ISOTOP and TURBOSWITCH are trademarks of STMicroelectronics.

November 1999 - Ed: 4B

ULTRA-FAST, SOFT RECOVERY.

VERY LOW OVERALL POWER LOSSES IN

BOTH THE DIODE AND THE COMPANION

TRANSISTOR.

HIGH FREQUENCY AND/OR HIGH PULSED

CURRENT OPERATION.

HIGH REVERSE VOLTAGE CAPABILITY.

LOW INDUCTANCE PACKAGE < 5 nH.

INSULATED PACKAGE : ISOTOP

TM

Electrical insulation : 2500V

RMS

Capacitance : < 45pF.

FEATURES AND BENEFITS

TURBOSWITCH 1200V drastically cuts losses in

all high voltage operations which require extremely

fast, soft and noise-free power diodes. Due to their

optimized switching performances they also highly

decrease power losses in any associated

switching IGBT or MOSFET in all freewheel mode

operations.

They are particularly suitable in Motor Control

circuitries, or in the primary of SMPS as snubber,

clamping or demagnetizing diodes. They are also

suitable for secondary of SMPS as high voltage

rectifier diodes.

DESCRIPTION

I

F(AV)

25A

V

RRM

1200V

t

rr

(typ)

60ns

V

F

(max)

1.9V

MAIN PRODUCT CHARACTERISTICS

Symbol

Parameter

Value

Unit

V

RRM

Repetitive peak reverse voltage

1200

V

I

F(RMS)

RMS forward current

50

A

I

FRM

Repetitive peak forward current

tp = 5

�

s F = 5kHz square

300

A

I

FSM

Surge non repetitive forward current

tp = 10ms sinusoidal

210

A

T

stg

Storage temperature range

- 65 to + 150

�C

T

j

Maximum operating junction temperature

150

�C

ABSOLUTE RATINGS (limiting values, per diode)

STTA2512P

STTA5012TV1/2

�

TURBOSWITCH

TM

ULTRA-FAST HIGH VOLTAGE DIODE

ISOTOP

TM

K2

A2

K1

A1

STTA5012TV1

K2

K1

A1

A2

STTA5012TV2

K

K

A

SOD93

STTA2512P

1/9

Symbol

Parameter

Test conditions

Min

Typ

Max

Unit

t

rr

Reverse recovery

time

Tj = 25�C

I

F

= 0.5 A I

R

= 1A Irr = 0.25A

I

F

= 1 A dI

F

/dt =-50A/

�

s V

R

=30V

60

110

ns

I

RM

Maximum reverse

recovery current

Tj = 125�C VR = 600V I

F

=25A

dI

F

/dt = -200 A/

�

s

dI

F

/dt = -500 A/

�

s

45

35

A

S factor

Softness factor

Tj = 125�C V

R

= 600V I

F

=25A

dI

F

/dt = -500 A/

�

s

1.2

/

DYNAMIC ELECTRICAL CHARACTERISTICS (per diode)

TURN-OFF SWITCHING

Symbol

Parameter

Test conditions

Min

Typ

Max

Unit

t

fr

Forward recovery time

Tj = 25�C

I

F

=25 A, dI

F

/dt = 200 A/

�

s

measured at 1.1

�

V

F

max

900

ns

V

Fp

Peak forward voltage

Tj = 25�C

I

F

=25A, dI

F

/dt = 200 A/

�

s

I

F

=40A, dI

F

/dt = 500 A/

�

s

35

30

V

TURN-ON SWITCHING

Symbol

Parameter

Test conditions

Min

Typ

Max

Unit

V

F

*

Forward voltage drop

I

F

=25A

Tj = 25�C

Tj = 125�C

1.3

2.1

1.9

V

V

I

R

**

Reverse leakage current

V

R

=0.8 x

V

RRM

Tj = 25�C

Tj = 125�C

2.0

150

8

�

A

mA

V

to

Threshold voltage

Ip < 3.I

F(AV)

Tj = 125�C

1.52

V

R

d

Dynamic resistance

15

m

Test pulses :

* tp = 380

�

s,

< 2%

** tp = 5 ms ,

< 2%

STATIC ELECTRICAL CHARACTERISTICS (per diode)

To evaluate the maximum conduction losses use the following equation :

P = V

to

x I

F(AV)

+ Rd x I

F

2

(RMS)

Symbol

Parameter

Conditions

Value

Unit

R

th(j-c)

Junction to case thermal

resistance

ISOTOP

Per diode

1.4

�C/W

ISOTOP

Total

0.75

SOD93

1.2

R

th(c)

Coupling thermal resistance

ISOTOP

Coupling

0.1

�C/W

P

1

Conduction power dissipation

I

F(AV)

= 25A

=0.5

ISOTOP

Tc= 70�C

57

W

SOD93

Tc= 82�C

P

max

Total power dissipation

Pmax = P1 + P3 (P3 = 10% P1)

