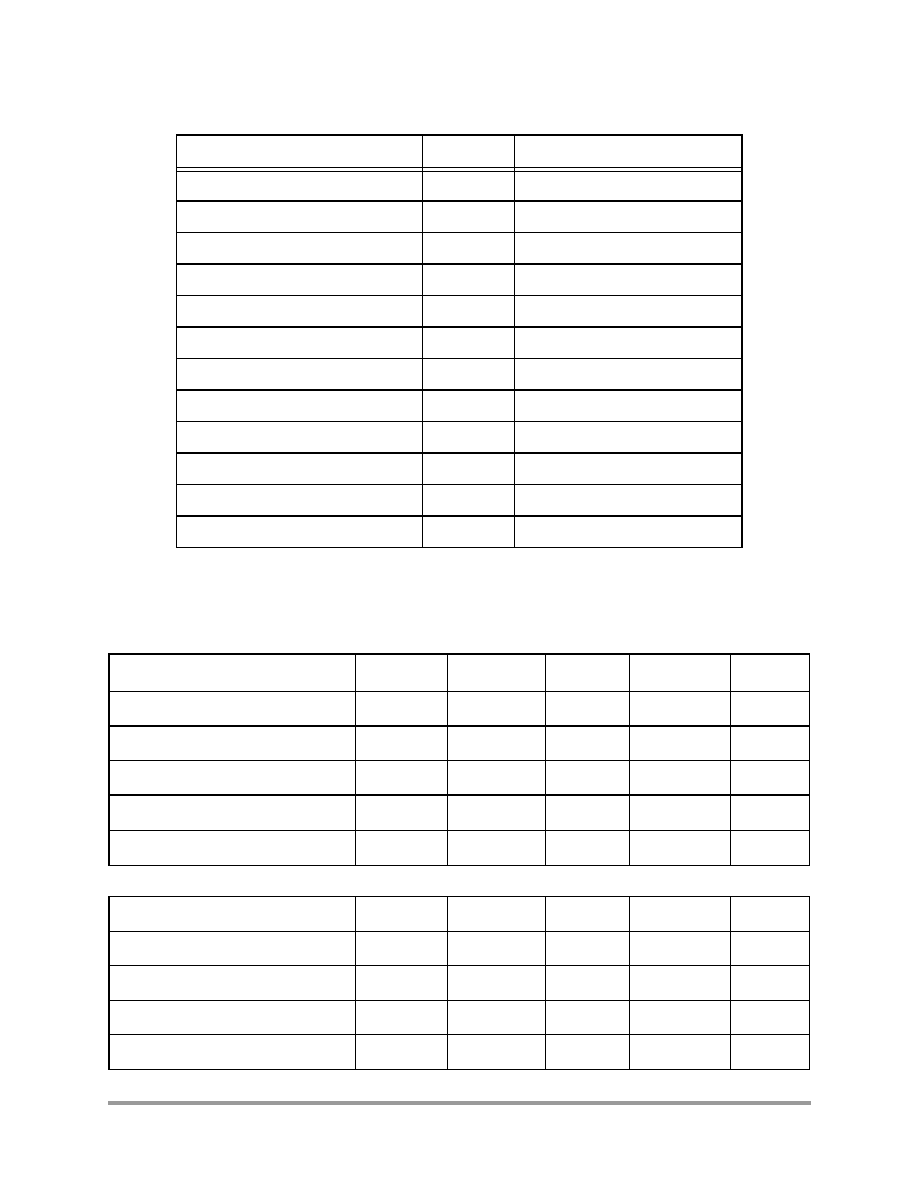

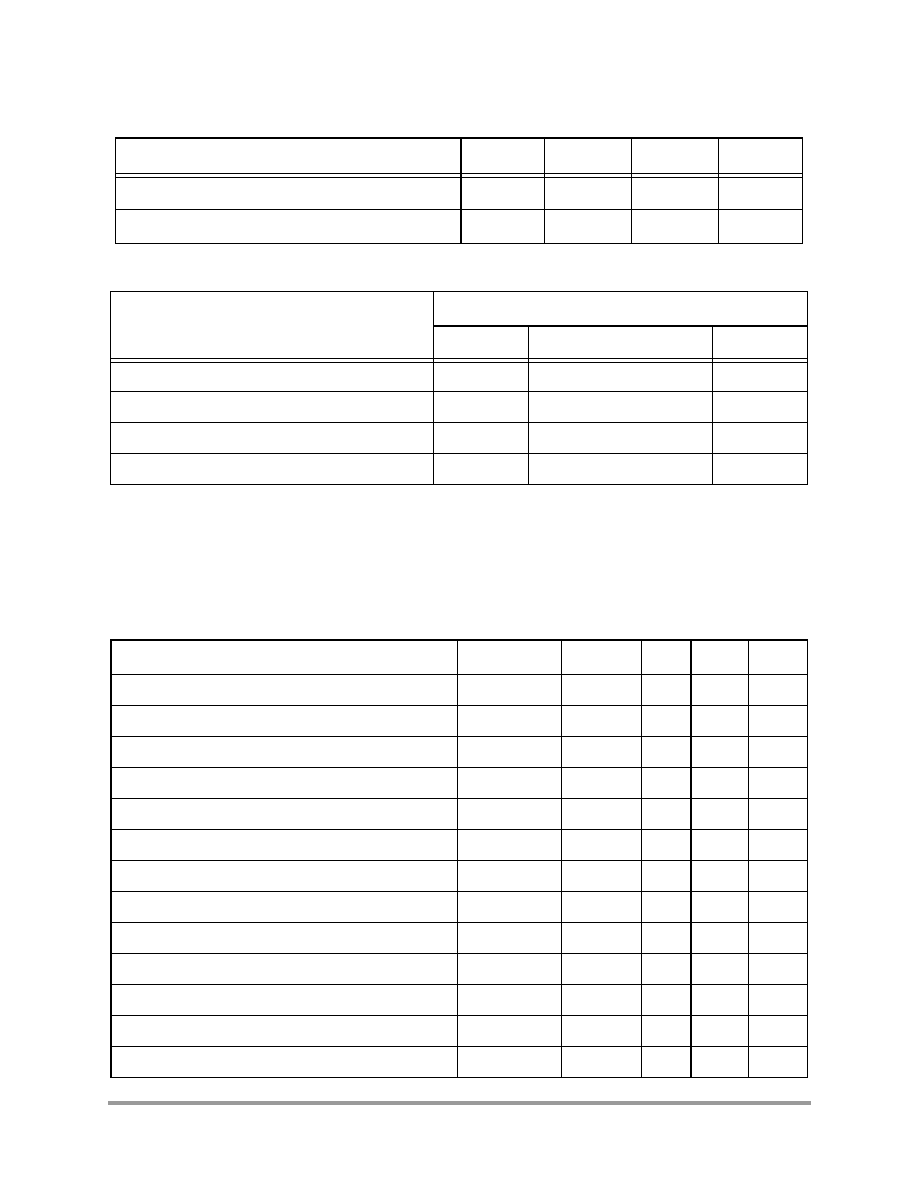

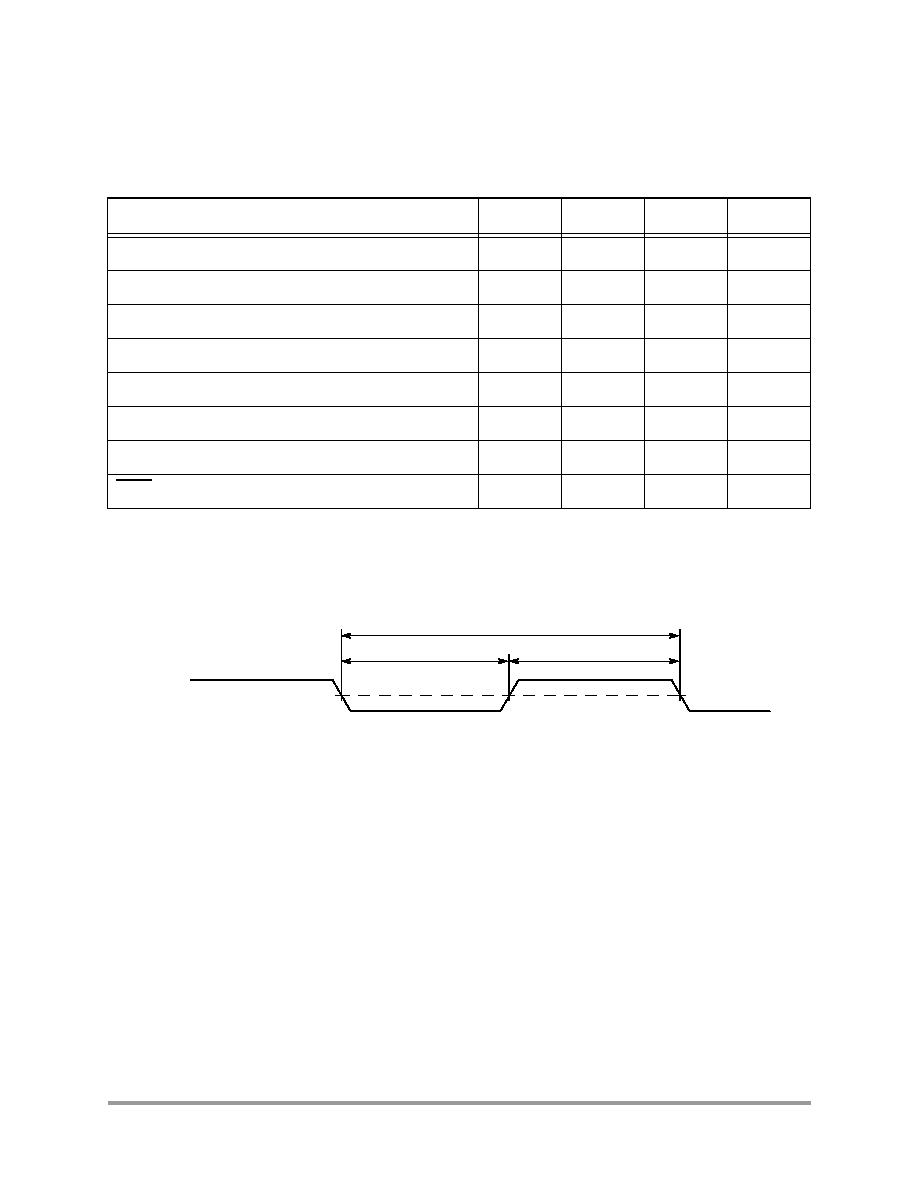

Table 18. Timing Symbols

Characteristic

Symbol

See Figure(s)

