| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: PCA9512 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

Philips

Semiconductors

PCA9512

Level shifting hot swappable

I

2

C and SMBus buffer

Product data sheet

2004 Oct 05

INTEGRATED CIRCUITS

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2

2004 Oct 05

DESCRIPTION

The PCA9512 is a hot swappable I

2

C and SMBus buffer that allows

I/O card insertion into a live backplane without corruption of the data

and clock buses and includes two dedicated supply voltage pins to

provide level shifting between 3.3 V and 5 V systems while

maintaining the best noise margin for each voltage level. Either pin

may be powered with supply voltages ranging from 2.7 V to 5.5 V

with no constraints on which supply voltage is higher. Control

circuitry prevents the backplane from being connected to the card

until a stop bit or bus idle occurs on the backplane without bus

contention on the card. When the connection is made, the PCA9512

provides bi-directional buffering, keeping the backplane and card

capacitances isolated.

The dynamic offset design of the PCA9510/11/12/13/14 I/O drivers

allow them to be connected to another PCA9510/11/12/13/14 device

in series or in parallel and to the A side of the PCA9517. The

PCA9510/11/12/13/14 can not connect to the static offset I/Os used

on the PCA9515/15A/16/16A/17 B side and PCA9518.

FEATURES

∑

Bi-directional buffer for SDA and SCL lines increases fanout and

prevents SDA and SCL corruption during live board insertion and

removal from multi-point backplane systems

∑

Compatible with I

2

C standard mode, I

2

C fast mode, and SMBus

standards

∑

V/

t rise time accelerators on all SDA and SCL lines with ability

to disable

V/

t rise time accelerators through the ACC pin for

lightly loaded systems

∑

5 V to 3.3 V level translation with optimum noise margin

∑

High-impedance SDA, SCL pins for V

CC

or V

CC2

= 0 V

∑

1 V precharge on all SDA and SCL lines

∑

Supports clock stretching and multiple master

arbitration/synchronization

∑

Operating power supply voltage range: 2.7 V to 5.5 V

∑

5.5 V tolerant I/Os

∑

0 kHz to 400 kHz clock frequency

∑

ESD protection exceeds 2000 V HBM per JESD22-A114,

200 V MM per JESD22-A115 and 1000 V CDM per JESD22-C101

∑

Latch-up testing is done to JESDEC Standard JESD78 which

exceeds 100 mA

∑

Packages offered: SO8, TSSOP8 (MSOP8)

APPLICATION

∑

cPCI, VME, AdvancedTCA cards and other multi-point backplane

cards that are required to be inserted or removed from an

operating system.

PIN CONFIGURATION

1

2

3

4

V

CC2

GND

SCLIN

SDAOUT

SDAIN

ACC

5

6

7

8

V

CC

SCLOUT

SW02070

TOP VIEW

Figure 1. Pin configuration.

PIN DESCRIPTION

PIN

SYMBOL

DESCRIPTION

1

V

CC2

Supply voltage for devices on the card

I

2

C-buses. Connect pull-up resistors from

SDAOUT and SCLOUT to this pin.

2

SCLOUT

Serial clock output to and from the SCL bus

on the card.

3

SCLIN

Serial clock input to and from the SCL bus

on the backplane.

4

GND

Ground. Connect this pin to a ground plane

for best results.

5

ACC

CMOS threshold digital input pin that

enables and disables the rise-time

accelerators on all four SDA and SCL pins.

ACC enables all accelerators when set to

V

CC2

, and turns them off when set to GND.

6

SDAIN

Serial data input to and from the SDA bus on

the backplane/long distance bus.

7

SDAOUT

Serial data output to and from the SDA bus

on the card.

8

V

CC

Power supply. From the backplane, connect

pull-up resistors from SDAIN and SCLIN to

this pin.

ORDERING INFORMATION

PACKAGES

TEMPERATURE RANGE

ORDER CODE

TOPSIDE MARK

DRAWING NUMBER

8-pin plastic SO

≠40

∞

C to +85

∞

C

PCA9512D

PCA9512

SOT96-1

8-pin plastic TSSOP (MSOP)

≠40

∞

C to +85

∞

C

PCA9512DP

9512

SOT505-1

Standard packing quantities and other packaging data are available at www.standardproducts.philips.com/packaging.

