| –≠–Ľ–Ķ–ļ—ā—Ä–ĺ–Ĺ–Ĺ—č–Ļ –ļ–ĺ–ľ–Ņ–ĺ–Ĺ–Ķ–Ĺ—ā: OPA561 | –°–ļ–į—á–į—ā—Ć:  PDF PDF  ZIP ZIP |

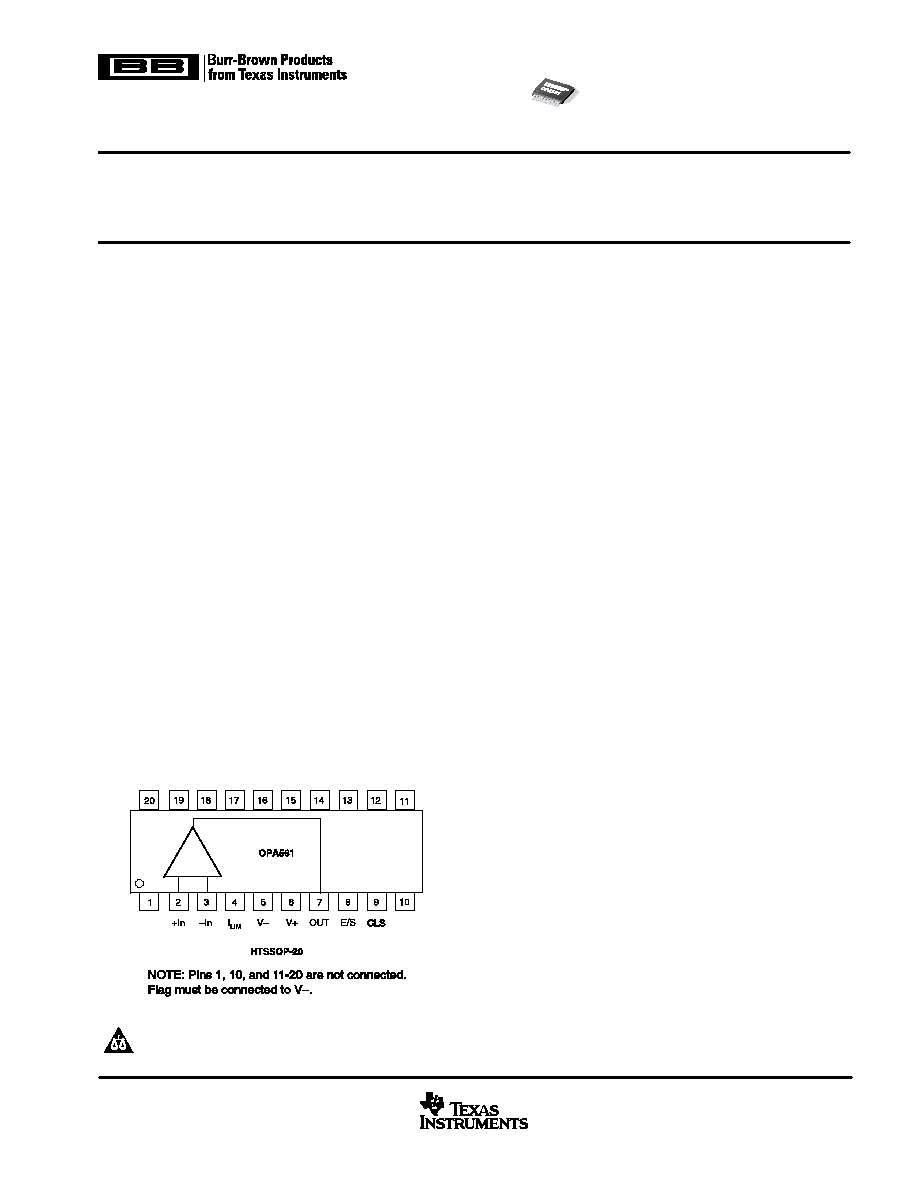

OPA561

SBOS206A ≠ DECEMBER 2001 ≠ REVISED JUNE 2002

High≠Current, High≠Speed

OPERATIONAL AMPLIFIER

1

www.ti.com

FEATURES

D

1.2A OUTPUT CURRENT

D

12Vp≠p OUTPUT VOLTAGE

D

WIDE POWER RANGE:

Single Supply: +7V to +15V

Dual Supply:

Ī

3.5V to

Ī

7.5V

D

FULLY PROTECTED:

Thermal Shutdown

Adjustable Current Limit

D

OUTPUT DISABLE CONTROL

D

17MHz GAIN≠BANDWIDTH PRODUCT

D

50V/

Ķ

s SLEW RATE

D

1MHz FULL≠POWER BANDWIDTH

D

THERMALLY ENHANCED HTSSOP≠20

PowerPAD PACKAGE

APPLICATIONS

D

POWER≠LINE COMMUNICATIONS

D

VALVE≠ACCUATOR DRIVERS

D

POWER SUPPLIES

D

TEST EQUIPMENT

D

TEC DRIVERS

D

LASER DIODE DRIVERS

DESCRIPTION

The OPA561 is a low≠cost, high≠current operational

amplifier capable of driving up to 1.2A pulses into reactive

loads. This monolithic integrated circuit provides high

reliability in demanding line≠carrier communications, laser

diode drivers, and motor control applications. The high

slew rate provides 1MHz full≠power bandwidth and

excellent linearity.

The OPA561 operates from either a single supply in the

range of 7V to 15V or dual power supplies of

Ī

3.5V to

Ī

7.5V for design flexibility. In single≠supply operation, the

input common≠mode range extends below ground. At

maximum output current, a wide output swing provides a

12Vp≠p capability with a nominal 15V supply.

The OPA561 is internally protected against over≠tempera-

ture conditions and current overloads. In addition, the

OPA561 is designed to provide an accurate, user≠se-

lected, current limit. The current limit can be adjusted from

0.2A to 1.2A with a low≠power resistor/potentiometer or

DAC (Digital≠to≠Analog Converter). The high≠speed

characteristics of the current control loop provide accuracy

even under pulsed load conditions.

The Enable/Status (E/S) pin performs two functions: it can

be monitored to determine if the device is in thermal

shutdown (active LOW), and it can also be forced LOW to

disable the output, disconnecting the load.

The OPA561 is available in the miniature, HTSSOP≠20

PowerPAD

, power package. This surface≠mount

package is thermally enhanced and has a very low thermal

resistance. Operation is specified over the extended

industrial temperature range, ≠40

_

C to +125

_

C.

PowerPAD is a registered trademark of Texas Instruments Incorporated

.

Copyright

2001, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments

semiconductor products and disclaimers thereto appears at the end of this data sheet.

OPA561

SBOS206A ≠ DECEMBER 2001 ≠ REVISED JUNE 2002

2

www.ti.com

ABSOLUTE MAXIMUM RATINGS

(1)

Supply Voltage, V≠ to V+

16V

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Voltage Range

(V≠) ≠ 0.4V to (V+) + 0.5V

. . . . . . . . . . . . . . . .

