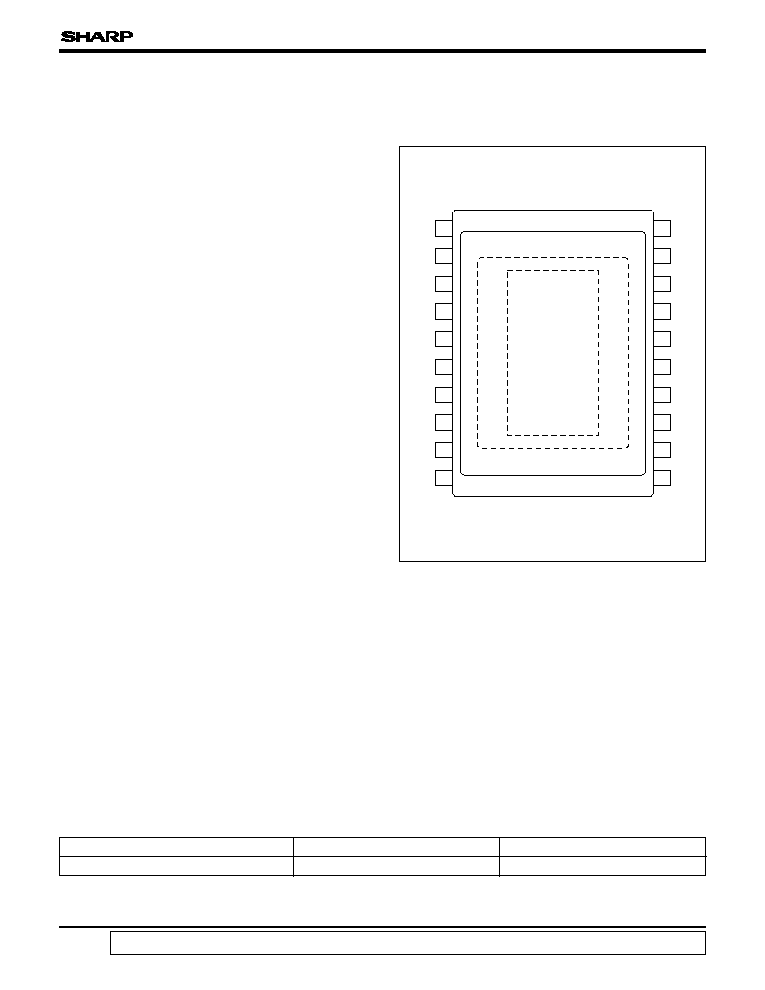

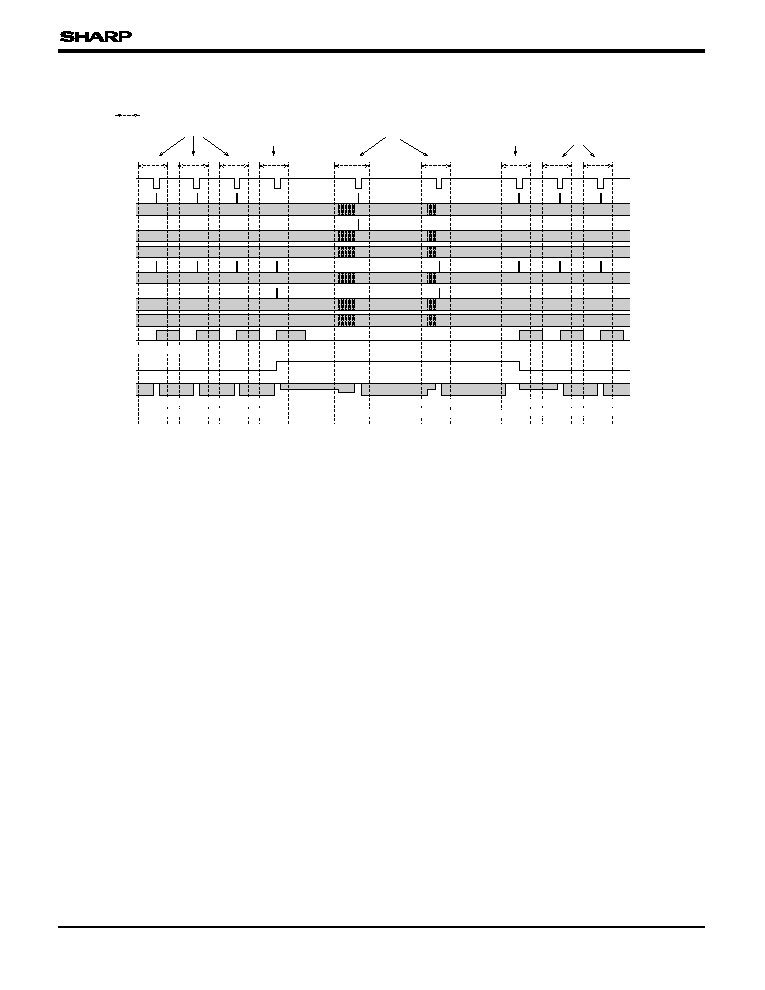

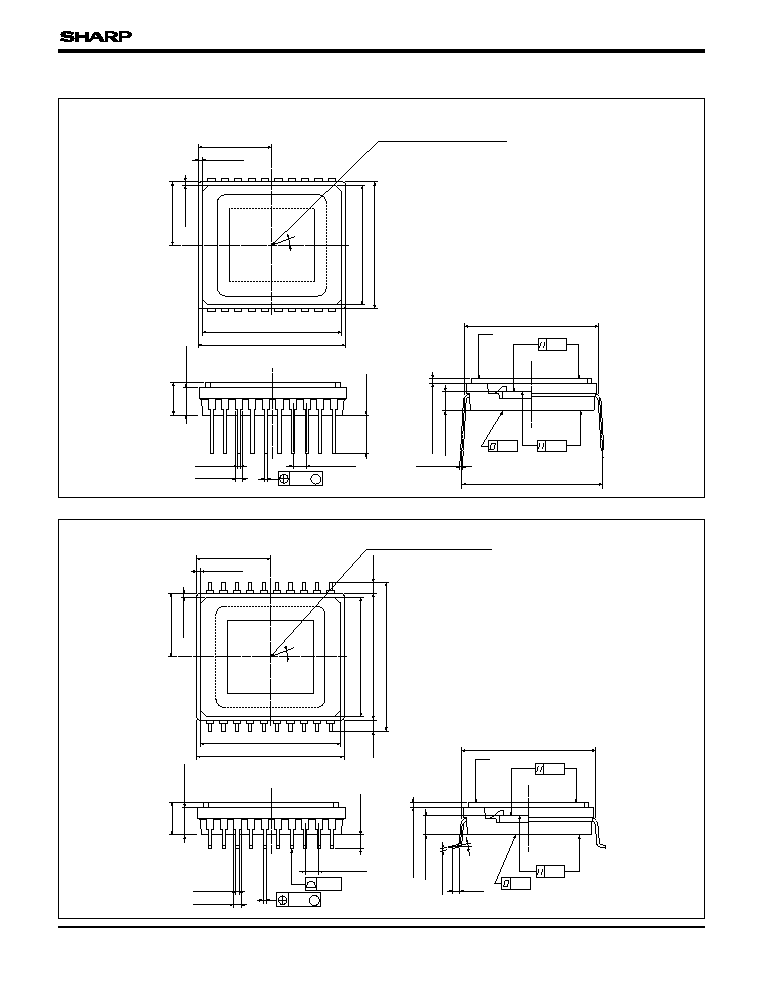