ISOTOP

Tc= 62�C

62.5

W

SOD93

Tc= 75�C

THERMAL AND POWER DATA (per diode)

STTA2512P / STTA5012TV1/2

2/9

0

5

10

15

20

25

30

0

10

20

30

40

50

60

IF(av) (A)

P1(W)

= 1

= 0.5

= 0.2

= 0.1

T

=tp/T

tp

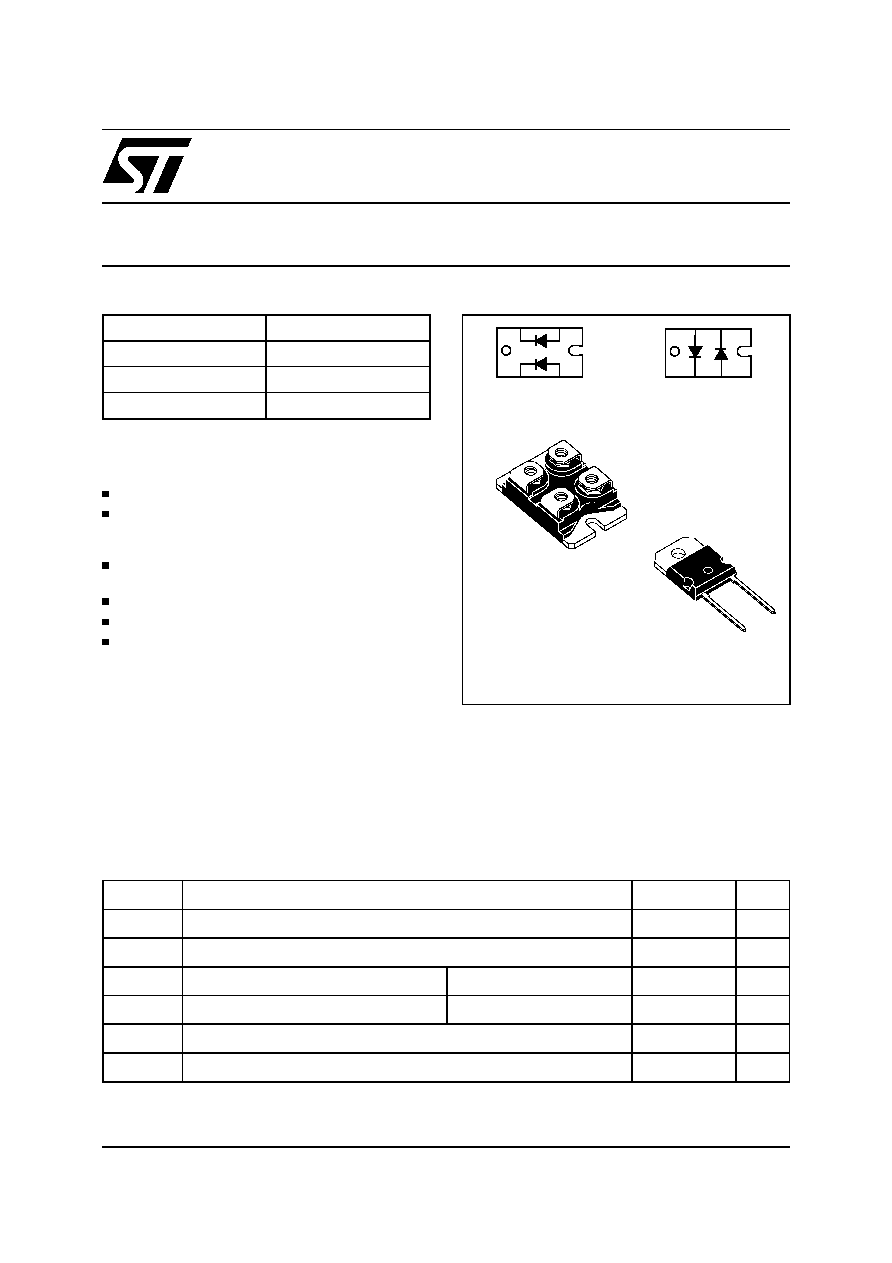

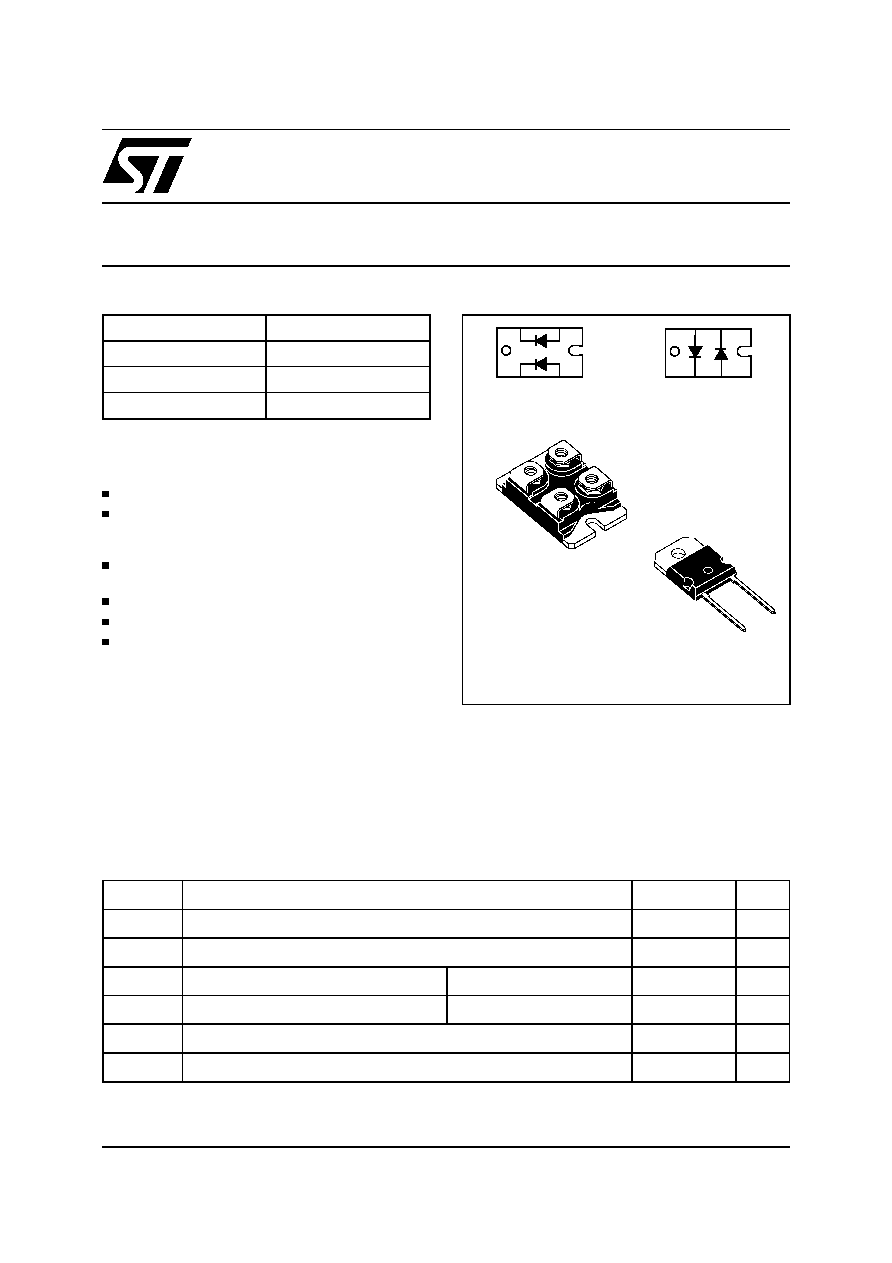

Fig. 1: Conduction losses versus average current

(per diode).

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

1

10

100

300

VFM(V)

IFM(A)

Tj=125�C

Fig. 2: Forward voltage drop versus forward

current (maximum values, per diode).

1E-3

1E-2

1E-1

1E+0

5E+0

0.0

0.2

0.4

0.6

0.8

1.0

tp(s)

Zth(j-c)/Rth(j-c)

= 0.2

= 0.5

Single pulse

= 0.1

Fig. 3-1: Relative variation of thermal impedance

junction to case versus pulse duration (per diode)

(ISOTOP).

1E-4

1E-3

1E-2

1E-1

1E+0

0.0

0.2

0.4

0.6

0.8

1.0

tp(s)

Zth(j-c)/Rth(j-c)

= 0.1

= 0.2

= 0.5

Single pulse

Fig. 3-2: Relative variation of thermal impedance

junction to case versus pulse duration (SOD93).

0

100

200

300

400

500

0

50

100

150

200

250

300

350

400

450

500

trr(ns)

VR=600V

Tj=125�C

IF=2*IF(av)

IF=IF(av)

IF=0.5*IF(av)

dIF/dt(A/�s)

Fig. 5: Reverse recovery time versus dI

F

/dt (90%

confidence, per diode).

0

100

200

300

400

500

0

5

10

15

20

25

30

35

40

45

50

55

IRM(A)

VR=600V

Tj=125�C

IF=2*IF(av)

IF=0.5*IF(av)

IF=IF(av)

dIF/dt(A/�s)

Fig. 4: Peak reverse recovery current versus dI

F

/dt

(90% confidence, per diode).

