| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: CS2082 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

©

Semiconductor Components Industries, LLC, 2001

July, 2001 ≠ Rev. 7

1

Publication Order Number:

CS2082/D

CS2082

Dual Airbag

Deployment ASIC

The CS2082 controls and monitors two airbag firing loops. The

independent firing loops are low≠ and high≠side controlled. Device

communication is through a Serial Peripheral Interface (SPI) port, and

includes frame error detection circuitry for data reliability.

Diagnostics include squib resistance measurement and continuous

monitoring for shorts to ground, shorts to battery, and for open loops.

The high≠ and low≠side drivers can be individually activated to

guarantee function and to identify shorts between firing loops.

Additional features include power on reset, overtemperature

protection, a charge pump, high≠side safing sensor closure detection,

an analog multiplexer, a monitor to ensure battery potential, and a

programmable monitor to ensure firing potential.

Features

∑

Serial Input Bus

∑

Two Squib Outputs

∑

Low≠ and High≠Side Control

∑

Monitors

≠

Squib Resistance

≠

Short to Ground or Battery

≠

Battery Potential

≠

Firing Potential

∑

Safing Sensor Detection

∑

60 V Peak Transient Voltage

http://onsemi.com

A

= Assembly Location

WL, L

= Wafer Lot

YY, Y

= Year

WW, W

= Work Week

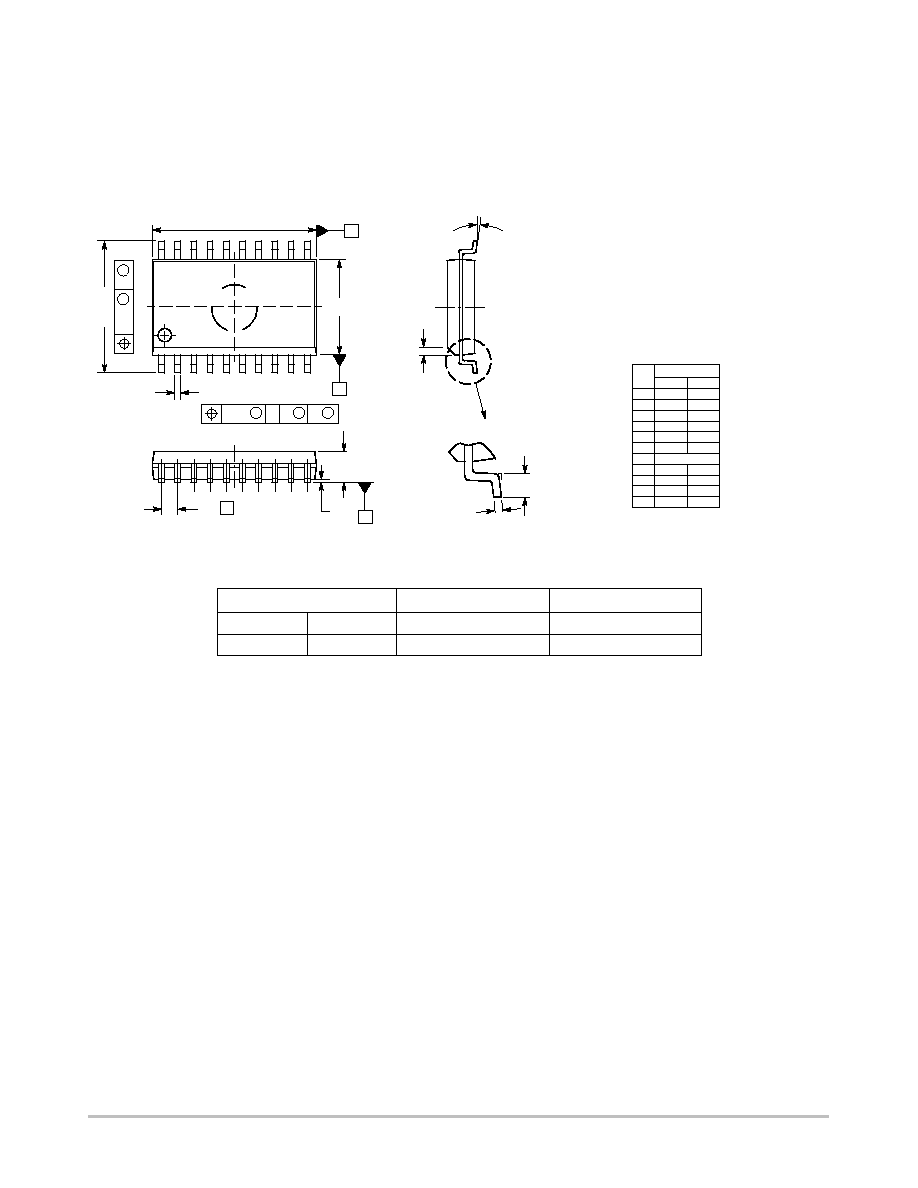

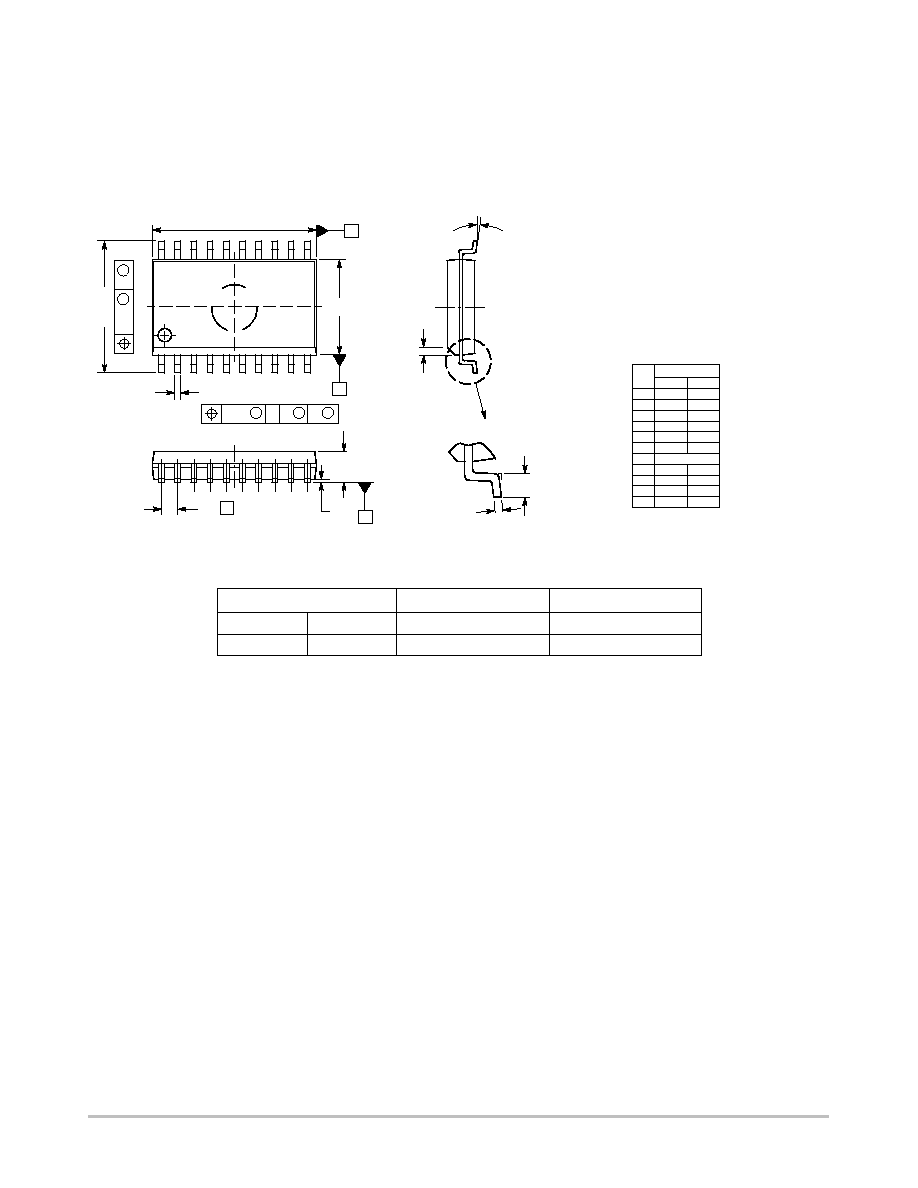

PIN CONNECTIONS AND

MARKING DIAGRAM

Device

Package

Shipping

ORDERING INFORMATION

SO≠20L

37 Units/Rail

SO≠20L

1000 Tape & Reel

SO≠20L

DW SUFFIX

CASE 751D

CS2082EDW20

CS2082EDWR20

1

CS2082

A

W

L

YYWW

20

A

IN

D

OUT

FG2

FG1

SL2

SL1

SH2

SH1

VR2

VR1

D

IN

V

RES

V

CC

CHRG

GND

V

BAT

A

OUT

CLK

CS

MR

CS2082

http://onsemi.com

2

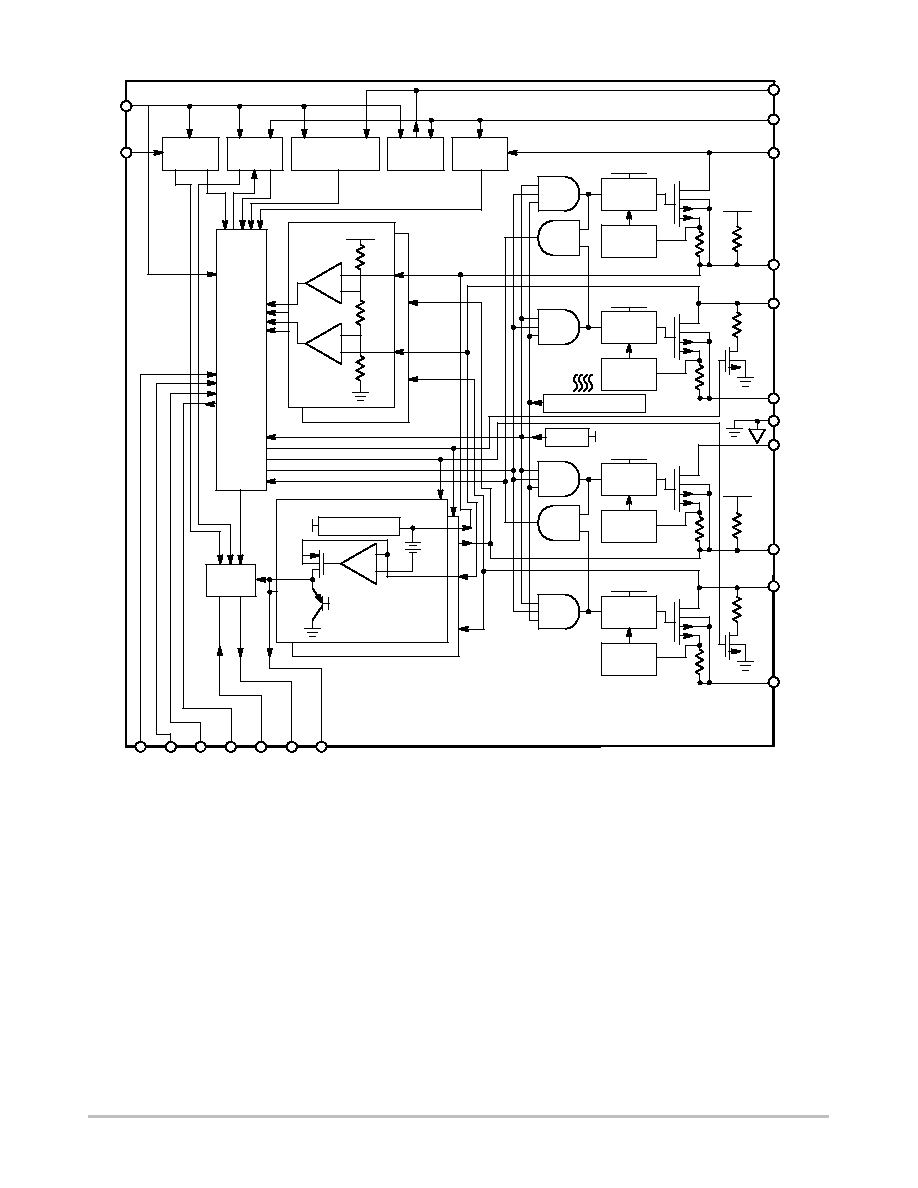

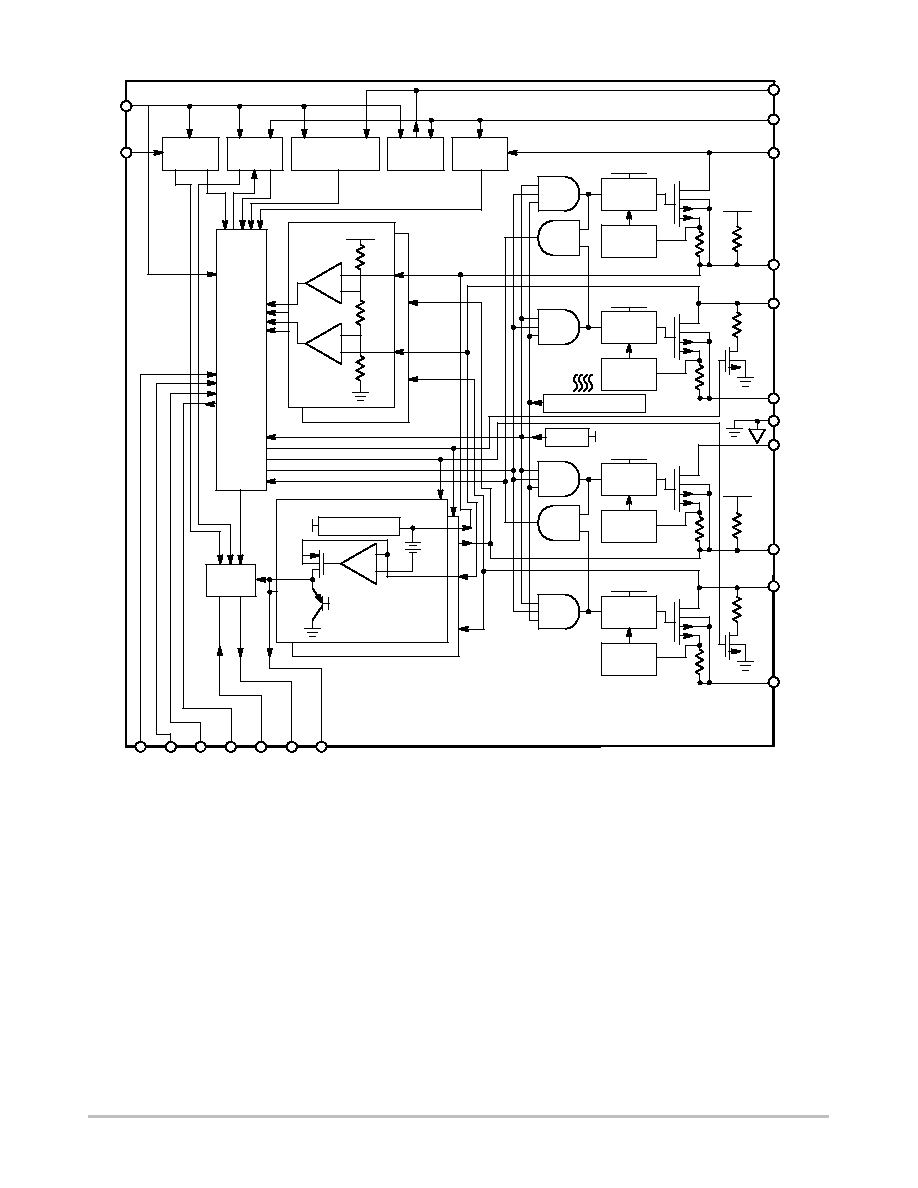

CS CLK D

IN

D

OUT

A

IN

A

OUT

MR

Battery

Monitor

V

RES

Monitor

Charge Pump

Monitor

Charge

Pump

Sensor

Monitor

+

≠

Diagnostic

+

≠

R

2R

R

V

BAT

1

2

Current

Limit

Gate

Drive

CHRG

1.5

Current

Limit

Gate

Drive

Current

Limit

Gate

Drive

Current

Limit

Gate

Drive

V

RES

1.5

CHRG

1.5

V

RES

1.5

V

BAT

V

BAT

10 k

10 k

10 k

10 k

CHRG

V

RES