PACKAGES FOR CCD AND CMOS DEVICES

16

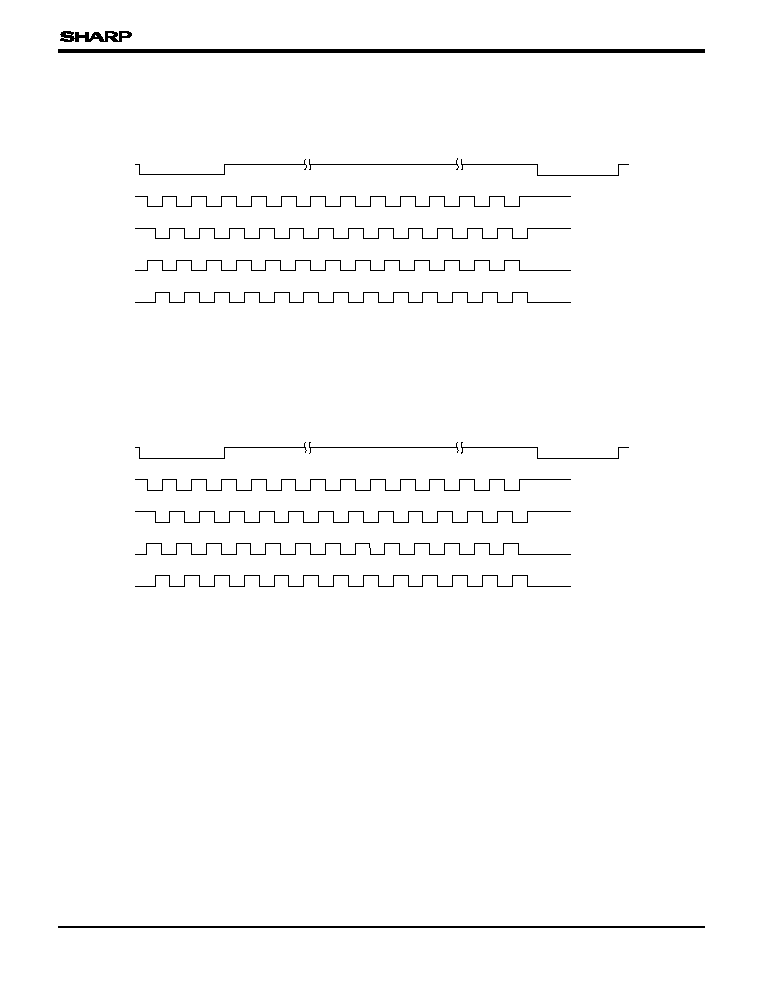

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