PROG/ERASE to NVSTR set up time

T

nvs

Figure 6

,

Figure 7

,

Figure 8

NVSTR hold time

T

nvh

Figure 6

,

Figure 7

NVSTR hold time(mass erase)

T

nvh1

Figure 8

NVSTR to program set up time

T

pgs

Figure 6

Program hold time

T

pgh

Figure 6

Address/data set up time

T

ads

Figure 6

Address/data hold time

T

adh

Figure 6

Recovery time

T

rcv

Figure 6

,

Figure 7

,

Figure 8

Cumulative program HV period

T

hv

Figure 6

Program time

T

prog

Figure 6

Erase time

T

erase

Figure 7

Mass erase time

T

me

Figure 8

Table 19. Flash Timing Parameters

Operating Conditions:

V

SS

= V

SSA

= 0 V, V

DD

= V

DDA

= 3.0≠3.6 V, T

A

= ≠40

∞

to +85

∞

C, C

L

50 pF

Characteristic

Symbol

Min Typ

Max Unit

Program time

T

prog

20

--

--

us

Erase time

T

erase

20

--

--

ms

Mass erase time

T

me

100

--

--

ms

Endurance

1

1.

One cycle is equal to an erase, program, and read.

E

CYC

10,000

20,000

--

cycles

Data Retention @ 5,000 Cycles

1

D

RET

10

30

--

years

The following parameters should only be used in the Manual Word Programming mode.

PROG/ERASE to NVSTR set up time

T

nvs

--

5

--

us

NVSTR hold time

T

nvh

--

5

--

us

NVSTR hold time(mass erase)