VR1

SH1

SL1

FG1

SH2

SL2

FG2

V

CC

V

BAT

Overtemperature

Reset

V

CC

GND

VR2

+

≠

Current Limit

+

50 mV

V

BAT

V

CC

Resistive

Measurement

2

1

Analog

MUX

SPI

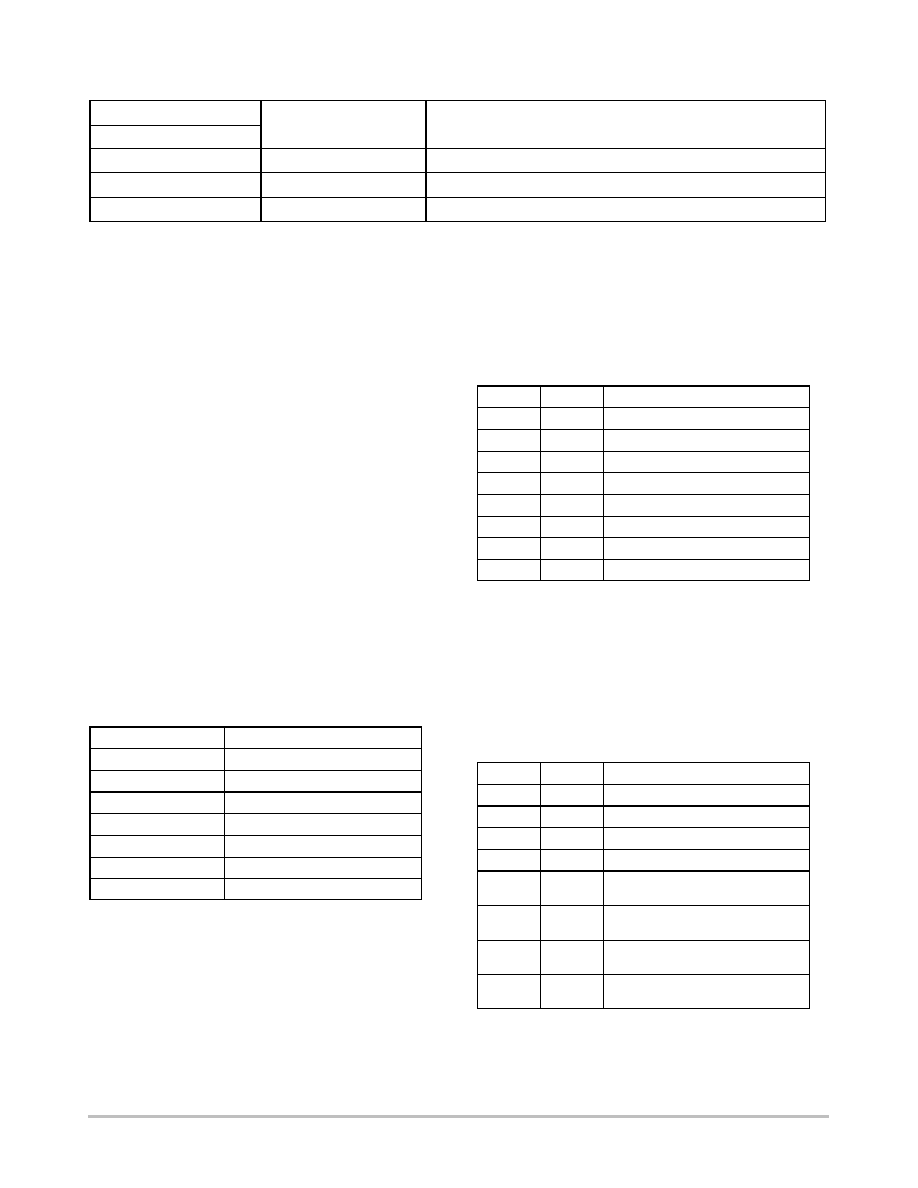

Figure 1. Block Diagram

CS2082

http://onsemi.com

3

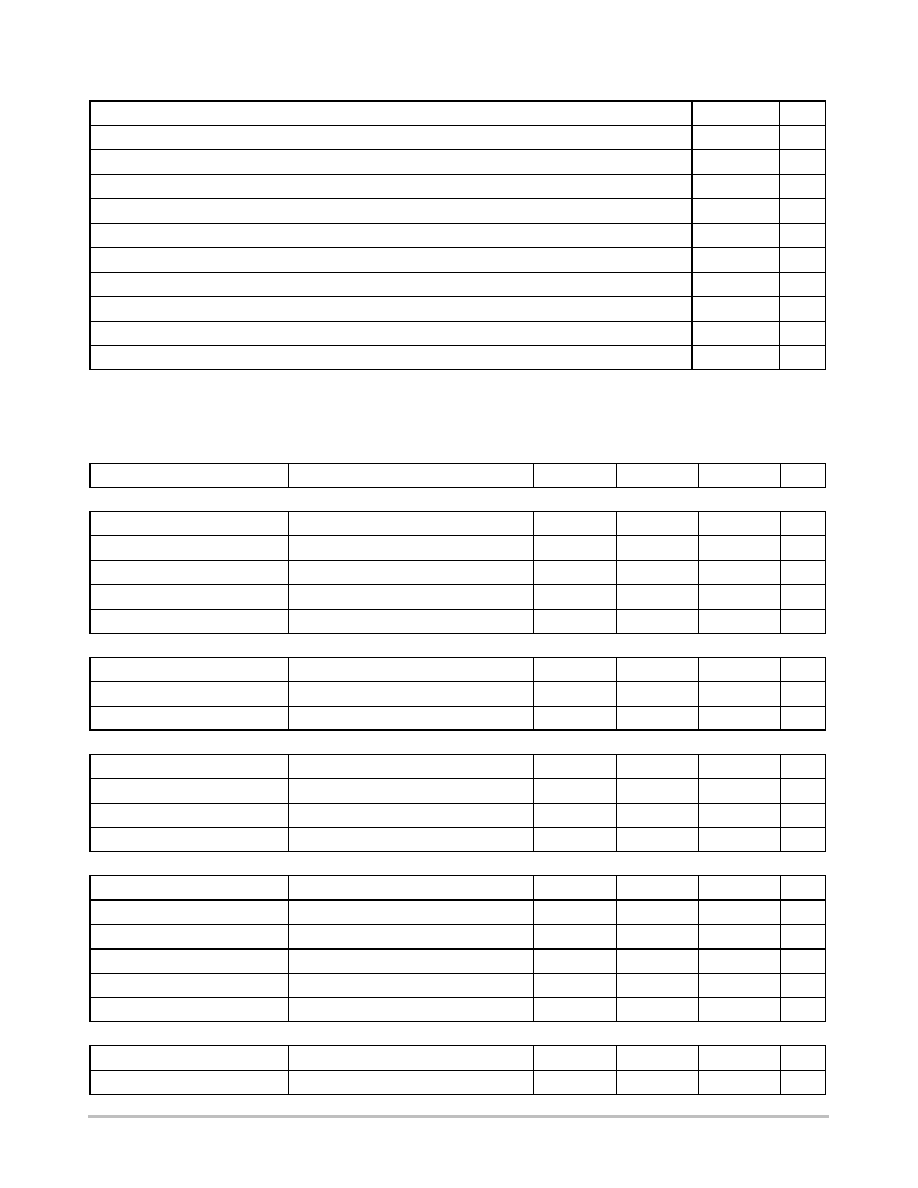

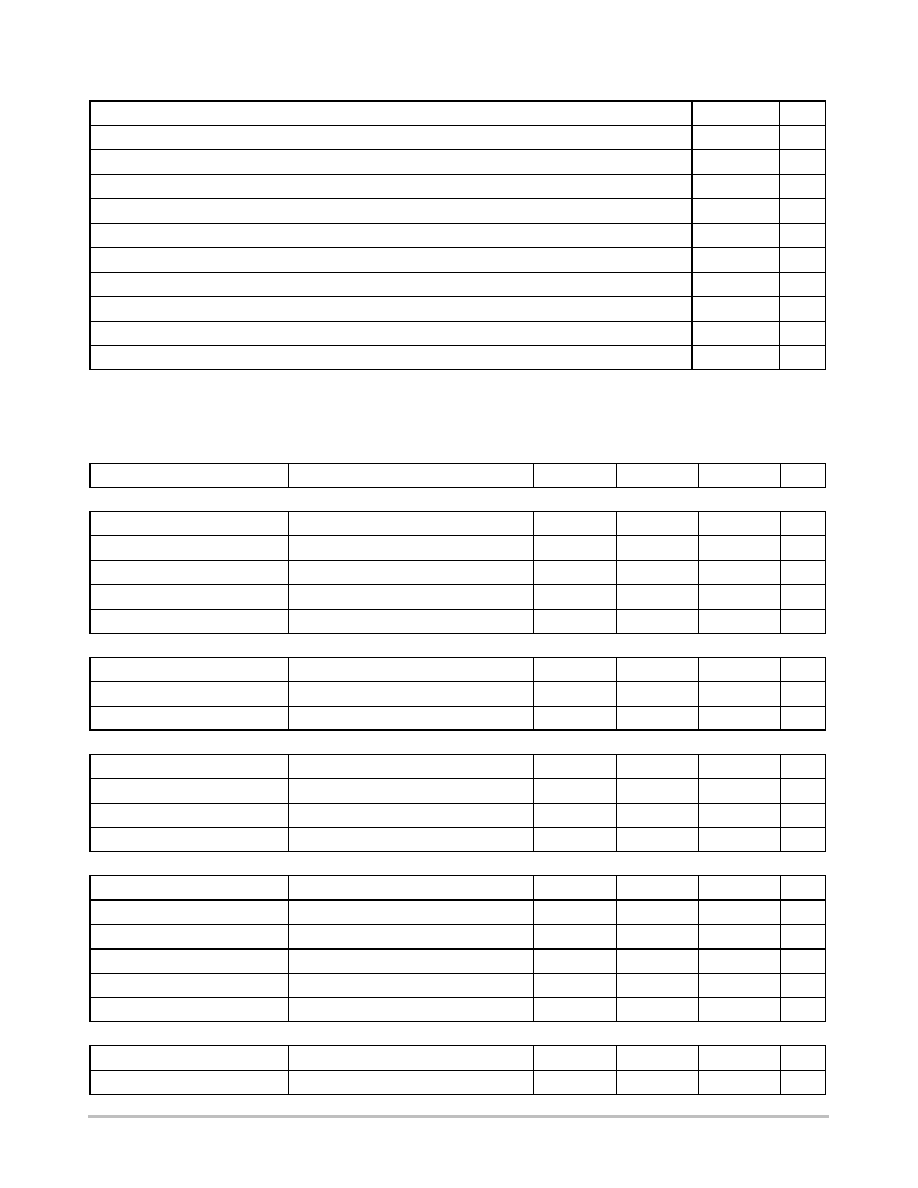

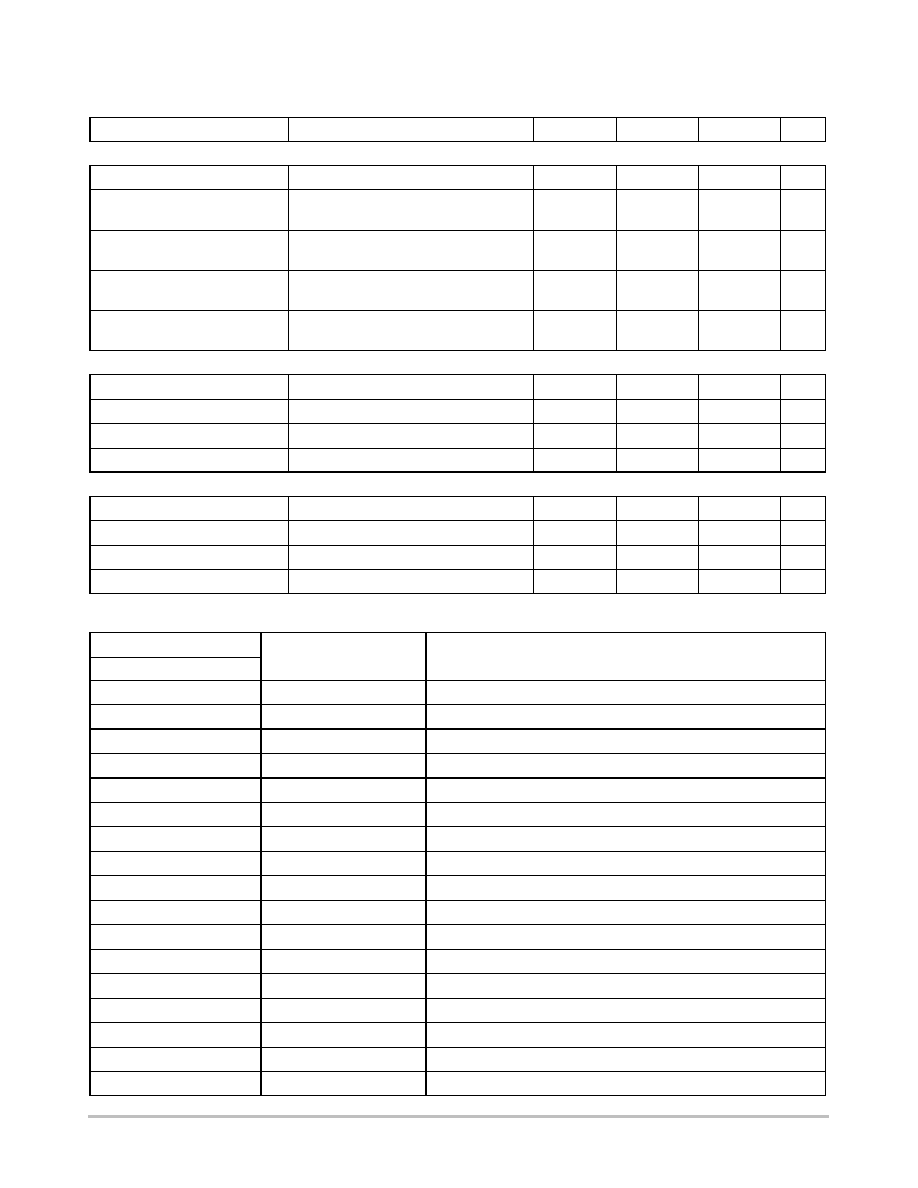

MAXIMUM RATINGS*

Rating

Value

Unit

Storage Temperature

≠40 to 150

∞

C

V

BAT

≠0.3 to 24

V

V

RES

≠0.3 to 30

V

V

CC

≠0.3 to 6.0

V

ESD Susceptibility (Human Body Model)

500

V

Power Dissipation (Non≠Firing)

0.15

W

Power Dissipation (Both Firing Loops With Squibs Shorted)

140

W

Power Dissipation (Squib Resistance Measurement)

1.6

W

Peak Transient Voltage (46 V Load Dump @ 14 V V

BAT

)

60

V

Lead Temperature Soldering:

Reflow: (SMD styles only) (Note 1)

230 peak

∞

C

1. 60 second maximum above 183

∞

C.

*The maximum package power dissipation must be observed.

ELECTRICAL CHARACTERISTICS

(4.75 V < V

CC

< 5.25 V, 8.0 V < V

RES

< 30 V, 9.0 V < V

BAT

< 18 V,

≠40

∞

C < T

A

< +85

∞

C; unless otherwise stated.)