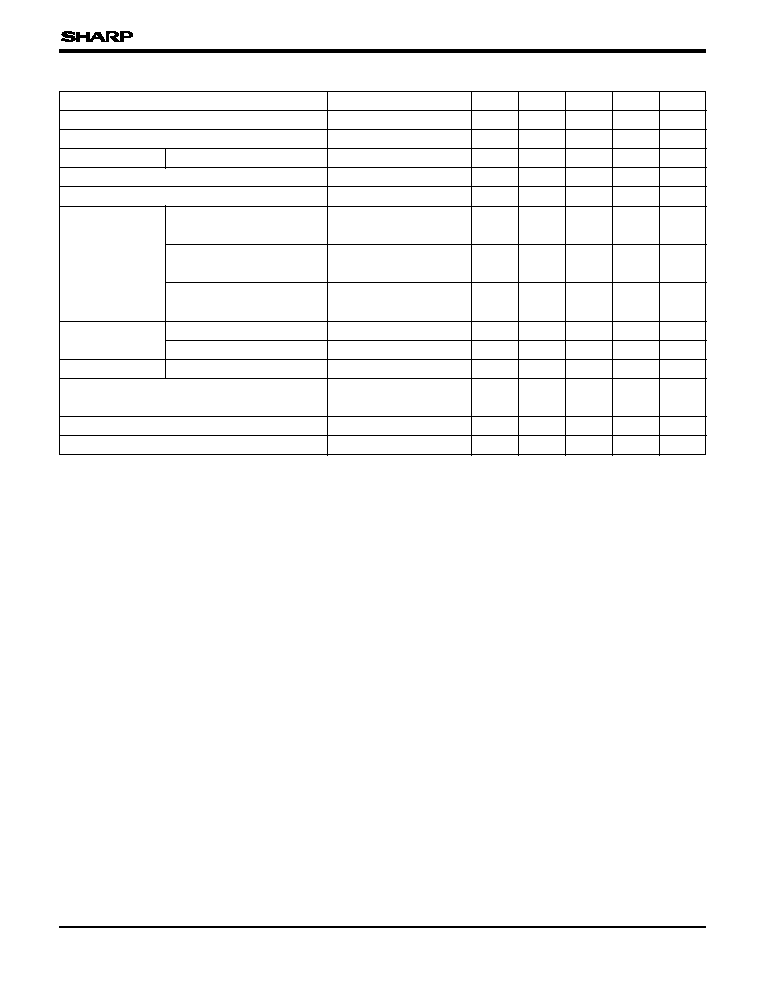

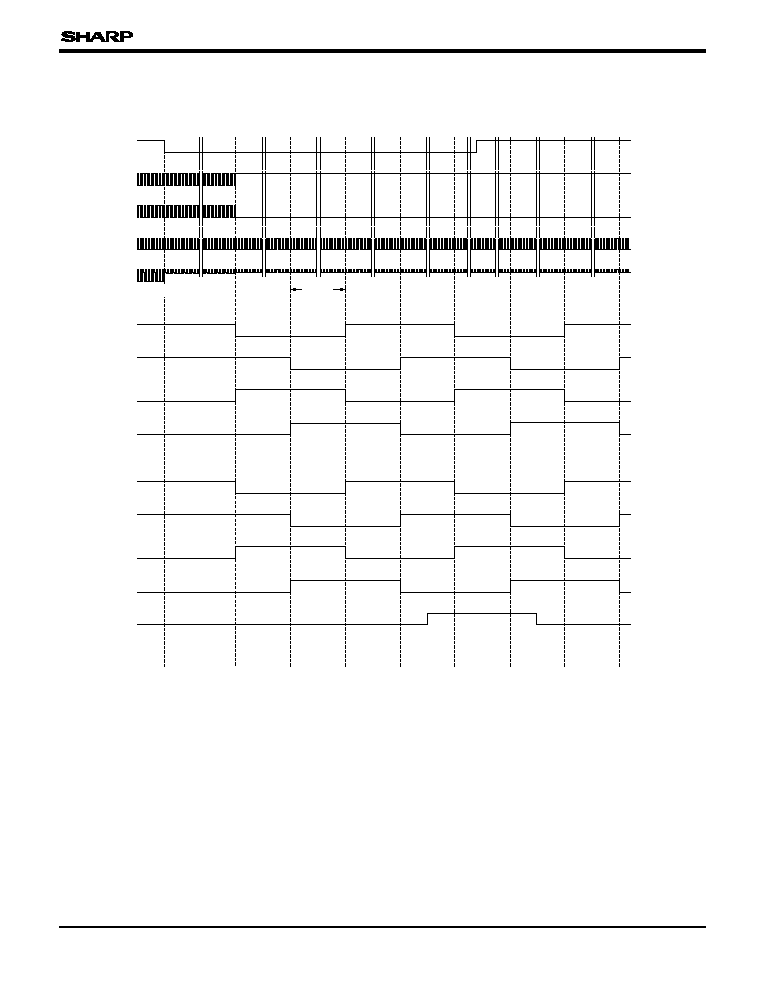

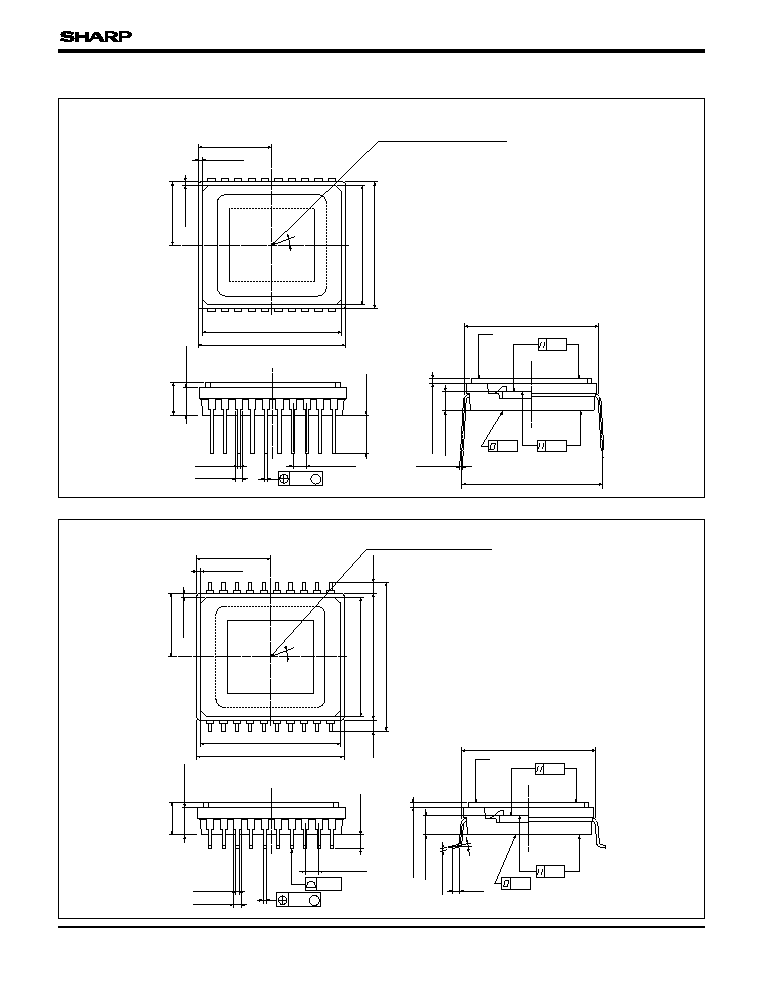

Glass Lid

Package

6.90