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2004 Oct 05

3

TYPICAL APPLICATION

SCLOUT

SDAOUT

R2

10 k

R1

10 k

C2

0.01

µ

F

PCA9512

SCLIN

SDAIN

V

CC

5 V

ACC

GND

SW02068

R3

10 k

C1

0.01

µ

F

R4

10 k

C3*

0.01

µ

F

C4*

0.01

µ

F

C5*

0.01

µ

F

C6*

0.01

µ

F

SCL

SDA

CARD_SCL

CARD_SDA

V

CC

V

CC2

CARD_V

CC

3 V

* CAPACITORS NOT REQUIRED IF BUS IS SUFFICIENTLY LOADED

R5

10 k

Figure 2. Typical application

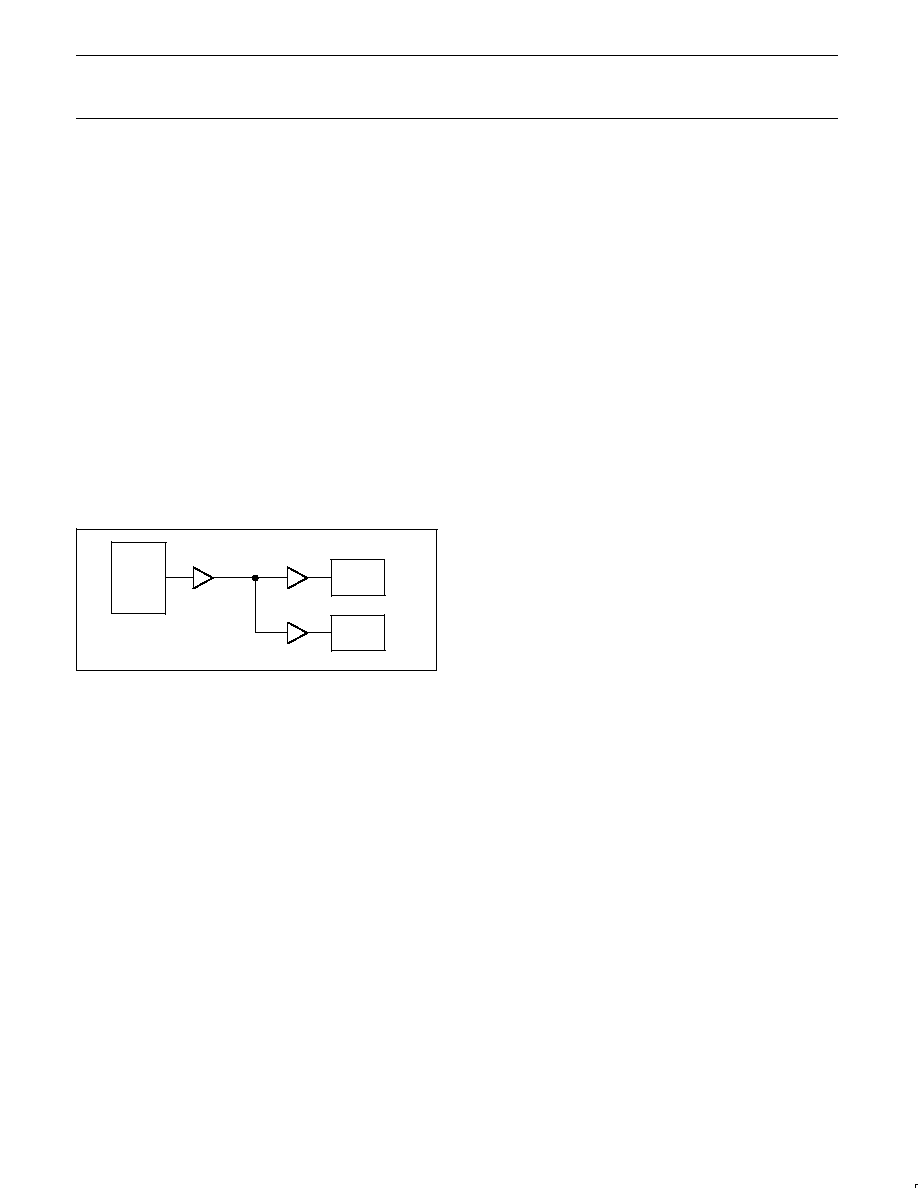

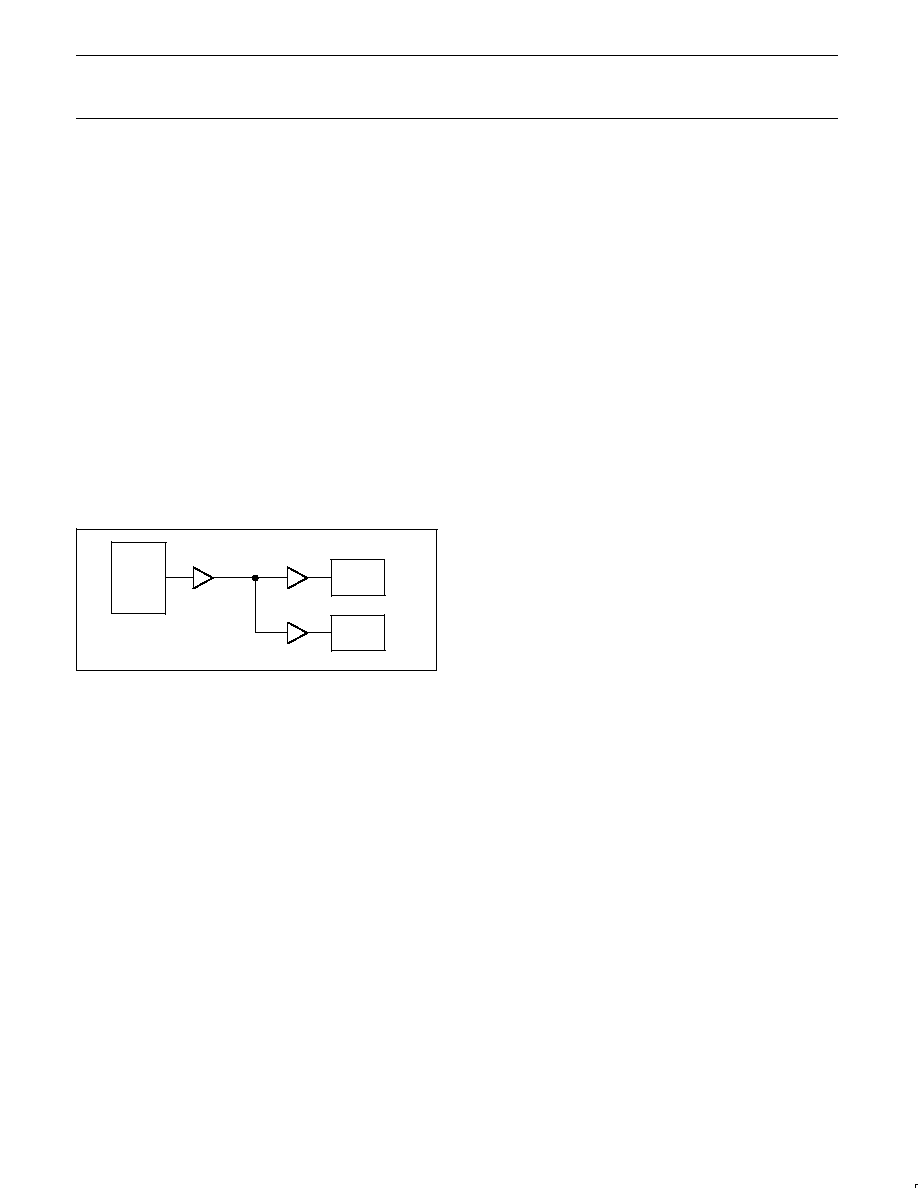

BLOCK DIAGRAM

2

SCLOUT

0.5 pF

RD

S

QB

UVLO

20 pF

STOP BIT AND

BUS IDLE

95

µ

s

DELAY

0.5

µ

A

UVLO

0.55V

CC

/

0.45V

CC

2 mA

SLEW RATE

DETECTOR

BACKPLANE-TO-CARD

CONNECTION

2 mA

SLEW RATE

DETECTOR

3

SCLIN

CONNECT

4

GND

SW02069

100 k

RCH4

100 k

RCH3

100 k

RCH2

100 k

RCH1

CONNECT

7

SDAOUT

CONNECT

2 mA

SLEW RATE

DETECTOR

BACKPLANE-TO-CARD

CONNECTION

2 mA

SLEW RATE

DETECTOR

CONNECT

6

SDAIN

1 VOLT

PRECHARGE

8

V

CC

CONNECT

1

V

CC2

A

CC

A

CC

5

ACC

CONNECT

CONNECT

0.55V

CC

/

0.45V

CC

Figure 3. Block diagram.