STTA2512P / STTA5012TV1/2

3/9

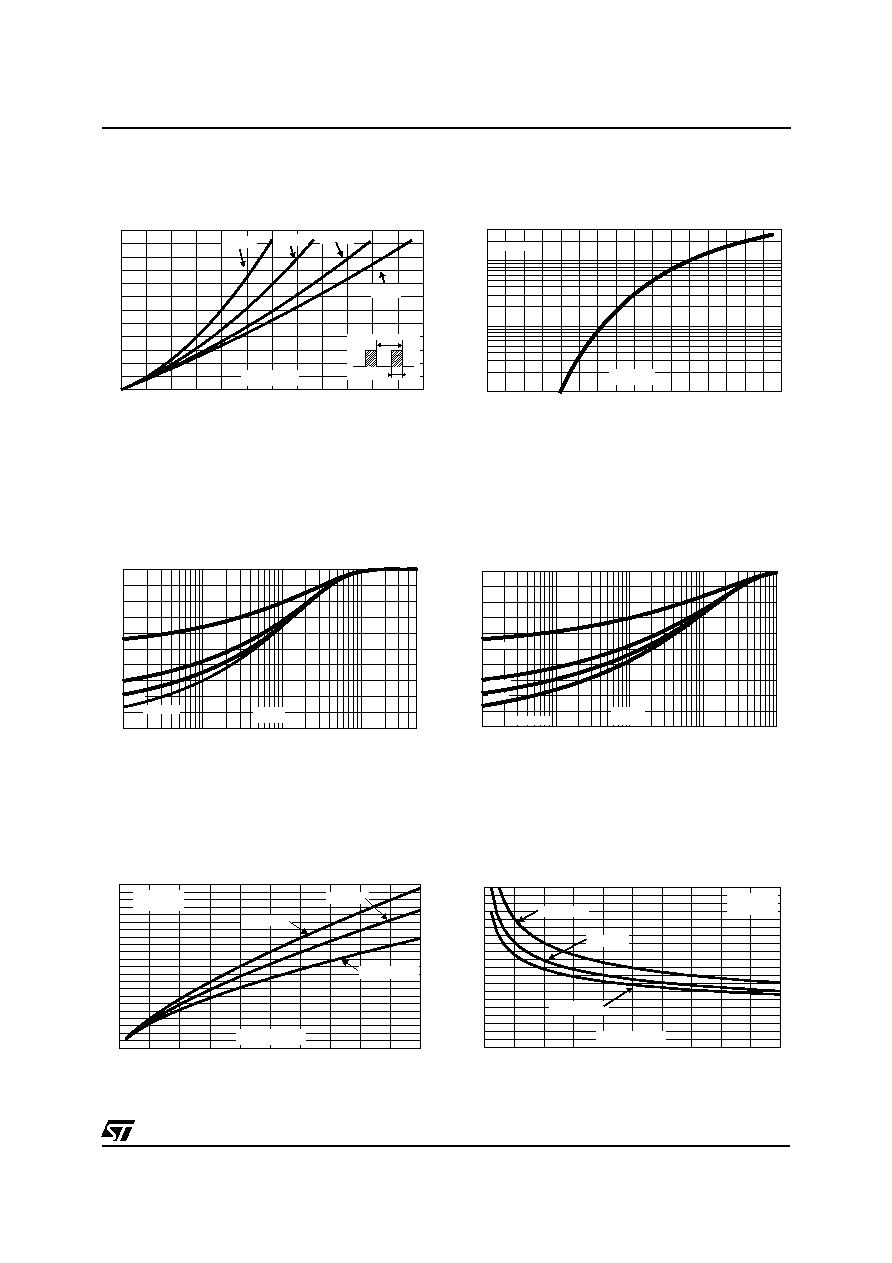

0

100

200

300

400

500

0.80

1.00

1.20

1.40

1.60

S factor

IF<2*IF(av)

VR=600V

Tj=125�C

dIF/dt(A/�s)