Ī0.075

0.40

Ī0.40

6.00

Ī0.075

0.40

Ī0.40

11.20

Ī0.10

(2)

12.00

Ī0.10

13.80

Ī0.10

13.00

Ī0.10

(2)

1

10

CCD

20

11

¨

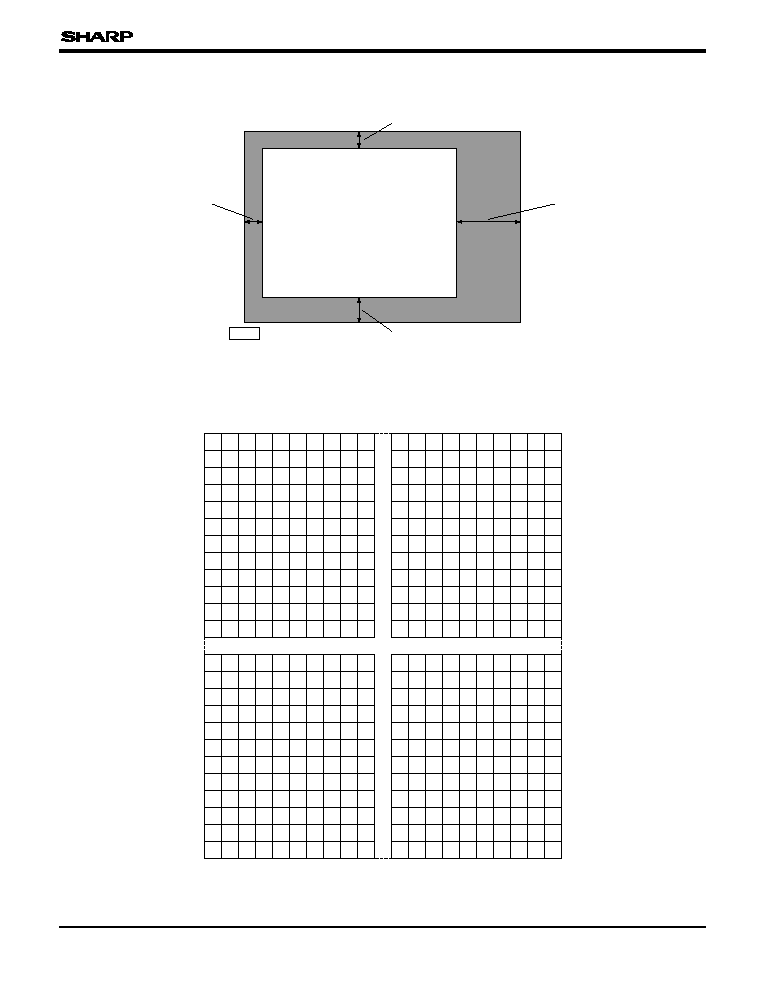

Center of effective imaging area

and center of package

Rotation error of die : ¨ = 1.0į

MAX.