Parameter

Test Conditions

Min

Typ

Max

Unit

Supply Requirements

V

CC

Quiescent Current

V

CC

= 5.25 V

≠

2.0

4.0

mA

V

BAT

Quiescent Current

V

BAT

= 18 V

≠

2.5

5.0

mA

V

BAT

Measurement Current

V

BAT

= 18 V, R

SQUIB

= 1.0

≠

≠

80

mA

V

RES

Quiescent Current

V

RES

= 30 V

≠

≠

1.0

mA

V

RES

Firing Current

V

RES

= 30 V

≠

≠

3.0

mA

Power on Reset

V

BAT

= 9.0 V, V

RES

= 10 V

Power Reset Active Voltage

V

CC

Falling

3.50

4.00

4.25

V

Power Reset Off Voltage

V

CC

Rising

3.65

4.20

4.50

V

Hysteresis

≠

50

≠

≠

mV

Low Side Driver

V

RES

= 8.0 V = V

RX

, V

CC

= 5.0 V, V

BAT

= 8.0 V

Saturation Voltage

I = 1.2 A

≠

≠

1.8

V

Current Limit (I

LIMIT

)

V

SLX

≠ V

FGX

= 5.0 V

1.2

1.6

2.0

A

Turn≠on Delay Time

From CS falling Edge, I

D

= 0.9

◊

I

LIMIT(MIN)

≠

≠

75

µ

s

Turn≠off Delay Time

From CS falling Edge, I

D

= 0.1

◊

I

LIMIT(MIN)

≠

≠

25

µ

s

High Side Driver

V

RES

= 8.0 V = V

RX

, V

CC

= 5.0 V, V

BAT

= 8.0 V

Saturation Voltage

I = 1.2 A

≠

≠

1.8

V

Current Limit (I

LIMIT

)

V

RX

≠ V

SHX

= 5.0 V

1.2

2.0

2.5

A

V

R1

Quiescent Current Drivers off

V

RX

= V

RES

= 30 V

≠

≠

1.0

mA

V

R2

Quiescent Current Drivers off

V

RX

= V

RES

= 30 V

≠

≠

100

µ

A

Turn≠on Delay Time

From CS falling Edge, I

D

= 0.9

◊

I

LIMIT(MIN)

≠

≠

100

µ

s

Turn≠off Delay Time

From CS falling Edge, I

D

= 0.1

◊

I

LIMIT(MIN)

≠

≠

25

µ

s

Thermal Shut Down

Thermal Shutdown Temp

Guaranteed by Design

150

180

210

∞

C

Thermal Hysteresis

Guaranteed by Design

30

40

60

∞

C

CS2082

http://onsemi.com

4

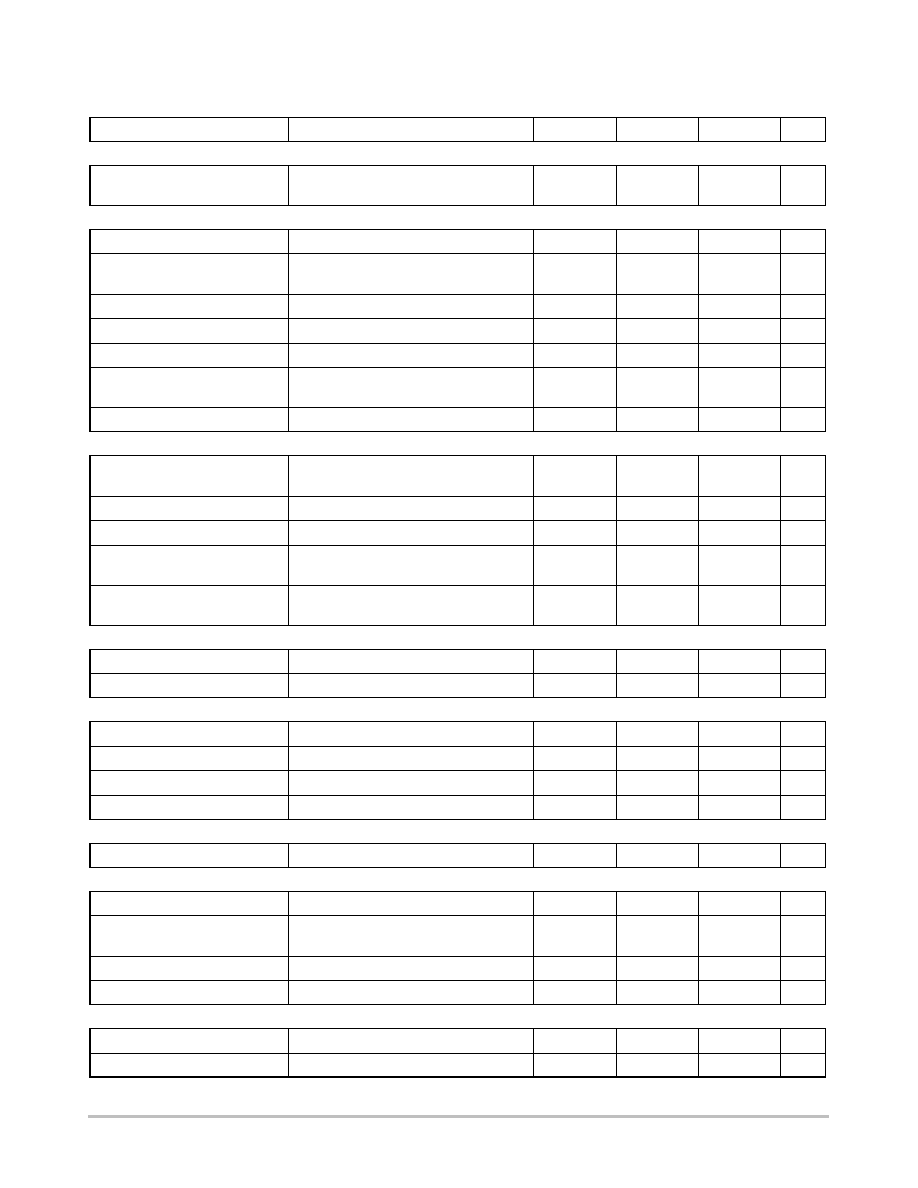

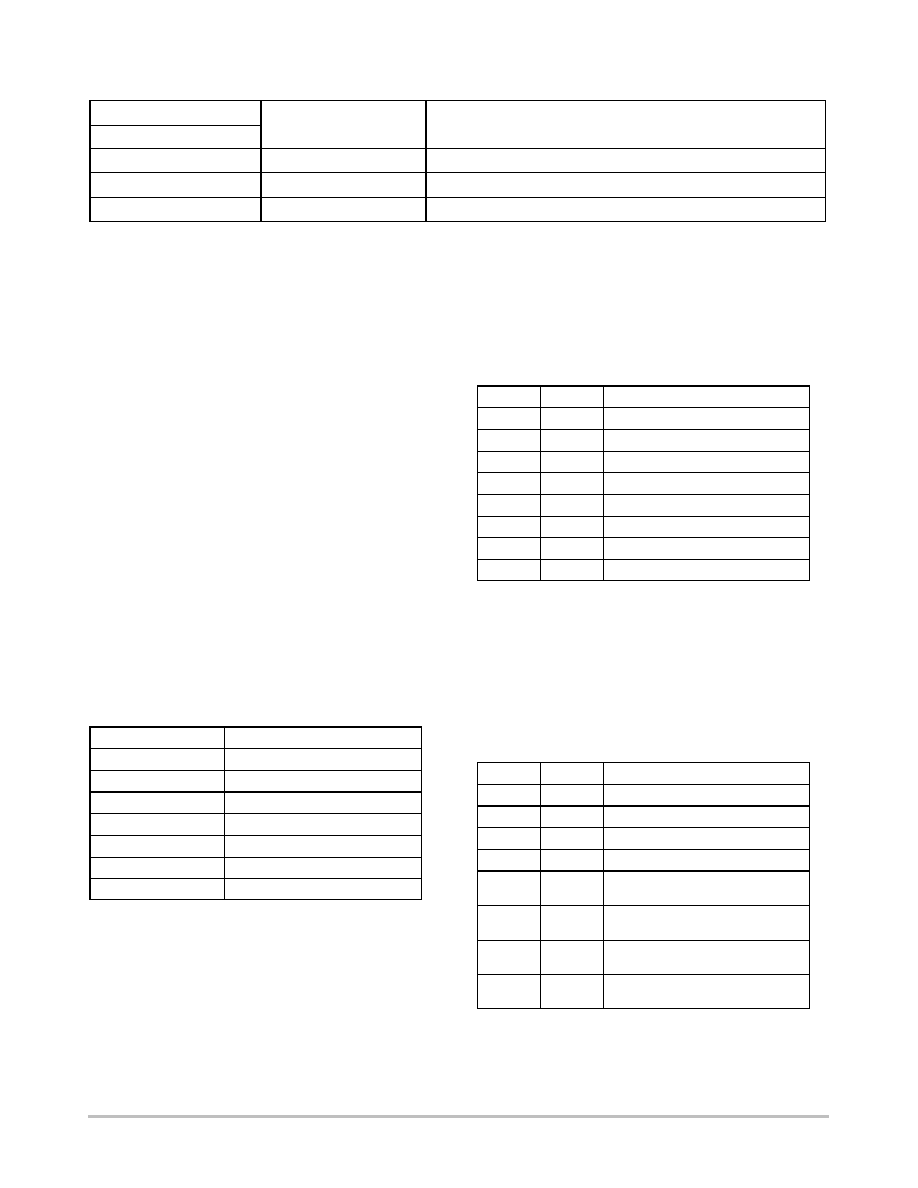

ELECTRICAL CHARACTERISTICS (continued)

(4.75 V < V

CC

< 5.25 V, 8.0 V < V

RES

< 30 V, 9.0 V < V

BAT

< 18 V,

≠40

∞

C < T

A

< +85

∞

C; unless otherwise stated.)

Parameter

Unit

Max

Typ

Min

Test Conditions

Thermal Shut Down

Time to Thermal Shutdown

R

SQUIB

= 0, V

RX

= 30 V, T = 85

∞

C,

Guaranteed by Design

7.0

≠

≠

ms

Squib Resistive Measurements

V

CC

= 5.0 V, R

MR

= 49.9

W

, V

RES

= 30 V

Squib Differential Voltage

V

DIFF

= SHx ≠ SLx, R

SQUIB

= 1.0

to 10

46

53

60

mV

Difference Between SHx & MR

current ≠ SHx reference

I

SQUIB

= 50 mA

≠1.0

≠

1.0

%

SHx Current Limit

R

SQUIB

= 0

67

100

133

mA

SLx Current Limit

R

MR

= 0

77

115

153

mA

MR Voltage Clamp

≠

V

CC

≠ 0.3

≠

V

CC

+ 0.3

V

Turn On Delay Time excluding

external Capacitors

≠

≠

≠

100

µ

s

Turn off Delay Time

≠

≠

≠

50

µ

s

Short Measurements

V

CC

= 5.0 V, V

RES

.