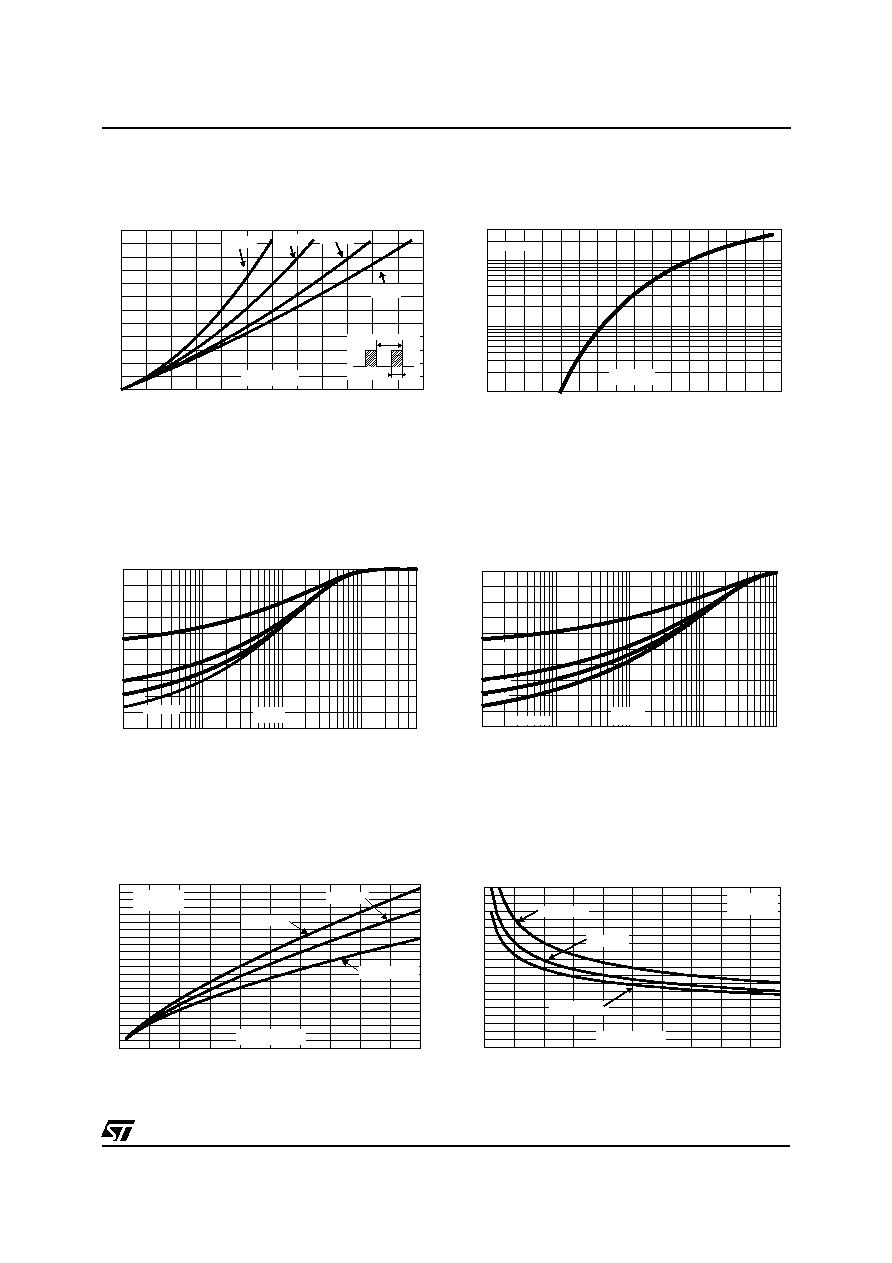

Fig. 6: Softness factor (tb/ta) versus dI

F

/dt (typical

values, per diode).

25

50

75

100

125

0.7

0.8

0.9

1.0

1.1

Tj(�C)

IRM

S factor

Fig. 7: Relative variation of dynamic parameters

versus junction temperature (reference Tj=125�C).

0

100

200

300

400

500

0

10

20

30

40

50

60

VFP(V)

Tj=125�C

IF=IF(av)

dIF/dt(A/�s)

Fig. 8: Transient peak forward voltage versus

dI

F

/dt (90% confidence, per diode).

0

100

200

300

400

500

200

400

600

800

1000

1200

1400

tfr(ns)

Tj=125�C

VFR=1.1*VF max.

IF=IF(av)

dIF/dt(A/�s)

Fig. 9: Forward recovery time versus dI

F

/dt (90%

confidence, per diode).