T

nvh1

--

100

--

us

NVSTR to program set up time

T

pgs

--

10

--

us

Recovery time

T

rcv

--

1

--

us

Flash Memory Characteristics

MOTOROLA

DSP56F802 Preliminary Technical Data

17

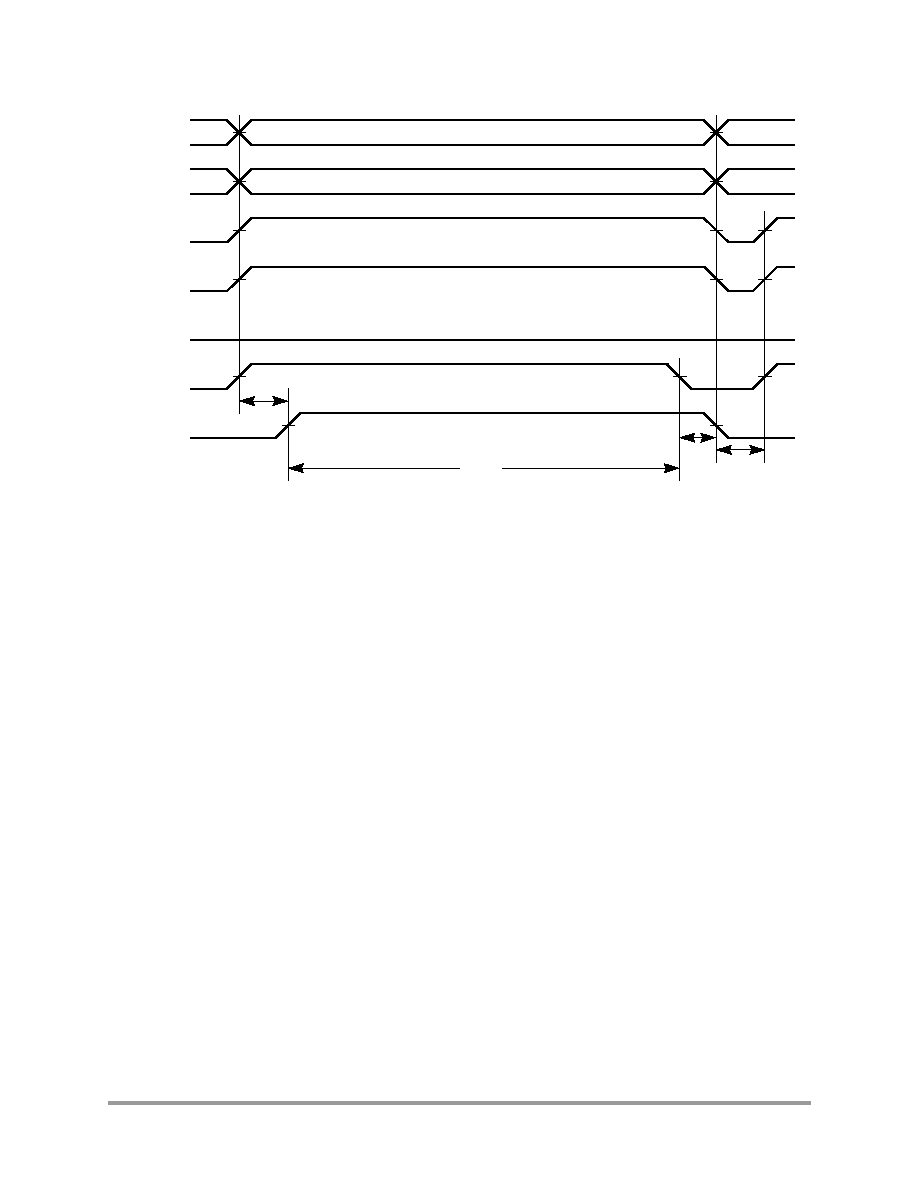

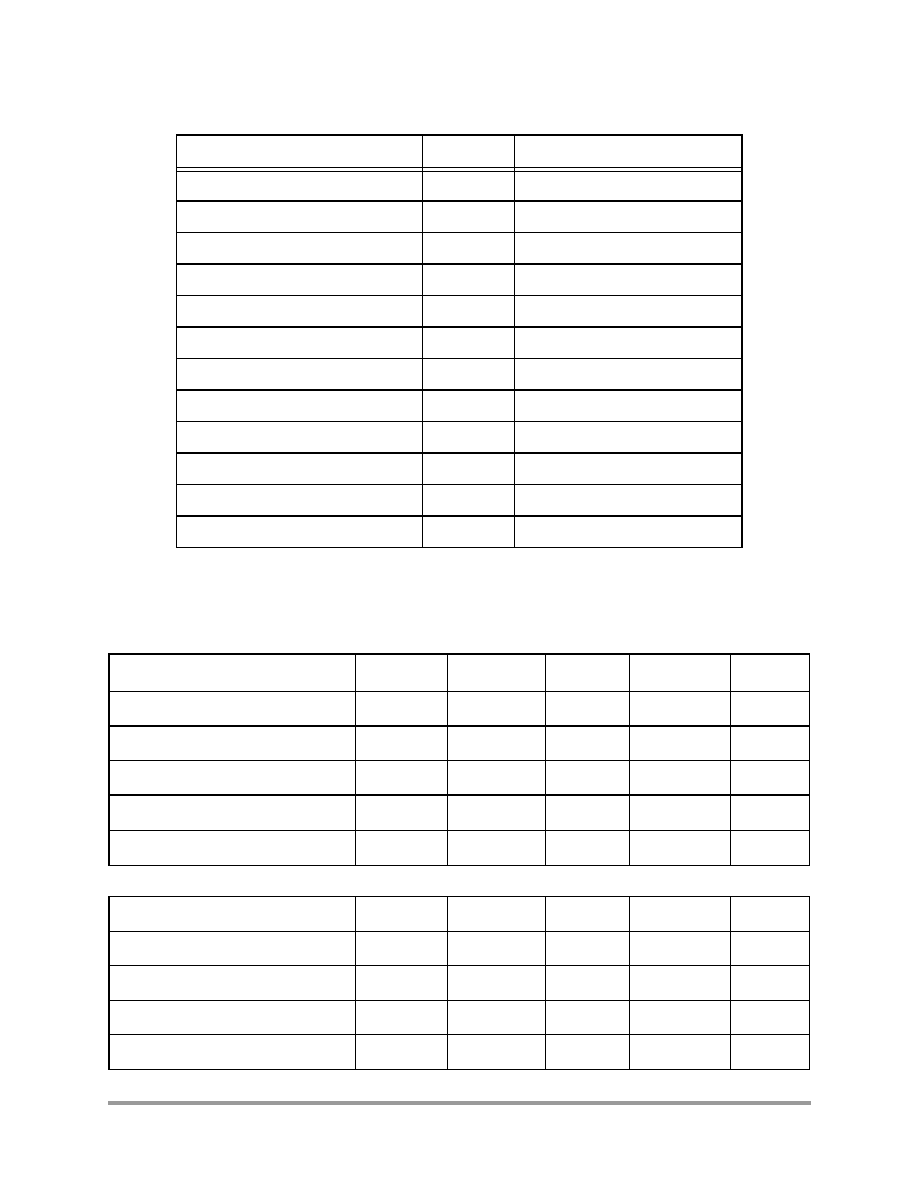

Figure 6. Flash Program Cycle

Figure 7. Flash Erase Cycle

XADR

YADR

YE

DIN

PROG

NVSTR

Tnvs

Tpgs

Tadh

Tprog

Tads

Tpgh

Tnvh

Trcv

Thv

IFREN

XE

XADR

YE=SE=OE=MAS1=0

ERASE

NVSTR

Tnvs

Tnvh

Trcv

Terase

IFREN

XE

18

DSP56F802 Preliminary Technical Data

MOTOROLA

Figure 8. Flash Mass Erase Cycle

3.5 Clock Operation

The DSP56F802 device clock is derived from an on-chip relaxation oscillator. The internal PLL generates

a master reference frequency that determines the speed at which chip operations occur.

The PRECS bit in the PLLCR (phase-locked loop control register) word (bit 2) must be set to 0 for internal

oscillator use.

3.5.1

Use of On-Chip Relaxation Oscillator

The DSP56F802 internal relaxation oscillator provides the chip clock without the need for an external

crystal or ceramic resonator. The frequency output of this internal oscillator can be corrected by adjusting

the 8-bit IOSCTL (internal oscillator control) register. Each bit added or deleted changes the output

frequency of the oscillator allowing incremental adjustment until the desired frequency is achieved. Figures

9 and 10 show the typical characteristics of the DSP56F802 relaxation oscillator with respect to temperature

and trim value.

During factory production test, an oscillator calibration procedure is executed which determines an

optimum trim value for a given device (8 MHz at 25

o

C). This optimum trim value is then stored at address

$103F in the Data Flash Information Block and recalled during a trim routine in the boot sequence (executed

after power-up and RESET). This trim routine automatically sets the oscillator frequency by programming

the IOSCTL register with the optimum trim value.

Due to the inherent frequency tolerances required for SCI communication, changing the factory-trimmed

oscillator frequency is not recommended. If modification of the Boot Flash contents are required, code must

be included which retrieves the optimum trim value (from address $103F in the Data Flash Information

Block) and writes it to the IOSCTL register. Note that the IFREN bit in the Data Flash control register must

be set in order to read the Data Flash Information Block.

XADR

YE=SE=OE=0

ERASE

NVSTR

Tnvs

Tnvh1

Trcv

Tme

MAS1

IFREN

XE

Clock Operation

MOTOROLA

DSP56F802 Preliminary Technical Data

19

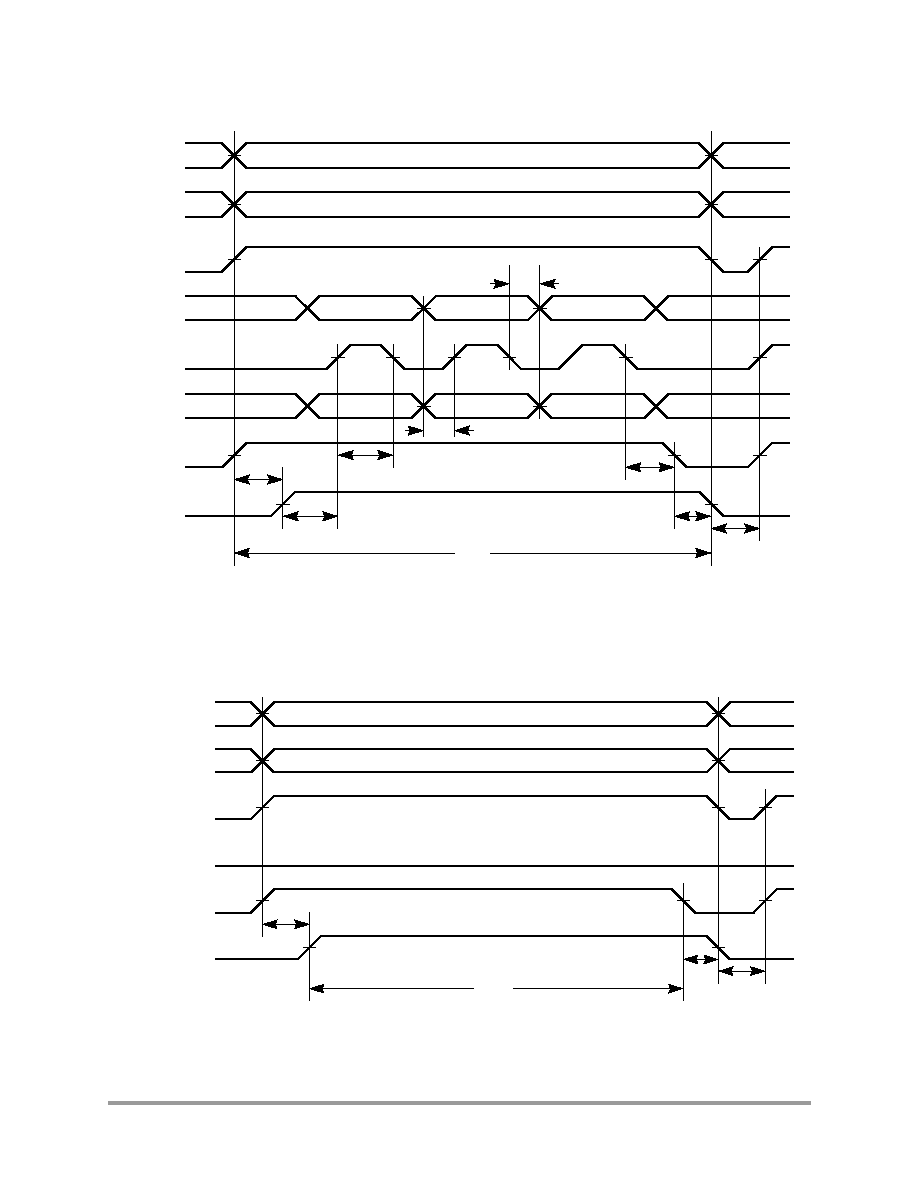

Figure 9. Typical Relaxation Oscillator Frequency vs. Temperature

(Trimmed to 8 MHz @ 25

o

C)

Table 20. Relaxation Oscillator Characteristics

Operating Conditions:

V

SS

= V

SSA

= 0 V, V

DD

= V

DDA

= 3.0≠3.6 V, T

A

= ≠40

∞

to +85

∞

C

Characteristic

Symbol

Min

Typ

Max

Unit

Frequency Accuracy

1

1.

Over full temperature range.

f

--

+2

+5

%

Frequency Drift over Temp

f/

t

--

+0.1

--

%/

o

C

Frequency Drift over Supply

f/

V

--

0.1

--

%/V

8.2

8.0

8.3

8.4

7.9

8.1

7.8

75

55

-40

35

-25

15

-5

85

Temperature (

o

C)