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2004 Oct 05

4

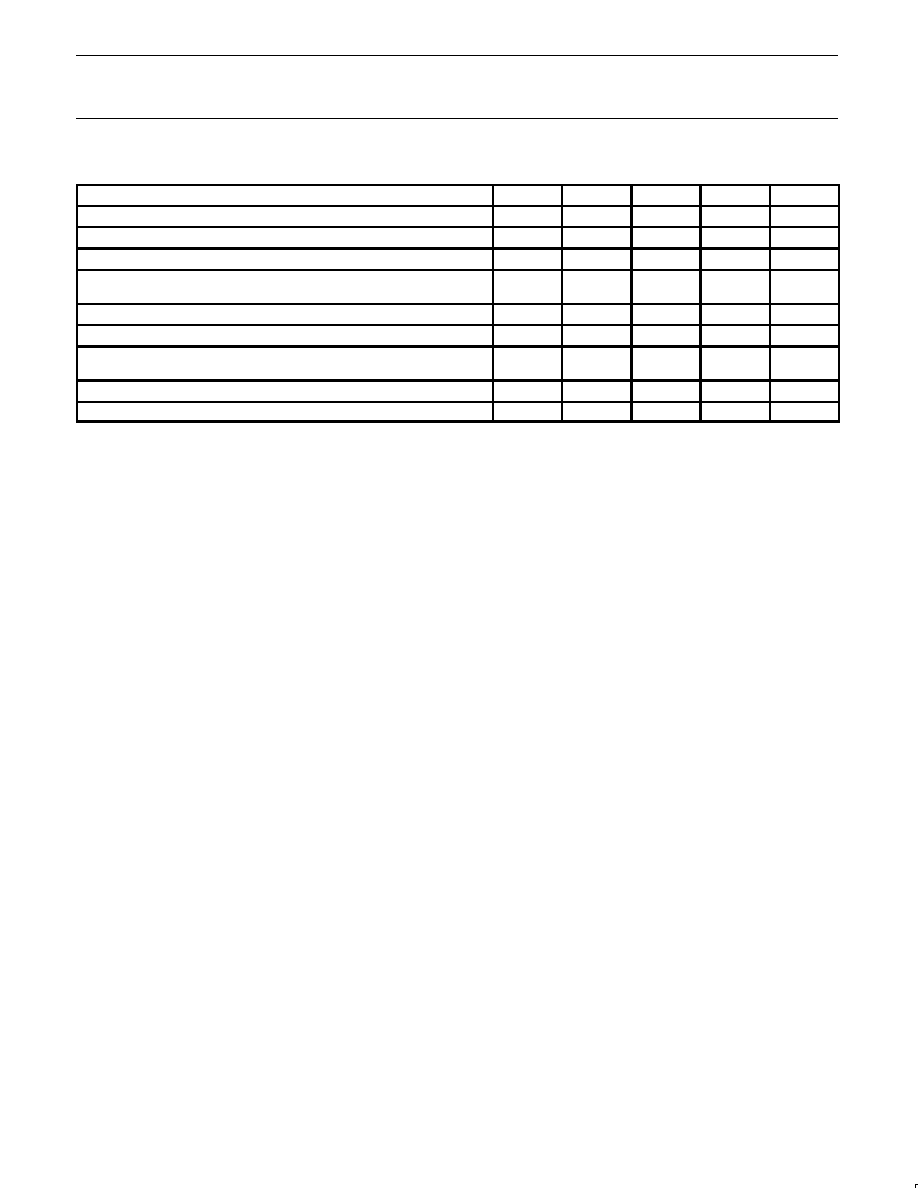

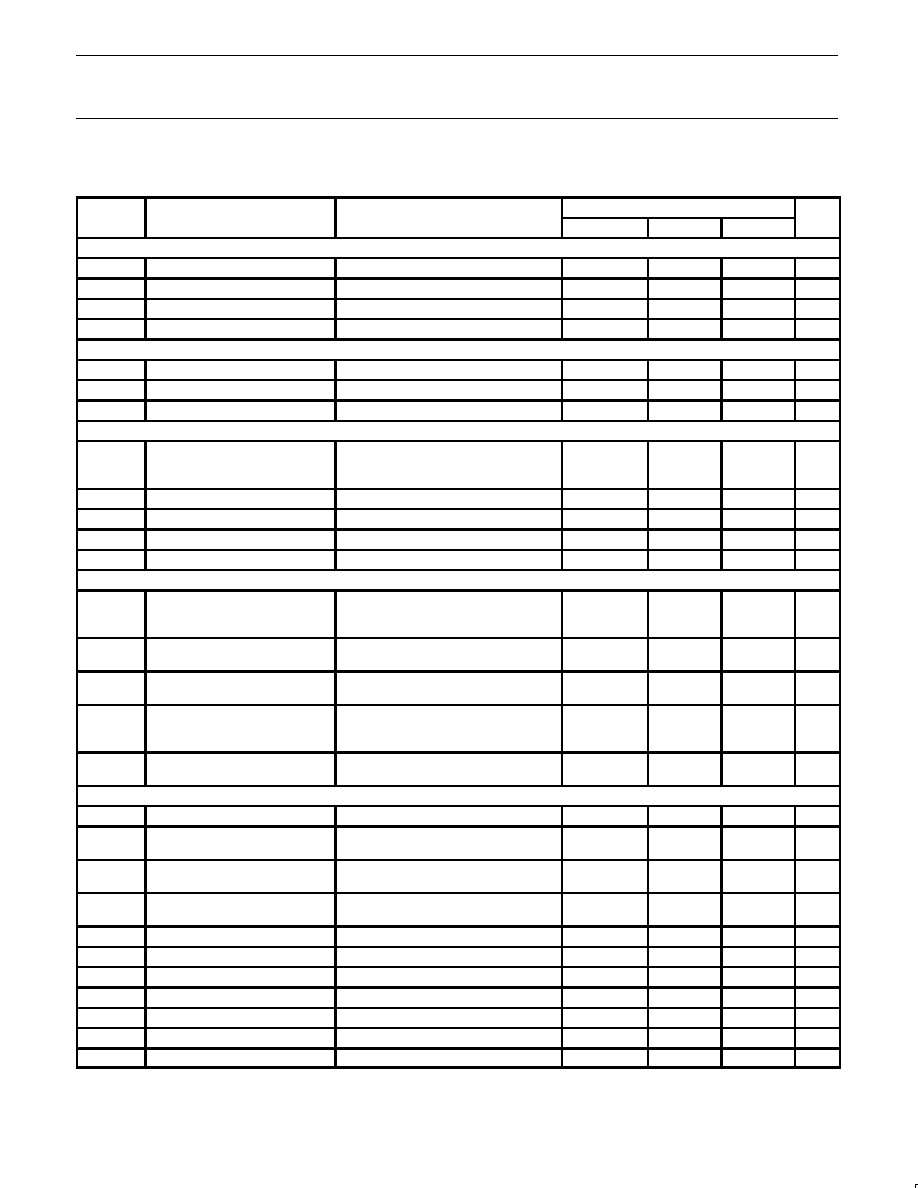

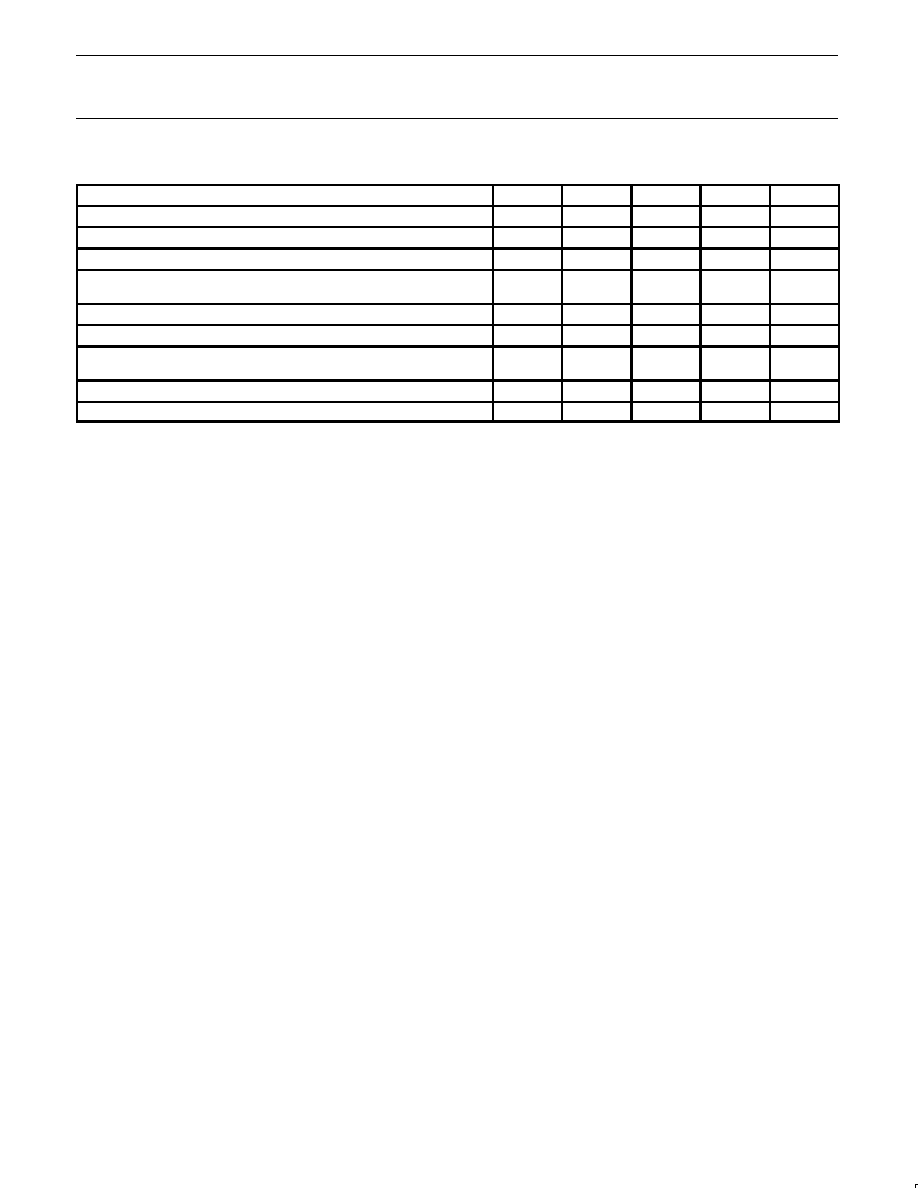

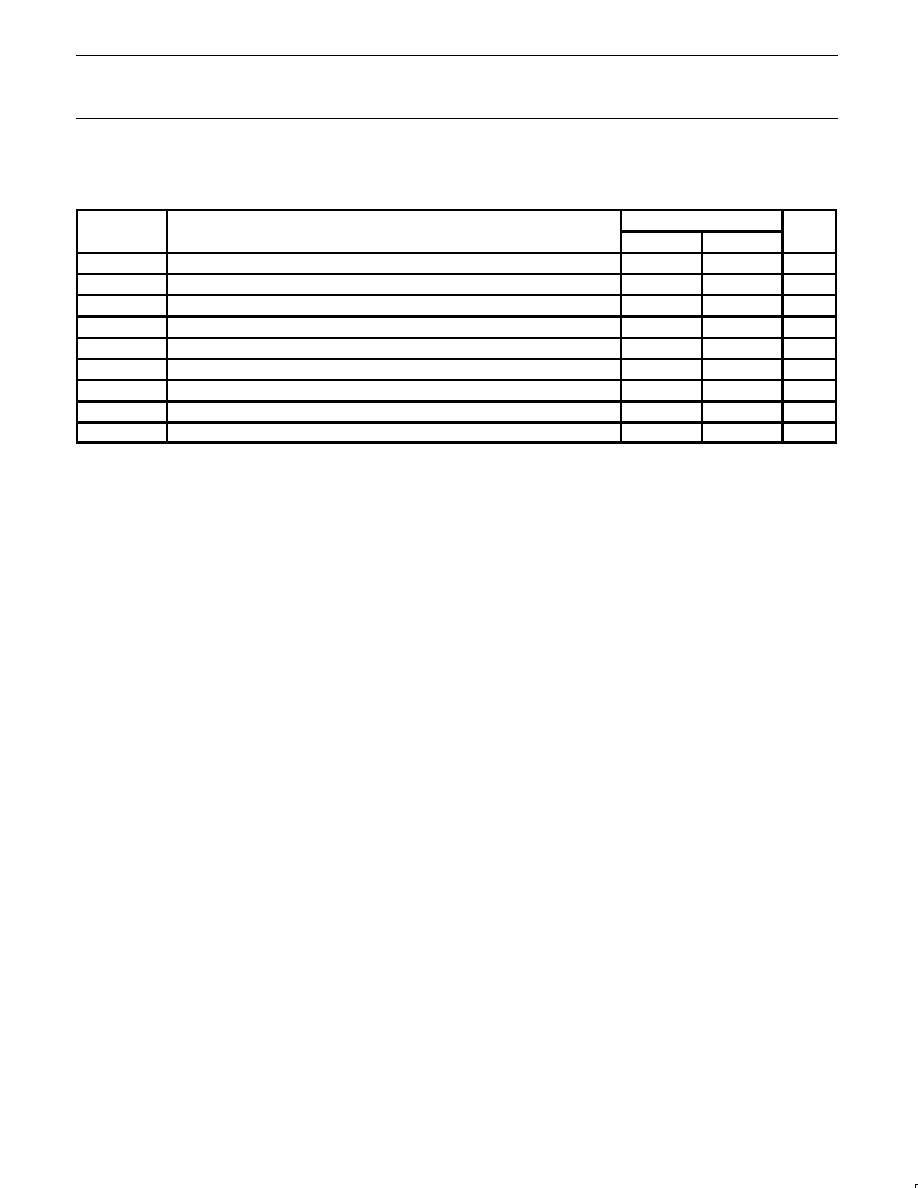

FEATURE SELECTION CHART

FEATURES

PCA9510

PCA9511

PCA9512

PCA9513

PCA9514

Idle detect

Yes

Yes

Yes

Yes

Yes

High impedance SDA, SCL pins for V

CC

= 0 V

Yes

Yes

Yes

Yes

Yes

Rise time accelerator circuitry on all SDA and SCL lines

--

Yes

Yes

Yes

Yes

Rise time accelerator circuitry hardware disable pin for lightly loaded

systems

--

--

Yes

--

--

Rise time accelerator threshold 0.8 V vs 0.6 V improves noise margin

--

--

--

Yes

Yes

Ready open drain output

Yes

Yes

--

Yes

Yes

Two V

CC

pins to support 5 V to 3.3 V level translation with improved noise

margins

--

--

Yes

--

--

1 V precharge on all SDA and SCL lines

IN only

Yes

Yes

--

--

92

µ

A current source on SCLIN and SDAIN for PICMG applications

--

--

--

Yes

--

OPERATION

Start-up

When the PCA9512 is powered up either V

CC

or V

CC2

may rise first

and either may be more positive or they may can be equal, however

the PCA9512 will not leave the under voltage lock out/initialization

state until both V

CC

and V

CC2

have gone above 2.5 V. If either V

CC

or V

CC2

drops below 2.0 V it will return to the under voltage lock

out/initialization state. In the under voltage lock out state the

connection circuitry is disabled, the rise time accelerators are

disabled, and the precharge circuitry is also disabled. After both V

CC

and V

CC2

are valid, independent of which is higher, the PCA9512

enters the initialization state, during this state the 1 V precharge

circuitry is activated and pulls up the SDA and SCL pins to 1 V

through individual 100 k

nominal resistors. At the end of the

initialization state the "Stop Bit And Bus Idle" detect circuit is

enabled. When all the SDA and SCL pins have been HIGH for the

bus idle time or when all pins are HIGH and a stop condition is seen

on the SDAIN and SCLIN pins, the connect circuitry is activated,

connecting SDAIN to SDAOUT and SCLIN to SCLOUT. The 1 V

precharge circuitry is disabled when the connection is made, unless

the ACC pin is LOW, the rise time accelerators are enabled at this

time also.

Connection Circuitry

Once the connection circuitry is activated, the behavior of SDAIN

and SDAOUT as well as SCLIN and SCLOUT become identical with

each acting as a bidirectional buffer that isolated the input bus

capacitance from the output bus capacitance while communicating

the logic levels. If V

CC

V

CC2

, then a level shifting function is also

performed between input and output. A LOW forced on either

SDAIN or SDAOUT will cause the other pin to be driven LOW by the

PCA9512. The same is also true for the SCL pins. Noise between

0.7V

CC

and V

CC

on the SDAIN and SCLIN pins and 0.7V

CC2

and

V

CC2

on the SDAOUT and SCLOUT pins is generally ignored

because a falling edge is only recognized when it falls below the

0.7V

CC

for SDAIN and SCLIN (or 0.7V

CC2

for SDAOUT and

SCLOUT pins) with a slew rate of at least 1.25 V/

µ

s. When a falling

edge is seen on one pin the other pin in the pair turns on a pull down

driver that is reference to a small voltage above the falling pin. The

driver will pull the pin down at a slow rate determined by the driver

and the load. The first falling pin may have a fast or slow slew rate, if

it is faster than the pull down slew rate then the initial pull down rate

will continue until it is LOW. If the first falling pin has a slow slew rate

then the second pin will be pulled down at its initial slew rate only

until it is just above the first pin voltage then they will both continue

down at the slew rate of the first. Once both sides are LOW they will

remain LOW until all the external drivers have stopped driving

LOWs. If both sides are being driven LOW to the same or nearly the

same value by external drivers, which is the case for clock

stretching and is typically the case for acknowledge, and one side

external driver stops driving, that pin will rise and rise above the

nominal offset voltage until the internal driver catches up and pulls it

back down to the offset voltage. This bounce is worst for low

capacitances and low resistances, and may become excessive.

When the last external driver stops driving a LOW, that pin will

bounce up and settle out just above the other pin as both rise

together with a slew rate determined by the internal slew rate control

and the RC time constant. As long as the slew rate is at least 1.25

V/

µ

s, when the pin voltage exceed 0.6 V the rise time accelerator

circuits are turned on and the pull down driver is turned off. If the

ACC pin is LOW the rise time accelerator circuits will be disabled

but the pull down driver will still turn off.