STTA2512P / STTA5012TV1/2

4/9

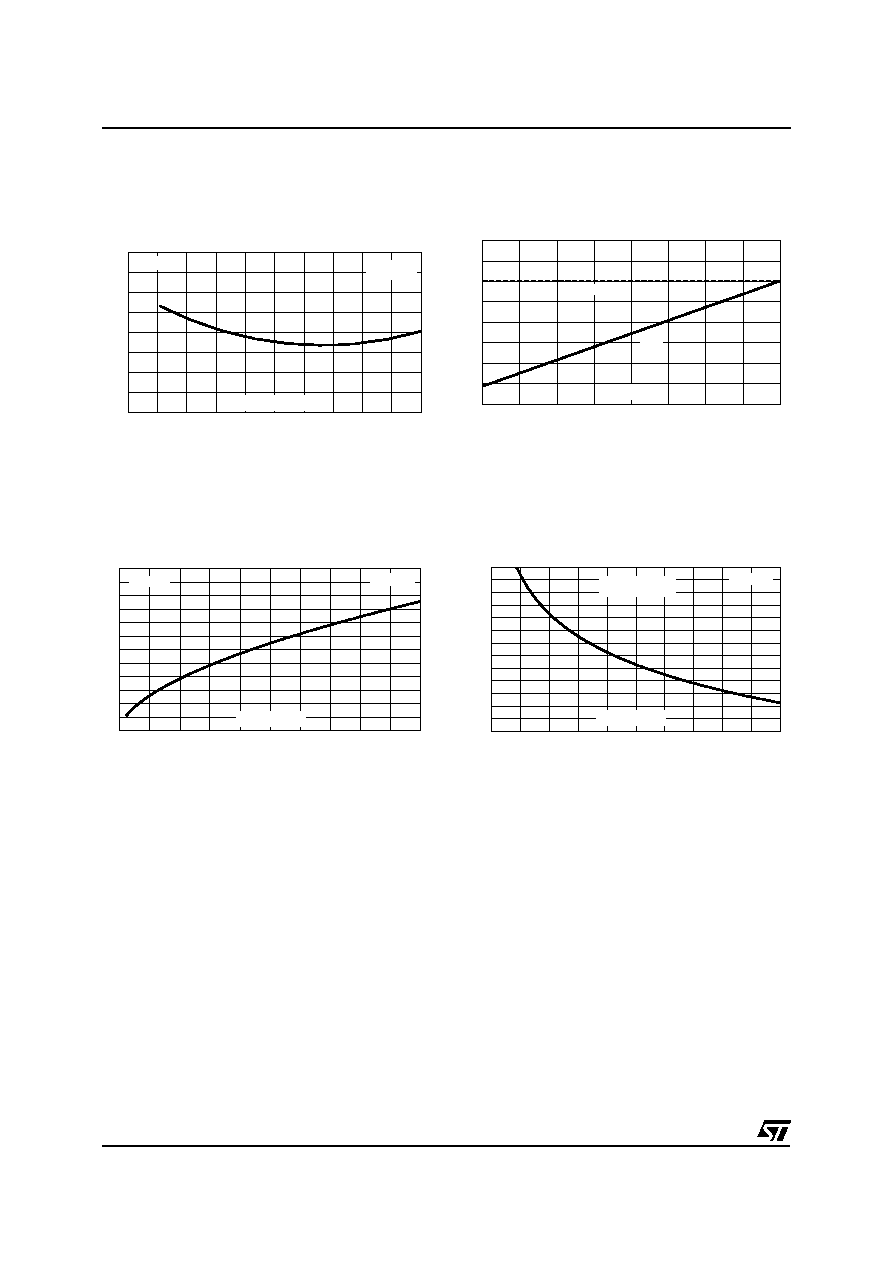

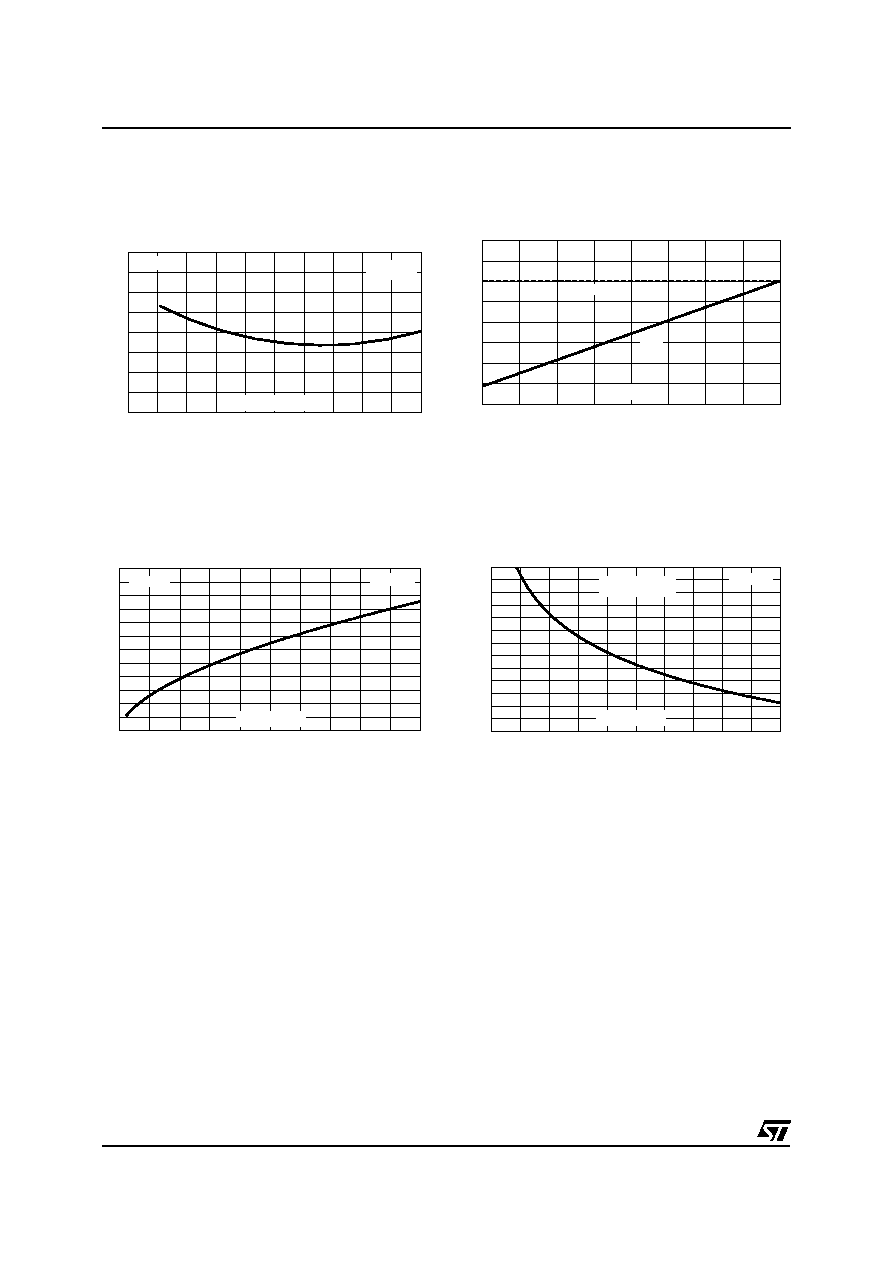

Fig. A : "FREEWHEEL" MODE.