Input Shutdown Voltage

(V≠) ≠ 0.4V to (V≠) + 5.0V

. . . . . . . . . . . . . .

Operating Temperature

≠40

į

C to +125

į

C

. . . . . . . . . . . . . . . . . . . .

Storage Temperature

≠65

į

C to +150

į

C

. . . . . . . . . . . . . . . . . . . . .

Junction Temperature

150

į

C

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead Temperature (soldering, 10s)

300

į

C

. . . . . . . . . . . . . . . . . . . .

NOTE: (1) Stresses above these ratings may cause permanent damage.

Exposure to absolute maximum conditions for extended periods may degrade

device reliability. These are stress ratings only, and functional operation of the

device at these or any other conditions beyond those specified is not implied.

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Texas

Instruments recommends that all integrated circuits be

handled with appropriate precautions. Failure to ob-

serve proper handling and installation procedures can

cause damage.

ESD damage can range from subtle performance

degradation to complete device failure. Precision

integrated circuits may be more susceptible to damage

because very small parametric changes could cause

the device not to meet its published specifications.

PACKAGE/ORDERING INFORMATION

PRODUCT

PACKAGE≠LEAD

PACKAGE

DESIGNATOR(1)

SPECIFIED

TEMPERATURE

RANGE

PACKAGE

MARKING

ORDERING

NUMBER

TRANSPORT

MEDIA, QUANTITY

OPA561PWP

HTSSOP 20

PWP

40

į

C to +125

į

C

OPA561

OPA561PWP

Rail, 70

OPA561PWP

HTSSOP≠20

PWP

≠40

į

C to +125

į

C

OPA561

OPA561PWP/2K

Tape and Reel, 2000

NOTE: (1) For the most current specification and package information, refer to our web site at www.ti.com.