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2004 Oct 05

5

Maximum number of devices in series

Each buffer adds about 0.065 V dynamic level offset at 25

∞

C with

the offset larger at higher temperatures. Maximum offset (V

OS

) is

0.150 V. The LOW level at the signal origination end (master) is

dependent upon the load and the only specification point is the

I

2

C-bus specification of 3 mA will produce V

OL

< 0.4 V, although if

lightly loaded the V

OL

may be

0.1 V. Assuming V

OL

= 0.1 V and

V

OS

= 0.1 V, the level after four buffers would be 0.5 V, which is only

about 0.1 V below the threshold of the rising edge accelerator (about

0.6 V). With great care a system with four buffers may work, but as

the V

OL

moves up from 0.1 V, noise or bounces on the line will result

in firing the rising edge accelerator thus introducing false clock

edges. Generally it is recommended to limit the number of buffers in

series to two.

The PCA9510 (rise time accelerator is permanently disabled) and

the PCA9512 (rise time accelerator can be turned off) are a little

different with the rise time accelerator turned off because the rise

time accelerator will not pull the node up, but the same logic that

turns on the accelerator turns the pull-down off. If the V

IL

is above

0.6 V and a rising edge is detected, the pull-down will turn off and

will not turn back on until a falling edge is detected; so if the noise is

small enough it may be possible to use more than two PCA9510 or

PCA9512 parts in series but is not recommended.

MASTER

buffer A

SLAVE B

buffer B

SLAVE C

buffer C

SW02353

common

node

Figure 4.

Consider a system with three buffers connected to a common node

and communication between the Master and Slave B that are

connected at either end of Buffer A and Buffer B in series as shown

in Figure 4. Consider if the V

OL

at the input of Buffer A is 0.3 V and

the V

OL

of Slave B (when acknowledging) is 0.4 V with the direction

changing from Master to Slave B and then from Slave B to Master.

Before the direction change you would observe V

IL

at the input of

Buffer A of 0.3 V and its output, the common node, is

0.4 V. The

output of Buffer B and Buffer C would be

0.5 V, but Slave B is

driving 0.4 V, so the voltage at Slave B is 0.4 V. The output of

Buffer C is

0.5 V. When the Master pull-down turns off, the input of

Buffer A rises and so does its output, the common node, because it

is the only part driving the node. The common node will rise to 0.5 V

before Buffer B's output turns on, if the pull-up is strong the node will

bounce. If the bounce goes above the threshold for the rising edge

accelerator

0.6 V the accelerators on both Buffer A and Buffer C

will fire contending with the output of Buffer B. The node on the input

of Buffer A will go HIGH as will the input node of Buffer C. After the

common node voltage is stable for a while the rising edge

accelerators will turn off and the common node will return to

0.5 V

because the Buffer B is still on. The voltage at both the Master and

Slave C nodes would then fall to

0.6 V until Slave B turned off. This

would not cause a failure on the data line as long as the return to

0.5 V on the common node (

0.6 V at the Master and Slave C)

occurred before the data setup time. If this were the SCL line, the

parts on Buffer A and Buffer C would see a false clock rather than a

stretched clock, which would cause a system error.

Propagation Delays

The delay for a rising edge is determined by the combined pull-up

current from the bus resistors and the PCA9512 and the effective

capacitance on the lines. If the pull-up currents are the same, any

difference in capacitance between the two sides. The t

PLH

may be

negative if the output capacitance is less than the input capacitance

and would be positive if the output capacitance is larger than the

input capacitance, when the currents are the same.

The t

PHL

can never be negative because the output does not start to

fall until the input is below 0.7V

CC

(or 0.7V

CC2

for SDAOUT and

SCLOUT) and the output pull down turn on has a nonzero delay,

and the output has a limited maximum slew rate and even it the

input slew rate is slow enough that the output catches up it will still

lag the falling voltage of the input by the offset voltage, The

maximum t

PHL

occurs when the input is driven LOW with zero delay

and the output is still limited by its turn on delay and the falling edge

slew rate, The output falling edge slew rate (which is a function of

temperature, V

CC

or V

CC2

, and process) as well as load current and

load capacitance.

Rise Time Accelerators

During positive bus transitions a 2 mA current source is switched on

to quickly slew the SDA and SCL lines HIGH once the input level of

0.6 V is exceeded. The rising edge rate should be at least 1.25 V/

µ

s

to guarantee turn on of the accelerators.

ACC Boost Current Enable

Users having lightly loaded systems may wish to disable the

rise-time accelerators. Driving this pin to ground turns off the

rise-time accelerators on all four SDA and SCL pins. Driving this pin

to the V

CC2

voltage enables normal operation of the rise-time

accelerators.

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2004 Oct 05

6

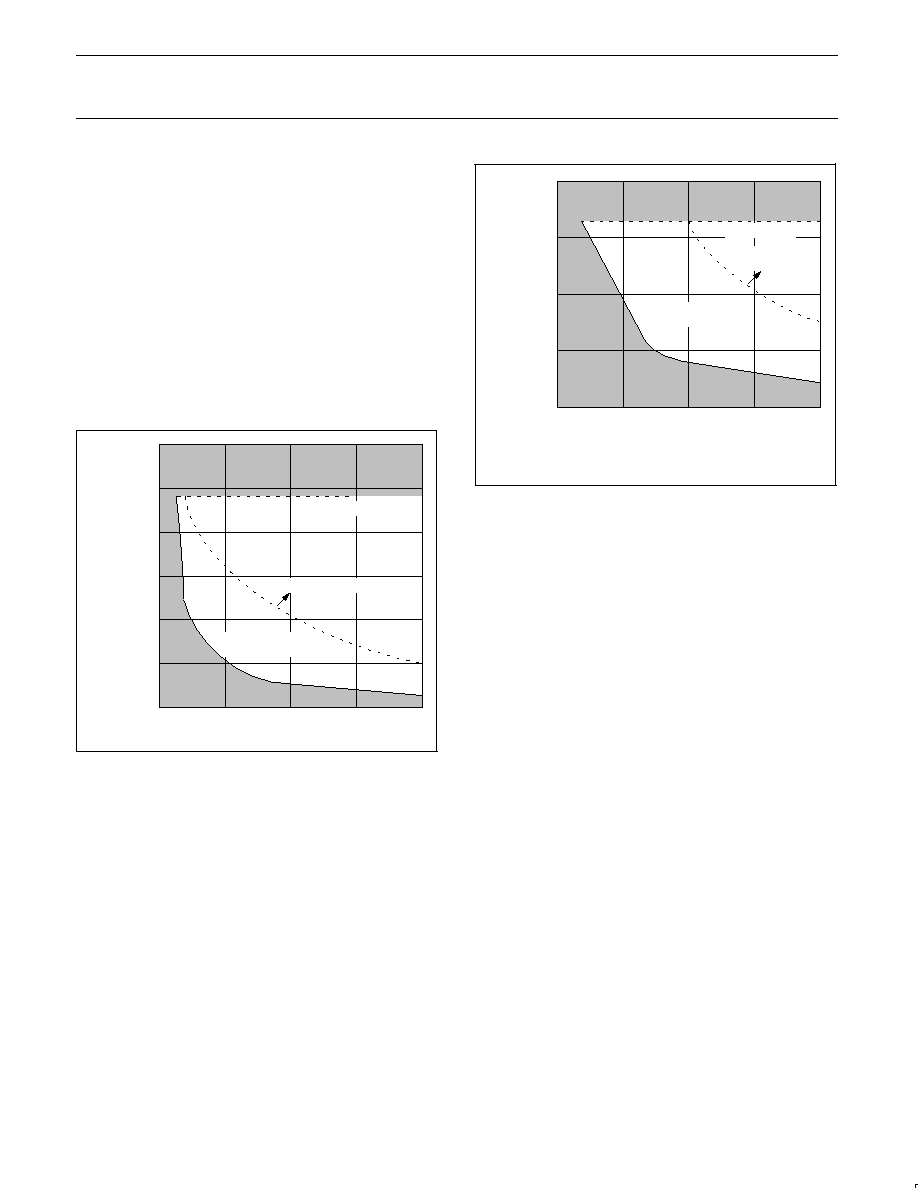

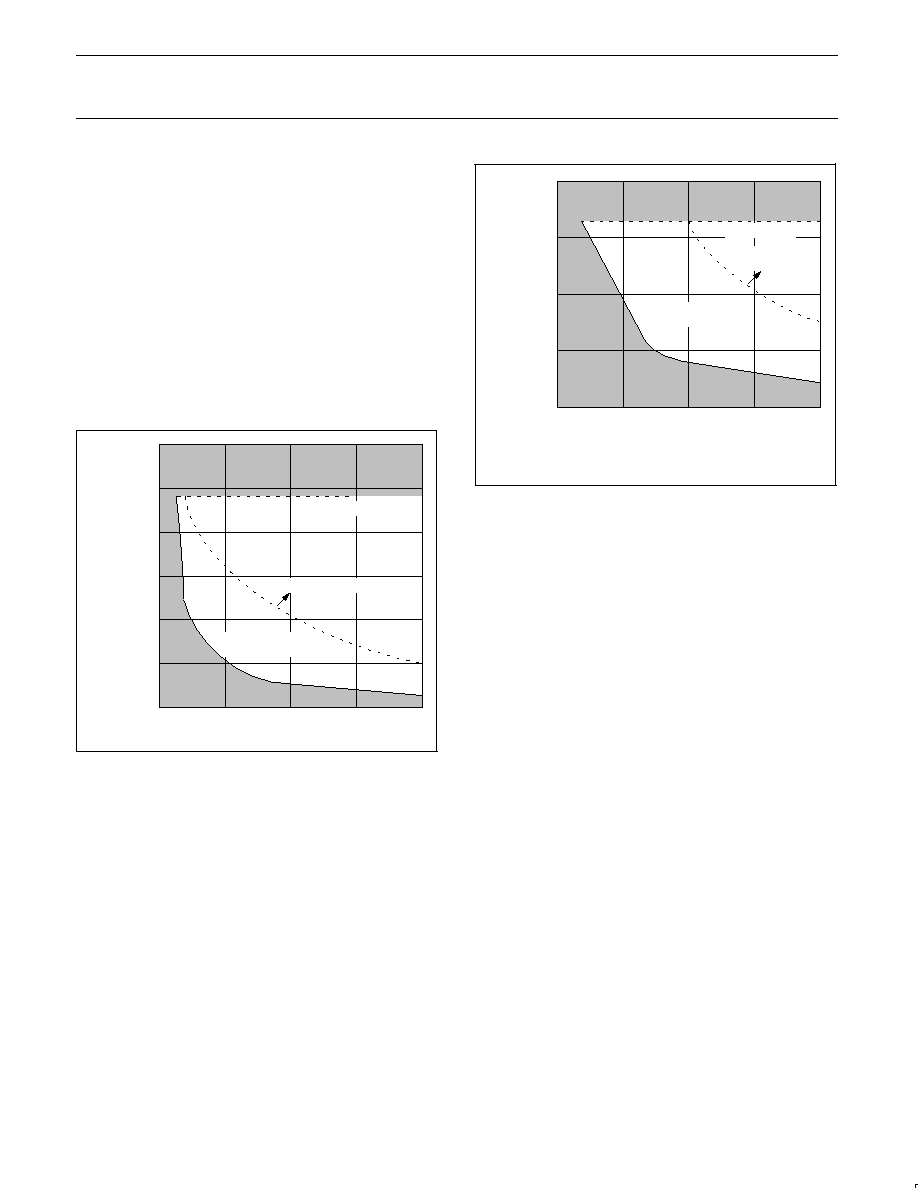

Resistor Pull-up Value Selection

The system pull-up resistors must be strong enough to provide a

positive slew rate of 1.25 V/

µ

s on the SDA and SCL pins, in order to

activate the boost pull-up currents during rising edges. Choose

maximum resistor value using the formula:

R

(V

CC(MIN)

≠ 0.6) (800,000)/C

where R is the pull-up resistor value in ohms, V

CC(MIN)

is the

minimum V

CC

voltage and C is the equivalent bus capacitance in

picofarads (pF).

