| –≠–Ľ–Ķ–ļ—ā—Ä–ĺ–Ĺ–Ĺ—č–Ļ –ļ–ĺ–ľ–Ņ–ĺ–Ĺ–Ķ–Ĺ—ā: ILX514 | –°–ļ–į—á–į—ā—Ć:  PDF PDF  ZIP ZIP |

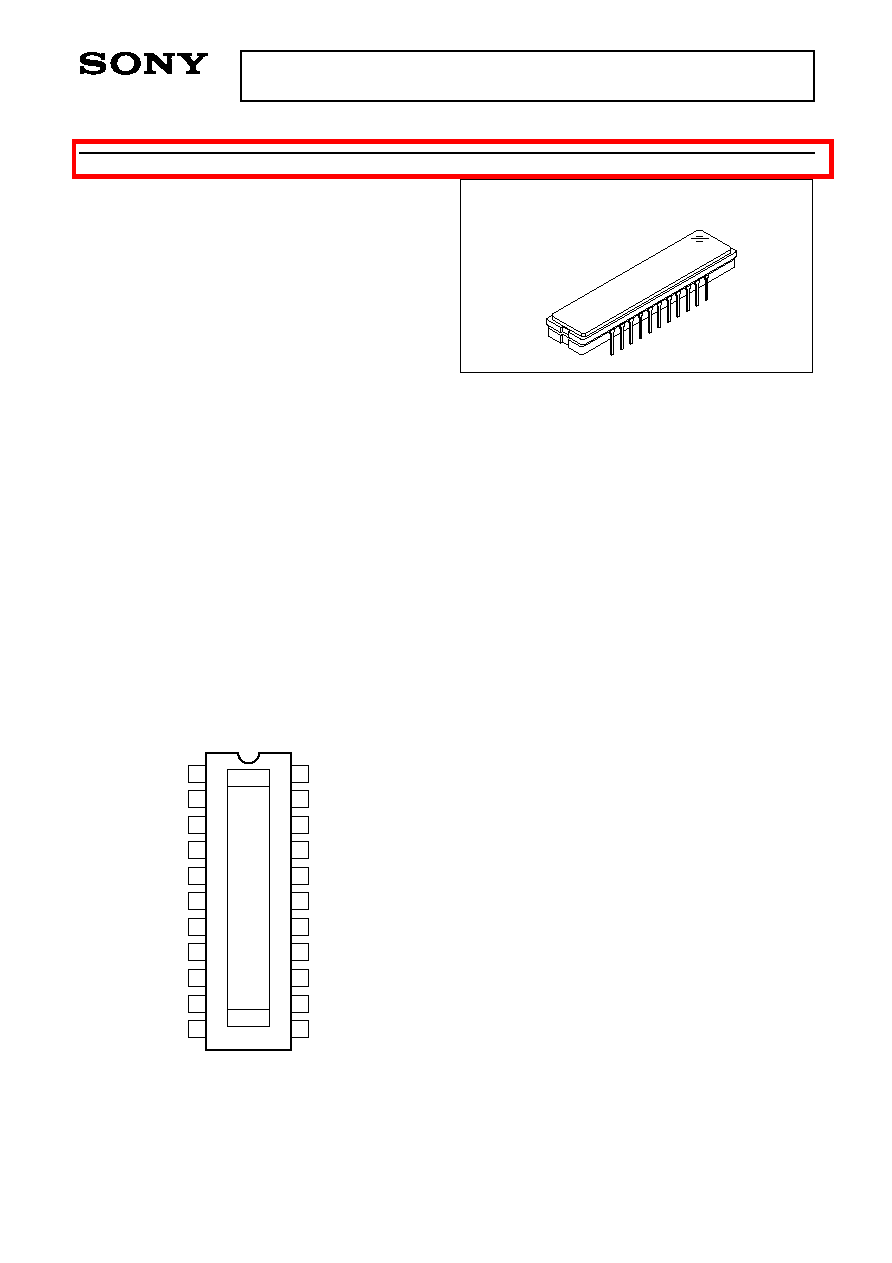

3918-pixel CCD Linear Image Sensor (B/W)

Description

The ILX514 is a reduction type CCD linear sensor

developed for high resolution facsimiles and copiers.

This sensor reads A4-size documents at a density of

400 DPI (Dot Per Inch). A built-in timing generator

and clock-drivers ensure direct drive at 5V logic for

easy use. In addition, reset pulse can be switched

between internal generation and external input.

Features

∑ Number of effective pixels: 3918 pixels

∑ Pixel size: 7Ķm

◊

7Ķm (7Ķm pitch)

∑ Built-in timing generator and clock-drivers

∑ Ultra low lag/ultra high sensitivity/low dark output

∑ Single output method

∑ Maximum clock frequency: 5MHz

Absolute Maximum Ratings

∑ Supply voltage

V

DD1

11

V

V

DD2

6

V

∑ Operating temperature

≠10 to +60

įC

∑ Storage temperature

≠30 to +80

įC

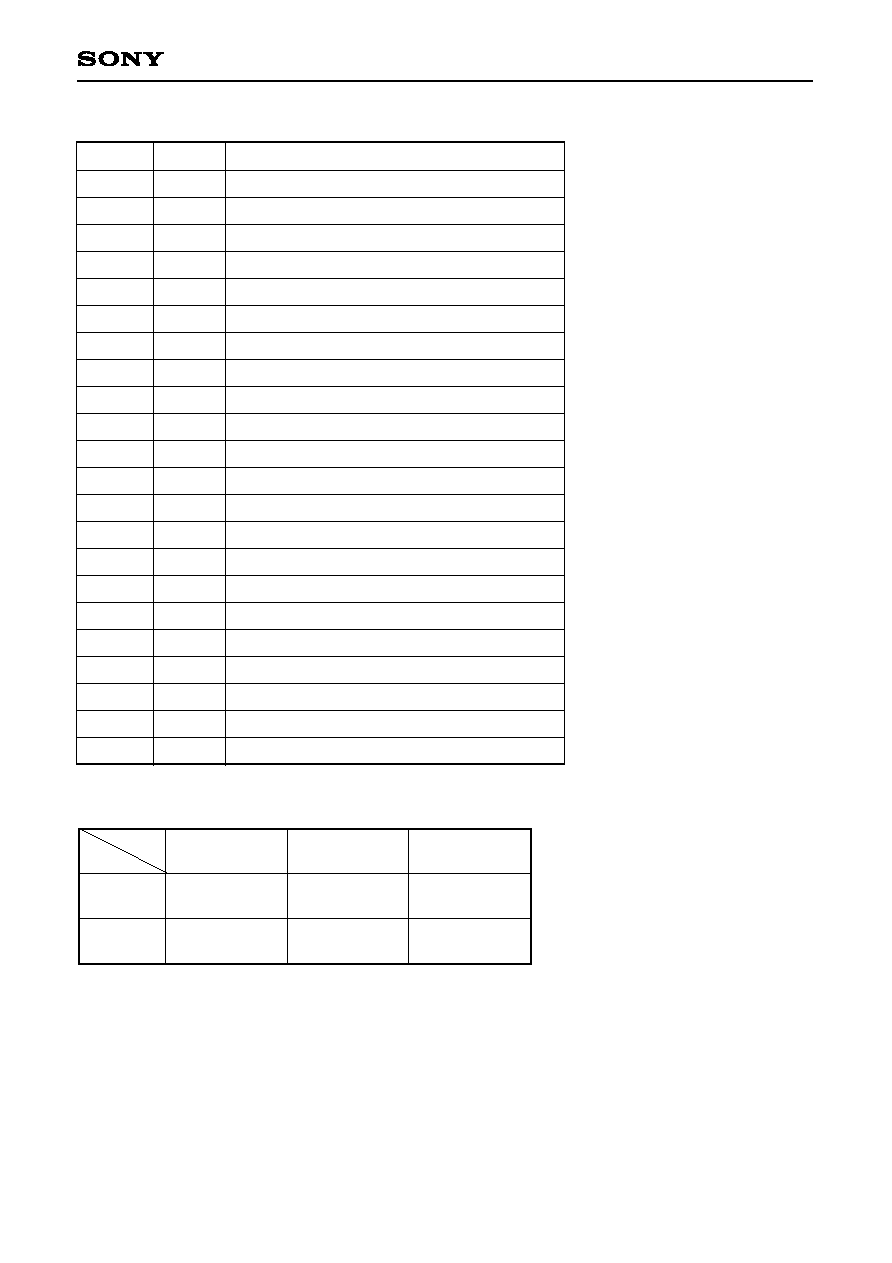

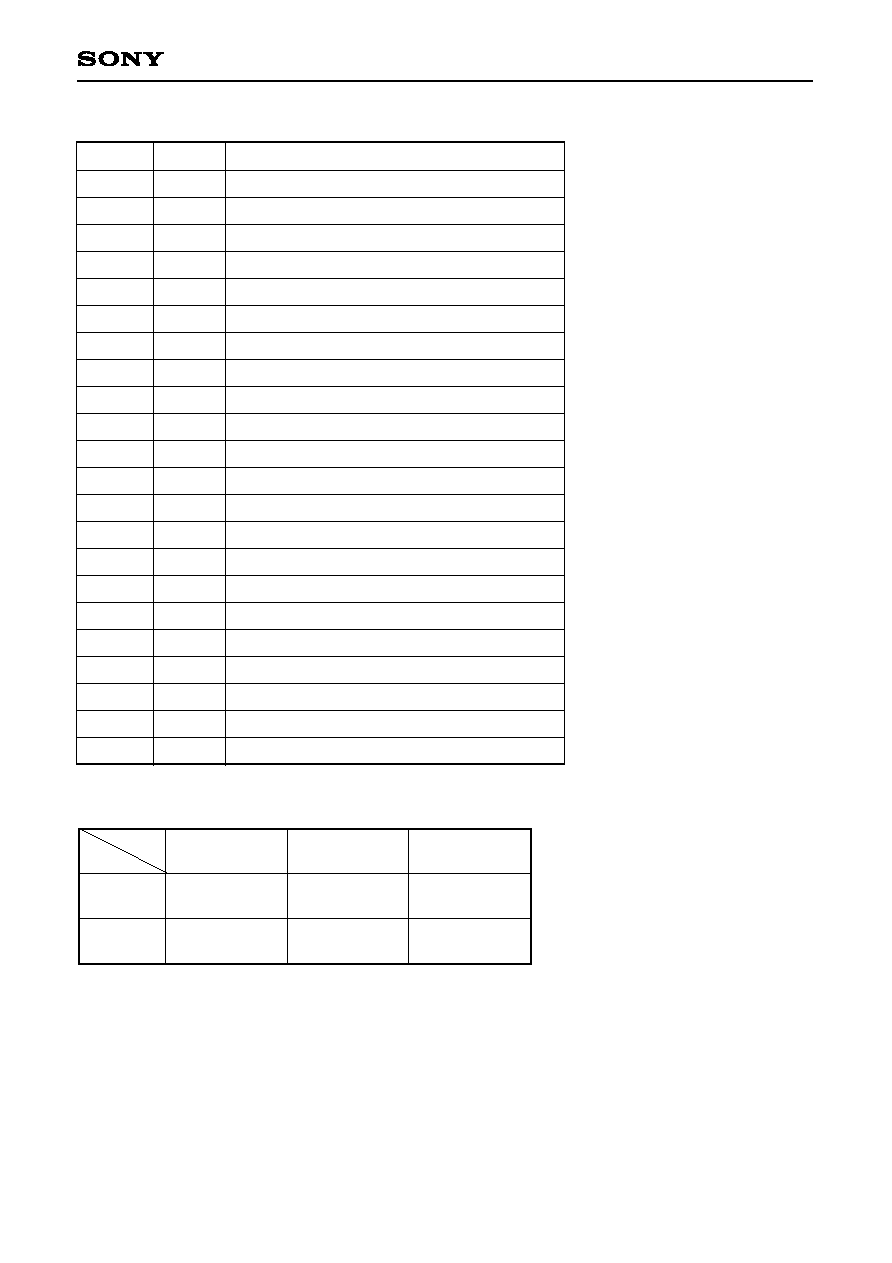

Pin Configuration (Top View)

≠ 1 ≠

E93302C78-PS

Sony reserves the right to change products and specifications without prior notice. This information does not convey any license by

any implication or otherwise under any patents or other right. Application circuits shown, if any, are typical examples illustrating the

operation of the devices. Sony cannot assume responsibility for any problems arising out of the use of these circuits.