TOTAL LOSSES

due to the diode

P = P1+ P2+ P3+ P4+ P5 Watts

SWITCHING

LOSSES

in the diode

SWITCHING

LOSSES

in the tansistor

due to the diode

CONDUCTION

LOSSES

in the diode

REVERSE

LOSSES

in the diode

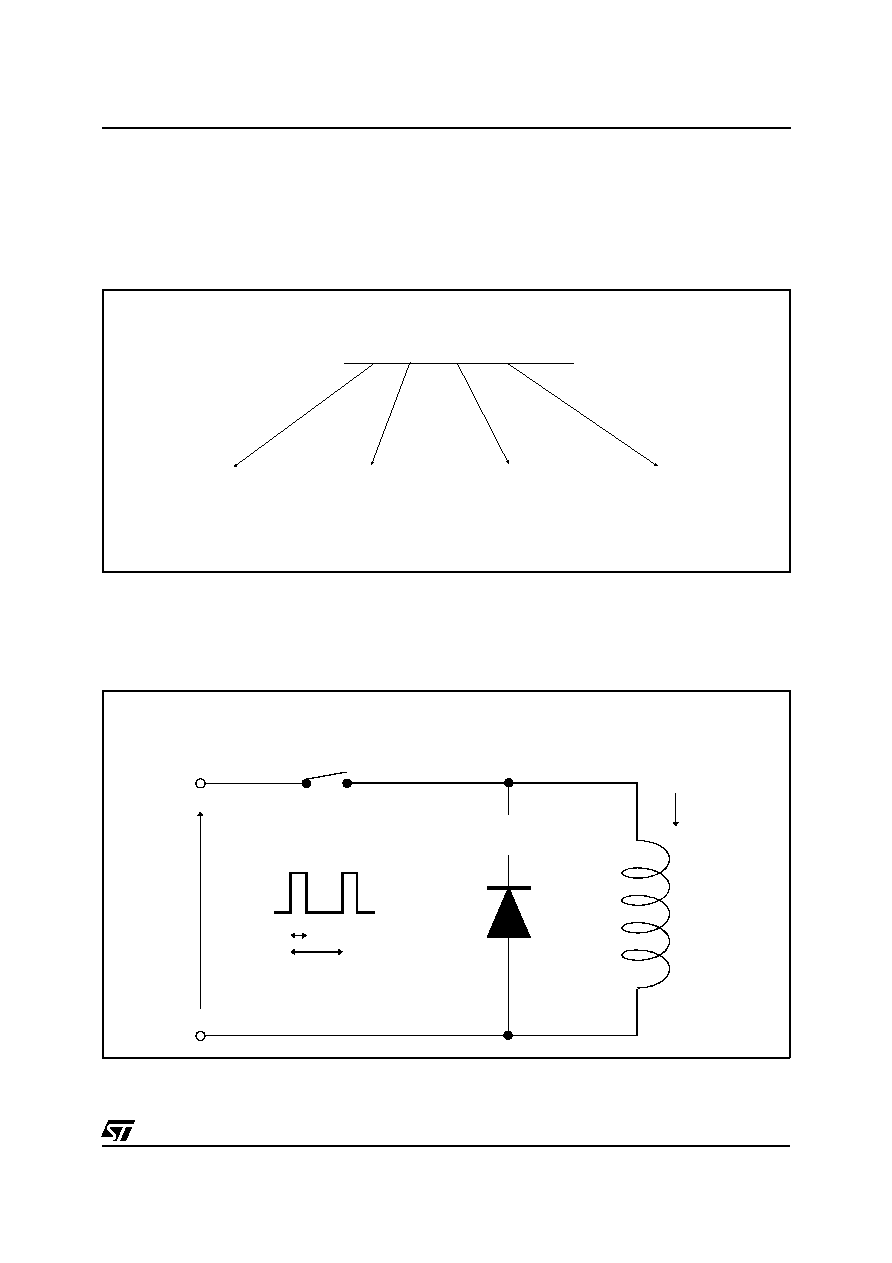

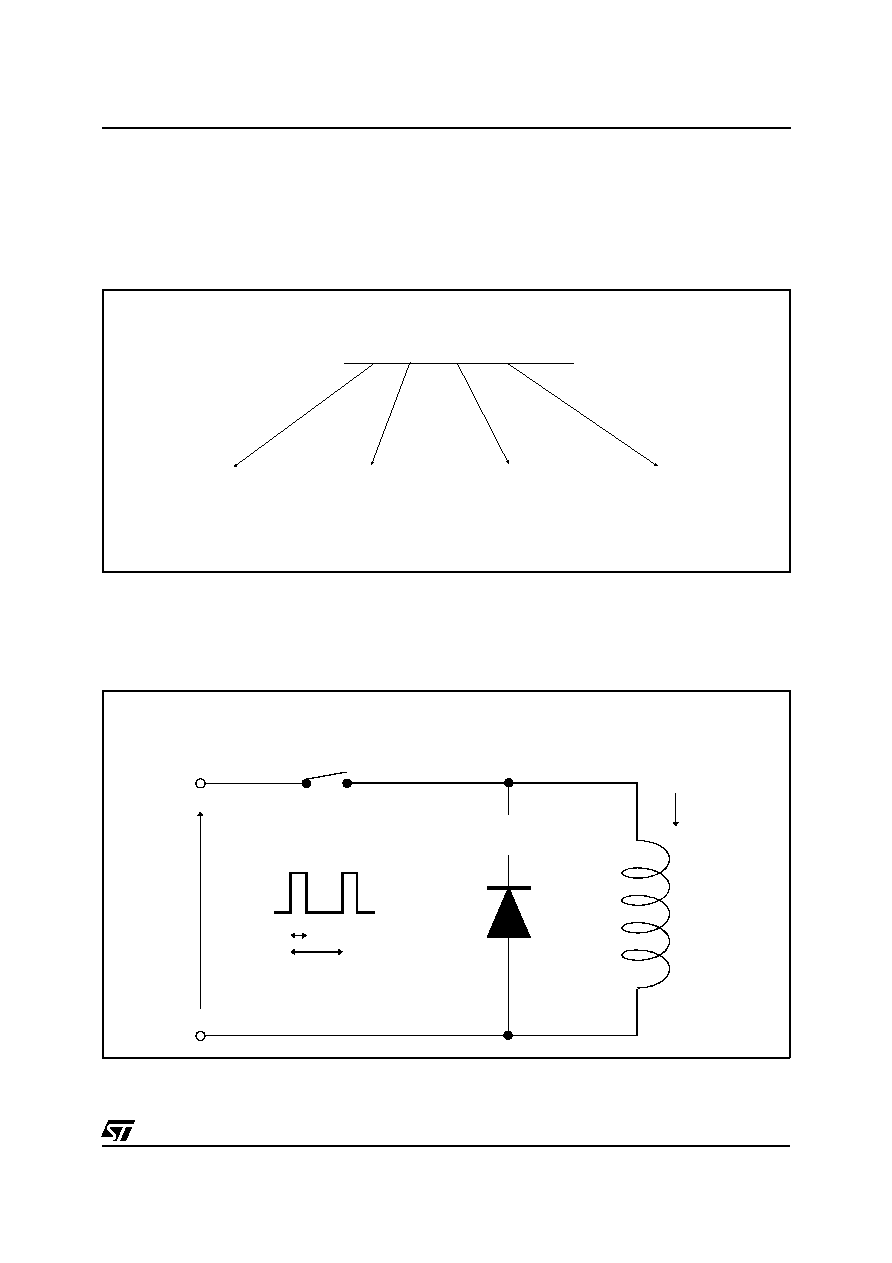

The 1200V TURBOSWITCH series has been

designed to provide the lowest overall power

losses in all high frequency or high pulsed current

operations. In such applications (Fig A to D),the

way of calculating the power losses is given below :

APPLICATION DATA

DIODE:

TURBOSWITCH

IL

LOAD

TRANSISTOR

SWITCHING

tp

T

F = 1/T

= tp/T

VR

STTA2512P / STTA5012TV1/2

5/9