| –≠–Ľ–Ķ–ļ—ā—Ä–ĺ–Ĺ–Ĺ—č–Ļ –ļ–ĺ–ľ–Ņ–ĺ–Ĺ–Ķ–Ĺ—ā: BYW29 | –°–ļ–į—á–į—ā—Ć:  PDF PDF  ZIP ZIP |

1/7

BYW29/F/FP/G-200

ģ

May 2002 - Ed: 4B

HIGH EFFICIENCY FAST RECOVERY DIODES

I

F(AV)

8 A

V

RRM

200 V

trr (max)

25 ns

V

F

(max)

0.85 V

MAIN PRODUCT CHARACTERISTICS

s

Very Low Forward Losses

s

Negligible switching losses

s

High surge current capability

s

Insulated

packages

(ISOWATT220AC,

TO-220FPAC):

Insulation voltage: 2000 VDC

Typical insulation capacitance = 12 pF

FEATURES AND BENEFITS

Single rectifier suited for Switch Mode Power

Supply and high frequency DC to DC converters.

Packaged

in

TO-220AC,

ISOWATT220AC,

TO-220FPAC and D

2

PAK, this device is intended

for use in high frequency inverters, free wheeling

and polarity protection applications.

DESCRIPTION

NC

A

K

Symbol

Parameter

Value

Unit

V

RRM

Repetitive peak reverse voltage

200

V

I

F(RMS)

RMS forward current

16

A

I

F(AV)

Average forward current

= 0.5

D

2

PAK /

TO-220AC

Tc =120įC

8

A

ISOWATT220AC

TO-220FPAC

Tc = 100įC

I

FSM

Surge non repetitive forward current

(All pins connected)