ILX514

22 pin DIP (Cer-DIP)

1

NC

2

GND

3

GND

4

RSSW

5

CLK

6

V

DD1

7

NC

8

NC

9

10

NC

11

ROG

12

NC

22

21

20

19

18

17

16

15

14

13

NC

V

DD1

RS/SH

GND

GND

V

DD1

GND

NC

1

3918

V

OUT

V

DD2

V

DD1

For the availability of this product, please contact the sales office.

≠ 2 ≠

ILX514

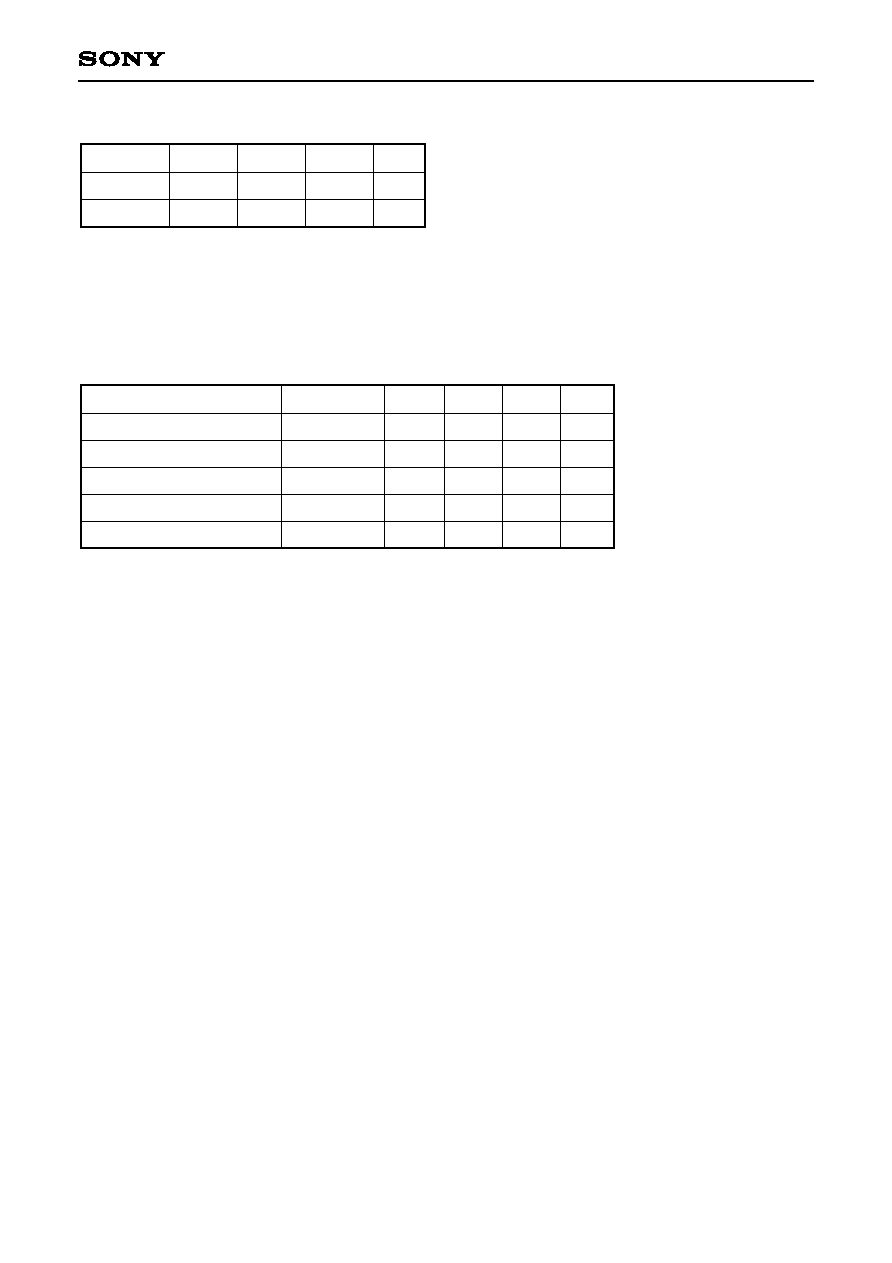

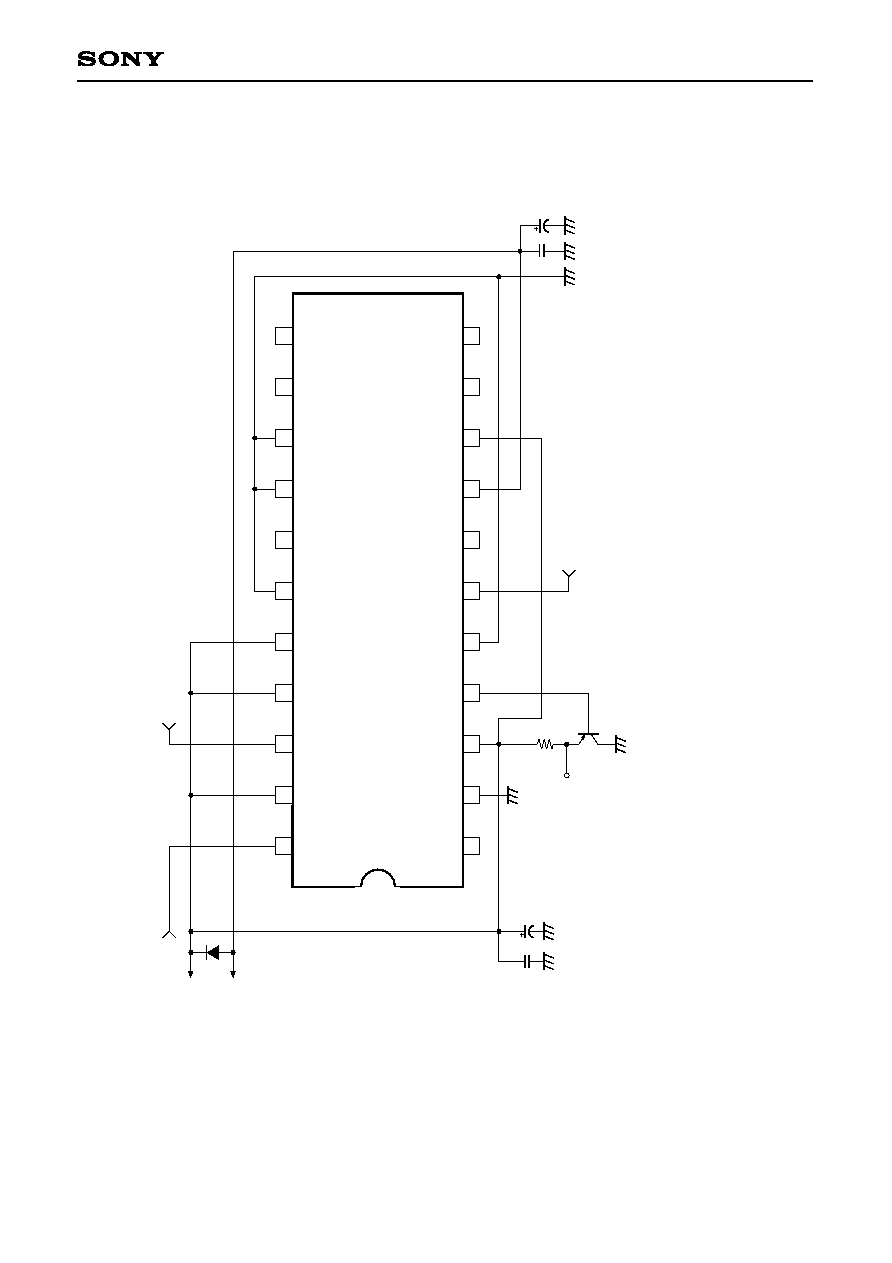

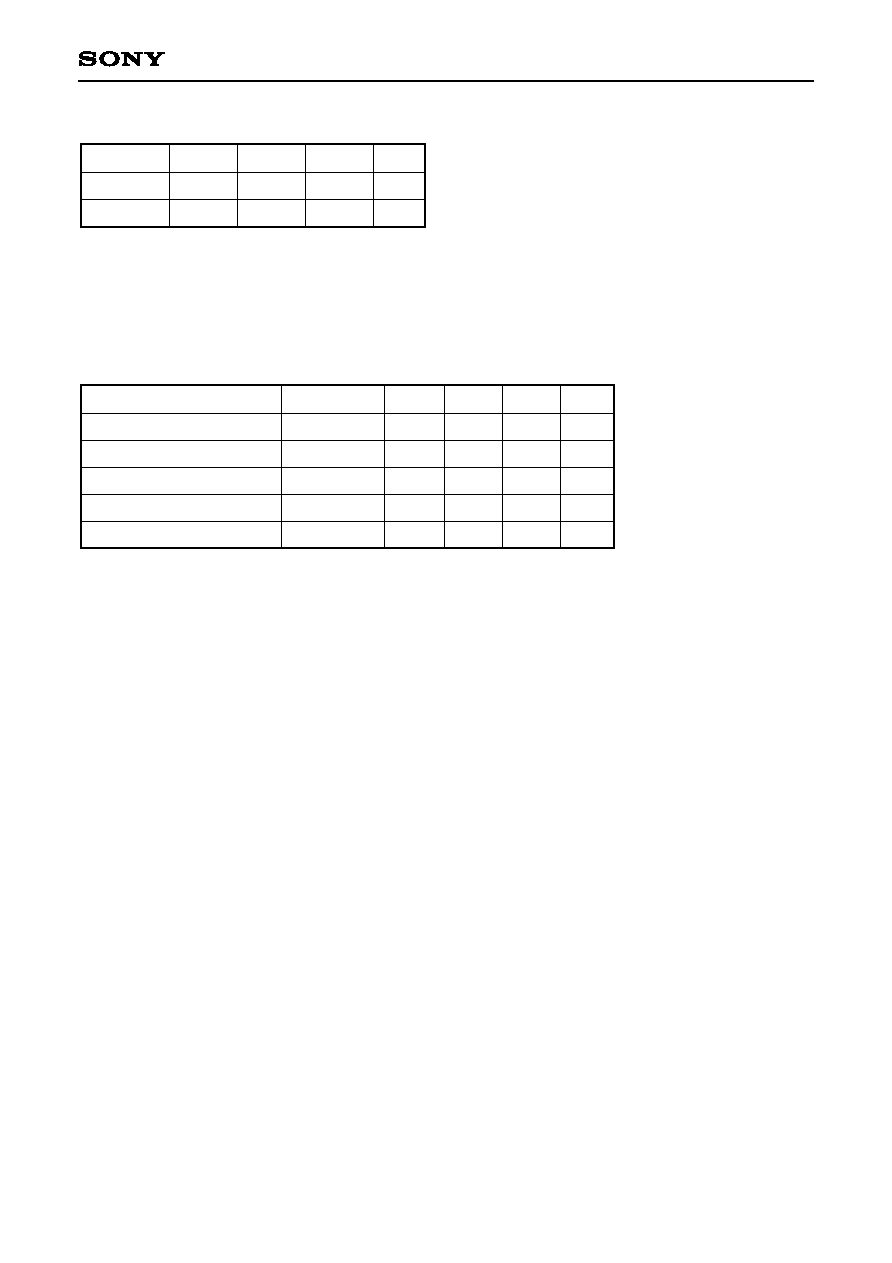

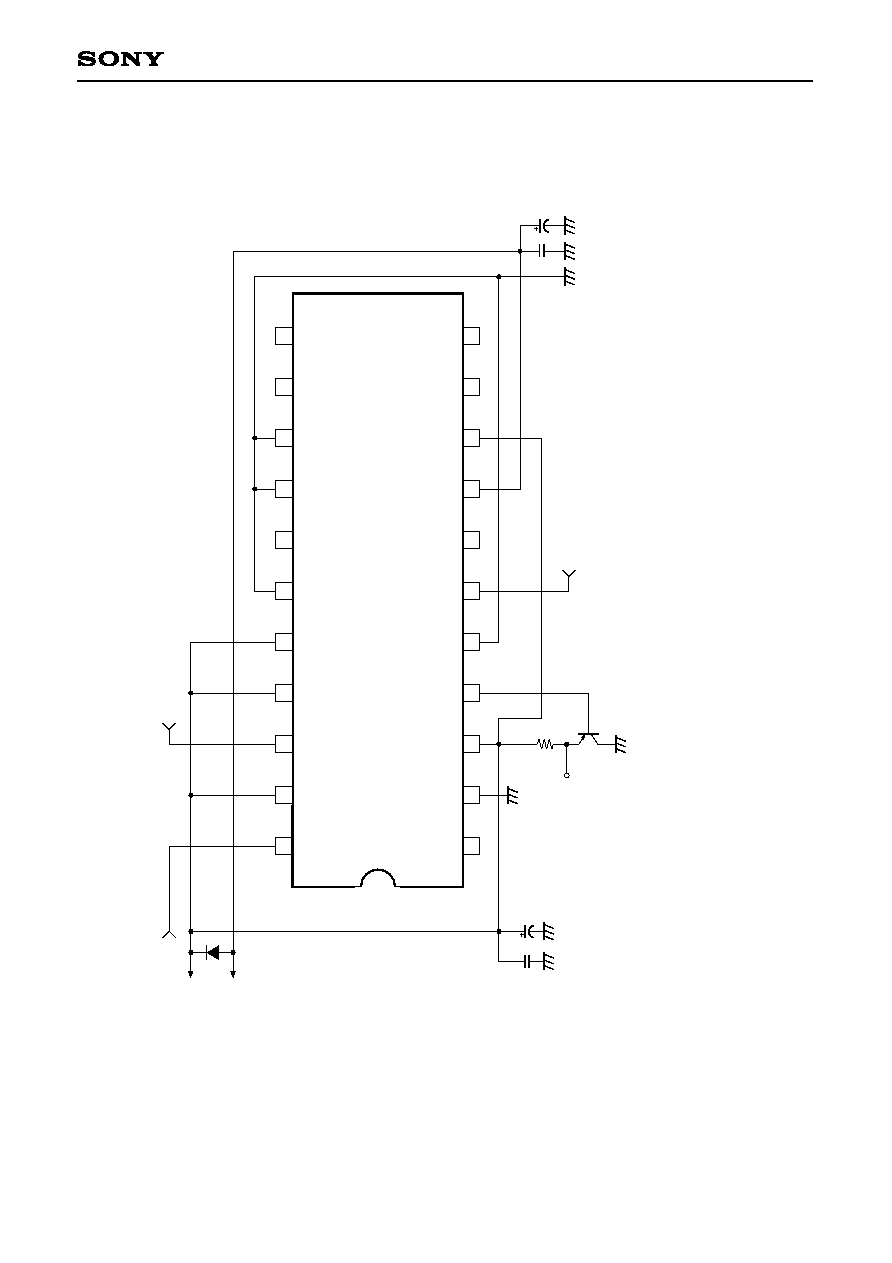

Block Diagram

V

OUT

GND

GND

RS/SH

CLK

V

DD1

V

DD2

NC

NC

NC

V

DD1

RSSW

NC

GND

GND

V

DD1

GND

NC

2

3

4

5

7

8

9

10

11

12

13

14

15

16

17

20

22

Read out gate

CCD analog shift register

Clock-drivers

Clock pulse generator

Sample-and-hold pulse generator

Mode

selector

Read out gate