In addition, regardless of the bus capacitance, always choose

R

16 k

for V

CC

= 5.5 V maximum, R

24 k

for V

CC

= 3.6 V

maximum. The start-up circuitry requires logic HIGH voltages on

SDAOUT and SCLOUT to connect the backplane to the card, and

these pull-up values are needed to overcome the precharge voltage.

See the curves in Figures 5 and 6 for guidance in resistor pull-up

selection.

30

20

15

21

5

0

0

100

200

300

400

C

BUS

(pF)

R

PULLUP

(k

)

25

RECOMMENDED

PULL-UP

R

MAX

= 24 k

RISE-TIME > 300 ns

SW02115

Figure 5. Bus requirements for 3.3 V systems

20

15

21

5

0

0

100

200

300

400

C

BUS

(pF)

R

PULLUP

(k

)

RECOMMENDED

PULL-UP

R

MAX

= 16 k

RISE-TIME

> 300 ns

SW02116

Figure 6. Bus requirements for 5 V systems

Minimum SDA and SCL Capacitance

Requirements

The device connection circuitry requires a minimum capacitance

loading on the SDA and SCL pins in order to function properly. The

value of this capacitance is a function of V

CC

and the bus pull-up

resistance. Estimate the bus capacitance on both the backplane and

the card data and clock buses, and refer to Figures 5 and 6 to

choose appropriate pull-up resistor values. Note from the figures

that 5 V systems should have at least 47 pF capacitance on their

buses and 3.3 V systems should have at least 22 pF capacitance for

proper operation of the PCA9512. Although the device has been

designed to be marginally stable with smaller capacitance loads, for

applications with less capacitance, provisions need to be made to

add a capacitor to ground to ensure these minimum capacitance

conditions if oscillations are noticed during initial signal integrity

verification.