( 1 : Effective imaging area)

( 2 : Lid's size)

12.20

Ī0.10

Refractive index : nd = 1.5

0.50

Ī0.05

(2)

1.41

Ī0.05

0.25

Ī0.10

12.20

0.04

0.02

0.02

(1)

(1)

A'

A

A

A'

0.64

TYP.

0.30

TYP.

P-1.27

TYP.

0.20 M

3.50

Ī0.10

2.40

Ī0.10

2.90

Ī0.10

CCD

+0.30

≠0

20 WDIP (WDIP020-P-0500)

PACKAGES

(Unit : mm)

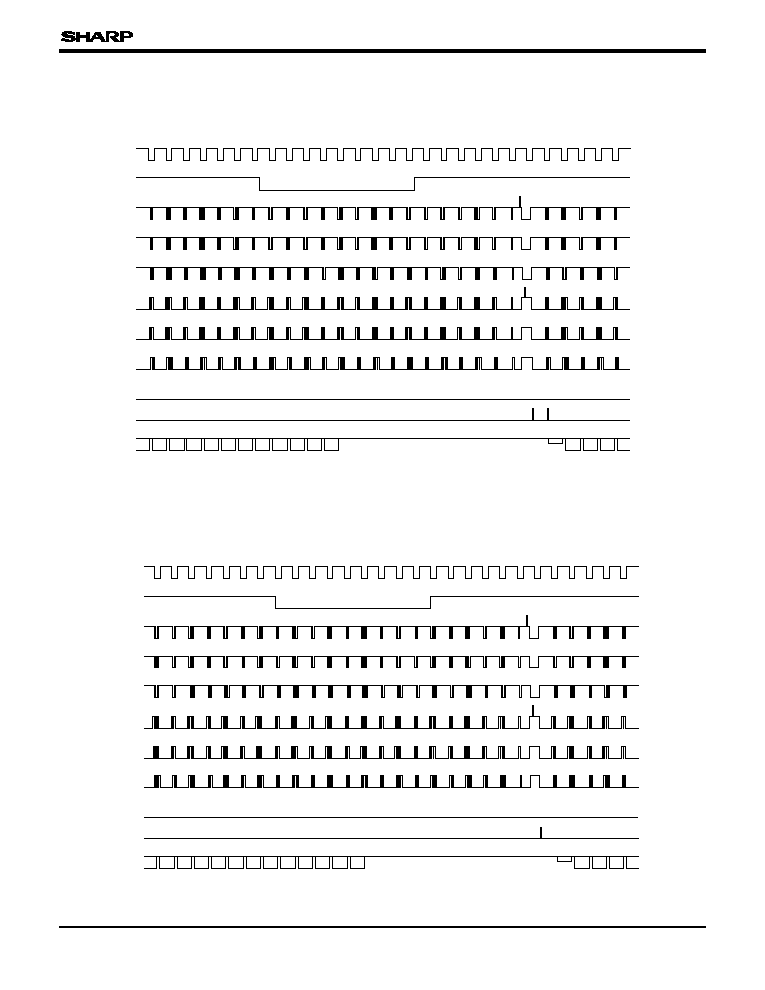