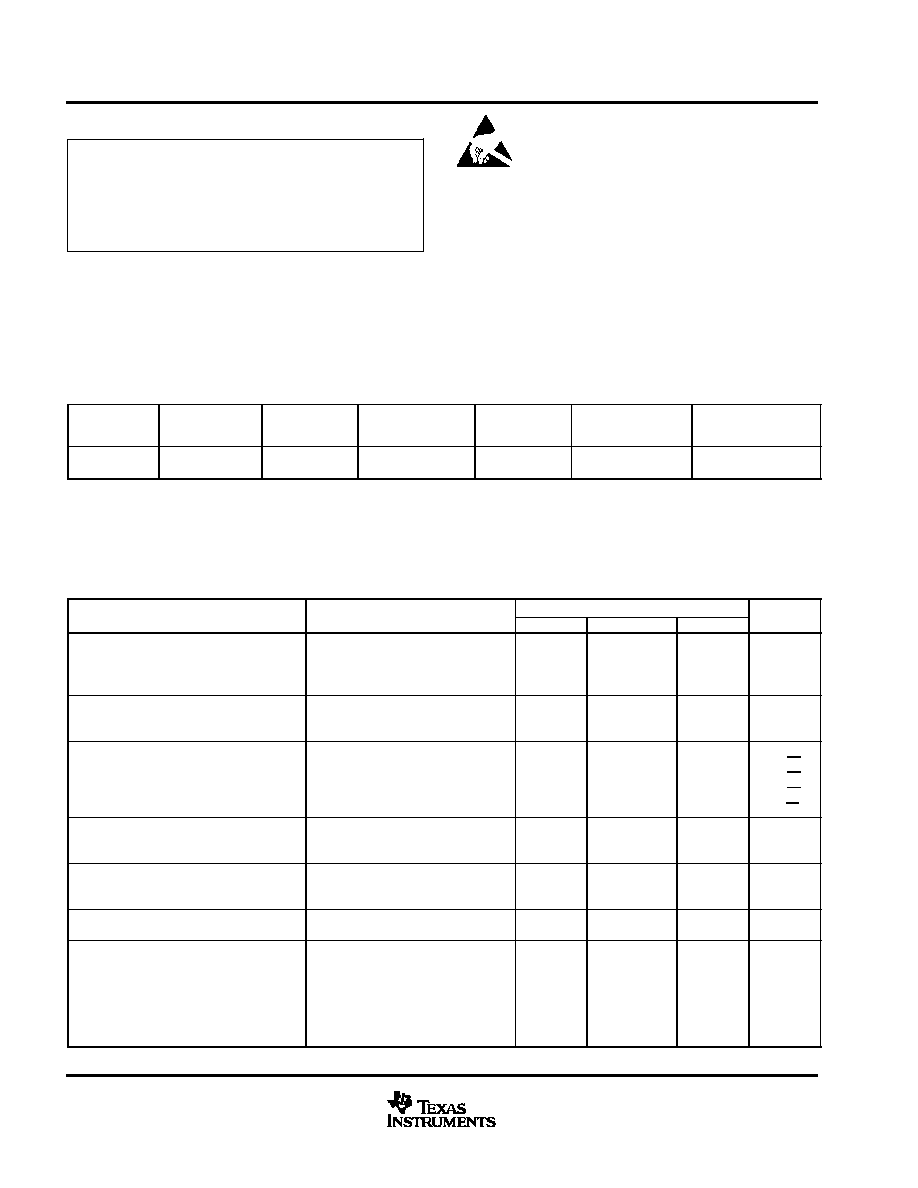

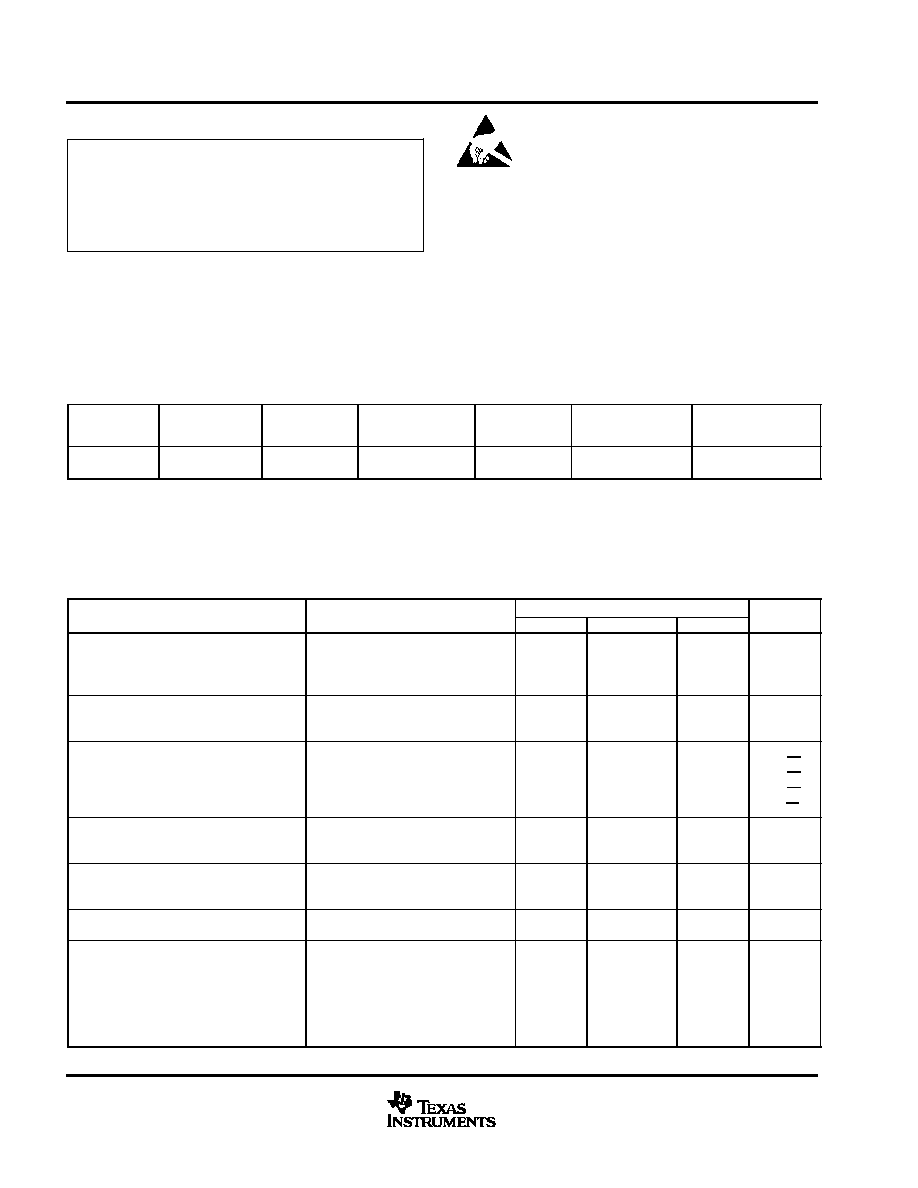

ELECTRICAL CHARACTERISTICS

BOLDFACE limits apply over the specified temperature range, T

A

= ≠40

į

C to +125

į

C

At TCASE = +25

į

C, VS = 15V, load connected to VS/2, and E/S enabled, unless otherwise noted.

OPA561PWP

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

OFFSET VOLTAGE

VS = 12V

Input Offset Voltage

VOS

VCM = 0V

Ī

1

Ī

20

mV

vs Temperature

dVOS/dT

Ī

50

Ķ

V/

į

C

vs Power Supply

PSRR

VCM = 0V, VS = 7V to 16V

25

150

Ķ

V/V

INPUT BIAS CURRENT(1)

Input Bias Current

IB

VCM = 0V

10

100

pA

Input Offset Current

IOS

VCM = 0V

10

100

pA

NOISE

Input Voltage Noise Density

en

f = 1kHz

83

nV/

Hz

f = 10kHz

32

nV/

Hz

f = 100kHz

14

nV/

Hz

Current Noise

in

f = 1kHz

4

fA/

Hz

INPUT VOLTAGE RANGE

Common≠Mode Voltage Range

VCM

Linear Operation

(V≠) ≠ 0.1

(V+) ≠ 3

V

Common≠Mode Rejection Ratio

CMRR VS = 15V, VCM = (V≠) ≠ 0.1V to (V+) ≠ 3V

70

80

dB

INPUT IMPEDANCE

Differential

1.8

S

1011 || 10

|| pF

Common≠Mode

1.8

S

1011 || 18.5

|| pF

OPEN≠LOOP GAIN

Open≠Loop Voltage Gain

AOL

VO = 10Vp≠p, RL = 5

80

100

dB

FREQUENCY RESPONSE

Gain≠Bandwidth Product

GBW

RL = 5

17

MHz

Slew Rate

SR

G = 1, 10V Step, RL = 5

50

V/

Ķ

s

Full≠Power Bandwidth

G = +2, VOUT = 10Vp≠p

1

MHz

Settling Time:

Ī

0.1%

G = ≠1, 10V Step

1

Ķ

s

Total Harmonic Distortion + Noise

THD+N

f = 1kHz, RL = 5

, G = +2, VO = 10Vp≠p

0.02

%

f = 1MHz

3

%

OPA561

SBOS206A ≠ DECEMBER 2001 ≠ REVISED JUNE 2002

3

www.ti.com

ELECTRICAL CHARACTERISTICS

(Cont.)

BOLDFACE limits apply over the specified temperature range, T

A

= ≠40

į

C to +125

į

C

At TCASE = +25

į

C, VS = 15V, load connected to VS/2, and E/S enabled, unless otherwise noted.

OPA561PWP

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

OUTPUT

Voltage Output, Positive

IO = 0.5A

(V+) ≠ 1

(V+) ≠ 0.7

V

Negative

IO = ≠0.5A

(V≠) + 1

(V≠) + 0.7

V

Positive

IO = 1A

(V+) ≠ 1.5

(V+) ≠ 1.2

V

Negative

IO = ≠1A

(V≠) + 1.5

(V≠) + 1.2

V

Maximum Continuous Current Output, dc

1.2

A

Output Impedance

ZO

G = +2, f = 100kHz

0.05

Ouput Current Limit Range

Ī

0.2 to

Ī

1.2

A

Current Limit Tolerance(2)

RCL = 2k

(ILIM =

Ī

1A)

Ī

50

mA

Asymmetry

Comparing Positive and Negative Limits

10

%

Current Limit Overshoot(3)

V = 5V Pulse (200ns tr), G = +2

50

%

Output Disabled

Output Resistance

10

M

Output Capacitance

140

pF

OUTPUT ENABLE/STATUS AND FLAG PINS

Shutdown Input Mode

VE/S HIGH (output enabled)(4)

E/S Pin Open or Forced HIGH

(V≠) + 2

(V≠) + 5

V

VE/S LOW (output disabled)

E/S Pin Forced LOW

(V≠) ≠ 0.4

(V≠) + 0.8

V

IE/S HIGH (output enabled)

E/S Pin Indicates HIGH

20

Ķ

A

IE/S LOW (output disabled)

E/S Pin Indicates LOW

0.1

Ķ

A

Output Disable Time

50

ns

Output Enable Time

3

Ķ

s

Thermal Shutdown Status

Normal Operation

Sourcing 20

Ķ

A

(V≠) + 2

V

Thermally Shutdown

(V≠) + 0.8

V

Current Limit Status

Normal Operation

Sourcing 20

Ķ

A

(V≠) + 0.8

V

Current Limit Flagged

(V≠) + 2

V

Junction Temperature at Shutdown

160

į

C

Reset Temperature from Shutdown

140

į

C

POWER SUPPLY

Specified Voltage

VS

15

V

Operating Voltage Range, (V+) ≠ (V≠)

7

16

V

Quiescent Current

IQ

ILIM Connected to V≠, IQ = 0

50

60

mA

vs Temperature

60

70

mA

Quiescent Current in Shutdown Mode

ILIM Connected to V≠

250

Ķ

A

TEMPERATURE RANGE

Specified Junction Temperature Range

≠40

+125

į

C

Storage Range

≠65

+150

į

C

Thermal Resistance

HTSSOP≠20 PowerPAD

JC

1.4

į

C/W

JA

2oz. Trace and 9in2 Copper Pad with Solder

32

į

C/W

JA

Without Heatsink

100

į

C/W

NOTES: (1) High≠speed test at TJ = +25

į

C. (2) See text for more information on on current limit accuracy. (3) Transient load transition time must be

200ns. (4) 402k

pull≠up resistor to V+ can be used to permanently enable the OPA561.