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2004 Oct 05

7

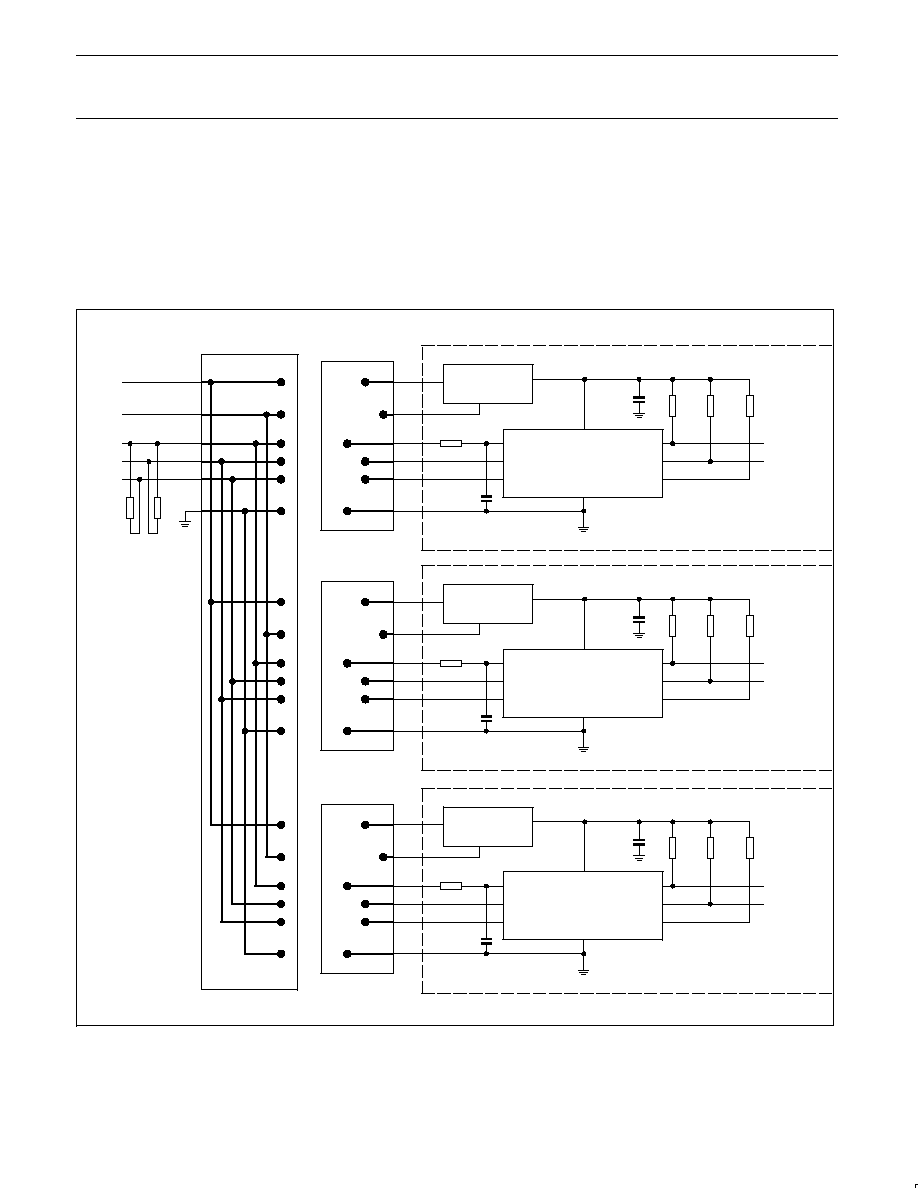

Hot Swapping and Capacitance Buffering

Application

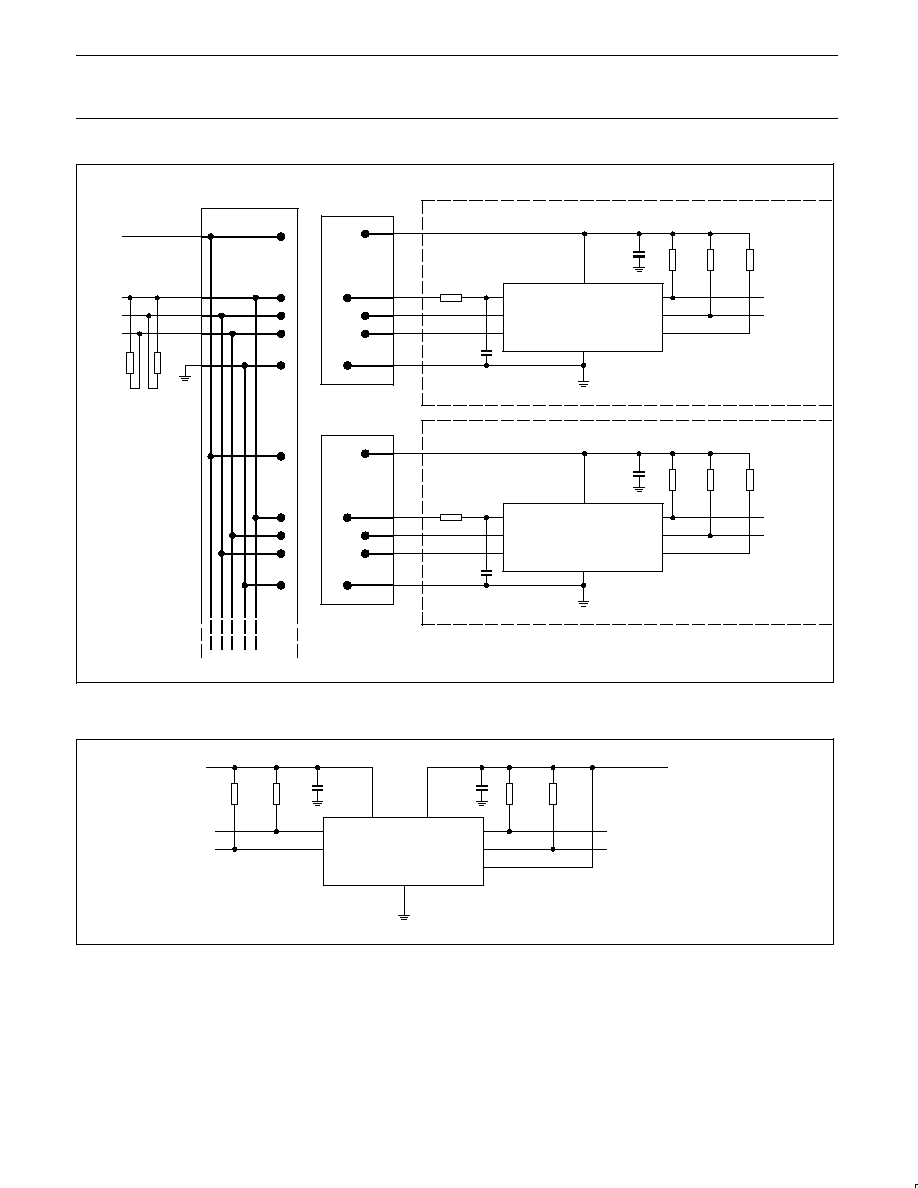

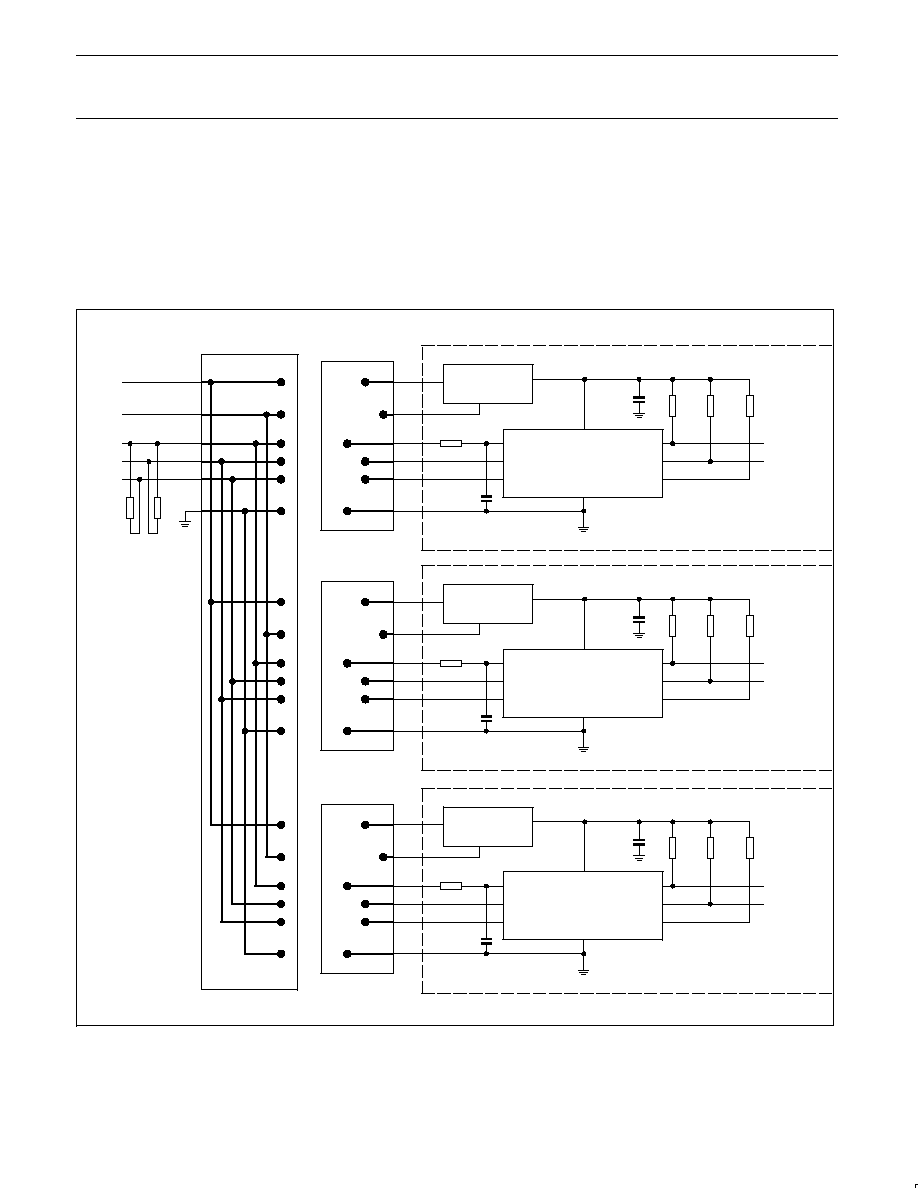

Figures 7 through 9 illustrate the usage of the PCA9512 in

applications that take advantage of both its hot swapping and

capacitance buffering features. In all of these applications, note that

if the I/O cards were plugged directly into the backplane, all of the

backplane and card capacitances would add directly together,

making rise- and fall-time requirements difficult to meet. Placing a

PCA9512 on the edge of each card, however, isolates the card

capacitance from the backplane. For a given I/O card, the PCA9512

drives the capacitance of everything on the card and the backplane

must drive only the the capacitance of the bus buffer, which is less

than 10 pF, the connector, trace, and all additional cards on the

backplane.

See Application Note

AN10160, Hot Swap Bus Buffer for more

information on applications and technical assistance.

C1

0.01

µ

F

R4

10 k

R5

10 k

POWER SUPPLY

HOT SWAP

I/O PERIPHERAL CARD 1

R6

10 k

R3 5.1

C2

0.01

µ

F

V

CC

V

CC2

SDAIN

SCLIN

SDAOUT

SCLOUT

ACC

GND

CARD1_SDA

CARD1_SCL

PCA9512

C3

0.01

µ

F

R8

10 k

R9

10 k

POWER SUPPLY

HOT SWAP

I/O PERIPHERAL CARD 2

R10

10 k

R7 5.1

C4

0.01

µ

F

V

CC

V

CC2

SDAIN

SCLIN

SDAOUT

SCLOUT

ACC

GND

CARD2_SDA

CARD2_SCL

PCA9512

C5

0.01

µ

F

R12

10 k

R13

10 k

POWER SUPPLY

HOT SWAP

I/O PERIPHERAL CARD N

R14

10 k

C6

0.01

µ

F

V

CC

V

CC2

SDAIN

SCLIN

SDAOUT

SCLOUT

ACC

GND

CARDN_SDA

CARDN_SCL

PCA9512

R1

10 k

R2

10 k

V

CC2

V

CC

SDA

SCL

BD_SEL

BACKPLANE

BACKPLANE

CONNECTOR

SW02117

R11 5.1

ST

AGGERED CONNECT

OR

ST

AGGERED CONNECT

OR

ST

AGGERED CONNECT

OR

NOTE: Application assumes bus capacitance within "proper operation" region of Figures 5 and 6.

Figure 7. Hot swapping multiple I/O cards into a backplane using the PCA9512 in a CompactPCI, VME, and AdvancedTCA system

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2004 Oct 05

8

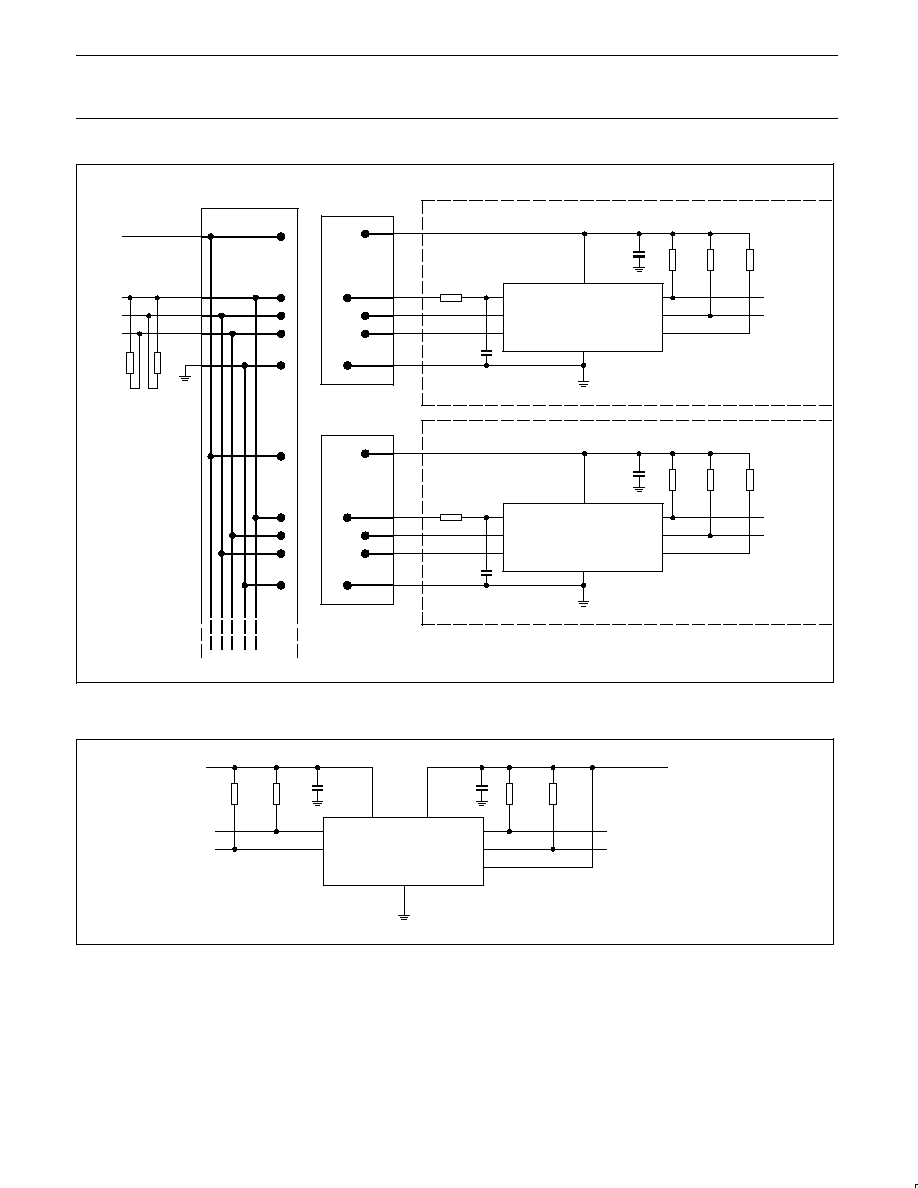

C1

0.01

µ

F

R4

10 k

R5

10 k

I/O PERIPHERAL CARD 1

R6

10 k

R3 5.1

C2

0.01

µ

F

V

CC

V

CC2

SDAIN

SCLIN

SDAOUT

SCLOUT

ACC

GND

CARD1_SDA

CARD1_SCL

PCA9512

C3

0.01

µ

F

R8

10 k

R9

10 k

I/O PERIPHERAL CARD 2

R10

10 k

R4 5.1

C4

0.01

µ

F

V

CC

V

CC2

SDAIN

SCLIN

SDAOUT

SCLOUT

ACC

GND

CARD2_SDA

CARD2_SCL

PCA9512

R1

10 k

R2

10 k

V

CC2

V

CC

SDA

SCL

BACKPLANE

BACKPLANE

CONNECTOR

SW02118

ST

AGGERED CONNECT

OR

ST

AGGERED CONNECT

OR

NOTE: Application assumes bus capacitance within "proper operation" region of Figures 5 and 6.

Figure 8. Hot swapping multiple I/O cards into a backplane using the PCA9512 with a custom connector

C1

0.01

µ

F

R3

10 k

R2

10 k

V

CC

V

CC2

SDAIN

SCLIN

SDAOUT

SCLOUT

ACC

GND

CARD_SDA

CARD_SCL

PCA9512

C2

0.01

µ

F

R4

10 k

R1

10 k

V

CC

5 V

CARD_V

CC

, 3 V

SCL

SCL

SW02119

NOTE: Application assumes bus capacitance within "proper operation" region of Figures 5 and 6.