O

u

tput

Freq

ue

ncy

20

DSP56F802 Preliminary Technical Data

MOTOROLA

Figure 10. Typical Relaxation Oscillator Frequency vs. Trim Value @ 25

o

C

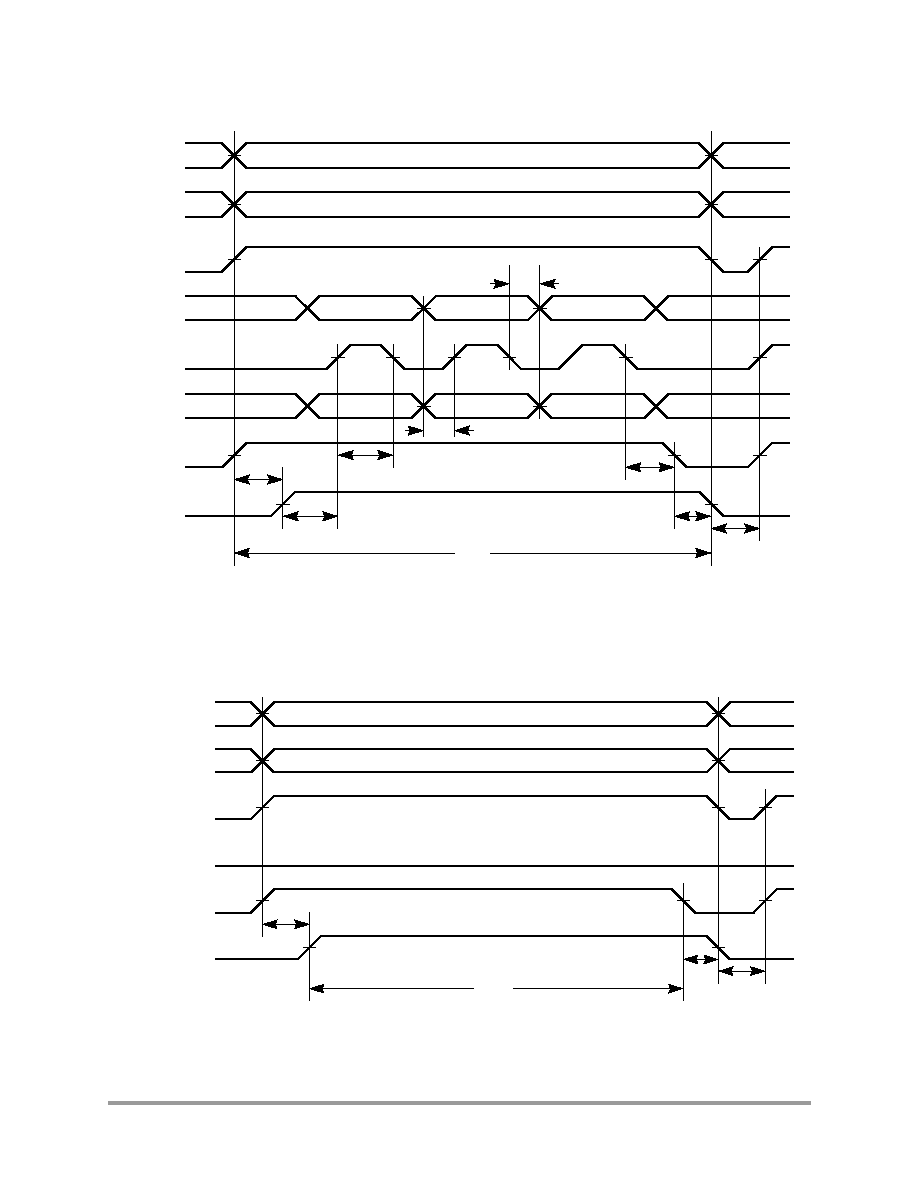

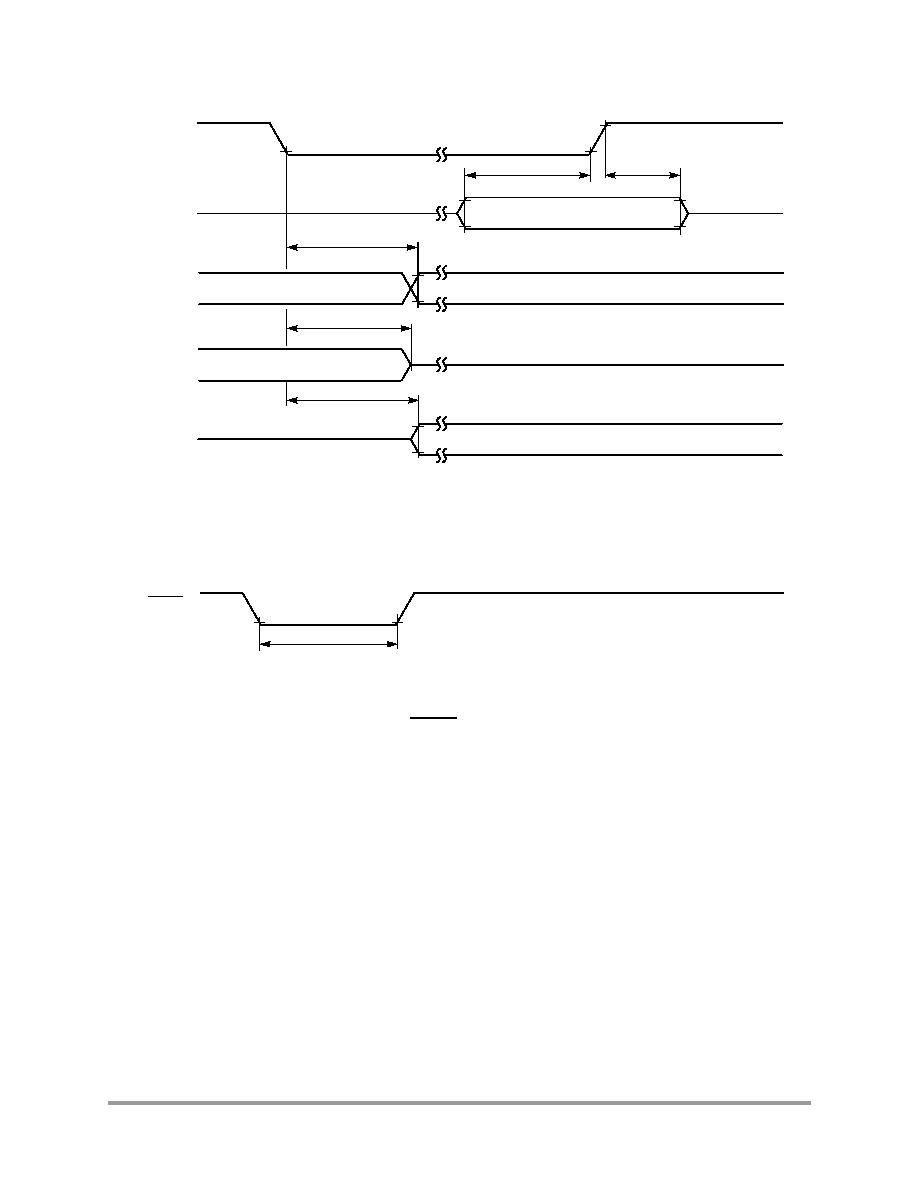

3.6 Reset, Stop, Wait, Mode Select, and Interrupt Timing

Table 21. Reset, Stop, Wait, Mode Select, and Interrupt Timing

1, 5

Operating Conditions:

V

SS

= V

SSA

= 0 V, V

DD

= V

DDA

= 3.0≠3.6 V, T

A

= ≠40

∞

to +85

∞

C, C

L

50 pF

1.

In the formulas, T = clock cycle. For an operating frequency of 80 MHz, T = 12.5 ns.

Characteristic

Symbol

Typical

Min

Typical

Max

Unit

RESET Assertion to Address, Data and Control Signals High

Impedance

t

RAZ

--

21

ns

Minimum RESET Assertion Duration

2

OMR Bit 6 = 0

OMR Bit 6 = 1

2.

Circuit stabilization delay is required during reset when using an external clock or crystal oscillator in two cases:

∑ After power-on reset

∑ When recovering from Stop state

t

RA

275,000T

128T

--

--

ns

ns

RESET De-assertion to First External Address Output

t

RDA

33T

34T

ns

Edge-sensitive Interrupt Request Width

t

IRW

1.5T

--

ns

0

10

20

30 40 50

60 70 80

90 A0 B0 C0 D0 E0

F0

5

6

7

8

9

10

11

Quad Timer Timing

MOTOROLA

DSP56F802 Preliminary Technical Data

21

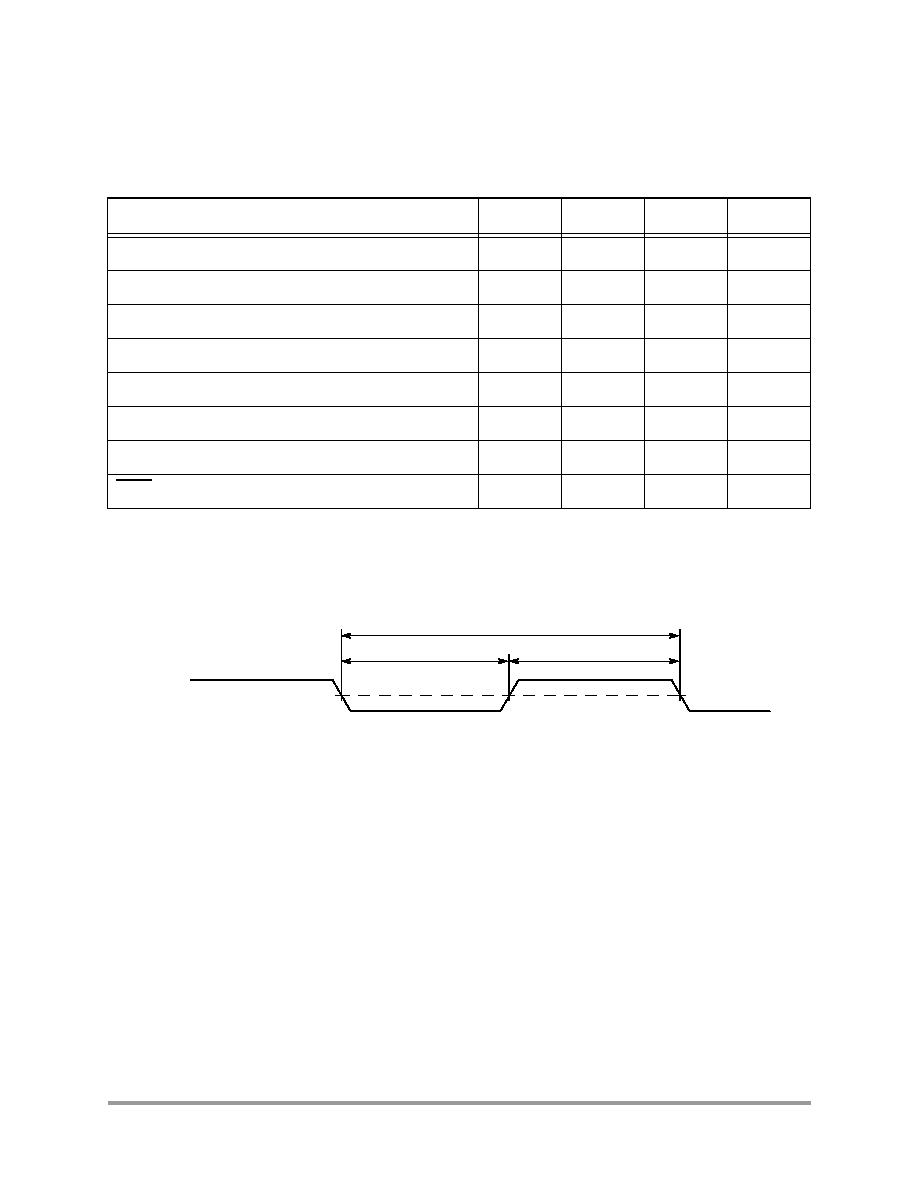

Figure 11. External Level-Sensitive Interrupt Timing

3.7 Quad Timer Timing

Table 22. Timer Timing

1, 2

Operating Conditions:

V

SS

= V

SSA

= 0 V, V

DD

= V

DDA

= 3.0≠3.6 V, T

A

= ≠40

∞

to +85

∞

C, C

L

50 pF, f

OP

= 80 MHz

1.

In the formulas listed, T = clock cycle. For 80 MHz operation, T = 12.5 ns.

2.

Parameters listed are guaranteed by design.

Characteristic

Symbol

Typical Min

Typical Max

Unit

Timer input period

P

IN

4T+6

--

ns

Timer input high/low period

P

INHL

2T+3

--

ns

Timer output period

P

OUT

2T

--

ns

Timer output high/low period

P

OUTHL

1T

--

ns

Figure 12. Timer Timing

General

Purpose

I/O Pin

IRQA

b) General Purpose I/O

t

IG

Timer Inputs

Timer Outputs

P

OUTHL

P

OUTHL

P

OUT

P

IN

P

INHL

P

INHL

22

DSP56F802 Preliminary Technical Data

MOTOROLA

3.8 Serial Communication Interface (SCI) Timing

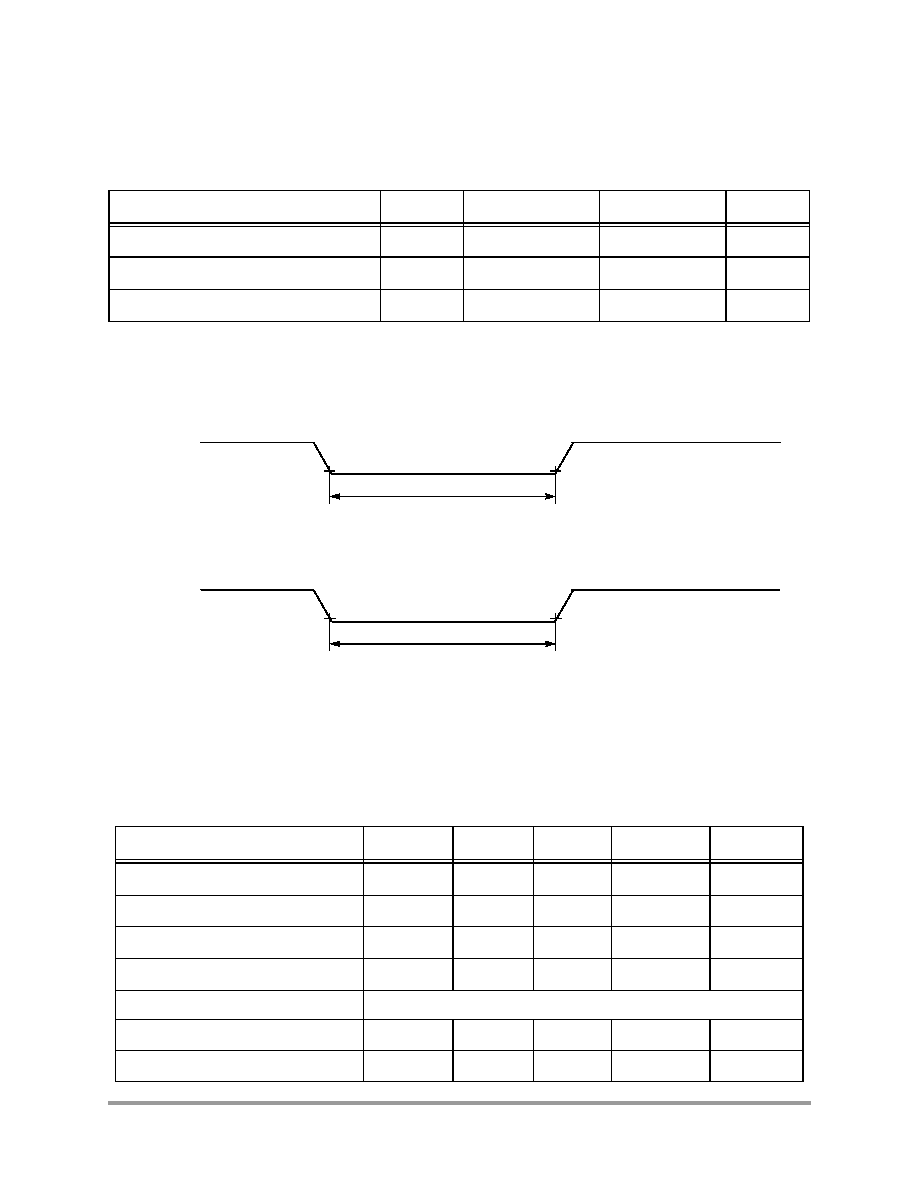

Figure 13. RXD Pulse Width

Figure 14. TXD Pulse Width

3.9 Analog-to-Digital Converter (ADC) Characteristics

Table 23. SCI Timing

Operating Conditions:

V

SS

= V

SSA

= 0 V, V

DD

= V

DDA

= 3.0≠3.6 V, T

A

= ≠40

∞

to +85

∞

C, C

L

50 pF, f

OP

= 80 MHz

Characteristic

Symbol

Min

Max

Unit

Baud Rate

1

1.

f

MAX

is the frequency of operation of the system clock in MHz.

BR

--

(f

MAX

*2.5)/(80)

Mbps

RXD

2

Pulse Width

2.

The RXD pin in SCI0 is named RXD0 and the RXD pin in SCI1 is named RXD1.

RXD

PW

0.965/BR

1.04/BR

ns

TXD

3

Pulse Width

3.

The TXD pin in SCI0 is named TXD0 and the TXD pin in SCI1 is named TXD1.

4.

Parameters listed are guaranteed by design.

TXD

PW

0.965/BR

1.04/BR

ns

Table 24. ADC Characteristics

Operating Conditions:

V

SS

= V

SSA

= 0 V, V

DD

= V

DDA

= 3.0≠3.6 V, V

REF

= V

DD

-0.3V, ADCDIV = 4, 9, or 14,

ADC clock = 4MHz, 3.0≠3.6 V, T

A

= ≠40

∞

to +85

∞

C, C

L

50 pF, f

OP

= 80 MHz

Characteristic

Symbol

Min

Typ

Max

Unit

Input voltages

V

ADIN

0

--

V

DDA

1

V

Resolution

R

ES

12

--

12

Bits

Integral Non-Linearity

2

INL

--

+/- 4

+/- 5

LSB

3

Differential Non-Linearity

DNL

--

+/- 0.9

+/- 1

LSB

3

Monotonicity

GUARANTEED

ADC internal clock

f

ADIC

0.5

--

5

MHz

Conversion range

R

AD

V

SSA

--

V

DDA

V

RXD

SCI receive

data pin

(Input)

RXD

PW

TXD

SCI receive

data pin

(Input)

TXD

PW

Analog-to-Digital Converter (ADC) Characteristics

MOTOROLA

DSP56F802 Preliminary Technical Data

23

Figure 15. Equivalent Analog Input Circuit

1.

Parasitic capacitance due to package, pin to pin, and pin to package base coupling. 1.8pf

2.

Parasitic capacitance due to the chip bond pad, ESD protection devices and signal routing.

2.04pf

3.

Equivalent resistance for the ESD isolation resistor and the channel select mux. 500 ohms

Sampling capacitor at the sample and hold circuit. Capacitor 4 is normally disconnected from the

input and is only connected to it at sampling time. 1pf

Power-up time

t

ADPU

--

2.5

--

msec

Conversion time

t

ADC

--

6

--

t

AIC

cycles

4

Sample time

t

ADS

--

1

--

t

AIC

cycles

4

Input capacitance

C

ADI

--

5

--

pF

4

Gain Error (transfer gain)

E

GAIN

1.00

1.10

1.15

--

Offset Voltage

V

OFFSET

+10

+230

+325

mV

Total Harmonic Distortion

THD

55

60

--

dB

Signal-to-Noise plus Distortion

SINAD

54

56

--

--

Effective Number of Bits

ENOB

8.5

9.5

--

bit

Spurious Free Dynamic Range

SFDR

60

65

--

dB

Spurious Free Dynamic Range

SFDR

65

70

--

dB

ADC Quiescent Current (both ADCs)

I

ADC

--

39.3

--

mA

V

REF

Quiescent Current (both ADCs)

I

VREF

--

11.85

14.5

mA

1.