OPA561

SBOS206A ≠ DECEMBER 2001 ≠ REVISED JUNE 2002

4

www.ti.com

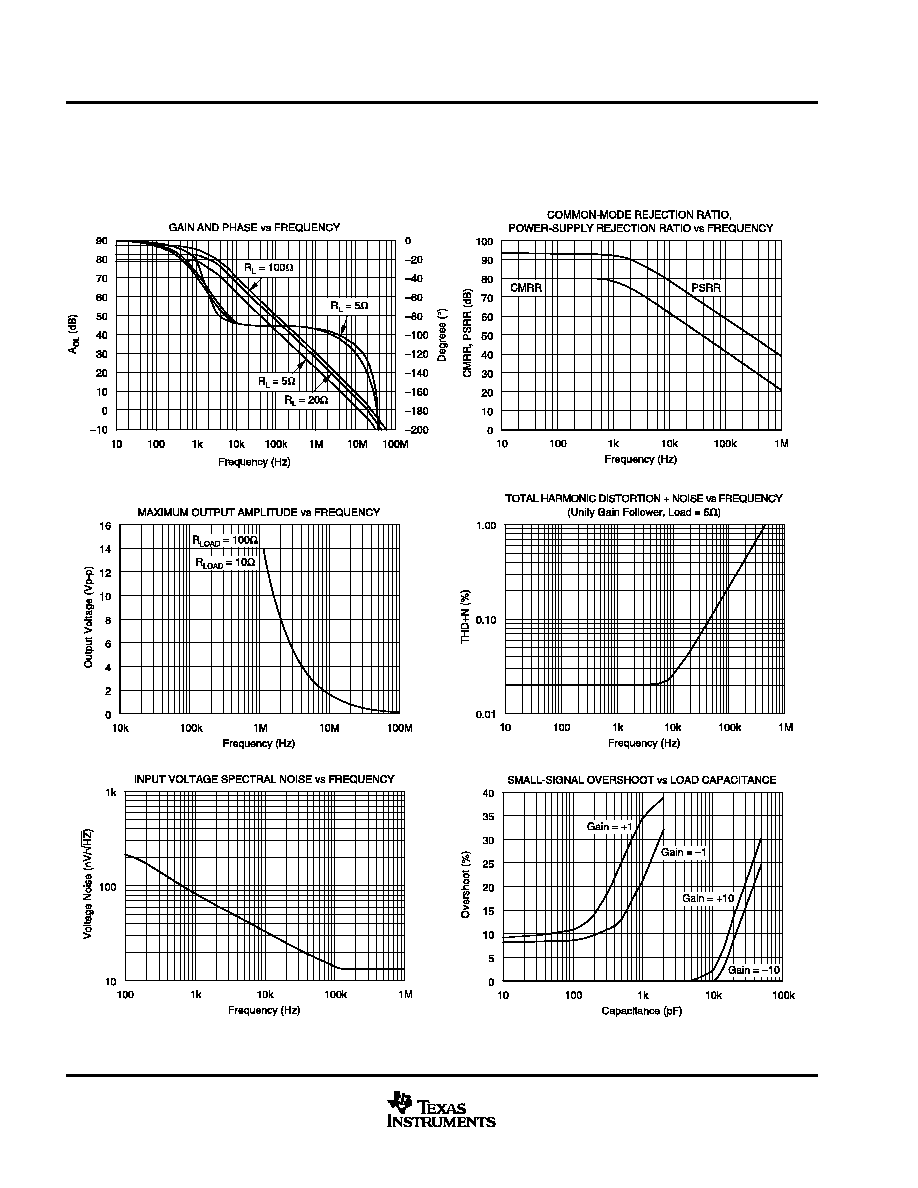

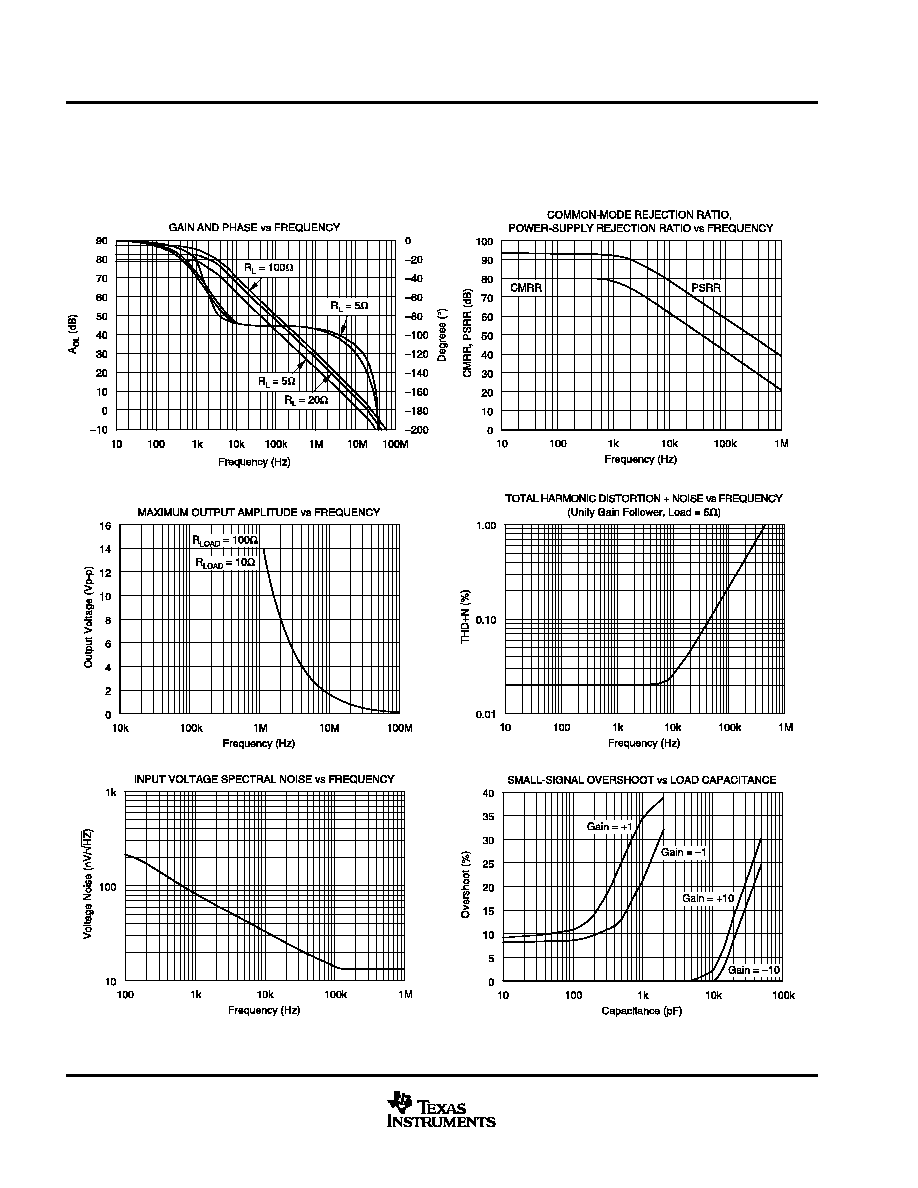

TYPICAL CHARACTERISTICS

At TCASE = +25

į

C, VS = 15V, and enabled, unless otherwise noted.