tp=10ms

sinusoidal

80

A

Tstg

Storage and junction temperature range

- 65 to + 150

įC

Tj

Maximum operating junction temperature

+ 150

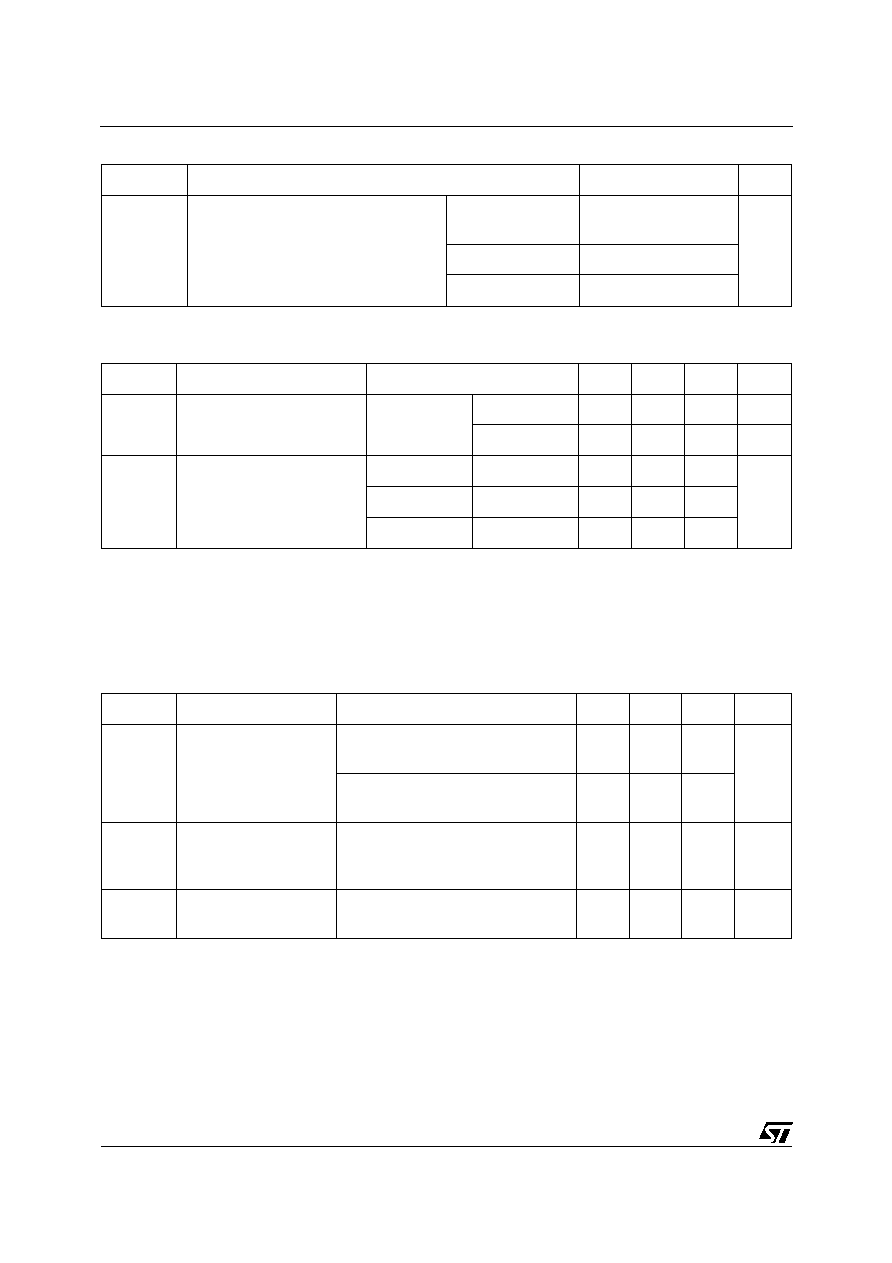

ABSOLUTE MAXIMUM RATINGS

D

2

PAK

BYW29G-200

TO-220AC

BYW29-200

TO-220FPAC

BYW29FP-200

ISOWATT220AC

BYW29F-200

A

K

K

A

K

A

K

A

BYW29/F/FP/G-200

2/7

Symbol

Parameter

Value

Unit

Rth (j-c)

Junction to case thermal resistance

TO-220AC

D2PAK

2.8

į

C/W

ISOWATT220AC

5

TO-220FPAC

5.5

THERMAL RESISTANCE

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

I

R

*

Reverse leakage current

V

R

= V

RRM

T

j

= 25įC

10

Ķ

A

T

j

= 100

į

C

0.6

mA

V

F **

Forward voltage drop

I

F

= 5 A

T

j

= 125

į

C

0.85

V

I

F

= 10 A

T

j

= 125

į

C

1.05

I

F

= 10 A

T

j

= 25

į

C

1.15

Pulse test :

* tp = 5 ms, duty cycle < 2 %

** tp = 380

Ķ

s, duty cycle < 2 %

To evaluate the conduction losses use the following equation :

P = 0.65 x I

F(AV)

+ 0.040 I

F

2

(RMS)