pulse generator

∑ Output amplifier

∑ Sample-and-hold circuit

∑ Feed through

suppression circuit

.

D116

D99

S3918

S3917

S2

S1

D98

D18

D17

18

19

21

CCD analog shift register

Read out gate

Clock-drivers

6

ROG

1

NC

NC

V

DD1

≠ 3 ≠

ILX514

Pin Description

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Symbol

NC

GND

V

DD1

V

OUT

GND

ROG

NC

V

DD2

RSSW

1

NC

NC

NC

NC

GND

GND

NC

GND

V

DD1

V

DD1

RS/SH

1

V

DD1

CLK

Description

NC

GND

9V power supply

Signal output

GND

Clock pulse

NC

5V power supply

Reset pulse swithover pin

NC

NC

NC

NC

GND

GND

NC

GND

9V power supply

9V power supply

Clock pulse or with S/H; without S/H switch

9V power supply

Clock pulse

1

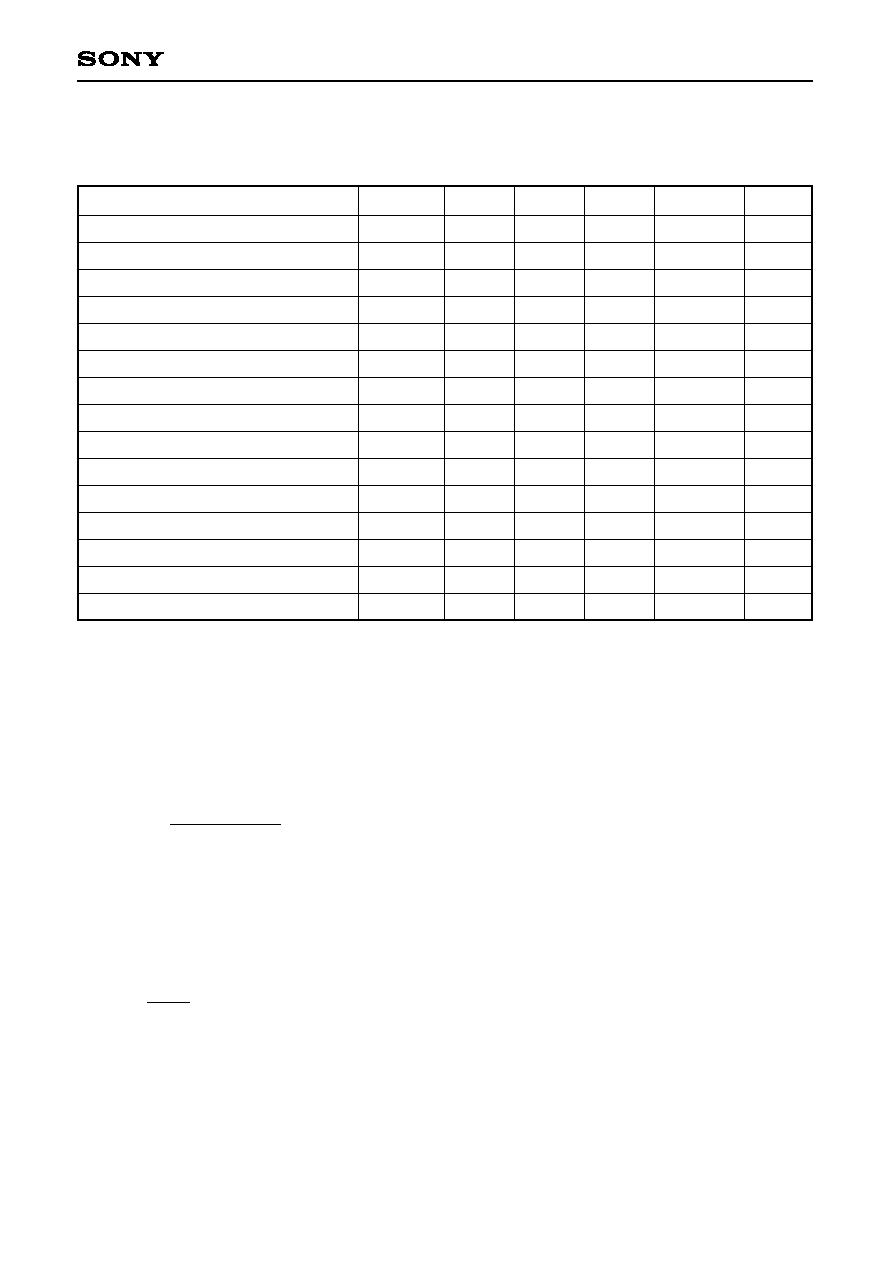

Output mode is changeable as follows.