OPA561

SBOS206A ≠ DECEMBER 2001 ≠ REVISED JUNE 2002

5

www.ti.com

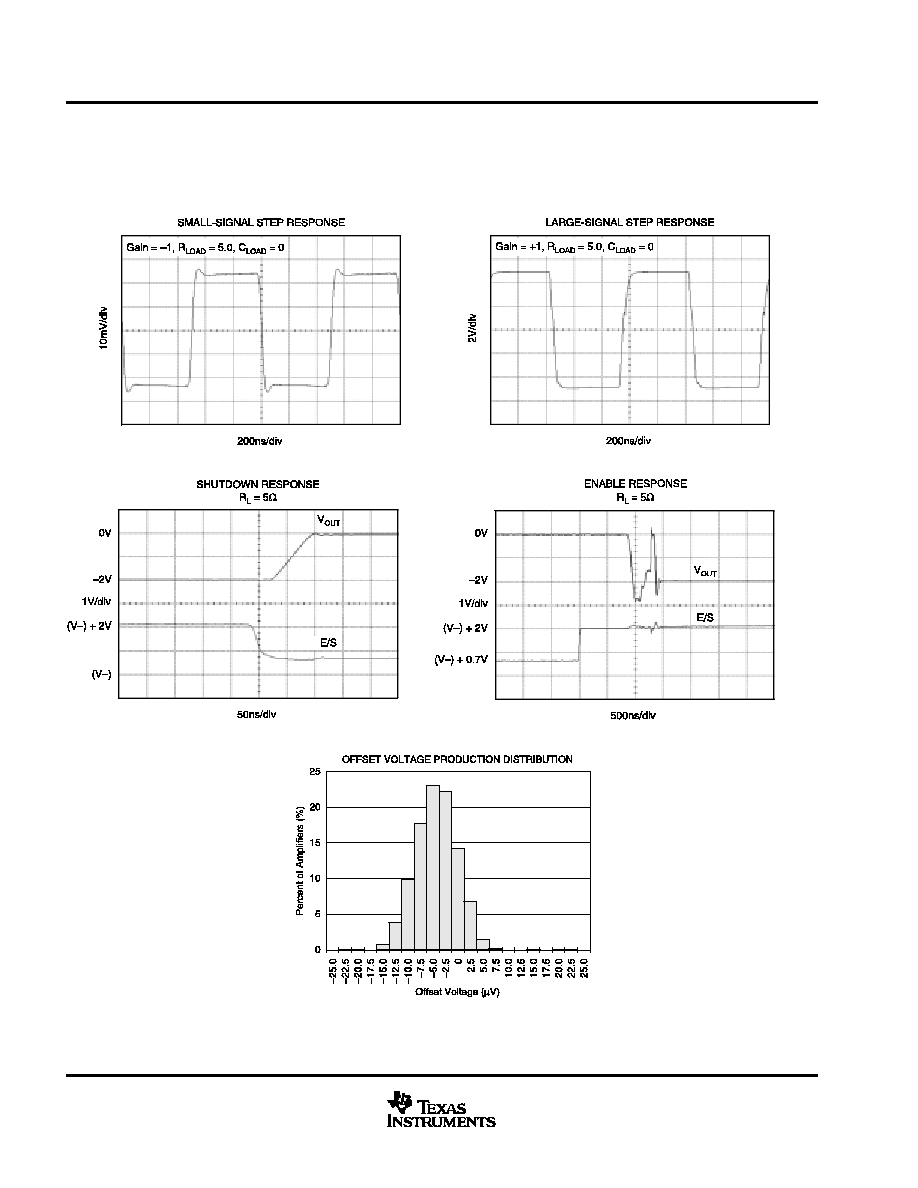

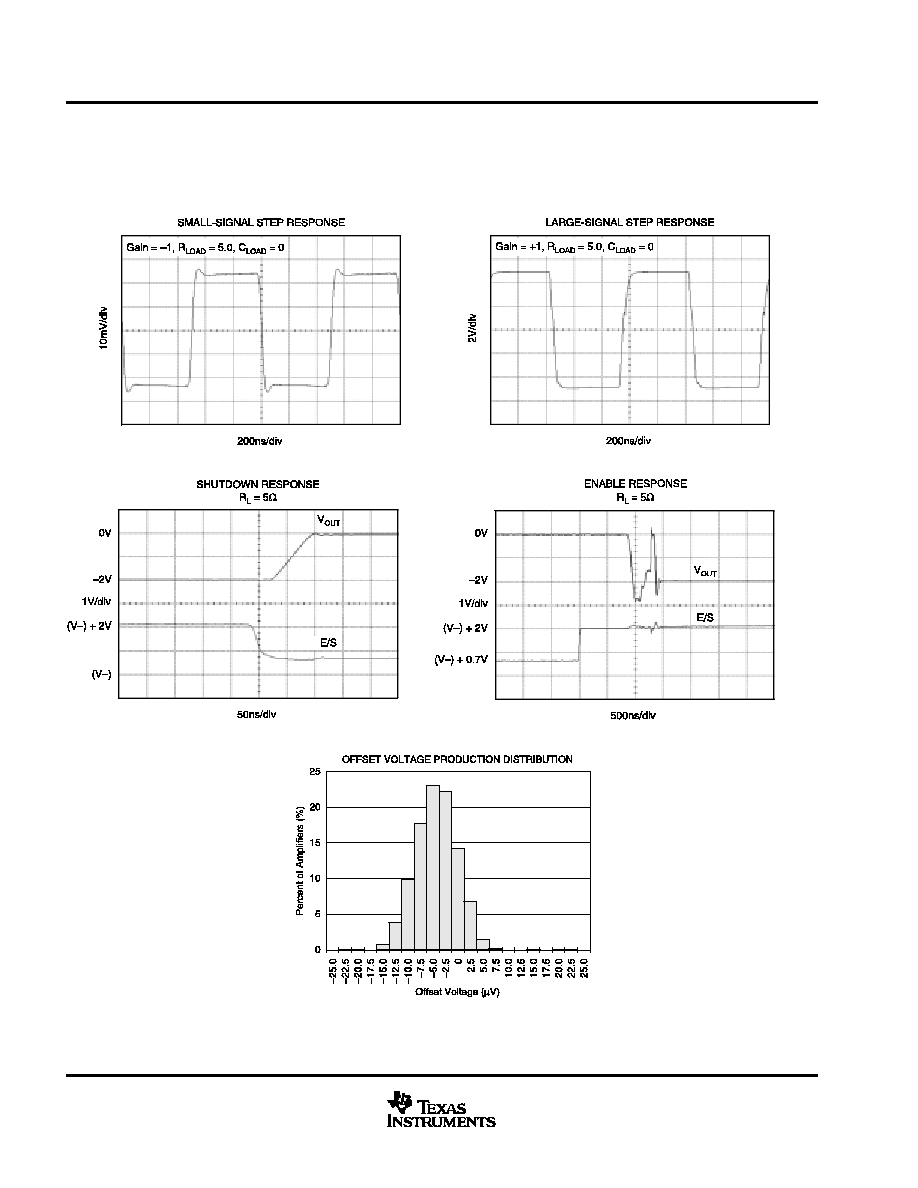

TYPICAL CHARACTERISTICS (Cont.)