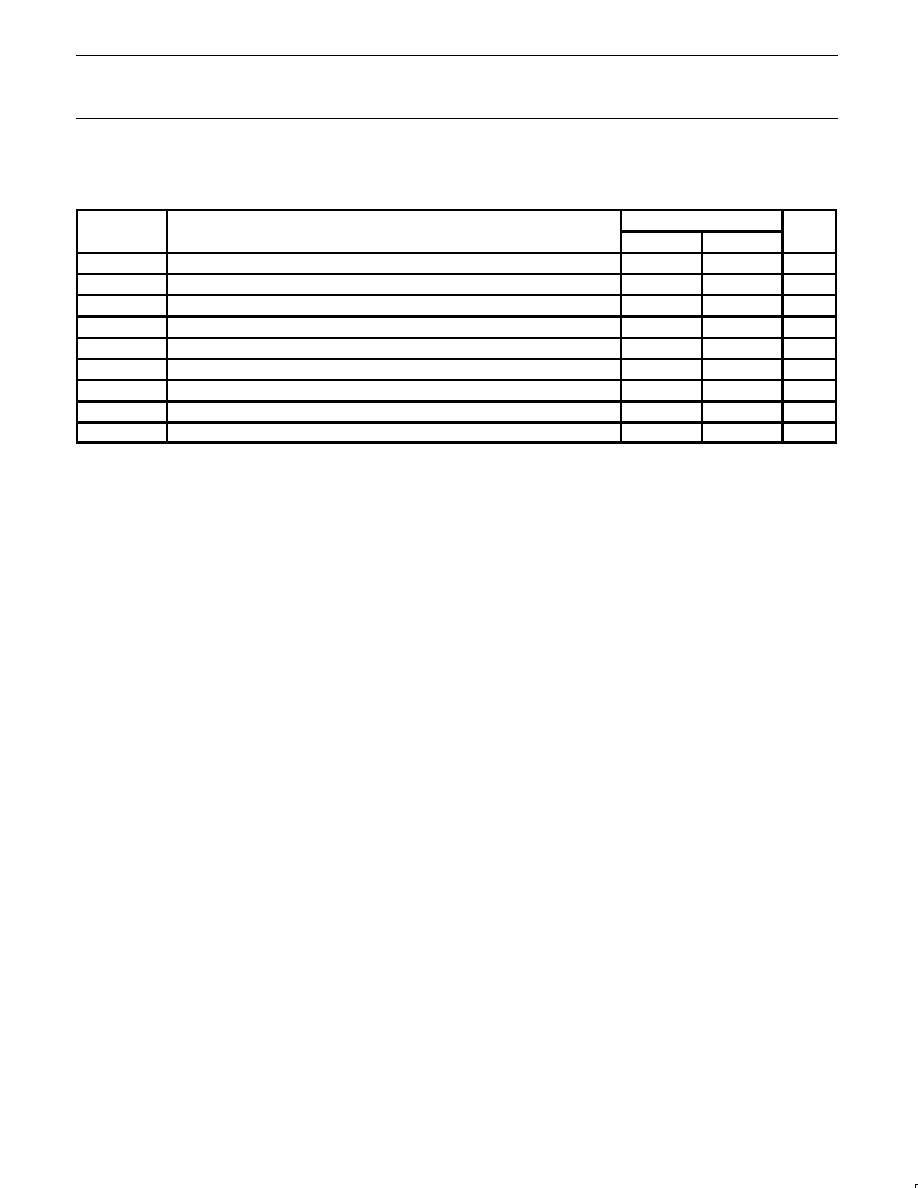

Figure 9. 5 V to 3.3 V level translator and bus buffer

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2004 Oct 05

9

ABSOLUTE MAXIMUM RATINGS

Limiting values in accordance with the Absolute Maximum System (IEC 134).

Voltages with respect to pin GND.

LIMITS

SYMBOL

PARAMETER

MIN.

MAX.

UNIT

V

CC

Supply voltage range V

CC

≠0.5

+7

V

V

CC2

Supply voltage range V

CC2

≠0.5

+7

V

V

n

SDAIN, SCLIN, SDAOUT, SCLOUT, ACC

≠0.5

+7

V

I

I

Maximum current for inputs

≠

±

20

mA

I

IO

Maximum current for I/O pins

≠

±

50

mA

T

opr

Operating temperature range

≠40

+85

∞

C

T

stg

Storage temperature range

≠65

+125

∞

C

T

sld

Lead soldering temperature (10 sec max)

--

+300

∞

C

T

j(max)

Maximum junction temperature

--

+125

∞

C

NOTE:

1. Stresses beyond those listed may cause permanent damage to the device. These are stress ratings only and functional operation of the

device at these or any other conditions beyond those indicated under "recommended operating conditions" is not implied. Exposure to

absolute-maximum-rated conditions for extended periods may affect device reliability.

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2004 Oct 05

10

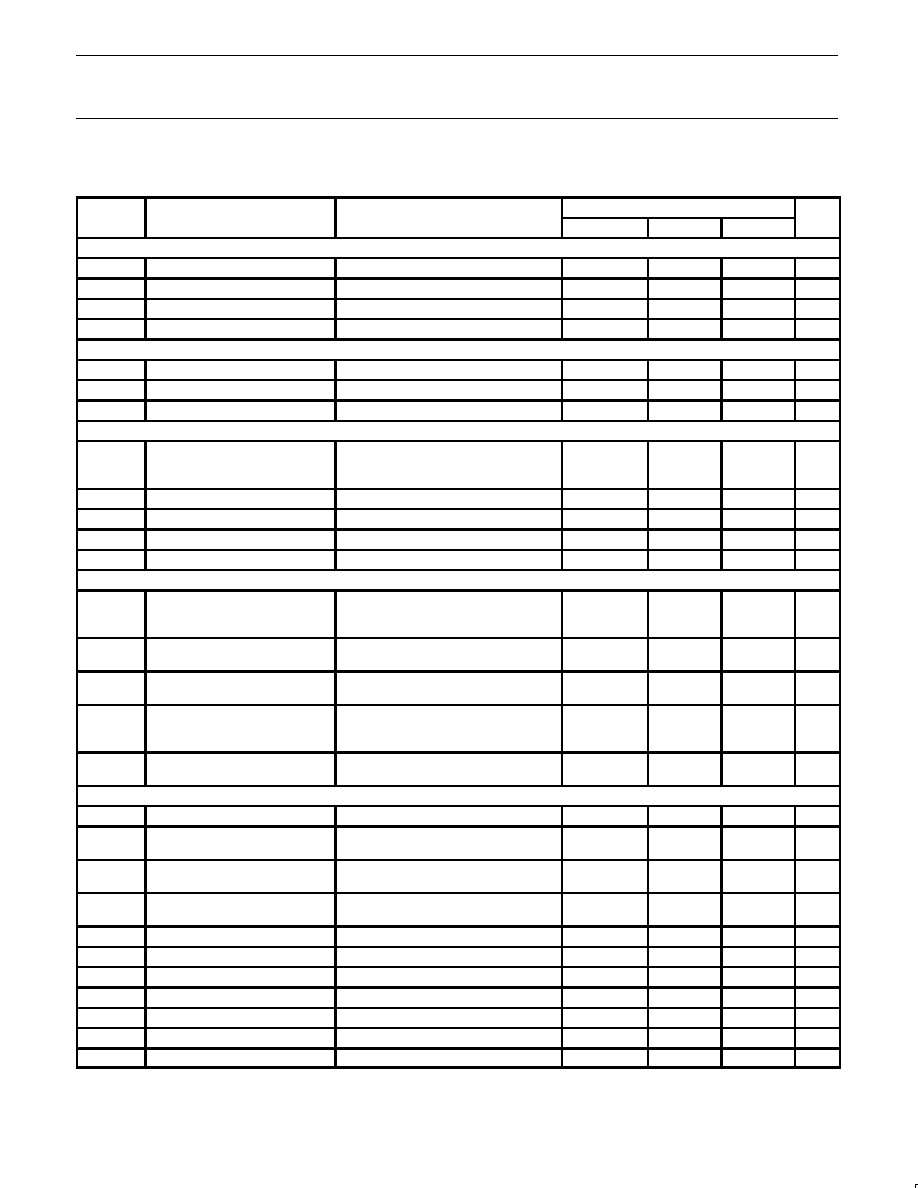

ELECTRICAL CHARACTERISTICS

V

CC

= 2.7 V to 5.5 V; T

amb

= ≠40

∞

C to +85

∞

C unless otherwise noted.

SYMBOL

PARAMETER

TEST CONDITIONS

LIMITS

UNIT

SYMBOL

PARAMETER

TEST CONDITIONS

MIN.

TYP.

MAX.

UNIT

Power supply

V

CC

Supply voltage

Note 1.

2.7

--

5.5

V

V

CC2

Card side supply voltage

Note 1.

2.7

--

5.5

V

I

VCCI

V

CC

supply current

V

CC

= 5.5 V; V

SDAIN

= V

SCLIN

= 0 V

--

1.2

3.6

mA

I

VCC2

V

CC

supply current

V

CC

= 5.5 V; V

SDAOUT

= V

SCLOUT

= 0 V

--

1.1

2.4

mA

Start-up circuitry

V

PRE

Precharge voltage

SDA, SCL floating; Note 1.

0.8

1.1

1.2

V

t

EN

Enable time on power-up

Note 6.

--

180

--

µ

s

t

IDLE

Bus idle time

Notes 1 and 7.

50

140

250

µ

s

Rise time accelerators

I

PULLUPAC

Transient boosted pull-up current

Positive transition on SDA, SCL,

ACC = 0.7 V

◊

V

CC2

; V

CC

= 2.7 V;

Slew rate = 1.25 V/

µ

s; Note 2.

1

2

--

mA

V

ACCDIS

Accelerator disable threshold

0.3

◊

V

CC2

0.5

◊

V

CC2

--

V

V

ACCEN

Accelerator enable threshold

--

0.5

◊

V

CC2

0.7

◊

V

CC2

V

I

VACC

A

CC

input current

≠1

±

0.1

1

µ

A

t

PDOFF

A

CC

delay, on/off

--

5

--

ns

Input≠output connection

V

OS

Input≠output offset voltage

10 k

to V

CC

on SDA, SCL;

V

CC

= 3.3 V, V

CC2

= 3.3 V;

V

IN

= 0.2 V; Note 1; Note 3.

0

70

150

mV

f

SCL_SDA

operating frequency

Guaranteed by design, not subject to

test

0

--

400

kHz

C

IN

Digital input capacitance

Guaranteed by design,

not subject to test

--

--

10

pF

V

OL

LOW-level output voltage

Input = 0 V. SDA, SCL pins;

I

SINK

= 3 mA; V

CC

= 2.7 V;

V

CC2

= 2.7 V; Note 1.