V

DDA

should be tied to the same potential as

V

DD

via separate traces. V

REF

must be equal to or less than V

DD

and must be greater than or equal to 2.7V.

2.

Measured in 10-90% range.

3.

LSB = Least Significant Bit.

4.

t

AIC

= 1/

f

ADIC

Table 24. ADC Characteristics (Continued)

Operating Conditions:

V

SS

= V

SSA

= 0 V, V

DD

= V

DDA

= 3.0≠3.6 V, V

REF

= V

DD

-0.3V, ADCDIV = 4, 9, or 14,

ADC clock = 4MHz, 3.0≠3.6 V, T

A

= ≠40

∞

to +85

∞

C, C

L

50 pF, f

OP

= 80 MHz

Characteristic

Symbol

Min

Typ

Max

Unit

1

2

3

4

ADC analog input

24

DSP56F802 Preliminary Technical Data

MOTOROLA

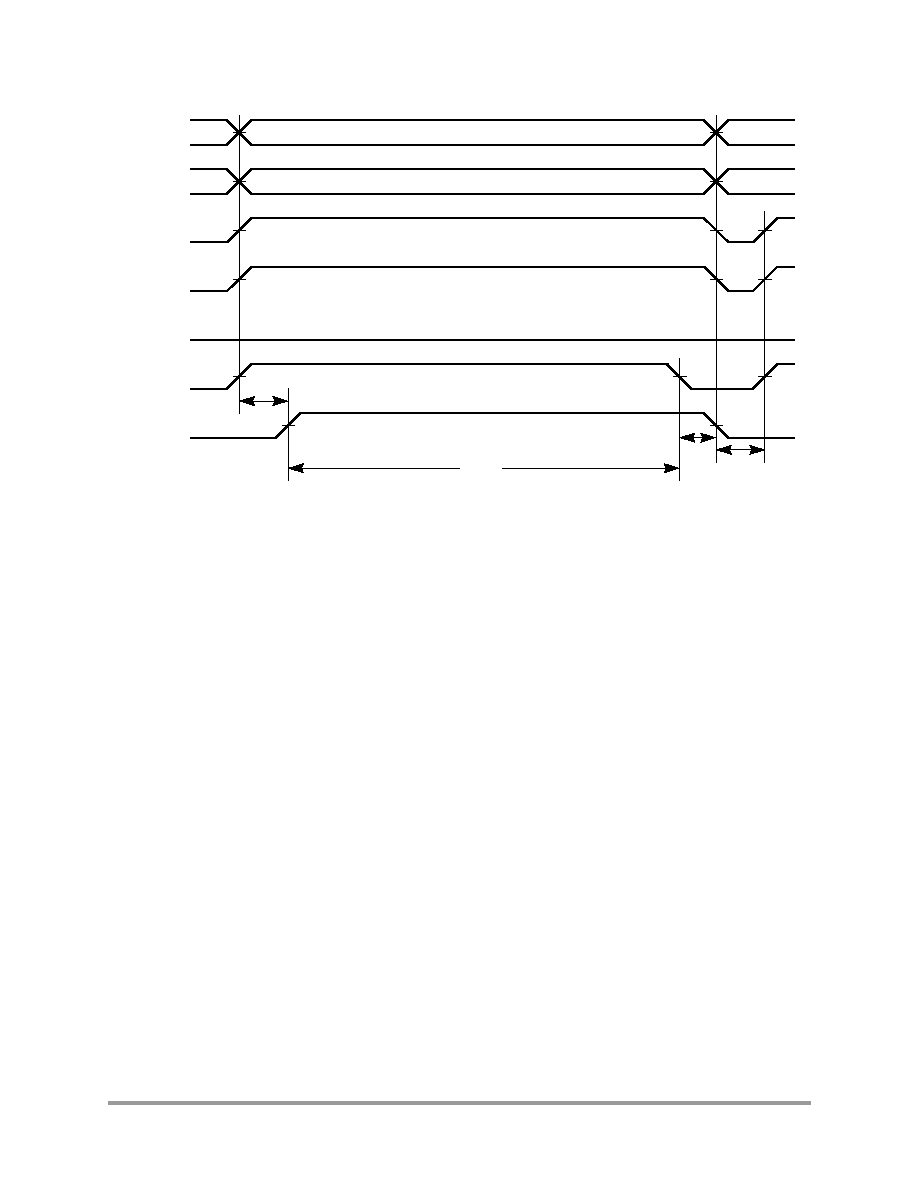

3.10 JTAG Timing

Table 25. JTAG Timing

1, 3

Operating Conditions:

V

SS

= V

SSA

= 0 V, V

DD

= V

DDA

= 3.0≠3.6 V, T

A

= ≠40

∞

to +85

∞

C, C

L

50 pF, f

OP

= 80 MHz

1.

Timing is both wait state and frequency dependent. For the values listed, T = clock cycle. For 80 MHz

operation, T = 12.5 ns.

Characteristic

Symbol

Min

Max

Unit

TCK frequency of operation

2

2.

TCK frequency of operation must be less than 1/8 the processor rate.

3.

Parameters listed are guaranteed by design.

f

OP

DC

10

MHz

TCK cycle time

t

CY

100

--

ns

TCK clock pulse width

t

PW

50

--

ns

TMS, TDI data setup time

t

DS

0.4

--

ns

TMS, TDI data hold time

t

DH

1.2

--

ns

TCK low to TDO data valid

t

DV

--

26.6

ns

TCK low to TDO tri-state

t

TS

--

23.5

ns

TRST assertion time

t

TRST

50

--

ns

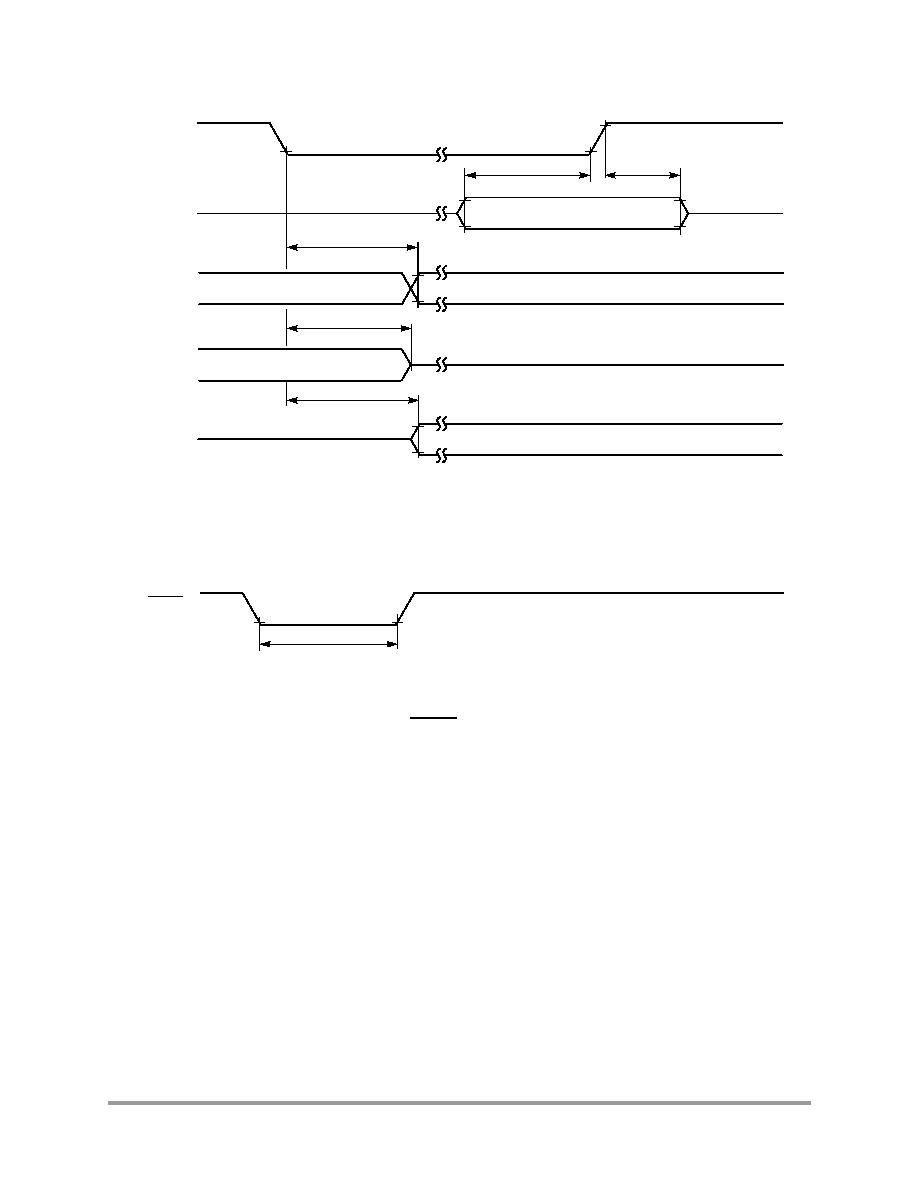

Figure 16. Test Clock Input Timing Diagram

TCK

(Input)