At TCASE = +25

į

C, VS = 15V, and E/S enabled, unless otherwise noted.

OPA561

SBOS206A ≠ DECEMBER 2001 ≠ REVISED JUNE 2002

6

www.ti.com

TYPICAL CHARACTERISTICS (Cont.)

At TCASE = +25

į

C, VS = 15V, and E/S enabled, unless otherwise noted.

OPA561

SBOS206A ≠ DECEMBER 2001 ≠ REVISED JUNE 2002

7

www.ti.com

APPLICATIONS INFORMATION

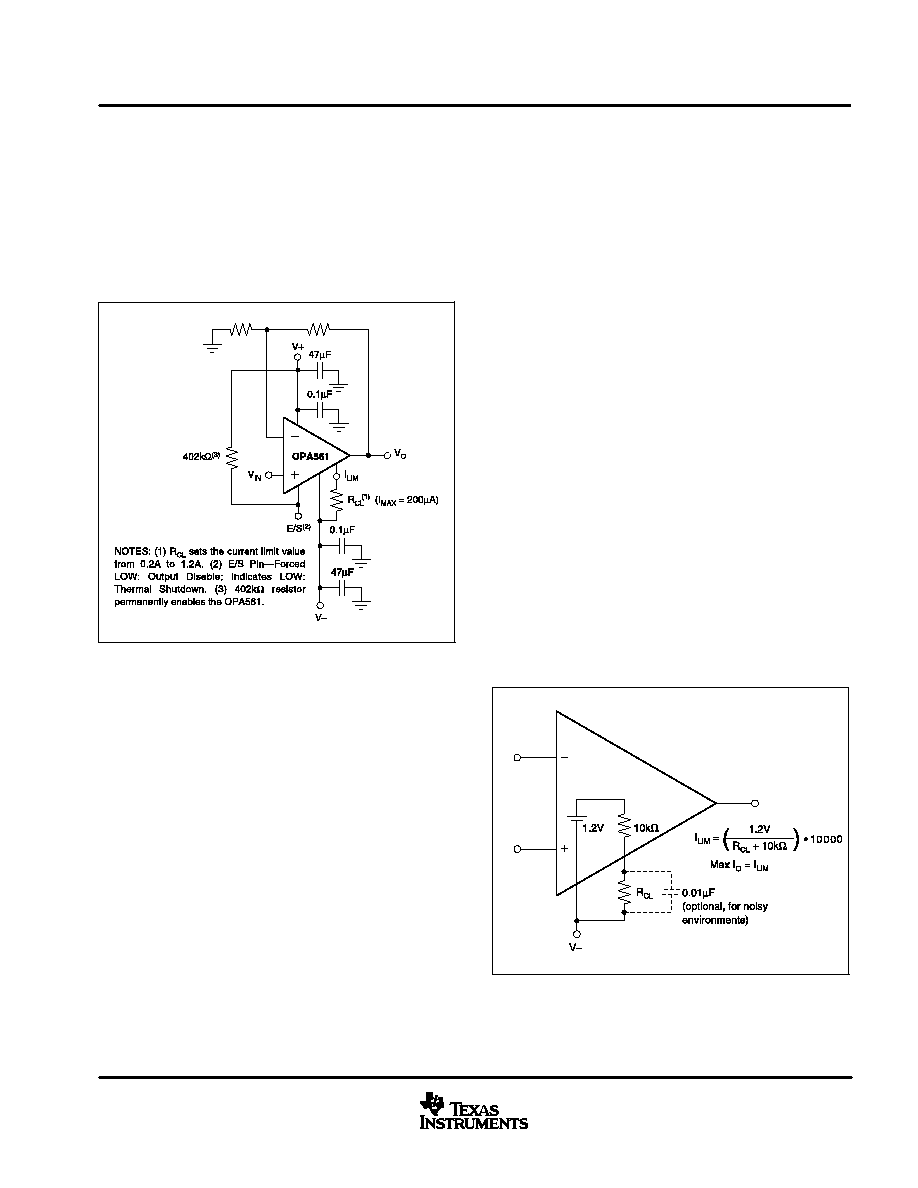

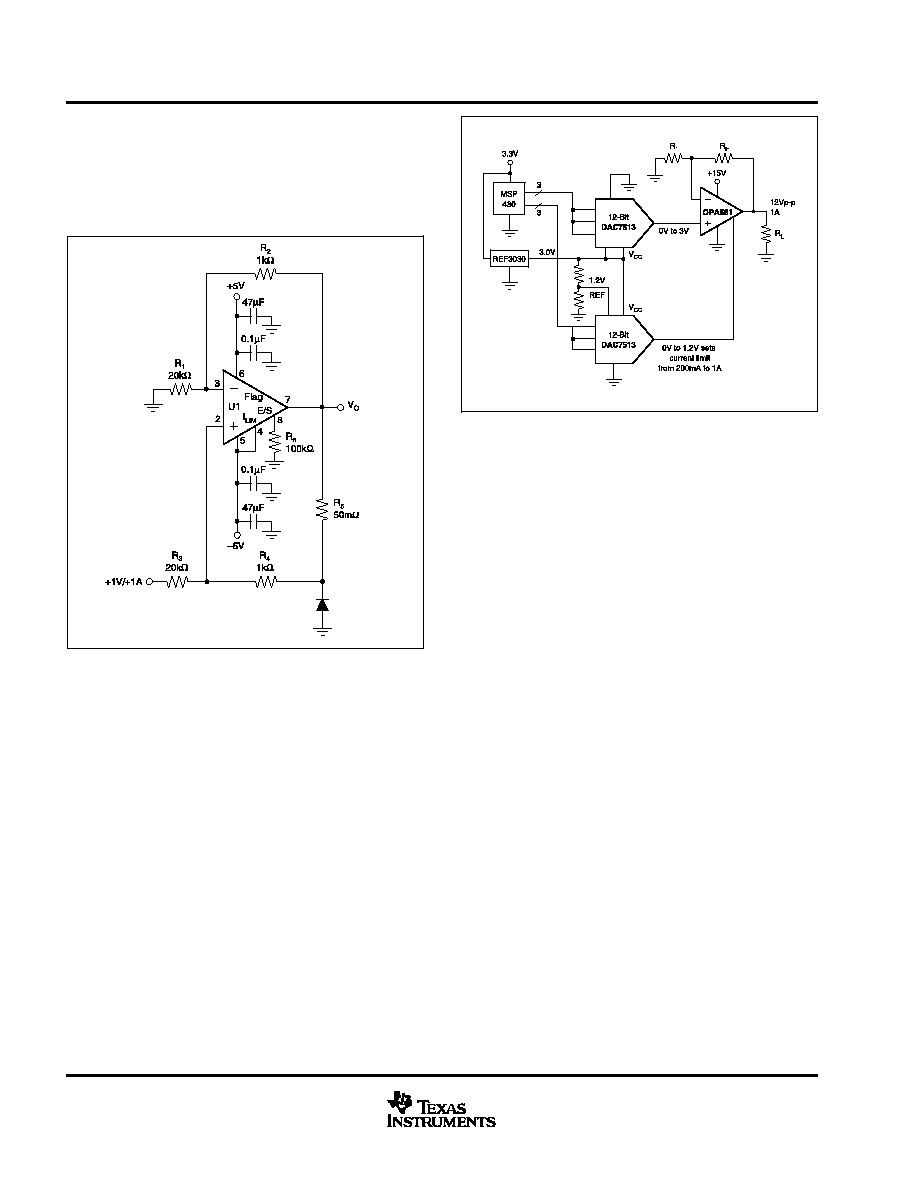

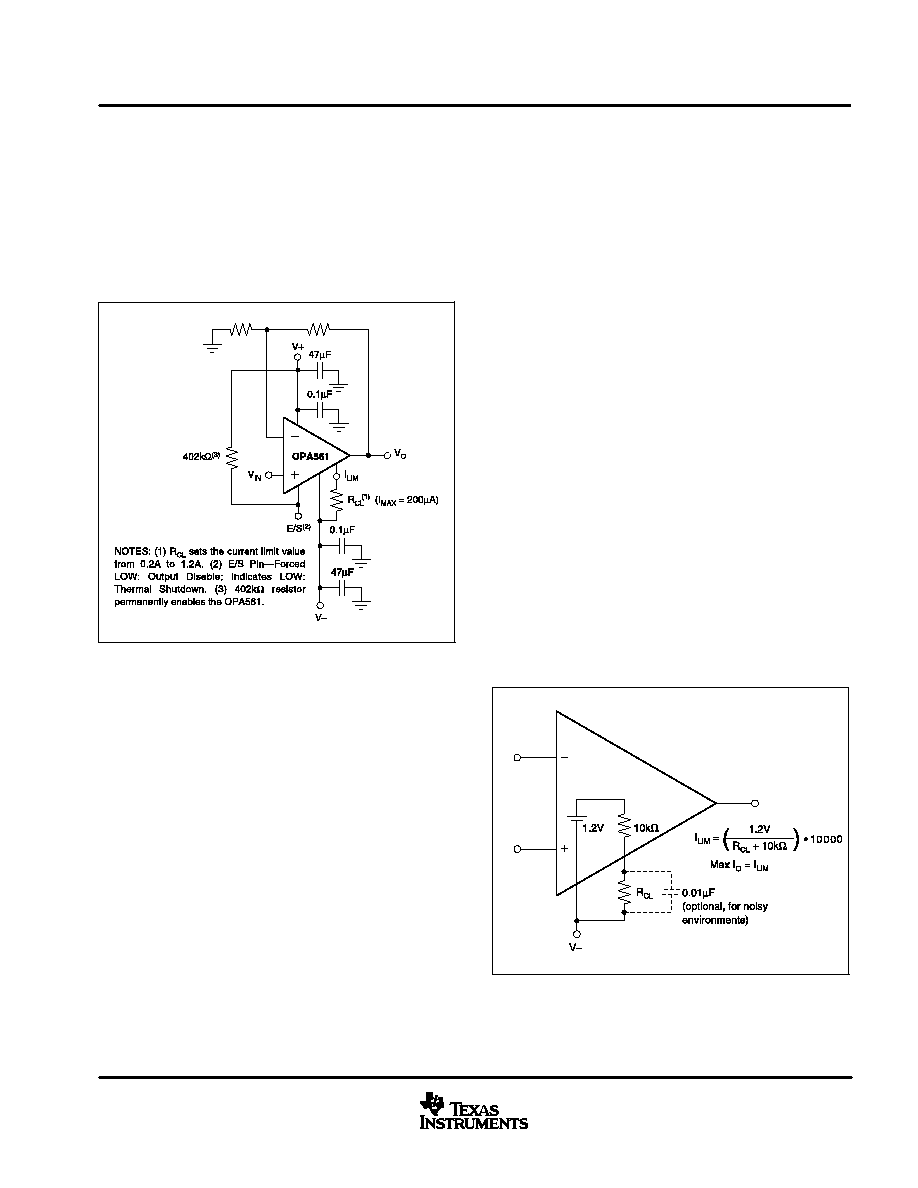

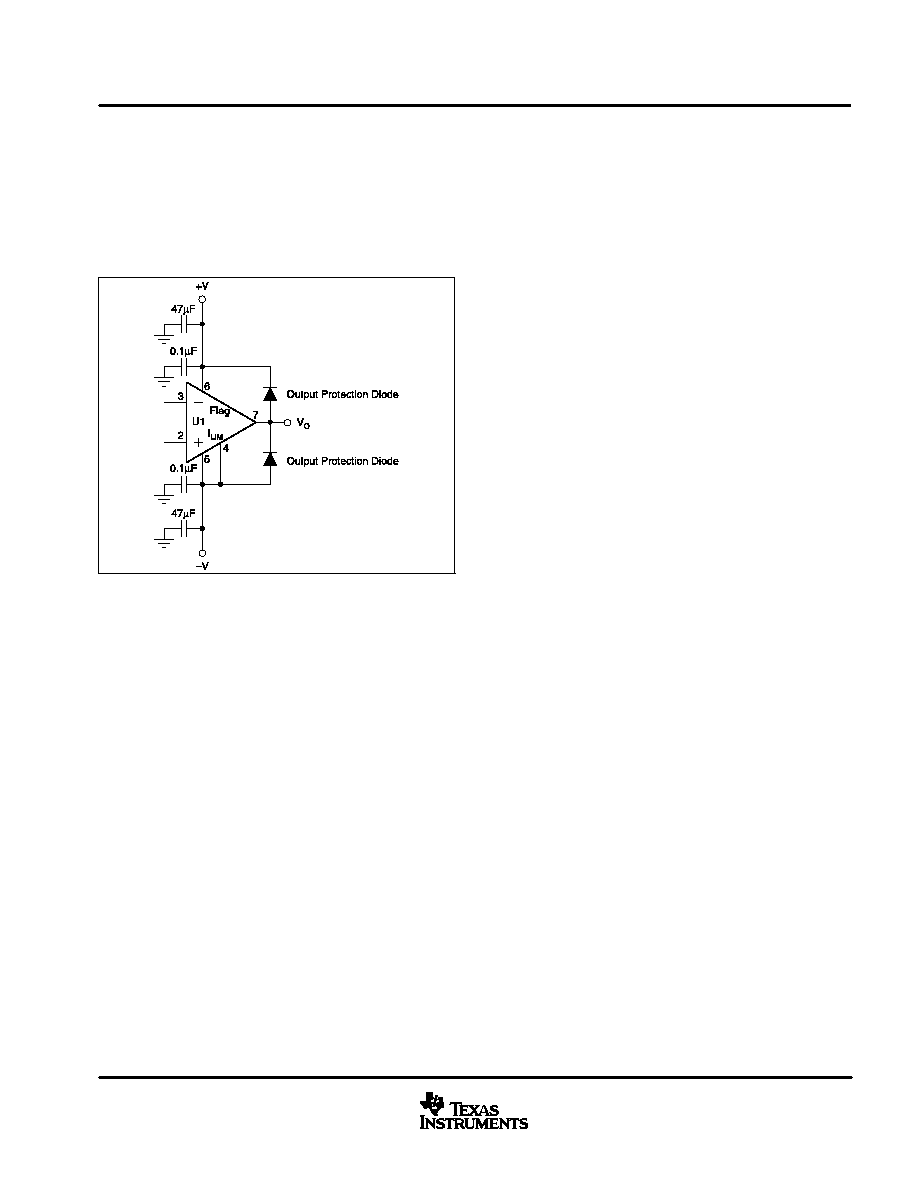

Figure 1 shows the OPA561 connected as a basic

noninverting amplifier. However, the OPA561 can be

used in virtually any op amp configuration.

Power≠supply terminals should be bypassed with low

series impedance capacitors. The technique of using a

ceramic and tantalum type in parallel is recommended.

Power≠supply wiring should have low series impedance.

FIGURE 1. Basic Circuit Connections.

POWER SUPPLIES

The OPA561 operates from single (+7V to +15V) or

dual (

Ī

3.5V to

Ī

7.5V) supplies with excellent

performance. Power≠supply voltages do not need to

be equal. For example, the positive supply could be

set to 10V with the negative supply at ≠5V, or

vice≠versa. Most behaviors remain unchanged

throughout the operating voltage range. Parameters

that vary significantly with operating voltage are

shown in the typical characteristics.

ADJUSTABLE CURRENT LIMIT

The OPA561's accurate, user≠defined, current limit can

be set from 0.2A to 1.2A by controlling the input to the I

LIM

pin. Unlike other designs that use a power resistor in

series with the output current path, the OPA561 senses

the load internally. This allows the current limit to be set

with low≠power components. In contrast, other designs

require one or two expensive power resistors that can

handle the full output current (1.2A in this case).

Current Limit Accuracy

Separate circuits monitor the positive and negative

currents. Each output is compared to a single internal

reference that is set by the external current limit resistor

(or voltage). The OPA561 employs a patented circuit

technique to achieve an accurate and stable current

limit. The output current limit has an accuracy of up to

5% on the 1A current limit. Due to internal matching