GND

V

DD1

GND

Internal RS

without S/H

--

V

DD1

Internal RS

with S/H

--

RS

--

External RS

without S/H

9pin

20pin

≠ 4 ≠

ILX514

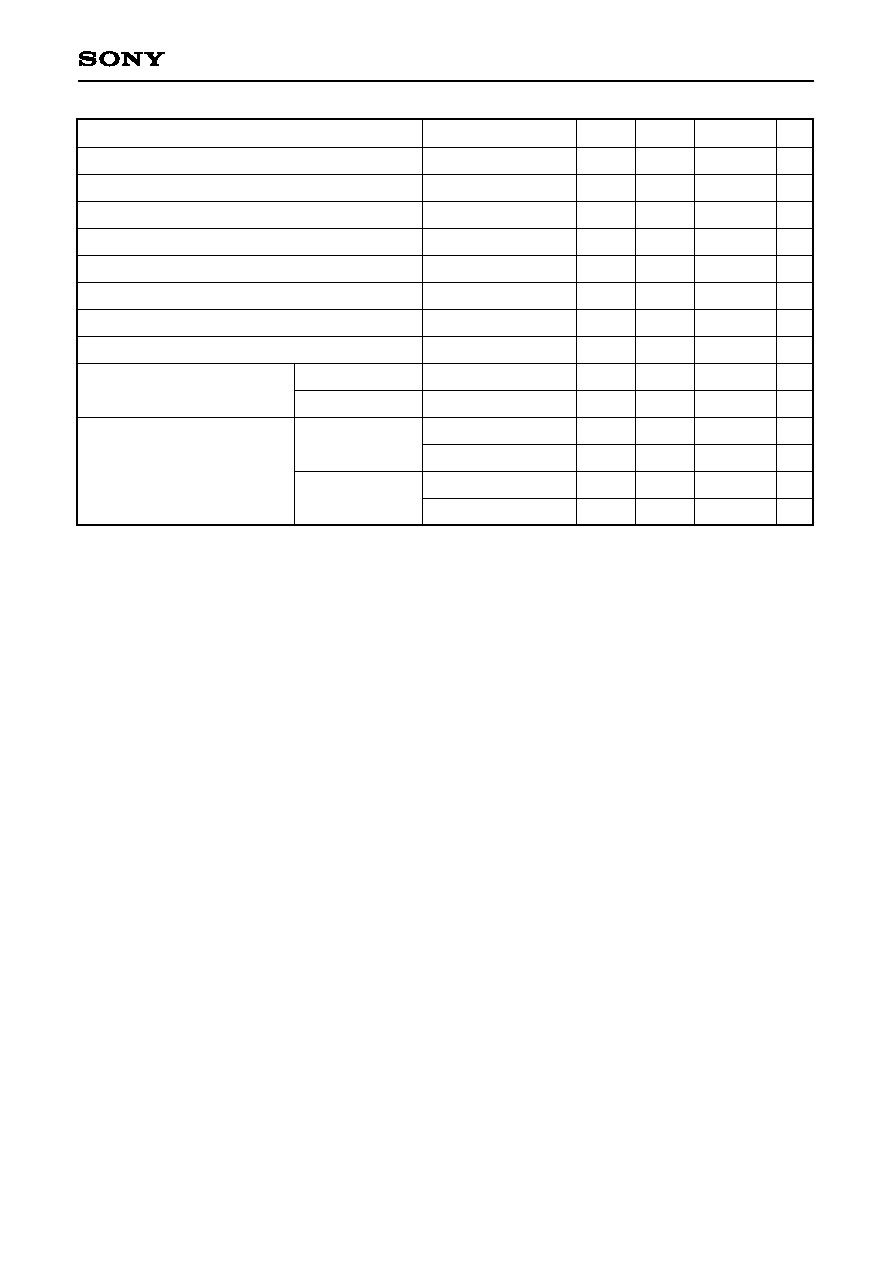

Item

V

DD1

V

DD2

Min.

8.5

4.75

Typ.

9.0

5.0

Max.

9.5

5.25

Unit

V

V

Recommended Voltage

Note) Rules for raising and lowering power supply voltage

To raise power supply voltage, first raise V

DD1

(9V) and then V

DD2

(5V).

To lower voltage, first lower V

DD2

(5V) and then V

DD1

(9V).

Item

Input capacity of

CLK pin

Input capacity of

ROG pin

Input capacity of RS/SH pin

Frequency of

CLK

Frequency of

RS

Min.

--

--

--

--

--

Typ.

10

10

10

1

1

Max.

--

--

--

5

5

Unit

pF

pF

pF

MHz

MHz

Symbol

C

CLK

C

ROG

C

RS/SH

f

CLK

f

RS

Clock Characteristics

≠ 5 ≠

ILX514

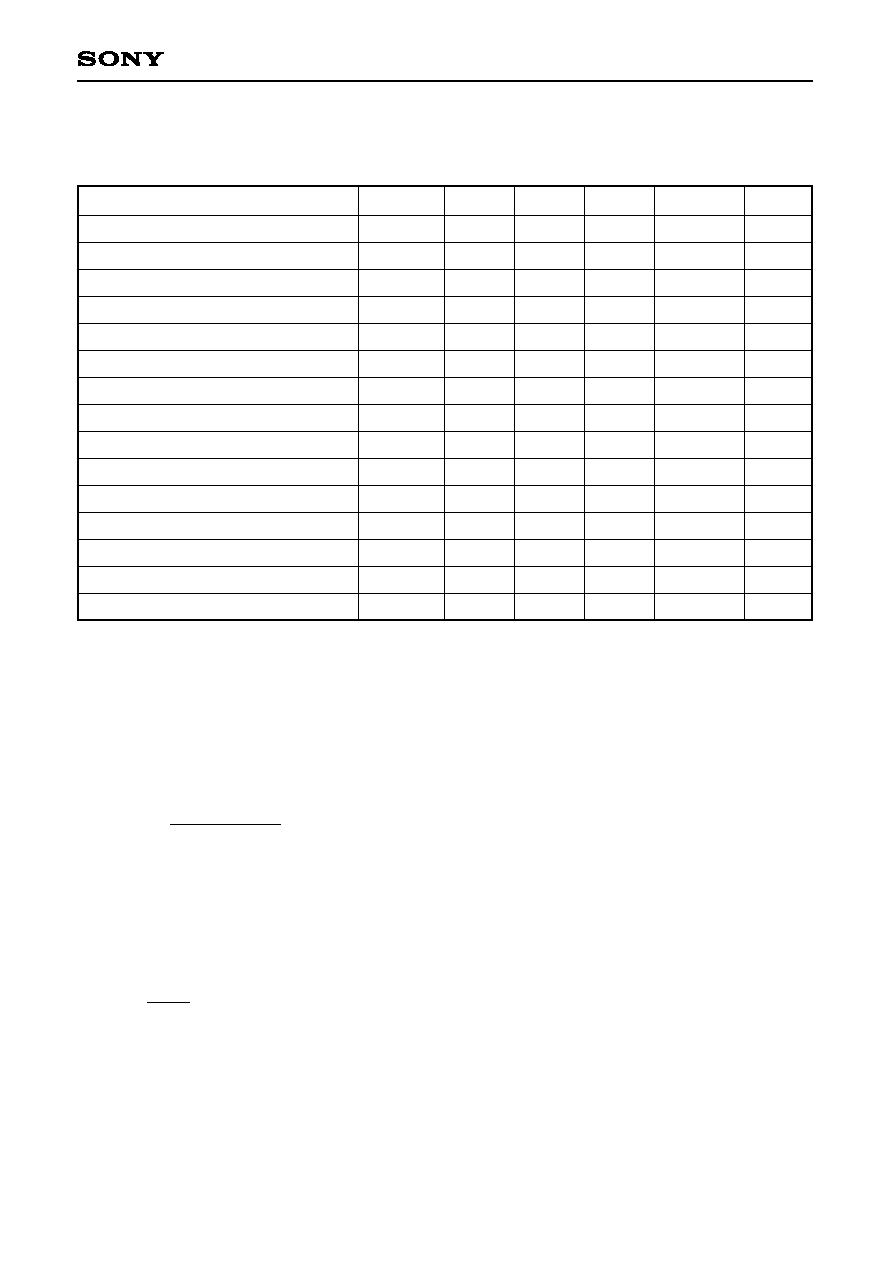

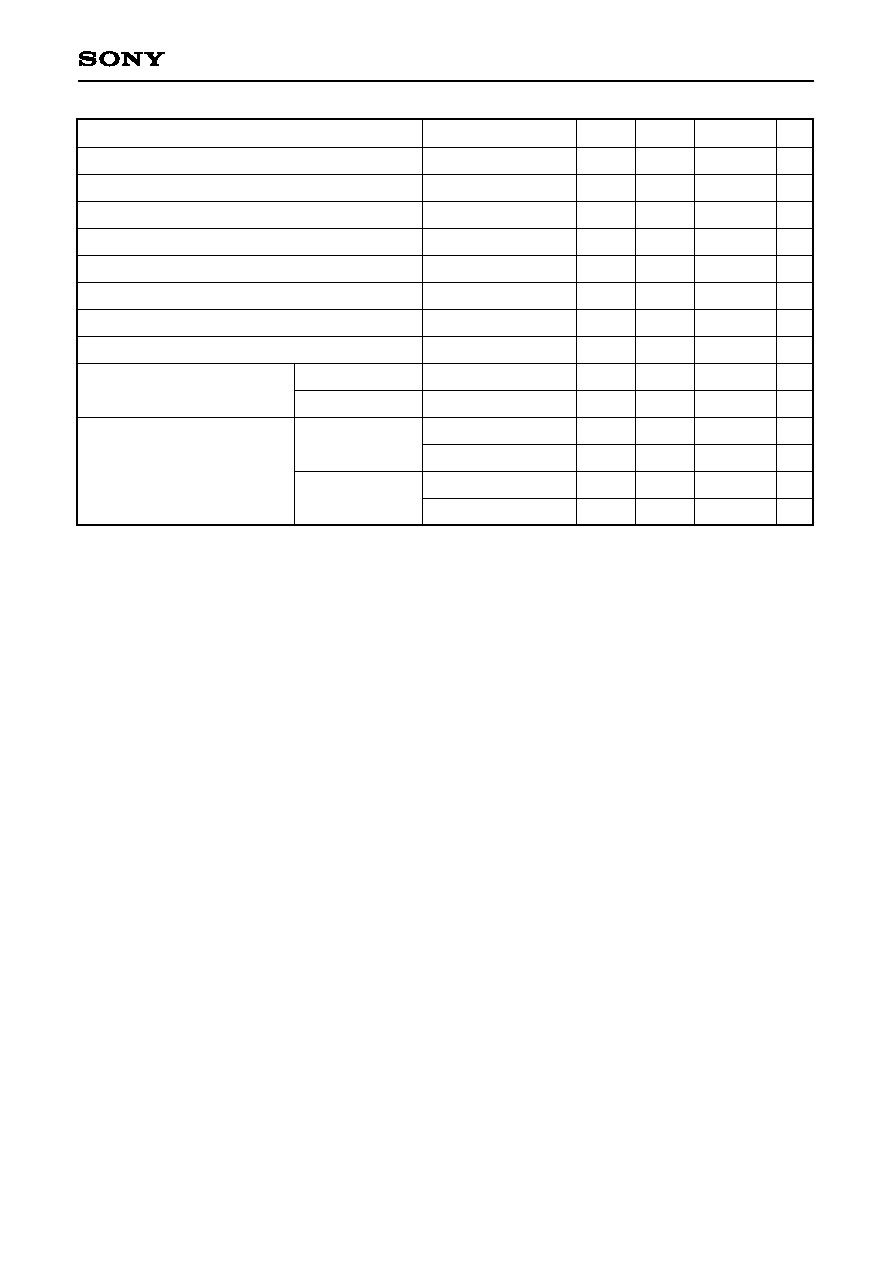

Item

Sensitivity 1

Sensitivity 2

Sensitivity nonuniformity

Saturation output voltage

Saturation exposure

Even and odd black level DC difference

Dark voltage average

Dark signal nonuniformity

Image lag

9V supply current

5V supply current

Total transfer efficiency

Output impedance

Offset level

Dynamic range

Min.