STATIC ELECTRICAL CHARACTERISTICS

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

t

rr

Reverse recovery

time

T

j

= 25įC

I

F

= 0.5A

Irr = 0.25 A

I

R

= 1A

25

ns

T

j

= 25

į

C

I

F

= 1A

dI

F

/dt = -50A/

Ķ

s

V

R

=

30V

35

t

fr

Forward recovery

time

T

j

= 25

į

C

I

F

= 1A

dI

F

/dt = 100A/

Ķ

s

V

FR

= 1.1 x V

F

max

15

ns

V

FP

Peak forward

voltage

T

j

= 25

į

C

I

F

= 1A

dI

F

/dt = 100A/

Ķ

s

2

V

RECOVERY CHARACTERISTICS

BYW29/F/FP/G-200

3/7

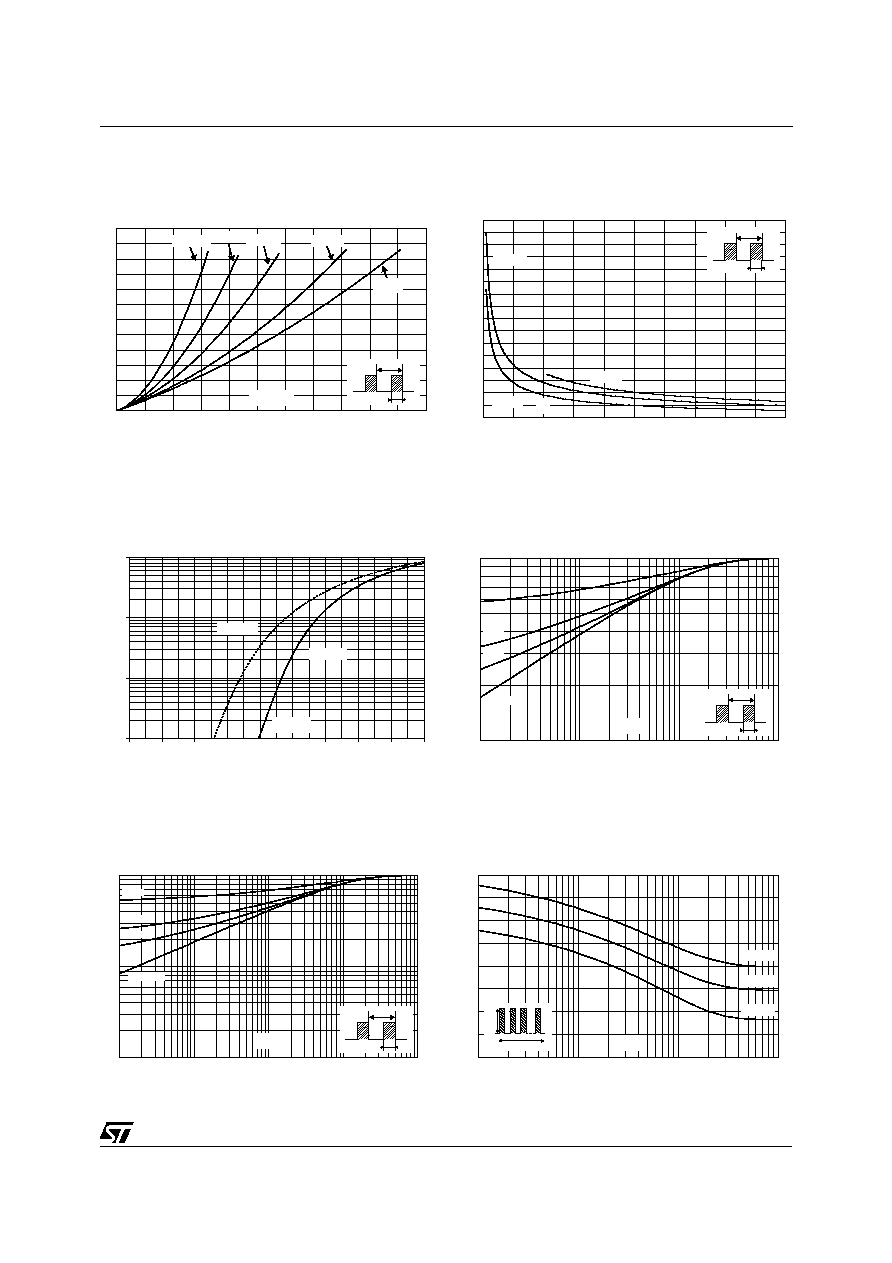

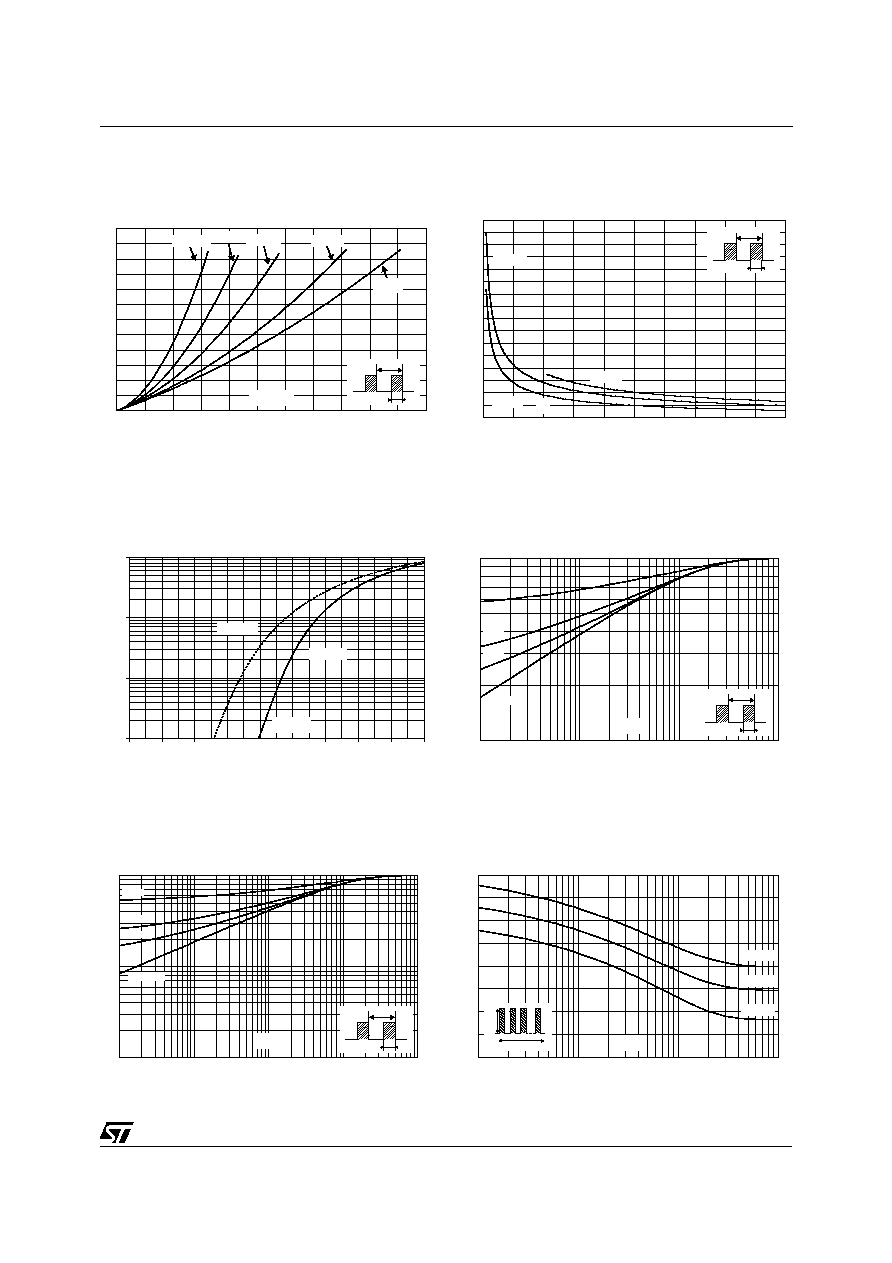

0

20

40

60

80

100

120

140

160

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

P = 10W

P = 5 W

P = 15W

T

=tp/T

tp

IM

IM(A)

Fig.2 : Peak current versus form factor.

0.1

1.0

10.0

100.0

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

VFM(V)

Tj=25įC

Tj=125įC

IFM(A)

Fig.3 : Forward voltage drop versus forward cur-

rent (maximum values).

0.1

1.0

1.E-03

1.E-02

1.E-01

1.E+00

tp(s)

T

=tp/T

tp

= 0.5

= 0.2

= 0.1

Single pulse

Zth(j-c)/Rth(j-c)

Fig.4-1 : Relative variation of thermal impedance

junction to case versus pulse duration (TO-220AC,

D

2

PAK).