V

BAT,

V

RX

.

V

BAT

SHx pull≠up resistance to V

BAT

SLx pull≠down resistance

V

BAT

= 18 V

4.0

4.0

10

10

17

17

k

k

Pull≠up resistor matching

≠

≠5.0

≠

5.0

%

Pull≠down resistor matching

≠

≠5.0

≠

5.0

%

Short to V

BAT

Trip

SHx short to Battery

SLx bit set to 1

0.73

◊

V

BAT

0.75

◊

V

BAT

0.77

◊

V

BAT

V

Short to GND Trip

SHx short to GND

SGx bit set to 1

0.23

◊

V

BAT

0.25

◊

V

BAT

0.27

◊

V

BAT

V

V

BAT

Monitoring

V

CC

= 5.0 V, External V

BAT

Diode not included, V

RES

= 30 V

V

BAT

Low Trip

BL bit set to 1 when below trip

7.5

8.5

9.5

V

V

BAT

High Trip

BL bit set to 0 when above trip

8.0

9.0

10

V

V

RES

Monitoring

V

CC

= 5.0 V, V

BAT

= 18 V

V

RES

Low Trip

$6d AUX register b0 = 0

15.7

17.5

19.3

V

V

RES

High Trip

$6d AUX register b0 = 0

16.5

18.5

20.5

V

V

RES

Low Trip

$6d AUX register b0 = 1

21.5

24.0

26.5

V

V

RES

High Trip

$6d AUX register b0 = 1

22.5

25

27.5

V

Safing Sensor Monitor

External Resistance Trip Range

SSC bit set when resistance is less

30

400

600

Charge Pump and Monitor

V

CC

= 5.0 V, V

BAT

= 10 V

Oscillator Frequency

V

RES

= 10 V

200

≠

800

kHz

Charge Pump charge time

C

CHG

= 0.1

µ

F, V

RES

= 8.0 V,

Chrg from 8.0 V to 14 V

≠

≠

20

ms

Charge Pump Low Voltage

CL bit set to 1 when below trip

14.5

16.0

17.5

V

Charge Pump High Voltage

CL bit set to 0 when above trip

15.0

17.5

18.0

V

Analog MUX

V

CC

= 5.0 V

A

OUT

Output Range

≠

0.1

≠

V

CC

≠ 0.1

V

A

IN

Input Range

≠

0

≠

V

CC

V

CS2082

http://onsemi.com

5

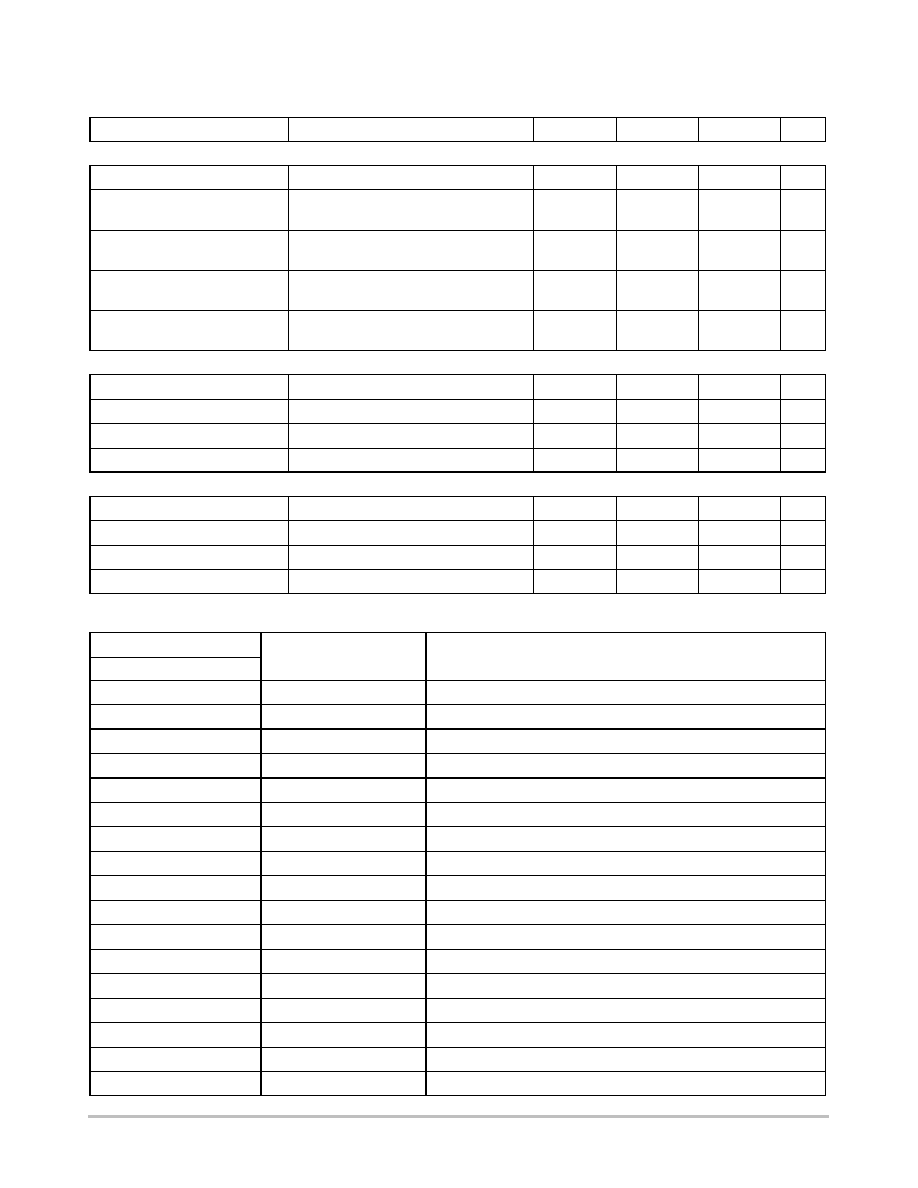

ELECTRICAL CHARACTERISTICS (continued)

(4.75 V < V

CC

< 5.25 V, 8.0 V < V

RES

< 30 V, 9.0 V < V

BAT

< 18 V,

≠40

∞

C < T

A

< +85

∞

C; unless otherwise stated.)

Parameter

Unit

Max

Typ

Min

Test Conditions

Analog MUX

V

CC

= 5.0 V

MUX internal voltage drop

I

OUT

= 100

µ

A

≠

≠

100

mV

Proportion of V

BAT

on A

OUT

with V

BAT

selected

≠

23

25

27

%

A

OUT

Impedance with V

BAT

selected

≠

6.0

15.0

35

k

Proportion of V

RES

on A

OUT

with V

RES

selected

≠

15

17

19

%

A

OUT

Impedance with V

RES

selected

≠

6.0

12.5

25.5

k

Digital Inputs ≠ D

IN

, CLK, CS

V

CC

= 5.25 V, V

BAT

= 18 V, V

RES

= 30 V

Input Low Voltage (V

IL

)

≠

0

≠

0.3

◊

V

CC

V

Input High Voltage (V

IH

)

≠

0.7

◊

V

CC

≠

V

CC

V

Input Voltage Hysteresis

≠

100

≠

≠

mV

Input Pull Down Current (I

IH

)

≠

50

100

200

µ

A

Digital Outputs ≠ D

OUT

V

CC

= 4.75 V, V

BAT

= 18 V, V

RES

= 30 V

Output Low Voltage (V

OL

)

I

SINK

= 1.0 mA

≠

≠

0.4

V

Output High Voltage (V

OH

)

I

SOURCE

= 1.0 mA

V

CC

≠ 0.75

≠

≠

V

Tri≠State Pull≠up Current

CS = 0, D

OUT

= 0

50

100

200

µ

A

Rise | Fall Time

C

LOAD

= 200 pF

≠

≠

50

ns

PACKAGE PIN DESCRIPTION

Package Lead Number

SO≠20L

Pin Symbol

Function

1

V

BAT

Battery Supply Voltage.

2

CHRG

Charge pump Storage.

3

V

RES

Reserve Supply Voltage.

4

VR1

Loop 1 Supply.

5

SH1

Squib 1 High Side.

6

SL1

Squib 1 Low Side.

7

FG1

Loop 1 Return.

8

D

OUT

Serial Port output.

9

CLK

Serial Port Clock.

10

MR

Squib Resistance Output Current.

11

CS

Serial Port Chip Select.

12

A

OUT

Analog MUX Output.

13

A

IN

Analog MUX Input.

14

FG2

Loop 2 Return.

15

SL2

Squib 2 Low Side.

16

SH2

Squib 2 High Side.

17

VR2

Loop 2 Supply.

CS2082

http://onsemi.com

6

PACKAGE PIN DESCRIPTION

(continued)

Package Lead Number

Function

Pin Symbol

SO≠20L

Function

Pin Symbol

18

D

IN

Serial Port Input.

19

V

CC

5.0 V Regulated Supply.

20

GND

Signal Ground.

FUNCTIONAL DESCRIPTION

The CS2082 is an automotive air bag deployment and

diagnostic system for up to two independent firing loops.

Communication with the ASIC is through a synchronous

serial port using Serial Peripheral Interface (SPI) protocol,

at CLK rates up to 2.0 MHz.

Data is simultaneously sent from the D

OUT

pin and

received at the D

IN

pin under the control of the CS and CLK

pins. Error detection logic is included in the SPI to guard

against glitches on either the CS or CLK logic signal inputs.

A valid CS frame must contain exactly 8 CLK cycles for

each CS low≠high≠low transition. Detection of a frame error

will cause input data for that frame to be ignored and an error

code ($FE) to be sent during the next valid CS frame.

The data at D

OUT

is sent MSB first and is guaranteed valid

before the rising edge of CLK. The 8 bits sent from D

OUT

after CS goes high will be the previous data received, data

from either the status register or the fault register, or the CS

frame error code ($FE).

The data at D

IN

is received MSB first and must be valid

before the rising edge of CLK. The 8 bits received at D

IN

before CS goes low will be the current command. Table 1

defines the legal 8≠bit SPI commands, where d = four data

bits and x = don't care. All other inputs will be ignored.