7.5

--

--

1.0

0.072

--

--

--

--

--

--

92

--

--

500

Typ.

10.8

24.6

4

1.5

0.139

1.0

0.3

0.6

0.02

16

2.1

98

600

3.0

5000

Max.

13.9

--

10

--

--

10

2

3

--

32

5.0

--

--

--

--

Unit

V/(lx ∑ s)

V/(lx ∑ s)

%

V

lx ∑ s

mV

mV

mV

%

mA

mA

%

V

--

Remarks

Note 2

Note 3

Note 4

Note 5

Note 6

Note 7

Note 8

Note 9

Note 10

--

--

--

--

Note 11

Note 12

Symbol

R1

R2

PRNU

V

SAT

SE

V

V

DRK

DSNU

IL

I

VDD1

I

VDD2

TTE

Z

O

V

OS

DR

Electro-optical Characteristics (Note 1)

(Ta = 25įC, V

DD1

= 9V, V

DD2

= 5V,

CLK = 1MHz, Internal

RS mode without S/H,

Light source = 3200K, IR cut filter, CM-500S (t = 1.0mm))

Notes)

1) In accordance with the given electrooptical characteristics, the even black level is defined as the mean

value of D8, D10, D12 and D14.

The odd black level is defined as the mean value of D7 , D9, D11 and D13.

2) For the sensitivity test light is applied with a uniform intensity of illumination.

3) W lamp (2854K)

4) PRNU is defined as indicated below. Ray incidence conditions are the same as for Note 2.

PRNU =

◊

100 [%]

Where the 3918 pixels are divided into blocks of 98, even and odd pixels, respectively (Even and odd last

blocks are 97). The maximum output of each block is set to V

MAX

, the minimum output to V

MIN

and the

average output to V

AVE

.

5) Use below the minimum value of the saturation output voltage.

6) Saturation exposure is defined as follows.

SE =

7) Indicates the DC difference in value between odd black level and even black level.

8) Optical signal accumulated time

int stands at 10ms.

(V

MAX

≠ V

MIN

)/2

V

AVE

V

SAT

R1

≠ 6 ≠

ILX514

9) The difference between the maximum and mean values of the dark output voltage is calculated for even

and odd respectively. The larger value is defined as the dark signal nonuniformity.

Optical signal accumulated time

int stands at 10ms.

10) V

OUT

= 500mV (Typ.)

11) Vos is defined as indicated below.

12) Dynamic range is defined as follows.

DR =

When optical accumulated time is shorter, the dynamic range gets wider because dark voltage is in

proportion to optical accumulated time.

V

SAT

V

DRK

Vout

GND

V

OS

≠ 7 ≠

ILX514

Application Circuit

When noise influence into output signal is large, connect pins indicated by (A) to the analog power supply and

pins indicated by (D) to the digital power supply, and also use a decoupling capacitor of large capacitance.

1

2

3

4

5

6

7

8

9

10

11

12

22

21

20

19

18

17

16

15

14

13

(A)

GND

CLK

(A)

V

OUT

(D)

V

DD2

ROG

NC

NC

RS/SH

(D)

GND

(D)

9V

5V

ROG

10Ķ

/10V

0.01Ķ

Output signal

1k

10Ķ

/16V

0.01Ķ

2SA1175

V

DD1

(D)

V

DD1

(A)

V

DD1

(A)

GND

(D)

GND

NC

NC

(A)

GND

NC

(D)

RSSW

NC

(A)

V

DD1

NC

RS

CLK

Application circuits shown are typical examples illustrating the operation of the devices. Sony cannot assume responsibility for

any problems arising out of the use of these circuits or for any infringement of third party patent and other right due to same.

This application circuit shows when

RS is used externally.

(

)

≠ 8 ≠

ILX514

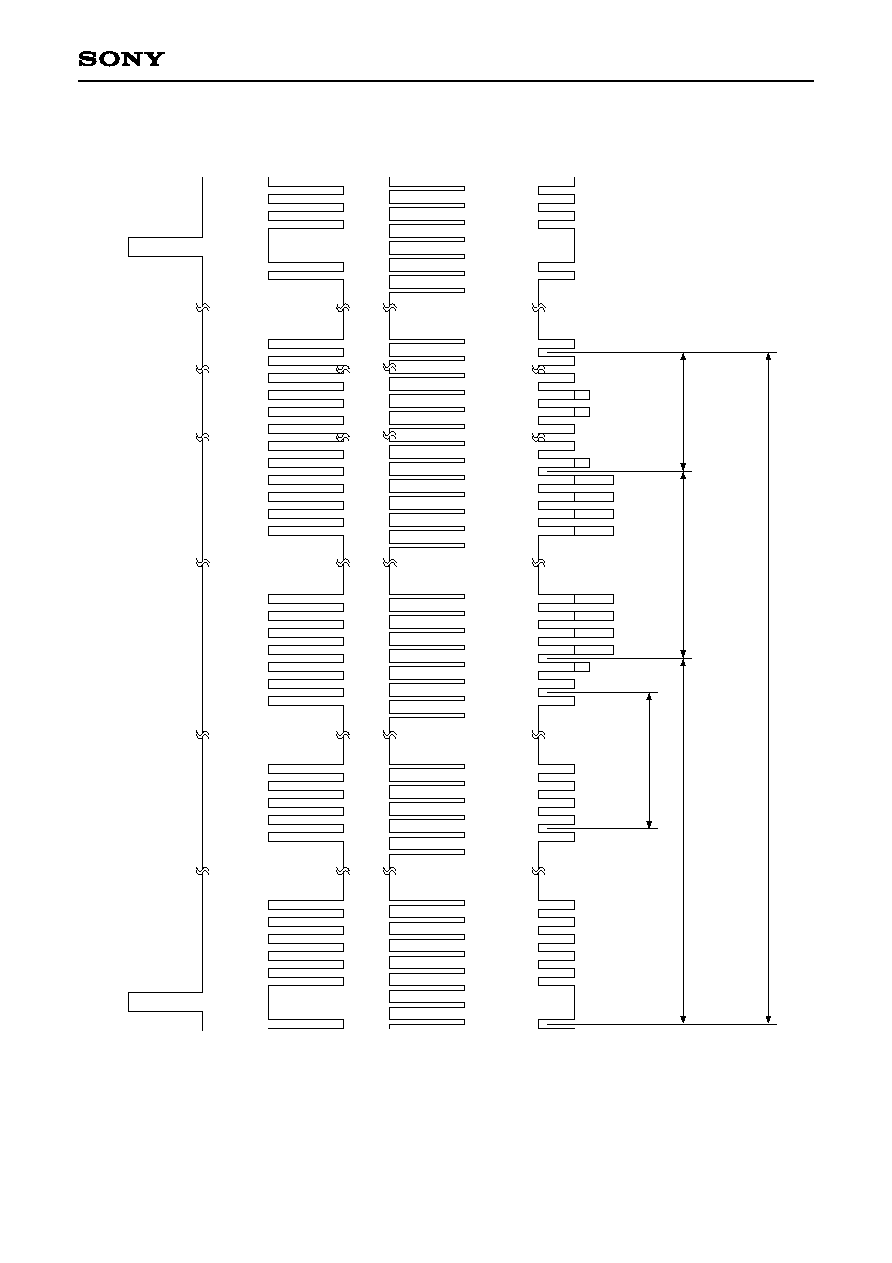

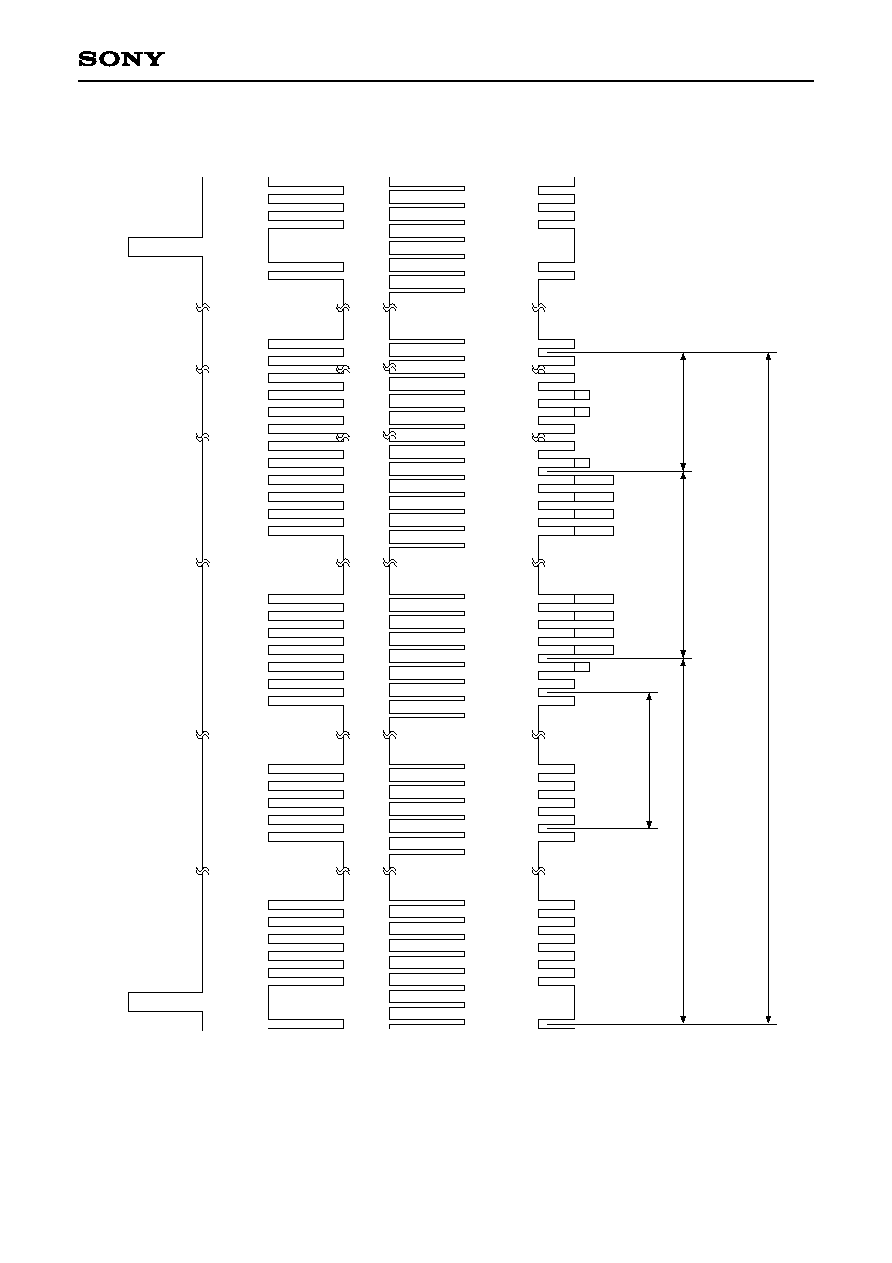

Clock Timing Diagram

ROG

CLK

VOUT

5

0

5

0

1

2

3

4

4034

1

2

D2

D1

D3

D4

D5

D6

D16

D17

D18

D19

D20

D96

D97

D98

S1

S2

S3

S4

S3915

S3916

S3917

S3918

D99

D100

D106

D107

D108

D109

1-line output period (4034 pixels)

Dummy signal (98 pixels)

Effective picture

elements signal

(3918 pixels)

Dummy signal

(18 pixels)

Optical black

(80 pixels)

RS

5

0

D116

This clock timing diagram shows when

RS is used externally.