limitations, the positive and negative current limits can

be slightly different. However, the values are typically

within 10% of each other.

Setting the Current Limit

Leaving the I

LIM

pin open could damage the part.

Connecting I

LIM

directly to V≠ programs the maximum

output current limit, typically 1.2A. The simplest method

for adjusting the current limit (I

LIM

) uses a resistor or

potentiometer connected between the I

LIM

pin and V≠

according to Equation 1:

I

LIM

= (1.2V/(R

CL

+ 10k

))

∑

10000

(1)

This external resistor determines a small internal

current which sets the desired output current limit.

Alternatively, the output current limit can be set by

applying a voltage to the I

LIM

pin. Figure 2 shows a

simplified schematic of the OPA561's current limit.

FIGURE 2. Adjustable Current Limit--Resistor Method.

OPA561

SBOS206A ≠ DECEMBER 2001 ≠ REVISED JUNE 2002

8

www.ti.com

ENABLE/STATUS (E/S) PIN

The Enable/Status Pin provides two unique functions: 1)

output disable by forcing the pin "LOW" and 2) thermal

shutdown indication by monitoring the voltage level at

the pin. One or both of these functions can be utilized on

the same device. For normal operation (output enabled),

the E/S pin must be pulled "HIGH" (at least 2V above V≠).

A small value capacitor connected between the E/S pin

and V≠ may be appropriate for noisy applications. To

enable the OPA561 permanently, the E/S pin can be tied

to V+ through a 402k

pull≠up resistor.

Output Disable

The shutdown pin is referenced to the negative supply

(V≠). Therefore, shutdown operation is slightly different

in single≠supply and dual≠supply applications.

In single≠supply operation, V≠ typically equals common

ground. Therefore, the shutdown logic signal and the

OPA561's shutdown pin are referenced to the same

potential. In this configuration, the logic pin and the

OPA561 enable can simply be tied together. Shutdown

occurs for voltage levels of < 0.8V. The OPA561 is

enabled at logic levels > 2V.

In dual≠supply operation, the logic pin is still referenced to

a logic ground. However, the shutdown pin of the OPA561

is still referenced to V≠. To shutdown the OPA561, the

voltage level of the logic signal needs to be level shifted

using an optocoupler, as shown in Figure 3.