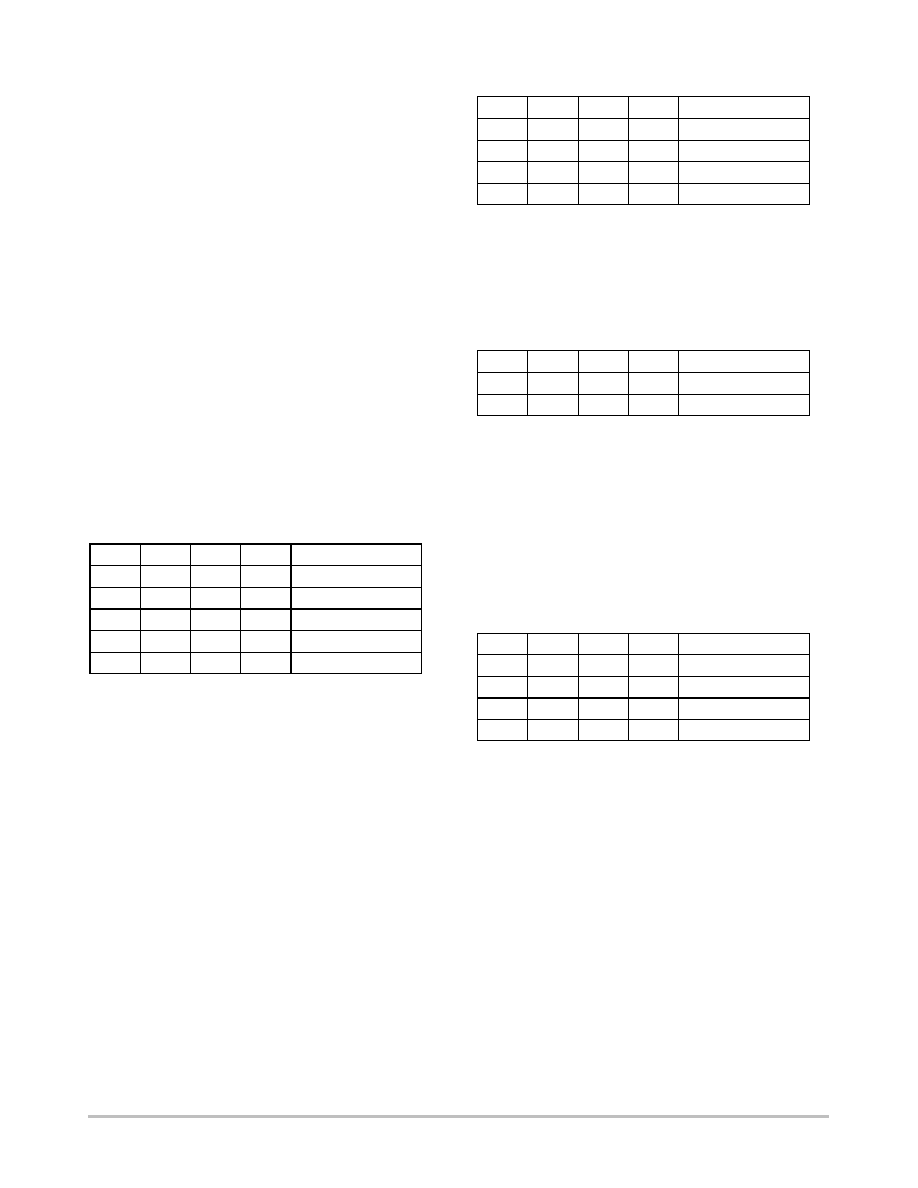

Table 1. Valid CS2082 SPI Commands

COMMAND

FUNCTION

$1x

Read Staus Register

$2x

Read Fault Register

$3d

Squib Resistance Measurements

$4d

Analog MUX Select

$5d

Low Side Switch Control

$6d

Auxiliary Control Register

$Ad

High Side Switch Control

Read Status Register ≠ $1x

The $1x command causes the data contained in the status

register to be sent from D

OUT

during the next valid CS

frame. The status register reports the condition of the firing

paths, closure detection of an external safing switch between

the V

RES

and VR1 pins, the state of the internal charge

pump, and the state of external V

BAT

and V

RES

power

supplies. The status register is an 8≠bit active≠high register

with bit definition as shown in Table 2.

Table 2. Status Register Bit Definition

BIT

VALUE

DESCRIPTION

D7

0

Always Logic zero

D6

0

Always Logic zero

D5

F1

SH1 and SL1 switches active

D4

F2

SH2 and SL2 switches active

D3

SSC

Safing Sensor is closed

D2

RL

V

RES

voltage is below trip

D1

BL

V

BAT

voltage is below trip

D0

CL

CHRG voltage is below trip

Read Fault Register ≠ $2x

The $2x command causes the data contained in the fault

register to be sent from D

OUT

during the next valid CS

frame. The register reports fire path faults by continuously

comparing each path to a portion of the voltage at the V

BAT

pin. The fault register is an 8≠bit active≠high register with

bit definition as shown in Table 3.

Table 3. Fault Register Bit Definition

BIT

VALUE

DESCRIPTION

D7

0

Always Logic zero

D6

0

Always Logic zero

D5

0

Always Logic zero

D4

0

Always Logic zero

D3

SB2

High Side of Sqib 2 above

75% V

BAT

trip threshold

D2

SB1

High Side of Sqib 1 above

75% V

BAT

trip threshold

D1

SG2

Low Side of Sqib 2 below

25% V

BAT

trip threshold

D0

SG1

Low Side of Sqib 1 below

25% V

BAT

trip threshold

CS2082

http://onsemi.com

7

Each SHx pin is pulled up to V

BAT

while each SLx pin is

pulled down to GND through separate nominal 10 k

resistors, thus biasing each normal fire path to about 1/2

V

BAT

. An open fire path has been detected if both the SBx

and SGx bits are set for that path. To detect faults between

fire paths and to test driver function, each driver should be

activated individually. The activated driver should cause its

respective fault bit to be set. If an activated driver does not

set its respective fault bit, a driver fault has been detected. If

an activated driver causes the fault bit of an inactivated

driver to be set, a fault between fire paths has been detected.

Table 4 defines the implied ranges over which the various

types of faults can be detected.

Table 4. Implied Resistive Fault Detection Ranges

Fault

Min

Nom

Max

Unit

Short to Ground

1

5

10

k

Short to Battery

1

5

10

k

Open

5

20

40

k

Driver Open

1

5

10

k

Driver Shorted

1

5

10

k

Squib to Squib

1

5

10

k

Squib Resistance Measurement ≠ $3d

The $3d command activates squib resistance

measurement for the selected firing path. The respective

active≠high bit definitions are shown in Table 5. At

power≠up, the default path is `None.'

Table 5. Squib Resistance Path Select

D3

D2

D1

D0

Path

x

x

0

0

NONE

x

x

0

1

SQUIB 1

x

x

1

0

SQUIB 2

x

x

1

1

NONE

Squib resistance is measured by forcing 50 mV nominal

(proportional to V

CC

) across the squib. The resulting squib

current is passed to an external load resistor at the MR pin,

converting the current back into a voltage. This voltage may

be read directly at the MR pin, or passed through the analog

multiplexer to be read at the A

OUT

pin. The known values of

the squib differential voltage (V

DIFF

) and the MR resistance

(R

MR

), and the measured MR voltage (V

MR

) indicate squib

resistance such that:

RSQUIB

+

RMR

VDIFF

VMR

Typical MR voltage response for R

MR

= 50

over a squib

resistance range of 0.6

to 6.0

is illustrated in Figure 2.

Figure 2. Typical MR Voltage Response

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

0.6

1.4

2.2

3.0

3.8

4.6

5.4

R

SQUIB

V

MR

Measurement accuracy of the CS2082 with combined

tolerances and with and external 1% load resistor at the MR

pin can be defined by the equation:

RSQ(E)

+

VDIFF(IDEAL)

RMR(IDEAL)

VDIFF

"

12%

RSQ(A)

"

1%

RMR

"

1%

+

RSQ(A)

)

12.5%

*

15.94%

where V

DIFF(IDEAL)

and R

MR(IDEAL)

are the assumed

values for the squib resistance solution algorithm, R

SQ(A)

is

the actual squib resistance, and R

SQ(E)

is the result of the

solution algorithm. An additional error may be added if the

MR voltage is measured through the analog multiplexer.

In operation, current is sourced from V

BAT

to the SHx pin,

through the squib to the SLx pin, and returned to ground

through the MR load resistor. Current clamps are provided

for both the SHx and SLx pins and a voltage clamp is

provided for the MR pin. These clamps along with the

resolution of the ADC are the constraining factors for the

minimum and maximum measurable squib resistance

values.

The minimum measurable squib resistance can be defined

as:

VDIFF(MIN)

ILIM(MAX)

v

RSQUIB(MIN)

v

VDIFF(MIN)

RMR(MIN)

VCLAMP(MAX)

The maximum measurable squib resistance can be

defined as:

RSQUIB(MAX)

+

VDIFF(MAX)

RMR(MAX)

(2n

*

1)

VCC(MIN)

In the above equations, V

DIFF

is the SHx≠SLx forced

differential voltage, I

LIM

is the SHx resistive measure

current limit, V

CLAMP

is the MR clamp voltage, R

MR

is the

toleranced MR load resistor value and n is the number of bits

of resolution of the ADC.

It should be noted that during resistive measurements,

faults to GND or BAT (dependent on V

BAT

voltage and

CS2082

http://onsemi.com

8

squib resistance) may be reported by the fault register and

should be ignored.

Power Dissipation during resistive measurement can be

calculated as:

P

+

ISQUIB(VBAT

*

VDIFF)

*

(ISQUIB

RMR)

where V

BAT

is the voltage at the CS2082 V

BAT

pin and

I

SQUIB

is the measurement current through the squib. A

typical value for P is 300 mW when V

BAT

= 13.5,

V

DIFF

= 50 mV, R

SQUIB

= 2.0

and R

MR

= 49.9

.

The resultant increase in power dissipation will cause a

corresponding increase in die temperature which will cause

a corresponding decrease in time to thermal shutdown of the

CS2082. To minimize the impact of squib resistive

measurements on time to thermal shutdown a 5% duty cycle

is recommended.

Analog MUX ≠ $4d

The $4d command selects one of five states at the A

OUT

pin. The states are: High≠Z; MR voltage; A

IN

voltage;

proportion of V

BAT

; proportion of V

RES

. The active≠high

Analog Mux select register bit definitions are shown in

Table 6. All other states will be interpreted as High≠Z. At

power≠up, the default state is `High≠Z.'