0

--

0.4

V

I

LI

Input leakage current

SDA, SCL pins = V

CC

= 5.5 V;

V

CC2

= 5.5 V

≠1

--

5

µ

A

Timing characteristics

f

I2C

I

2

C operating frequency

Note 4

0

--

400

kHz

t

BUF

Bus free time between stop and

start condition

Note 4

1.3

--

--

µ

s

t

HD;STA

Hold time after (repeated) start

condition

Note 4

0.6

--

--

µ

s

t

SU;STA

Repeated start condition setup

time

Note 4

0.6

--

--

µ

s

t

SU;STO

Stop condition setup time

Note 4

0.6

--

--

µ

s

t

HD;DAT

Data hold time

Note 4

300

--

--

ns

t

SU;DAT

Data setup time

Note 4

100

--

--

ns

t

LOW

Clock LOW period

Note 4

1.3

--

--

µ

s

t

HIGH

Clock HIGH period

Note 4

0.6

--

--

µ

s

t

f

Clock, data fall time

Notes 4 and 5

20 + 0.1

◊

C

B

--

300

ns

t

r

Clock, data rise time

Notes 4 and 5

20 + 0.1

◊

C

B

--

300

ns

NOTES:

1. This specification applies over the full operating temperature range.

2. I

PULLUPAC

varies with temperature and V

CC

voltage, as shown in the Typical Performance Characteristics section.

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2004 Oct 05

11

3. The connection circuitry always regulates its output to a higher voltage than its input. The magnitude of this offset voltage as a function of

the pull-up resistor and V

CC

voltage is shown in the Typical Performance Characteristics section.

4. Guaranteed by design, not production tested.

5. C

B

= total capacitance of one bus line in pF.

6. Enable time is from power-up of V

CC

and V

CC2

2.7 V to when idle or stop time begins.

7. Idle time is from when SDAx and SCLx are HIGH after enable time has been met.

TYPICAL PERFORMANCE CHARACTERISTICS

SW02343

TEMPERATURE (

∞

C)

≠40

+25

+85

1.5

1.3

1.1

0.9

0.7

I

CC

(mA)

1.4

1.2

1.0

0.8

V

CC

= 5.5 V

V

CC

= 2.7 V

V

CC

= 3.3 V

Figure 10. I

CC

versus Temperature (Note 1)

SW02346

TEMPERATURE (

∞

C)

≠40

+25

+85

12

8

4

0

I

PULLUP

AC

(mA)

10

6

2

V

CC

= 5 V

V

CC

= 2.7 V

V

CC

= 3.3 V

Figure 11. I

PULLUPAC

versus Temperature

V

CC

= 3.3 V

SW02344

TEMPERATURE (

∞

C)

≠40

+25

+85

460

t

PHL

(ns)

440

400

380

V

CC

= 2.7 V

V

CC

= 5.5 V

C

IN

= C

OUT

= 100 pF

R

PULLUPIN

= R

PULLUPOUT

= 10 k

420

Figure 12. Input≠output t

PHL

versus Temperature

SW02154

R

PULLUP

(

)

10,000

20,000

30,000

100

80

60

40

90

70

50

0

40,000

V

CC

= 3.3 V OR 5.5 V

V

OUT

≠ V

IN

(mV)

Figure 13. Connection circuitry V

OUT

≠ V

IN

NOTE:

1. I

CC2

(Pin 1) typical current averages 0.1 mA less than I

CC

on Pin 8.

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2004 Oct 05

12

TEST CIRCUIT

PULSE

GENERATOR

V

I

V

O

CL= 100 pF

V

CC

DEFINITIONS

R

L

=

Load resistor.

C

L

=

Load capacitance includes jig and probe capacitance

R

T

=

Termination resistance should be equal to the output

impedance Z

O

of the pulse generators.

V

CC

R

T

D.U.T.

R

L

= 10 k

SW02345

Figure 14. Test circuitry for switching times

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2004 Oct 05

13

SO8:

plastic small outline package; 8 leads; body width 3.9 mm

SOT96-1

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2004 Oct 05

14

TSSOP8:

plastic thin shrink small outline package; 8 leads; body width 3 mm

SOT505-1

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2004 Oct 05

15

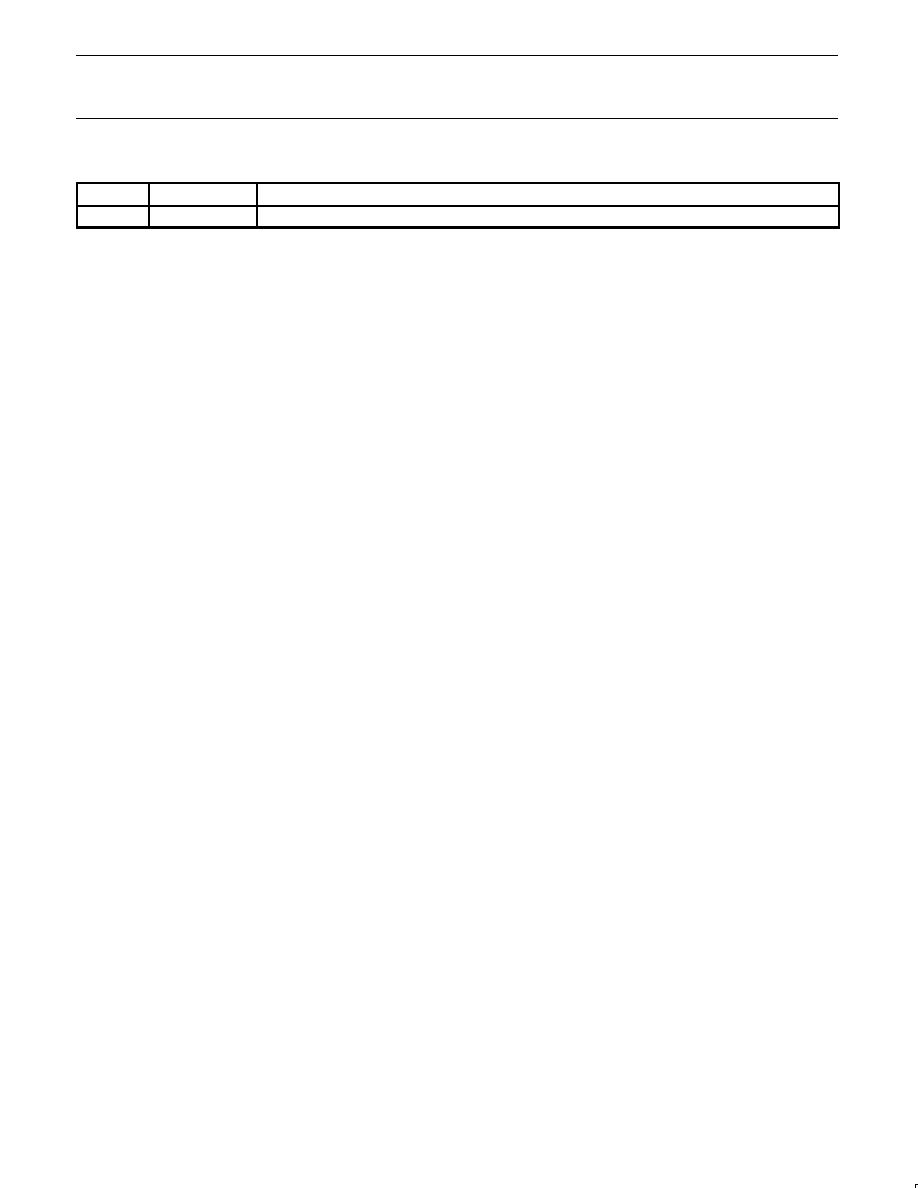

REVISION HISTORY

Rev

Date

Description

_1

20041005

Product data sheet (9397 750 14005).

Philips Semiconductors

Product data sheet

PCA9512

Level shifting hot swappable I

2

C and SMBus buffer

2004 Oct 05

16

Purchase of Philips I

2

C components conveys a license under the Philips' I

2

C patent

to use the components in the I

2

C system provided the system conforms to the

I

2

C specifications defined by Philips. This specification can be ordered using the

code 9398 393 40011.

Definitions

Short-form specification -- The data in a short-form specification is extracted from a full data sheet with the same type number and title. For detailed information see

the relevant data sheet or data handbook.

Limiting values definition -- Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 60134). Stress above one or more of the limiting

values may cause permanent damage to the device. These are stress ratings only and operation of the device at these or at any other conditions above those given

in the Characteristics sections of the specification is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information -- Applications that are described herein for any of these products are for illustrative purposes only. Philips Semiconductors make no

representation or warranty that such applications will be suitable for the specified use without further testing or modification.

Disclaimers

Life support -- These products are not designed for use in life support appliances, devices, or systems where malfunction of these products can reasonably be

expected to result in personal injury. Philips Semiconductors customers using or selling these products for use in such applications do so at their own risk and agree

to fully indemnify Philips Semiconductors for any damages resulting from such application.

Right to make changes -- Philips Semiconductors reserves the right to make changes in the products--including circuits, standard cells, and/or software--described

or contained herein in order to improve design and/or performance. When the product is in full production (status `Production'), relevant changes will be communicated

via a Customer Product/Process Change Notification (CPCN). Philips Semiconductors assumes no responsibility or liability for the use of any of these products, conveys

no license or title under any patent, copyright, or mask work right to these products, and makes no representations or warranties that these products are free from patent,

copyright, or mask work right infringement, unless otherwise specified.

Contact information

For additional information please visit

http://www.semiconductors.philips.com.

Fax: +31 40 27 24825

For sales offices addresses send e-mail to:

sales.addresses@www.semiconductors.philips.com.

©

Koninklijke Philips Electronics N.V. 2004

All rights reserved. Published in the U.S.A.

Date of release: 10-04

Document number:

9397 750 14005

Philips

Semiconductors

Data sheet status

[1]

Objective data

Preliminary data

Product data

Product

status

[2] [3]

Development

Qualification

Production

Definitions

This data sheet contains data from the objective specification for product development.

Philips Semiconductors reserves the right to change the specification in any manner without notice.

This data sheet contains data from the preliminary specification. Supplementary data will be published

at a later date. Philips Semiconductors reserves the right to change the specification without notice, in

order to improve the design and supply the best possible product.

This data sheet contains data from the product specification. Philips Semiconductors reserves the

right to make changes at any time in order to improve the design, manufacturing and supply. Relevant

changes will be communicated via a Customer Product/Process Change Notification (CPCN).

Data sheet status

[1] Please consult the most recently issued data sheet before initiating or completing a design.

[2] The product status of the device(s) described in this data sheet may have changed since this data sheet was published. The latest information is available on the Internet at URL

http://www.semiconductors.philips.com.

[3] For data sheets describing multiple type numbers, the highest-level product status determines the data sheet status.

Level

I

II

III