0

2

4

6

8

10

12

0

1

2

3

4

5

6

7

8

9

10

11

IF(av)(A)

PF(av)(W)

= 0.05

= 0.1

= 0.2

= 0.5

= 1

T

=tp/T

tp

Fig.1 : Average forward power dissipation versus

average forward current.

0

10

20

30

40

50

60

70

80

1.E-03

1.E-02

1.E-01

1.E+00

t(s)

Tc=25įC

Tc=75įC

Tc=120įC

IM(A)

I

M

t

=0.5

Fig.5-1 : Non repetitive surge peak forward current

versus overload duration (TO-220AC, D

2

PAK).

0.0

0.1

1.0

1.E-03

1.E-02

1.E-01

1.E+00

1.E+01

tp(s)

Zth(j-c)/Rth(j-c)

T

=tp/T

tp

= 0.5

= 0.2

= 0.1

Single pulse

Fig.4-2 :Relative variation of thermal impedance

junction

to

case

versus

pulse

duration

(TO-220FPAC, ISOWATT220AC).

BYW29/F/FP/G-200

4/7

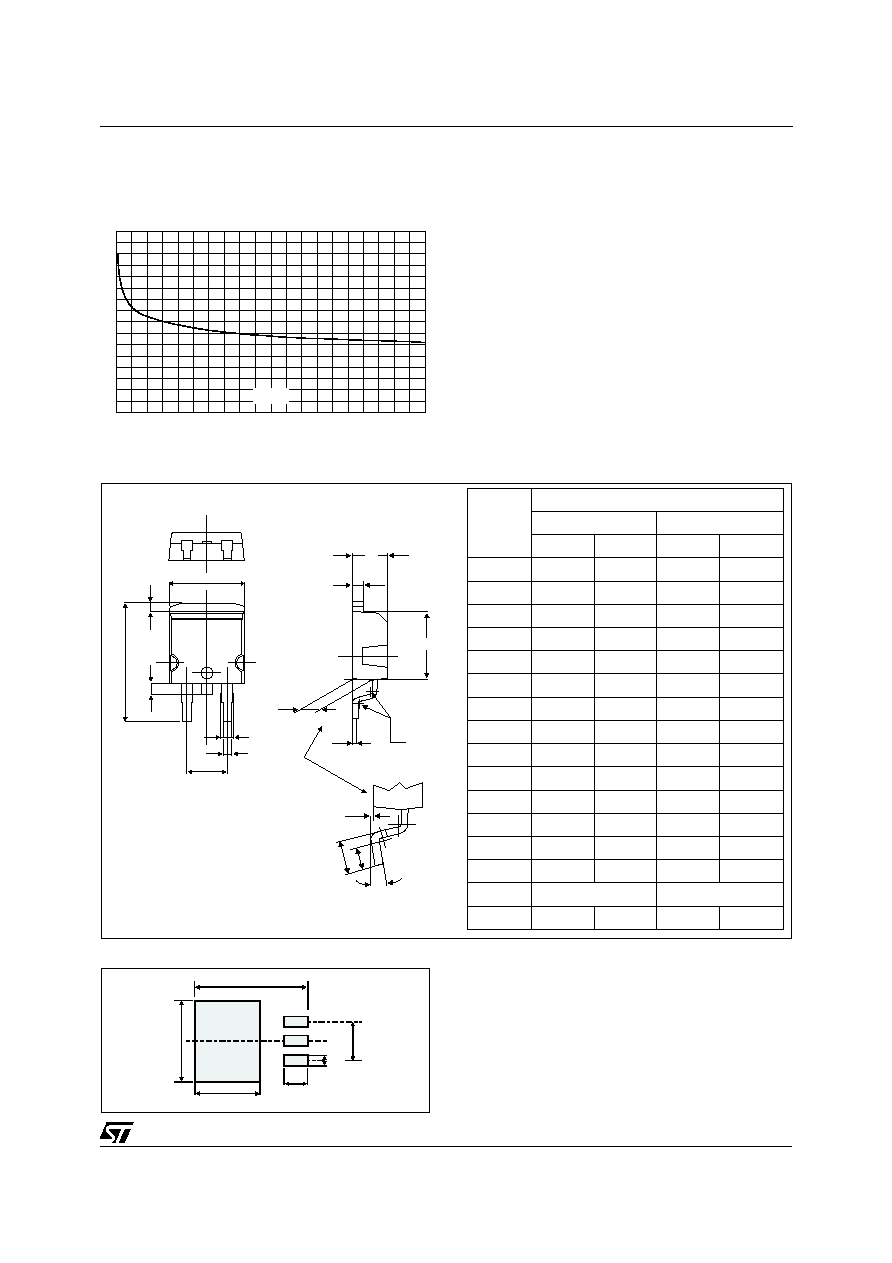

0

10

20

30

40

50

60

1.E-03

1.E-02

1.E-01

1.E+00

t(s)

Tc=25įC

Tc=75įC

Tc=100įC

IM(A)

I

M

t

=0.5

Fig.5-2 : Non repetitive surge peak forward cur-