Table 6. Analog MUX Output Select

D3

D2

D1

D0

State

0

0

0

0

High≠Z

0

0

0

1

MR

0

0

1

0

AIN

0

1

0

0

BAT

1

0

0

0

RES

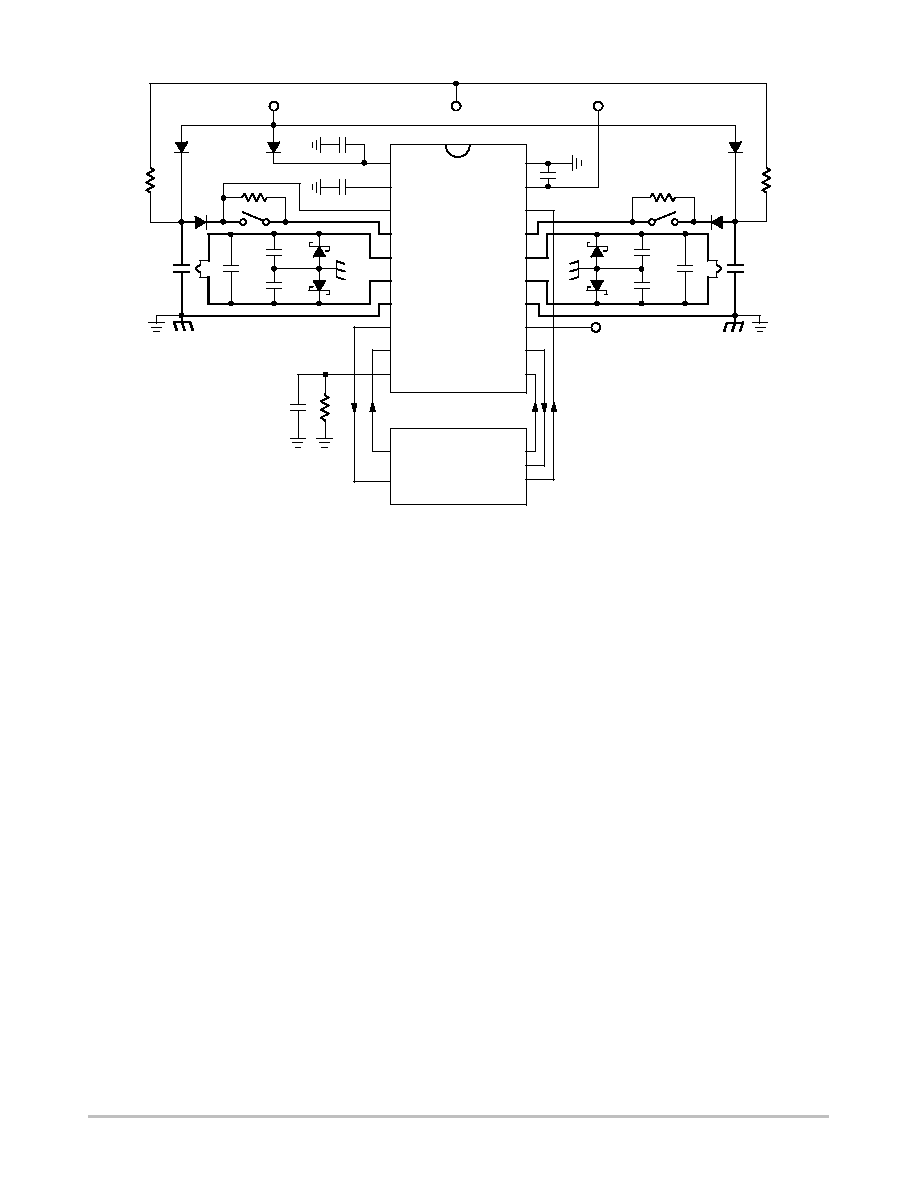

Low Side Switch Control ≠ $5d

The $5d command activates the low side switches. When

a data bit is low that switch is turned on. More than one

switch can be activated at a time. Bit assignment is shown in

Table 7. At power≠up, no switches are active.

Table 7. Low Side Switch Select

D3

D2

D1

D0

Active

x

x

0

0

BOTH

x

x

0

1

SL2

x

x

1

0

SL1

x

x

1

1

NONE

Auxiliary Control Register ≠ $6d

The $6d command selects the V

RES

Monitoring trip

threshold. The threshold determines when the $1x Status

Register reports V

RES

= 1. Bit assignment is shown in Table

8. At power≠up, default trip is 17 V.

Table 8. V

RES

Monitor Trip Select

D3

D2

D1

D0

Trip

x

x

x

0

17 V

x

x

x

1

23 V

High Side Switch Control ≠ $Ad

The $Ad command activates the high side switches. When

a data bit is high, that switch is turned on. More than one

switch can be activated at a time. Bit assignment is shown in

Table 9. Note that the $5d and $Ad commands are binary

complements, i.e., by sending 1010xx11, both high side

switches are activated, and by sending the complement

0101xx00, both low side switches are activated. At

power≠up, no switches are active.