≠ 9 ≠

ILX514

Clock Pulse Waveform Conditions

CLK,

ROG pulse related

Internal

RS mode

External

RS mode

t8

CLK

t9

t2

t1

t3

ROG

t8

t9

t4

t5

t10

t10

t11

CLK

Vout

t4

t5

CLK

t8

t9

t7

t6

RS

t10

t12

t13

≠ 10 ≠

ILX514

1

Recommended condition during

CLK = 1MHz.

Unit

ns

ns

ns

ns

ns

ns

ns

ns

V

V

ns

ns

ns

ns

Item

ROG,

CLK pulse timing

ROG,

CLK pulse timing

ROG pulse high level period

CLK pulse high level period

CLK pulse low level period

RS pulse low level period

CLK,

RS pulse timing

Input clock pulse rise/fall time

Input clock pulse voltage

Signal output delay time

High level

Low level

Internal

RS

External

RS

Max.

--

--

--

--

--

--

t1 + t2

10

5.5

0.5

--

--

--

--

Typ.

200

1000

1000

500

1

500

1

100

1

550

1

5

5.0

--

110

65

40

75

Min.

100

800

800

100

100

40

100

--

4.5

0

--

--

--

--

Symbol

t1

t3

t2

t4

t5

t6

t7

t8, t9

V

CLK

, V

ROG

V

RS

t10

t11

t12

t13

≠ 11 ≠

ILX514

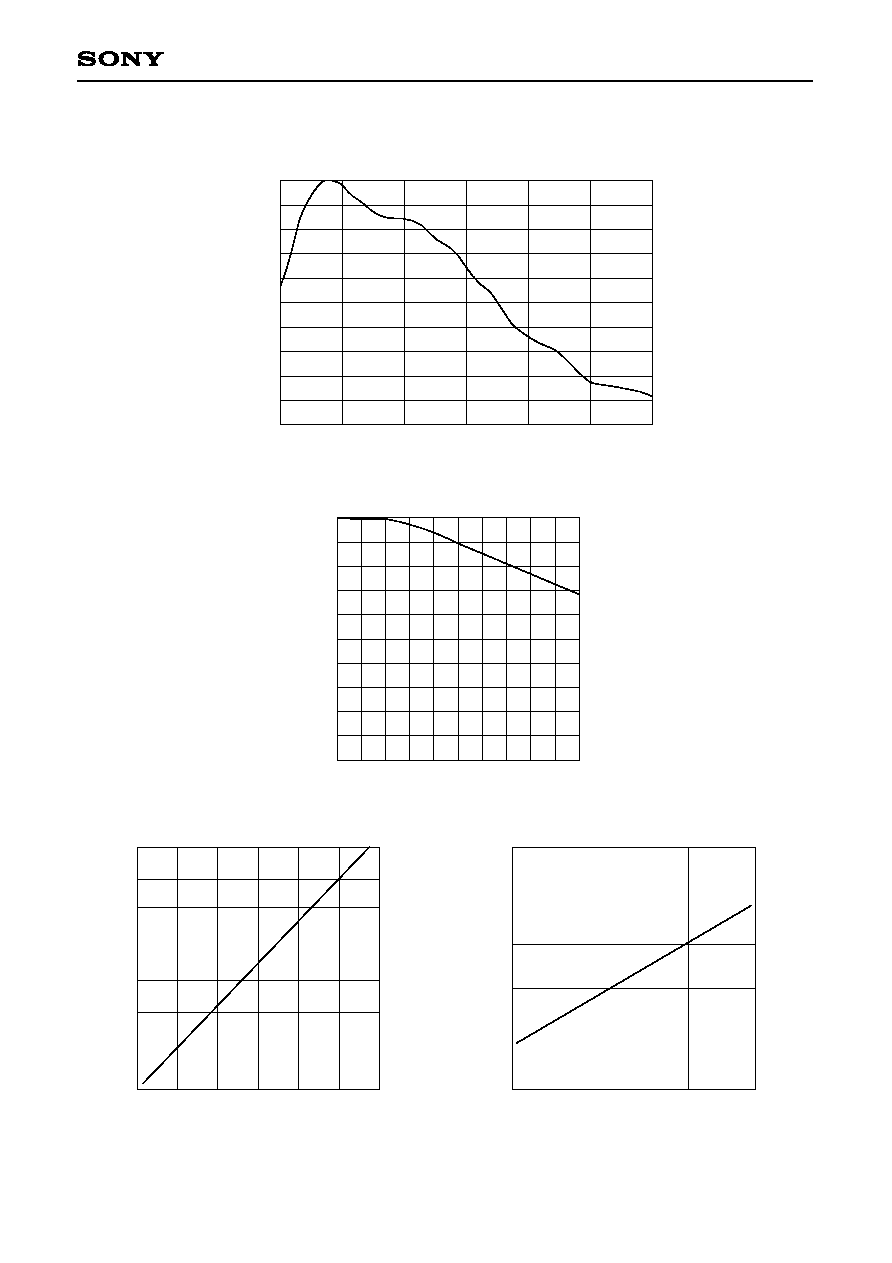

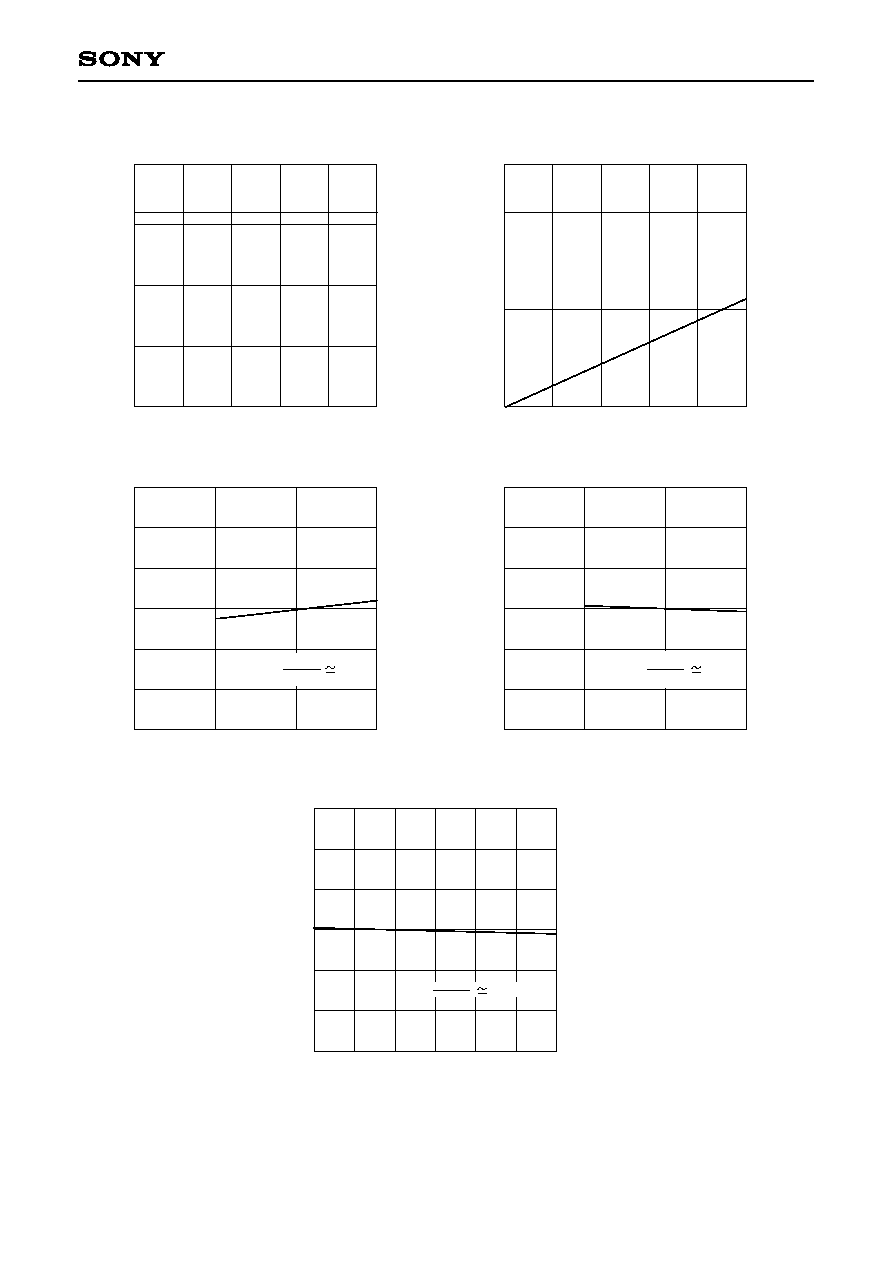

0

0.2

0.4

0.6

0.8

1.0

0

MTF

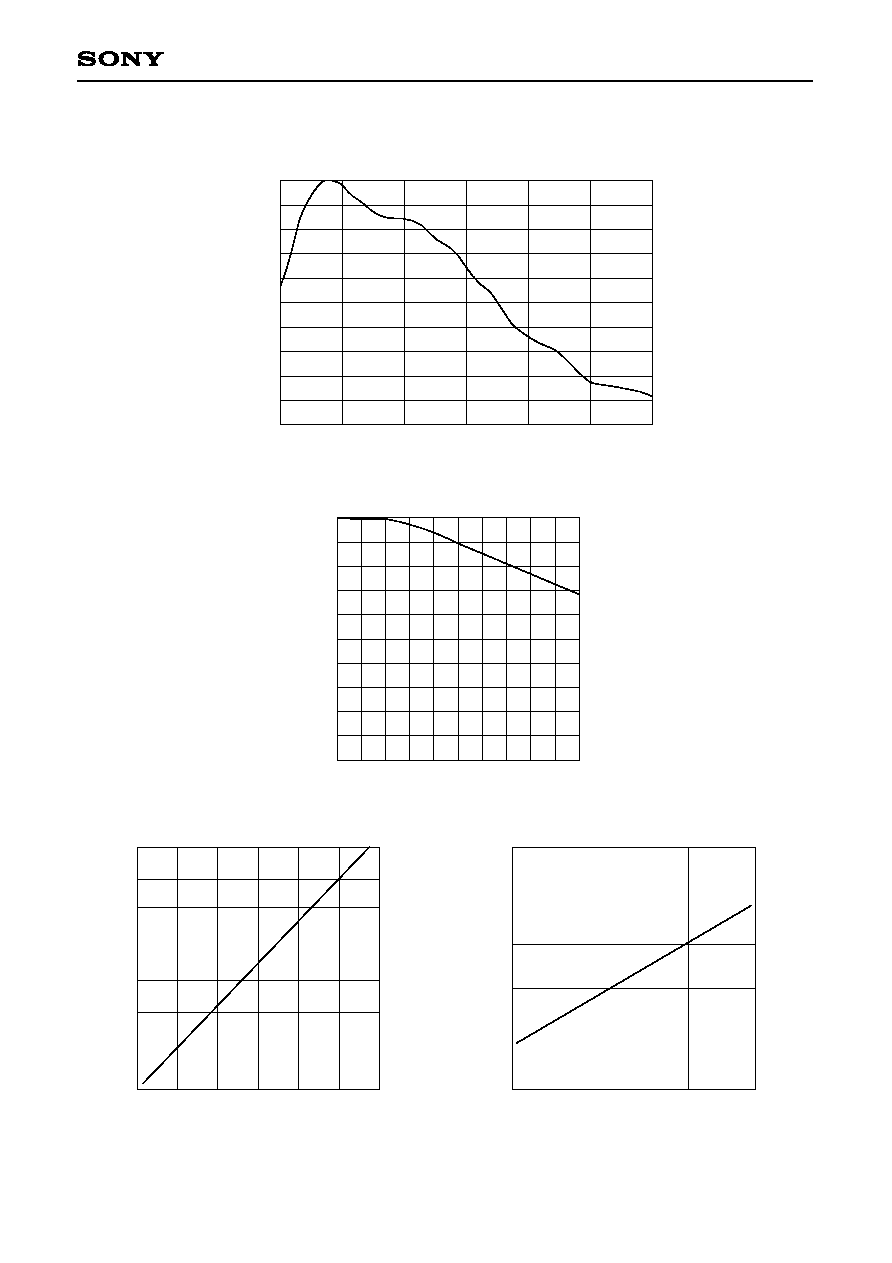

MTF of main scanning direction (Standard characteristics)