rent versus overload duration (TO-220FPAC,

ISOWATT220AC).

0

1

2

3

4

5

6

7

8

9

10

0

25

50

75

100

125

150

Tamb(įC)

Rth(j-a)=Rth(j-c)

Rth(j-a)=15įC:W

TO-220AC/D≤PAK

TO-220FPAC

ISOWATT220AC

IF(av)(A)

Fig.6 : Average current versus ambient tempera-

ture. (

= 0.5)

10

100

1000

10

100

1000

dIF/dt(A/Ķs)

IF=8A

VR=100V

Tj=100įC

Qrr(nC)

Fig.8 : Reverse recovery charges versus dI

F

/dt

(90%confidence).

10

100

1

10

100

1000

VR(V)

F=1MHz

Vosc=30mV

Tj=25įC

C(pF)

Fig.7 : Junction capacitance versus reverse volt-

age applied (Typical values).

1

10

100

10

100

1000

dIF/dt(A/Ķs)

IF=8A

VR=100V

Tj=100įC

IRM(A)

Fig.9 : Peak reverse recovery current versus

dIF/dt (90% confidence).

0.00

0.25

0.50

0.75

1.00

1.25

1.50

0

25

50

75

100

125

150

Tj(įC)

IRM

QRR

IF=8A

VR=100V

Qrr; IRM[Tj] / Qrr; IRM[Tj=125įC]

Fig.10 : Dynamic parameters versus junction tem-

perature.