V

M

V

IL

V

M

= V

IL

+ (V

IH

≠ V

IL

)/2

V

M

V

IH

t

PW

t

PW

t

CY

JTAG Timing

MOTOROLA

DSP56F802 Preliminary Technical Data

25

Figure 17. Test Access Port Timing Diagram

Figure 18. TRST Timing Diagram

Input Data Valid

Output Data Valid

Output Data Valid

TCK

(Input)

TDI

(Input)

TDO

(Output)

TDO

(Output

)

TDO

(Output)

TMS

t

DV

t

DV

t

TS

t

DS

t

DH

TRST

(Input)

t

TRST

26

DSP56F802 Preliminary Technical Data

MOTOROLA

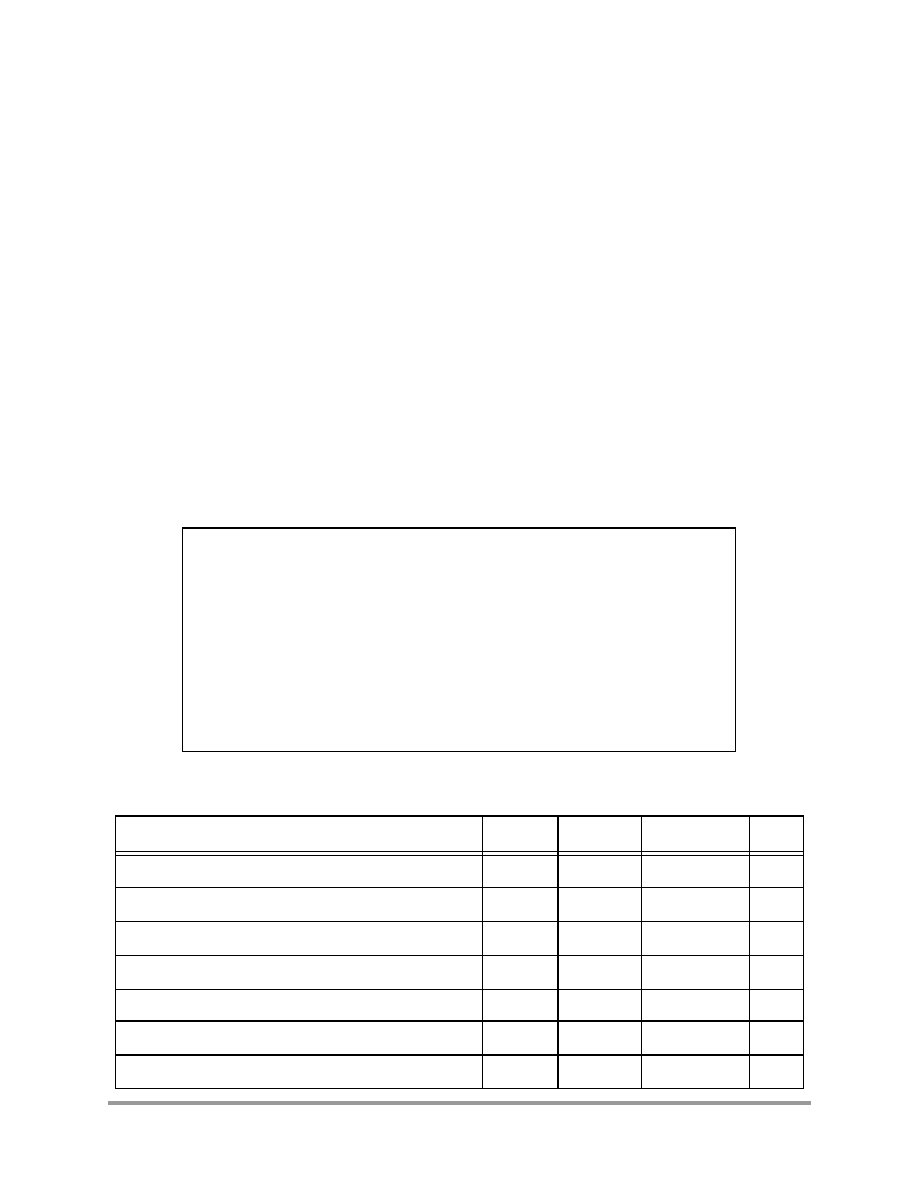

Part 4 Packaging

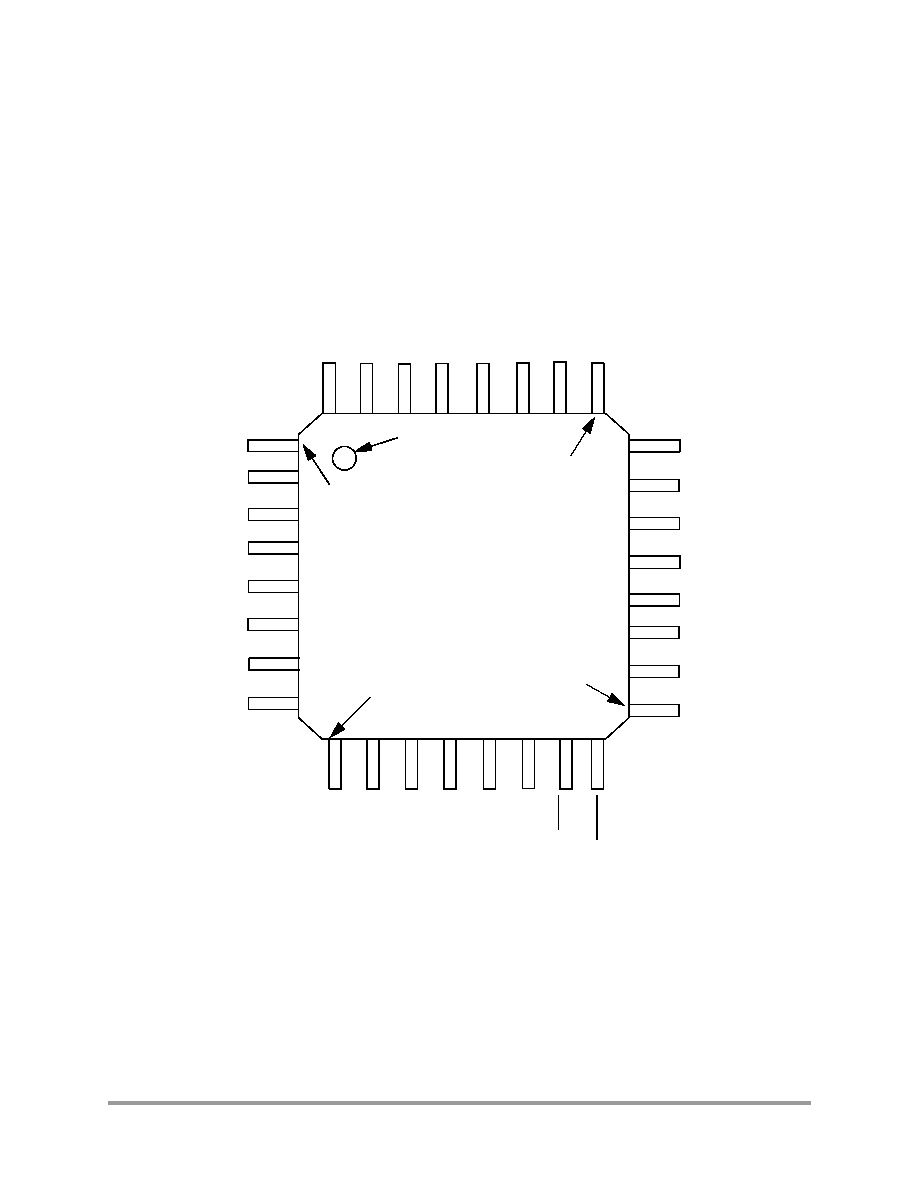

4.1 Package and Pin-Out Information DSP56F802

This section contains package and pin-out information for the 32-pin LQFP configuration of the

DSP56F802.

Figure 19. Top View, DSP56F802 32-pin LQFP Package

PIN 1

ORIENTATION

MARK

PWMA4

PWMA5

TD1

TD2

TXDO

VSS

VDD

RXD0

TCS

TCK

TM

S

TD

I

VCAPC2

TDO

TR

S

T

RESET

ANA3

VREF

ANA2

FAULTA0

VSS

VDD

VSSA

VDDA

PWM

A

3

PWM

A

2

PWM

A

1

VCAPC1

PWM

A

0

ANA7

ANA6

ANA4

9

25

17

Motorola

DSP56F802

Package and Pin-Out Information DSP56F802

MOTOROLA

DSP56F802 Preliminary Technical Data

27

Table 26. DSP56F802 Pin Identification by Pin Number

Pin No.

Signal Name

Pin No.

Signal Name

Pin No.

Signal Name

Pin No.