Normalized spatial frequency

0.2

0.4

0.6

0.8

1.0

0

Spatial frequency [cycles/mm]

14.3

28.6

42.9

57.1

71.4

Spectral sensitivity characteristics

(Standard characteristics)

400

500

600

700

800

900

1000

Wavelength [nm]

0.2

0.4

0.6

0.8

1.0

0

Relative sensitivity

1

0.5

1

0.1

Output voltage rate

Integration time output voltage characteristics

(Standard characteristics)

int ≠ Integration time [ms]

10

5

0

0.5

1

5

10

0.1

Output voltage rate

Dark signal output temperature characteristics

(Standard characteristics)

Ta ≠ Ambient temperature [įC]

10

20

30

40

60

50

Example of Representative Characteristics (V

DD1

= 9V, V

DD2

= 5V, Ta = 25įC)

≠ 12 ≠

ILX514

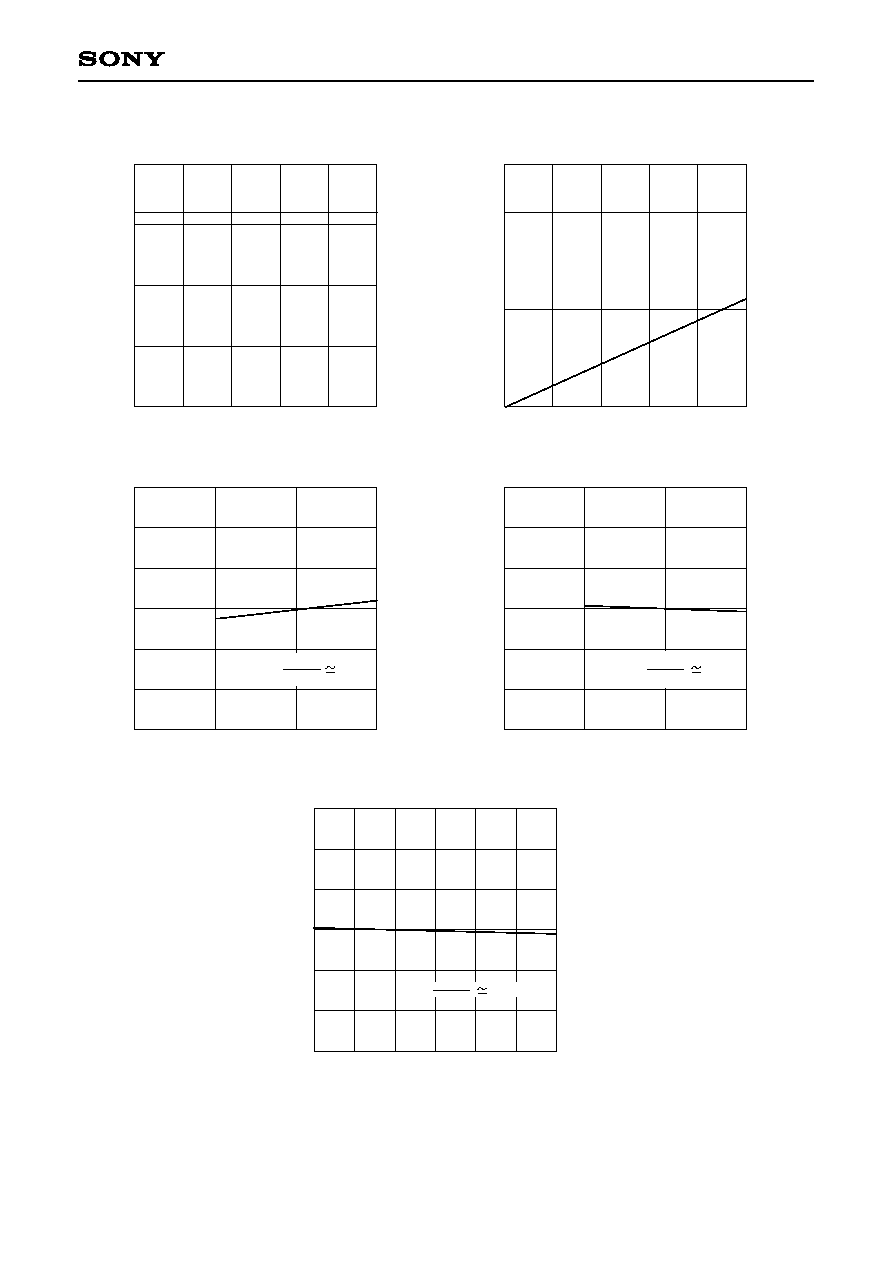

0

5

10

15

0

IV

DD1

≠ V

DD1

supply current [mA]

Operational frequency characteristics of the V

DD1

supply current (Standard characteristics)

f

CLK ≠

CLK clock frequency [MHz]

1

2

3

5

4

0

10

0

IV

DD2

≠ V

DD2

supply current [mA]

Operational frequency characteristics of the V

DD2

supply current (Standard characteristics)

f

CLK ≠

CLK clock frequency [MHz]

1

2

3

5

4

20

1

2

3

0

Vos ≠ Offset level [V]

Offset level vs. V

DD2

characteristics

(Standard characteristics)

V

DD2

[V]

4.75

5

5.25

5

4

6

Ta = 25įC

≠0.14

Vos

V

DD2

1

2

3

0

Vos ≠ Offset level [V]

Offset level vs. V

DD1

characteristics

(Standard characteristics)

V

DD1

[V]

8.5

9

9.5

5

4

6

Ta = 25įC

0.35

Vos

V

DD1

1

2

3

0

Vos ≠ Offset level [V]

Offset level vs. Temperature characteristics

(Standard characteristics)

Ta ≠ Ambient temperature [įC]

20

40

60

5

4

6

Vos

Ta

0

30

50

10

≠0.8mV/įC

≠ 13 ≠

ILX514

Notes on Handling

1) Static charge prevention

CCD image sensors are easily damaged by static discharge. Before handling be sure to take the following

protective measures.

a) Either handle bare handed or use non chargeable gloves, clothes or material.

Also use conductive shoes.

b) When handling directly use an earth band.

c) Install a conductive mat on the floor or working table to prevent the generation of static electricity.

d) Ionized air is recommended for discharge when handling CCD image sensor.

e) For the shipment of mounted substrates, use boxes treated for prevention of static charges.

2) Regulation for raising and lowering the power supply voltage

When raising the supply voltage, first raise V

DD1

(9V) and then V

DD2

(5V).

Similarly, lower V

DD2

(5V) first and then V

DD1

(9V).

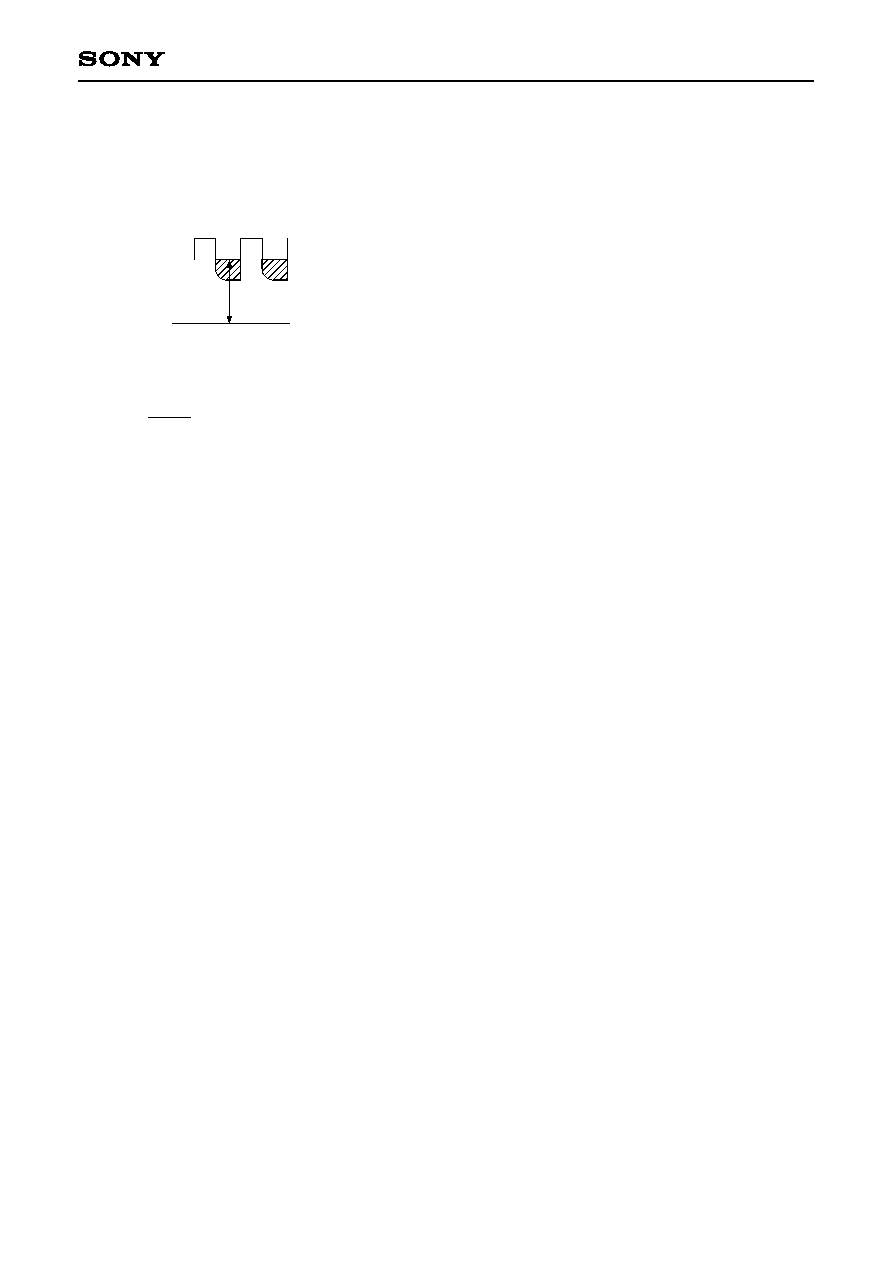

3) Notes on handling CCD Cer-DIP Packages

The following points should be observed when handling and installing cer-DIP packages.

a) Remain within the following limits when applying a static load to the ceramic portion of the package:

(1) Compressive strength: 39N/surface (Do not apply any load more than 0.7mm inside the outer perimeter

of the glass portion.)