5/7

BYW29/F/FP/G-200

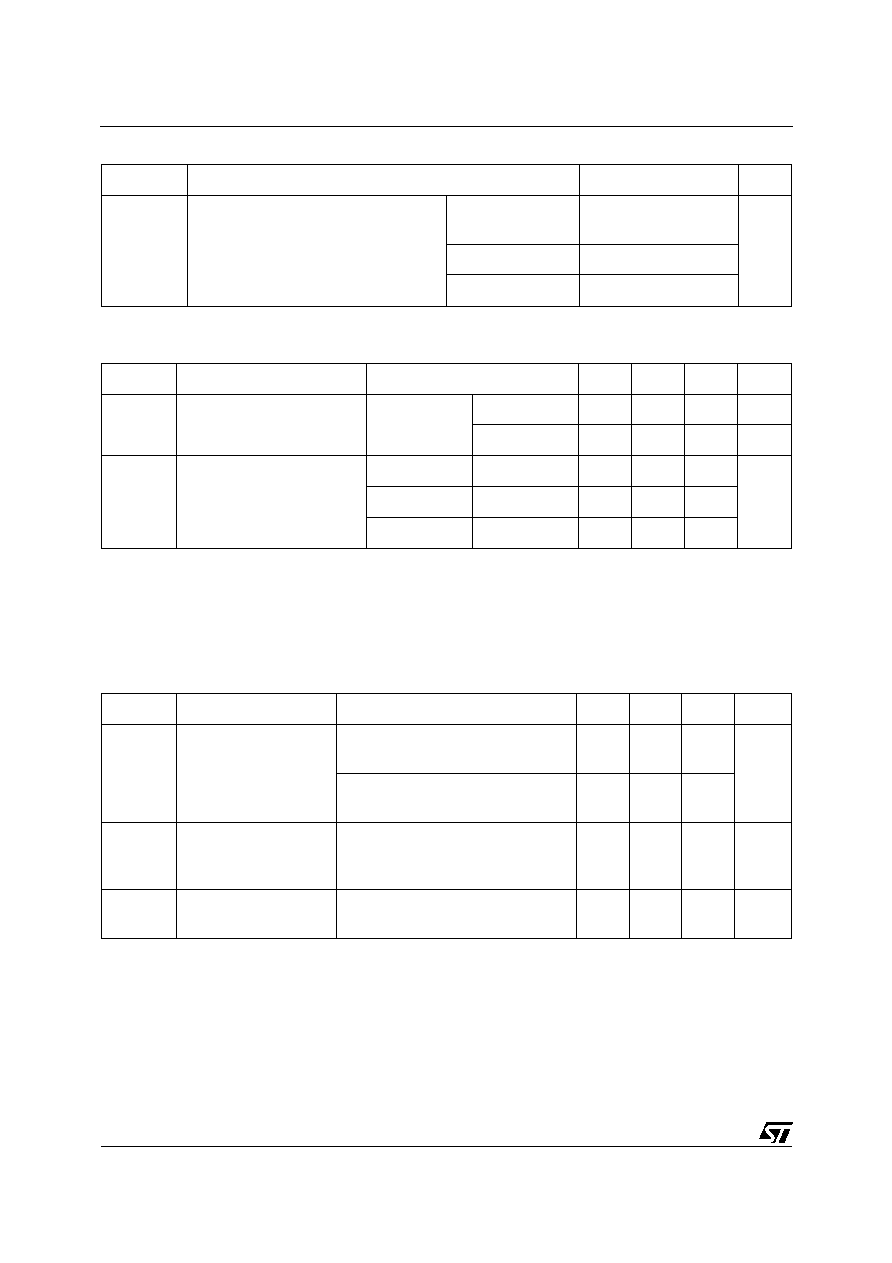

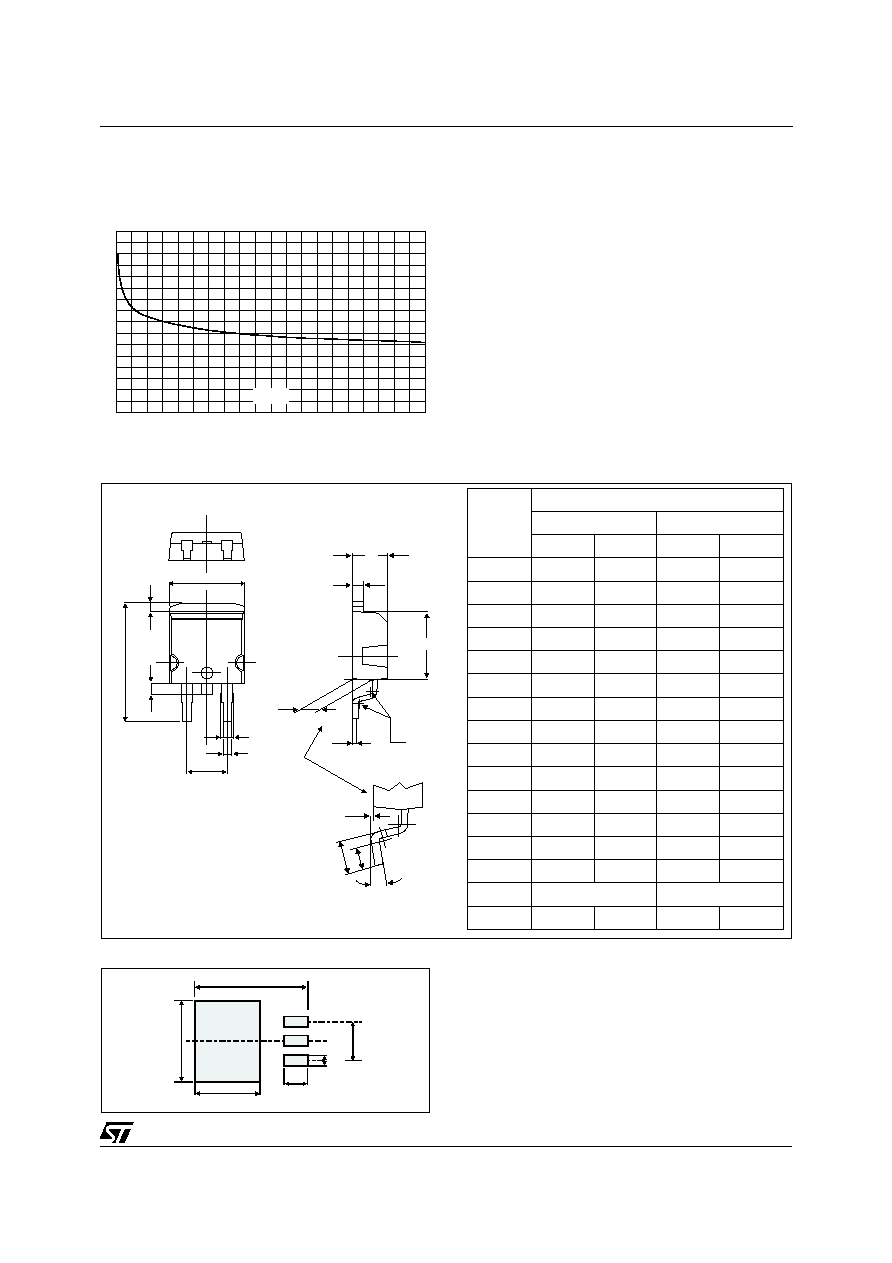

PACKAGE MECHANICAL DATA

D

2

PAK (Plastic)

A

C2

D

R

A2

M

V2

C

A1

G

L

L3

L2

B

B2

E

*

* FLAT ZONE NO LESS THAN 2mm

REF.

DIMENSIONS

Millimeters

Inches

Min.

Max.

Min.

Max.

A

4.40

4.60

0.173

0.181

A1

2.49

2.69

0.098

0.106

A2

0.03

0.23

0.001

0.009

B

0.70

0.93

0.027

0.037

B2

1.14

1.70

0.045

0.067

C

0.45

0.60

0.017

0.024

C2

1.23

1.36

0.048

0.054

D

8.95

9.35

0.352

0.368

E

10.00

10.40

0.393

0.409

G

4.88

5.28

0.192

0.208

L

15.00

15.85

0.590

0.624

L2

1.27

1.40

0.050

0.055

L3

1.40

1.75

0.055

0.069

M

2.40

3.20

0.094

0.126

R

0.40 typ.

0.016 typ.

V2

0į

8į

0į

8į

8.90

3.70

1.30

5.08

16.90

10.30

FOOT PRINT (in millimeters)

0

10

20

30

40

50

60

70

80

0

2

4

6

8

10

12

14

16

18

20

S(cm≤)

Rth(j-a)(įC/W)

Fig.11 : Thermal resistance junction to ambient

versus copper surface under tab (Epoxy printed

circuit board FR4, copper thickness: 35Ķm) for

D

2

PAK.