Signal Name

1

PWMA4

9

TCS

17

V

DDA

25

ANA4

2

PWMA5

10

TCK

18

V

SSA

26

ANA6

3

TD1

11

TMS

19

V

DD

27

ANA7

4

TD2

12

TDI

20

V

SS

28

PWMA0

5

TXDO

13

VCAPC2

21

FAULTA0

29

VCAPC1

6

V

SS

14

TDO

22

ANA2

30

PWMA1

7

V

DD

15

TRST

23

VREF 31

PWMA2

8

RXD0

16

RESET

24

ANA3

32

PWMA3

28

DSP56F802 Preliminary Technical Data

MOTOROLA

Figure 20. 32-pin LQFP Mechanical Information (Case 873A)

NOTES:

1.

DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2.

CONTROLLING DIMENSION: MILLIMETER.

3.

DATUM PLANE A, B AND D TO BE DETERMINED

AT DATUM PLANE H.

4.

DIMENSIONS D AND E TO BE DETERMINED AT

SEATING PLANE C.

5.

DIMENSIONS b DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL NOT CAUSE THE LEAD

WIDTH TO EXCEED THE MAXIMUM b DIMENSION

BY MORE THEN 0.08 MM. DAMBAR CANNOT BE

LOCATED ON THE LOWER RADIUS OR THE FOOT.

MINIMUM SPACE BETWEEN PROTRUSION AND

ADJACENT LEAD OR PROTURSION: 0.07 MM.

6.

DIMENSIONS D1 AND E1 DO NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE PROTRUSION IS 0.25

MM PER SIDE. D1 AND E1 ARE MAXIMUM PLASTIC

BODY SIZE DIMENSIONS INCLUDING MOLD

MISMATCH.

7.

EXACT SHAPE OF EACH CORNER IS OPTIONAL.

8.

THESE DIMENSIONS APPLY TO THE

FLAT SECTION OF THE LEAD

DIM

A

MIN

MAX

MILLIMETERS

A1

A2

b

b1

0.30

0.40

c

0.09

0.20

c1

0.09

0.16

D

D1

7.00 BSC

e

E

E1

L1

1.00 REF

O

0

7

O1

12

L

0.70

R1

0.08

0.20

R2

∞

1.40

1.60

0.05

1.45

0.15

1.35

0.45

0.30

9.00 BSC

S

0.20 REF

0.80 BSC

9.00 BSC

7.00 BSC

0.50

∞

∞

REF

0.08

--

Thermal Design Considerations

MOTOROLA

DSP56F802 Preliminary Technical Data

29

Part 5 Design Considerations

5.1 Thermal Design Considerations

An estimation of the chip junction temperature, T

J

, in

∞

C can be obtained from the equation:

Equation 1:

Where:

T

A

= ambient temperature ∞C

R

JA

= package junction-to-ambient thermal resistance ∞C/W

P

D

= power dissipation in package

Historically, thermal resistance has been expressed as the sum of a junction-to-case thermal resistance and

a case-to-ambient thermal resistance:

Equation 2:

Where:

R

JA

= package junction-to-ambient thermal resistance ∞C/W

R

JC

= package junction-to-case thermal resistance ∞C/W

R

CA

= package case-to-ambient thermal resistance ∞C/W

R

JC

is device-related and cannot be influenced by the user. The user controls the thermal environment to

change the case-to-ambient thermal resistance, R

CA

. For example, the user can change the air flow around

the device, add a heat sink, change the mounting arrangement on the Printed Circuit Board (PCB), or

otherwise change the thermal dissipation capability of the area surrounding the device on the PCB. This

model is most useful for ceramic packages with heat sinks; some 90% of the heat flow is dissipated through

the case to the heat sink and out to the ambient environment. For ceramic packages, in situations where the

heat flow is split between a path to the case and an alternate path through the PCB, analysis of the device

thermal performance may need the additional modeling capability of a system level thermal simulation tool.

The thermal performance of plastic packages is more dependent on the temperature of the PCB to which the

package is mounted. Again, if the estimations obtained from R

JA

do not satisfactorily answer whether the

thermal performance is adequate, a system level model may be appropriate.

Definitions:

A complicating factor is the existence of three common definitions for determining the junction-to-case

thermal resistance in plastic packages:

∑

Measure the thermal resistance from the junction to the outside surface of the package (case) closest

to the chip mounting area when that surface has a proper heat sink. This is done to minimize

temperature variation across the surface.

∑

Measure the thermal resistance from the junction to where the leads are attached to the case. This

definition is approximately equal to a junction to board thermal resistance.

∑

Use the value obtained by the equation (T

J

≠ T

T

)/P

D

where T

T

is the temperature of the package

case determined by a thermocouple.

T

J

T

A

P

D

R

JA

◊

(

)

+

=

R

JA

R

JC

R

CA

+

=

30

DSP56F802 Preliminary Technical Data

MOTOROLA

The junction-to-case thermal resistances quoted in this data sheet are determined using the first definition

on page 45. From a practical standpoint, that value is also suitable for determining the junction temperature

from a case thermocouple reading in forced convection environments. In natural convection, using the

junction-to-case thermal resistance to estimate junction temperature from a thermocouple reading on the

case of the package will estimate a junction temperature slightly hotter than actual. Hence, the new thermal

metric, Thermal Characterization Parameter, or

JT

, has been defined to be (T

J

≠ T

T

)/P

D

. This value gives

a better estimate of the junction temperature in natural convection when using the surface temperature of

the package. Remember that surface temperature readings of packages are subject to significant errors

caused by inadequate attachment of the sensor to the surface and to errors caused by heat loss to the sensor.

The recommended technique is to attach a 40-gauge thermocouple wire and bead to the top center of the

package with thermally conductive epoxy.

5.2 Electrical Design Considerations

Use the following list of considerations to assure correct DSP operation:

∑

Provide a low-impedance path from the board power supply to each V

DD

pin on the DSP, and from

the board ground to each V

SS

(GND) pin.

∑

The minimum bypass requirement is to place six 0.01≠0.1

µ

F capacitors positioned as close as

possible to the package supply pins. The recommended bypass configuration is to place one bypass

capacitor on each of the ten V

DD

/V

SS

pairs, including V

DDA

/V

SSA.

The VCAP capacitors must be

150 milliohm or less ESR capacitors.

∑

Ensure that capacitor leads and associated printed circuit traces that connect to the chip V

DD

and

V

SS

(GND) pins are less than 0.5 inch per capacitor lead.

∑

Use at least a four-layer Printed Circuit Board (PCB) with two inner layers for V

DD

and V

SS

.

∑

Bypass the V

DD

and V

SS

layers of the PCB with approximately 100

µ

F, preferably with a high-

grade capacitor such as a tantalum capacitor.

∑

Because the DSP output signals have fast rise and fall times, PCB trace lengths should be minimal.

∑

Consider all device loads as well as parasitic capacitance due to PCB traces when calculating

capacitance. This is especially critical in systems with higher capacitive loads that could create

higher transient currents in the V

DD

and GND circuits.

∑

Take special care to minimize noise levels on the VREF, V

DDA

and V

SSA

pins.

CAUTION

This device contains protective circuitry to guard against

damage due to high static voltage or electrical fields.

However, normal precautions are advised to avoid

application of any voltages higher than maximum rated

voltages to this high-impedance circuit. Reliability of

operation is enhanced if unused inputs are tied to an

appropriate voltage level.

Electrical Design Considerations

MOTOROLA

DSP56F802 Preliminary Technical Data

31

∑

Designs that utilize the TRST pin for JTAG port or OnCE module functionality (such as

development or debugging systems) should allow a means to assert TRST whenever RESET is

asserted, as well as a means to assert TRST independently of RESET. Designs that do not require

debugging functionality, such as consumer products, should tie these pins together. TRST must be

asserted at power up for proper operation.

∑

Because the Flash memory is programmed through the JTAG/OnCE port, designers should provide

an interface to this port to allow in-circuit Flash programming.

Part 6 Ordering Information

Table 27

lists the pertinent information needed to place an order. Consult a Motorola Semiconductor sales

office or authorized distributor to determine availability and to order parts.

Table 27. DSP56F802 Ordering Information

Part

Supply

Voltage

Package Type

Pin

Count

Frequency

(MHz)

Order Number

DSP56F802

3.0≠3.6 V

Low Profile Plastic Quad Flat Pack

(LQFP)

32

80

DSP56F802TA80

DSP56F802/D

MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are the property of their

respective owners. © Motorola, Inc. 2002.

How to reach us:

USA/EUROPE/Locations Not Listed: Motorola Literature Distribution; P.O. Box 5405, Denver, Colorado 80217. 1≠303≠675≠2140 or 1≠800≠441≠2447

JAPAN: Motorola Japan Ltd.; SPS, Technical Information Center, 3≠20≠1, Minami≠Azabu. Minato≠ku, Tokyo 106≠8573 Japan. 81≠3≠3440≠3569

ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; Silicon Harbour Centre, 2 Dai King Street, Tai Po Industrial Estate, Tai Po, N.T., Hong Kong. 852≠26668334

Technical Information Center: 1≠800≠521≠6274

HOME PAGE: http://www.motorola.com/semiconductors/

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty, representation or guarantee regarding the

suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. "Typical" parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including

"Typicals" must be validated for each customer application by customer's technical experts. Motorola does not convey any license under its patent rights nor the

rights of others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and the Stylized M Logo are registered trademarks of Motorola, Inc. Motorola,

Inc. is an Equal Opportunity/Affirmative Action Employer.