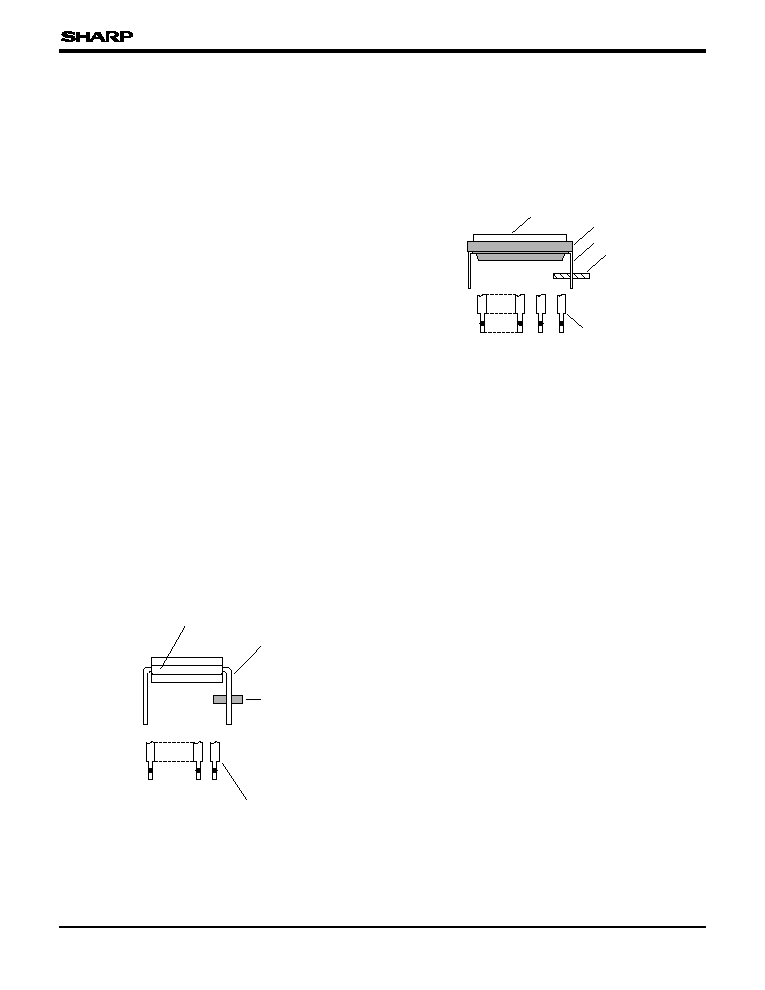

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,

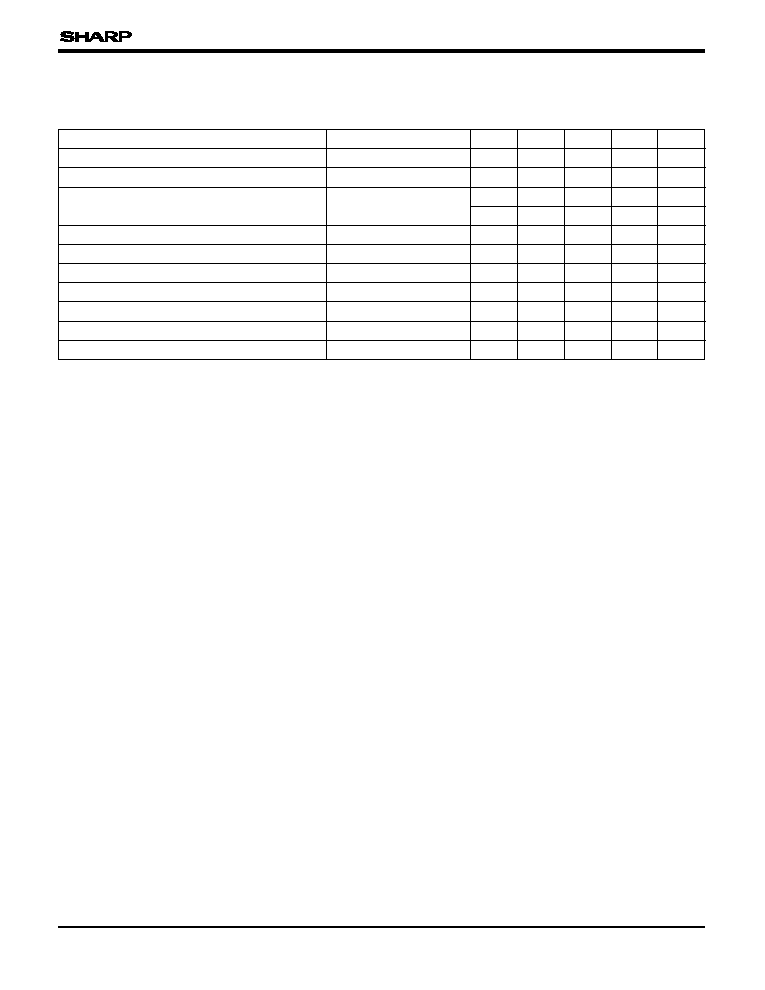

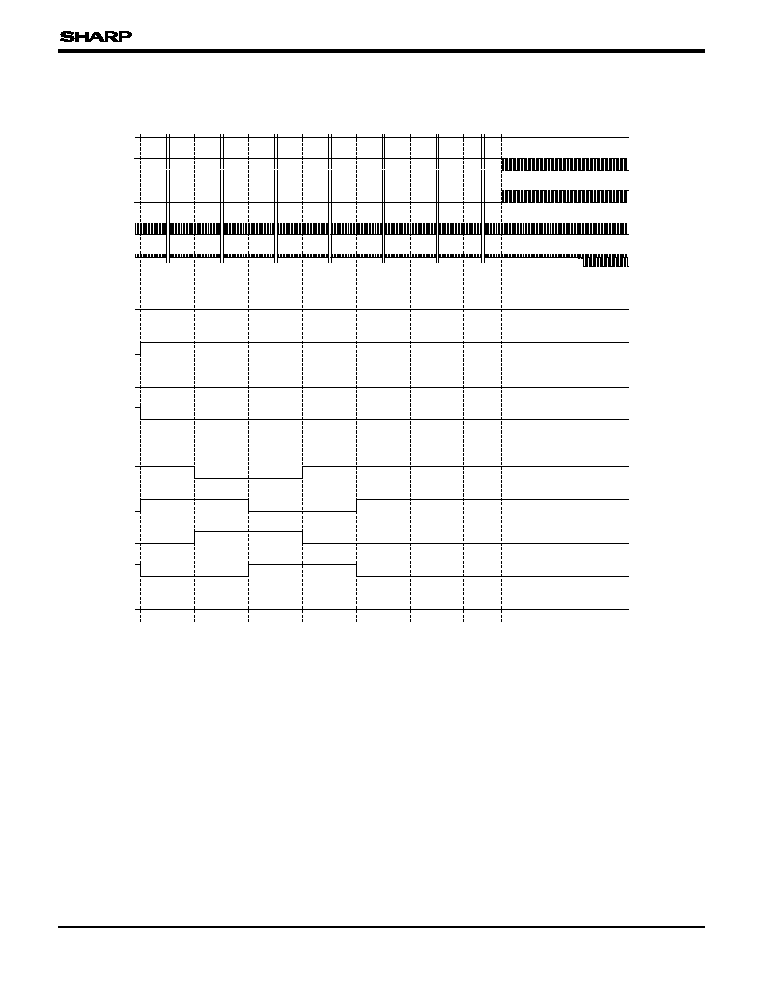

Glass Lid

Package

6.90

Ī0.075

0.40

Ī0.40

6.00

Ī0.075

0.40

Ī0.40

11.20

Ī0.10

(2)

12.00

Ī0.10

(1.00)

(1.00)

14.00

Ī0.10

13.80

Ī0.10

13.00

Ī0.10

(2)

1

10

CCD

20

11

¨

Center of effective imaging area

and center of package

Rotation error of die : ¨ = 1.0į

MAX.

( 1 : Effective imaging area)

( 2 : Lid's size)

12.20

Ī0.10

Refractive index : nd = 1.5

0.50

Ī0.05

(2)

1.41

Ī0.05

0.25

Ī0.10

0.83

CCD

0.04

0.02

0.02

(1)

(1)

A'

A

1-5į

A

A'

P-1.27

TYP.

0.64

TYP.

0.30

TYP.

0.10

0.20 M

1.00

Ī0.10

2.40

Ī0.10

2.90

Ī0.10

20 WSOP (WSOP020-P-0525)