Table 9. High Side Switch Select

D3

D2

D1

D0

Active

x

x

0

0

NONE

x

x

0

1

SH1

x

x

1

0

SH2

x

x

1

1

BOTH

CS2082

http://onsemi.com

9

GND

V

CC

D

IN

VR2

SH2

SL2

FG2

A

IN

A

OUT

CS

V

BAT

CHRG

V

RES

VR1

SH1

SL1

FG1

D

OUT

CLK

MR

CS2082

C

CM

C

CM

C

CM

C

CM

C

DM

C

DM

+

+

C

RES

C

RES

MCU

C

MR

V

IGN

V

CC

V

BOOST

Analog

Input

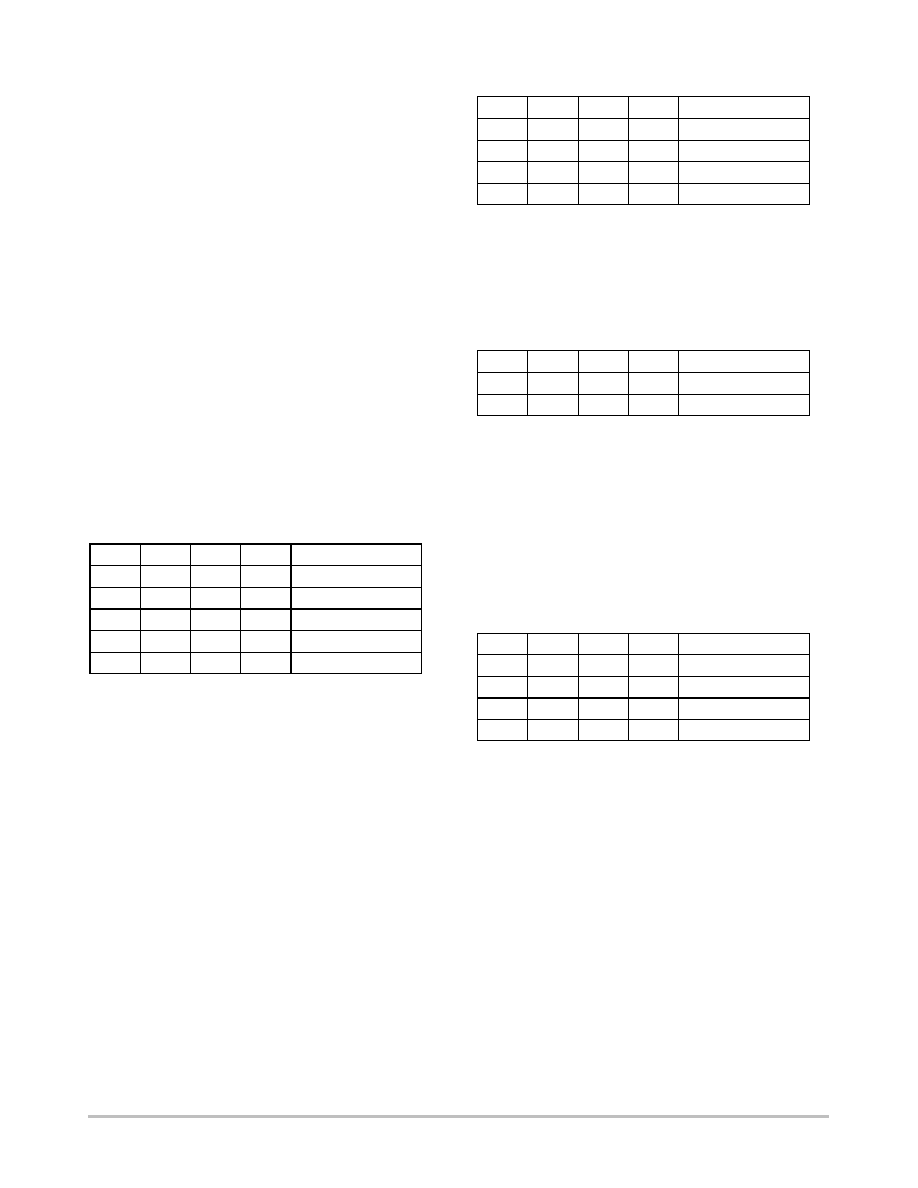

Figure 3. Application Diagram

CS2082

http://onsemi.com

10

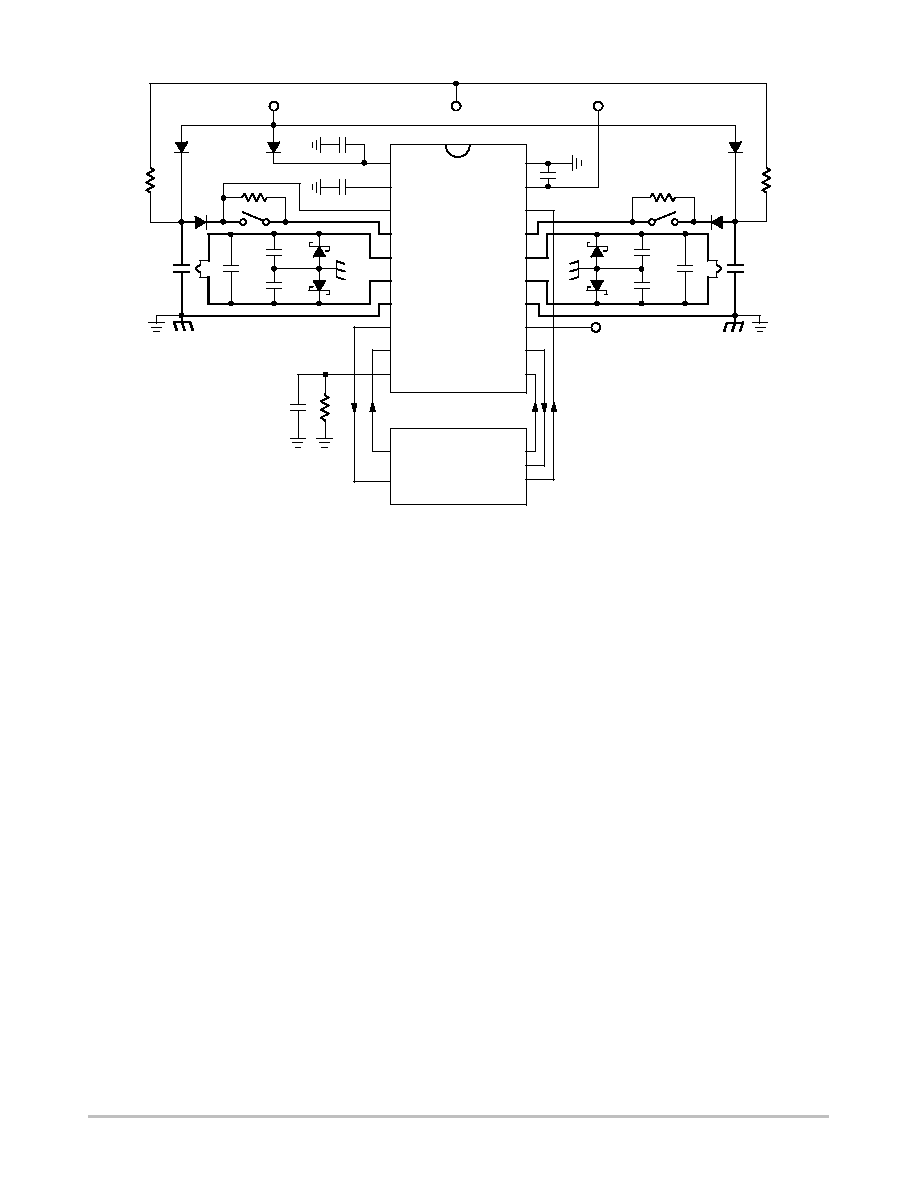

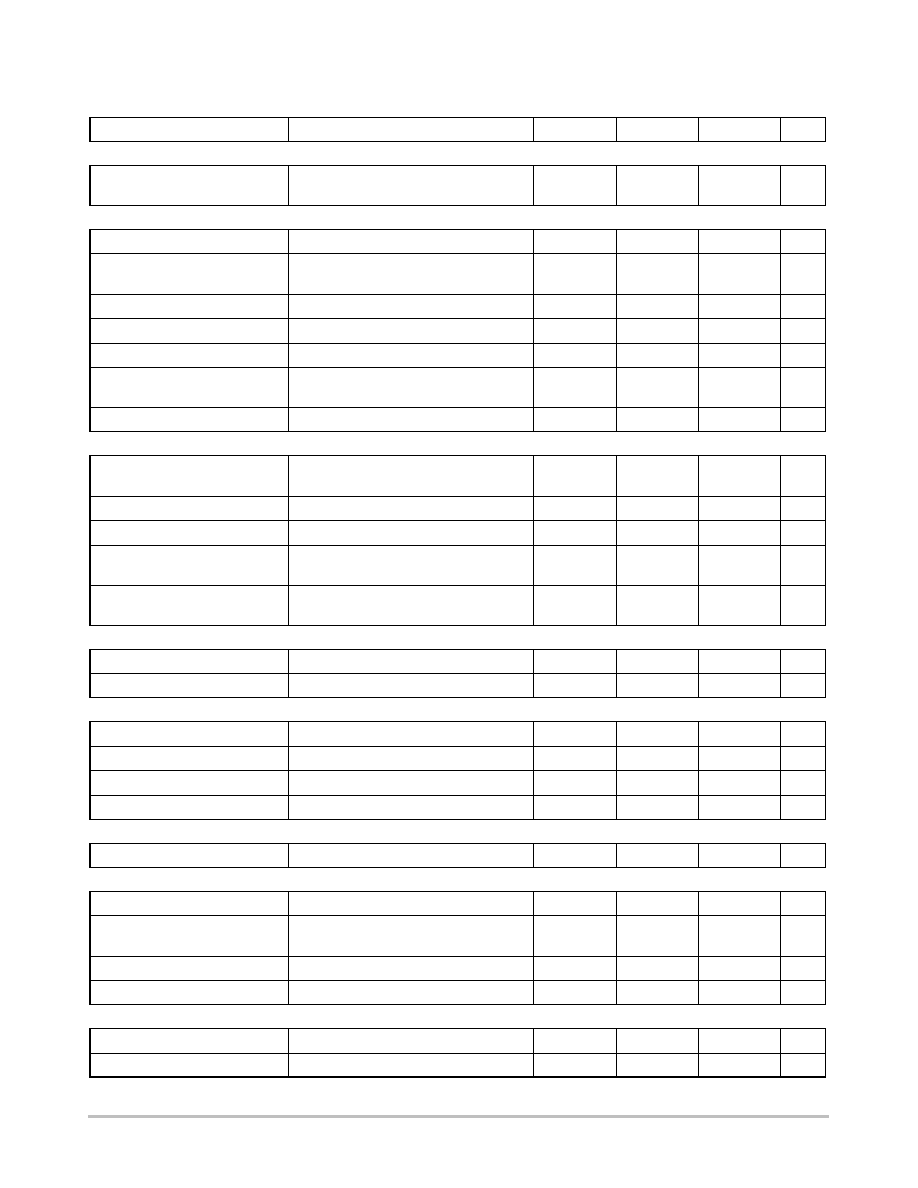

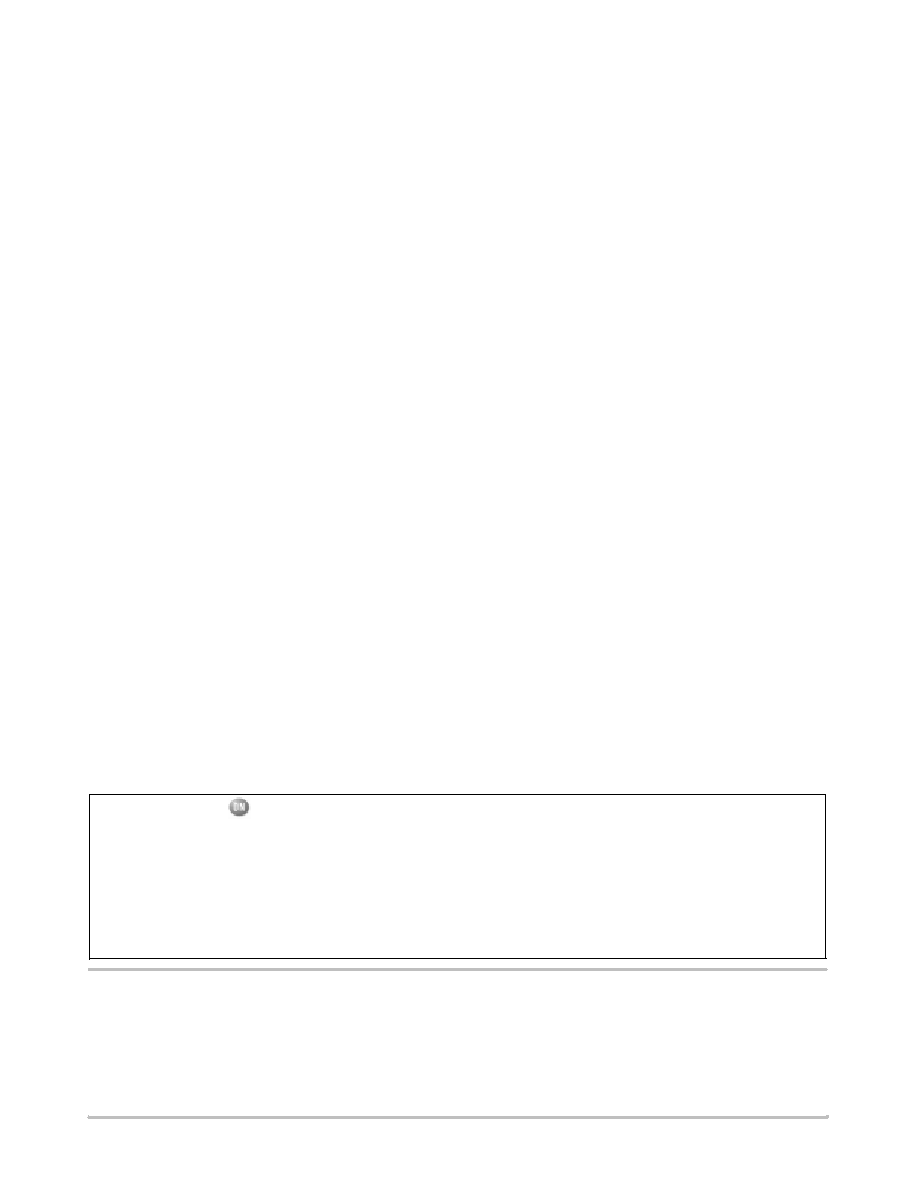

PACKAGE DIMENSIONS

SO≠20L

DW SUFFIX

CASE 751D≠05

ISSUE F

20

1

11

10

B

20X

H

10X

C

L

18X

A1

A

SEATING

PLANE

q

h

X 45

_

E

D

M

0.25

M

B

M

0.25

S

A

S

B

T

e

T

B

A

DIM

MIN

MAX

MILLIMETERS

A

2.35

2.65

A1

0.10

0.25

B

0.35

0.49

C

0.23

0.32

D

12.65

12.95

E

7.40

7.60

e

1.27 BSC

H

10.05

10.55

h

0.25

0.75

L

0.50

0.90

q

0

7

NOTES:

1. DIMENSIONS ARE IN MILLIMETERS.

2. INTERPRET DIMENSIONS AND TOLERANCES

PER ASME Y14.5M, 1994.

3. DIMENSIONS D AND E DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 PER SIDE.

5. DIMENSION B DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE PROTRUSION SHALL

BE 0.13 TOTAL IN EXCESS OF B DIMENSION AT

MAXIMUM MATERIAL CONDITION.

_

_

PACKAGE THERMAL DATA

Parameter

SO≠20L

Unit

R

JC

Typical

17

∞

C/W

R

JA

Typical

90

∞

C/W

CS2082

http://onsemi.com

11

Notes

CS2082

http://onsemi.com

12

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability,

including without limitation special, consequential or incidental damages. "Typical" parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including "Typicals" must be

validated for each customer application by customer's technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

JAPAN: ON Semiconductor, Japan Customer Focus Center

4≠32≠1 Nishi≠Gotanda, Shinagawa≠ku, Tokyo, Japan 141≠0031

Phone: 81≠3≠5740≠2700

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

CS2082/D

Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303≠675≠2175 or 800≠344≠3860 Toll Free USA/Canada

Fax: 303≠675≠2176 or 800≠344≠3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

N. American Technical Support: 800≠282≠9855 Toll Free USA/Canada