(2) Shearing strength:

29N/surface

(3) Tensile strength:

29N/surface

(4) Torsional strength:

0.9Nm

b) In addition, if a load is applied to the entire surface by a hard component, bending stress may be

generated and the package may fracture, etc., depending on the flatness of the ceramic portion.

Therefore, for installation, either use an elastic load, such as a spring plate, or an adhesive.

c) Be aware that any of the following can cause the glass to crack: because the upper and lower ceramic

layers are shielded by low-melting glass,

(1) Applying repetitive bending stress to the external leads.

(2) Applying heat to the external leads for an extended period of time with soldering iron.

(3) Rapid cooling or heating.

(4) Applying a load or impact to a limited portion of the low-melting glass with a small-tipped tool such as

tweezers.

(5) Prying the upper or lower ceramic layers away at a support point of the low-melting glass.

Note that the preceding notes should also be observed when removing a component from a board after it

has already been soldered.

29N

29N

0.9Nm

(2)

(3)

(4)

39N

Low-melting glass

(1)

Upper ceramic layer

Lower ceramic layer

≠ 14 ≠

ILX514

4) Soldering

a) Make sure the package temperature does not exceed 80įC.

b) Solder dipping in a mounting furnace causes damage to the glass and other defects. Use a grounded 30W

soldering iron and solder each pin in less than 2 seconds. For repairs and remount, cool sufficiently.

c) To dismount an image sensor, do not use a solder suction equipment.

When using an electric desoldering tool, ground the controller. For the control system, use a zero cross

type.

5) Dust and dirt protection

a) Operate in clean environments.

b) Do not either touch glass plates by hand or have any object come in contact with glass surfaces. Should

dirt stick to a glass surface, blow it off with an air blower. (For dirt stuck through static electricity ionized

air is recommended.)

c) Clean with a cotton bud and ethyl alcohol if the grease stained.

Be careful not to scratch the glass.

d) Keep in a case to protect from dust and dirt. To prevent dew condensation, preheat or precool when

moving to a room with great temperature differences.

6) Exposure to high temperatures or humidity will affect the characteristics.

Accordingly avoid storage or usage in such conditions.

7) CCD image sensors are precise optical equipment that should not be subject to mechanical shocks.

≠ 15 ≠

ILX514

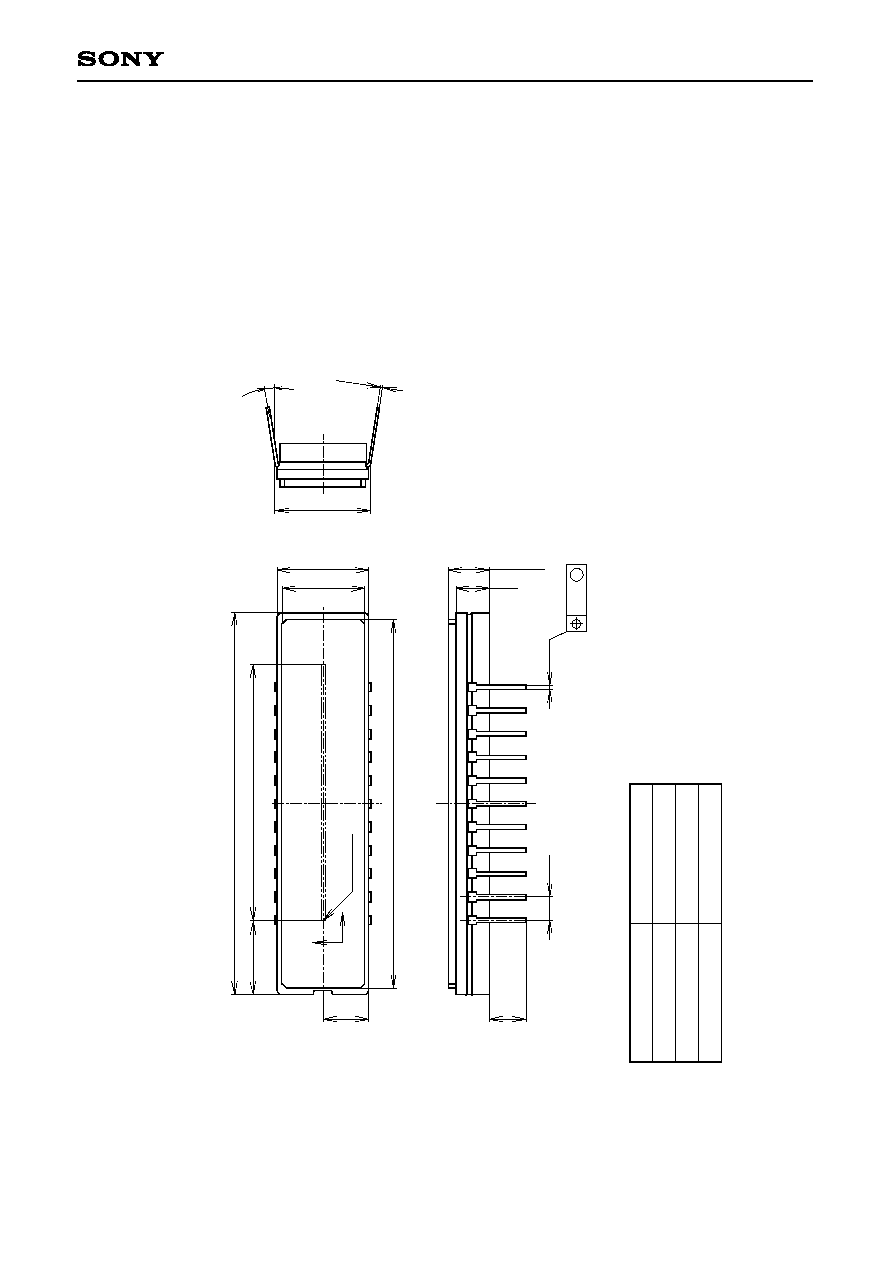

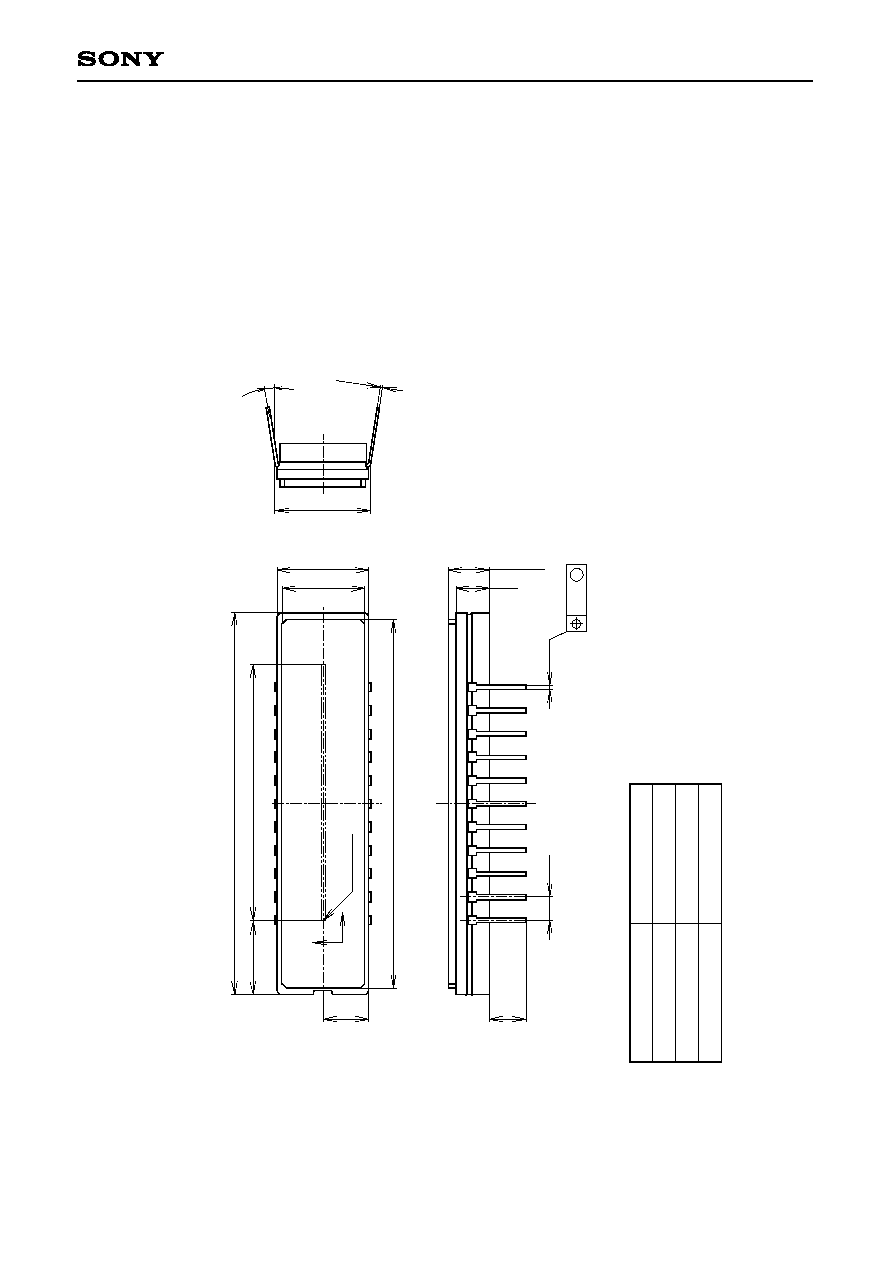

Package Outline

Unit: mm

PACKAGE STRUCTURE

V

H

8.19 Ī

0.8

22

27.426 (7Ķ

m

◊

3918Pixels)

41.6 Ī

0.5

1

11

12

No.1 Pixel

40.2

5.0 Ī 0.5

4.0 Ī 0.5

2.54

0.51

3.65

4.45 Ī 0.5

0.25

0į to 9į

10.16

10.0 Ī 0.5

9.0

0.3

1.

The height from the bottom to the sensor surface is 2.45 Ī

0.3mm.

2.

The thickness of the cover glass is 0.8mm, and the refractive index is 1.5.

22pin DIP (400mil)

(AT STAND OFF)

M

PACKAGE MATERIAL

LEAD TREATMENT

LEAD MATERIAL

PACKAGE WEIGHT

Cer-DIP

TIN PLATING

42 ALLOY

5.2g