FIGURE 3. OPA561 Shutdown Configuration for Dual

Supplies.

To disable the output, the E/S pin is pulled "LOW", no

greater than 0.8V above V≠. This function can be used

to conserve power during idle periods. The typical time

required to shut down the output is 50ns. To return the

output to an enabled state, the E/S pin should be pulled

to at least 2.0V above V≠. Typically, the output is

enabled within 3

Ķ

s. It should be noted that pulling the

E/S pin HIGH (output enabled) does not disable the

internal thermal shutdown.

Ensuring Microcontroller Compatibility

Not all microcontrollers output the same logic state after

power≠up or reset. 8051≠type microcontrollers, for

example, output logic HIGH levels on their ports while

other models power up with logic LOW levels after

reset.

In configuration (a) as shown in Figure 3, the shutdown

signal is applied on the cathode side of the photodiode

within the optocoupler. A high logic level causes the

OPA561 to be enabled, and a low logic level shuts the

OPA561 down. In configuration (b) of Figure 3, with the

logic signal applied on the anode side, a high level

causes the OPA561 to shutdown and low level enables

the op amp.

OVER≠CURRENT FLAG

The OPA561 features an over≠current status flag (CLS,

Pin 9) that can be monitored to see if the load exceeds

the current limit. The output signal of the over current

limit flag is compatible to standard logic. The CLS signal

is referenced to V≠. A voltage level of less than (V≠) +

0.8V indicates normal operation and a level of greater

than (V≠) + 2 indicates that the OPA561 is in current

limit. The flag is HIGH as long as the output of the

OPA561 is in current limit. At very low signal

frequencies, typically < 1kHz, both the upper (sourcing

current) and lower current limit (sinking current) are

monitored. At frequencies > 1kHz, due to internal circuit

limitations, the flag output signal for the upper current

limit becomes delayed and shortened. The flag signal

for the lower current limit is unaffected by this behavior.

As the signal frequency increases further, only the lower

current limit (sinking current) is output on Pin 9.

OUTPUT STAGE COMPENSATION

The complex load impedances common in power op amp

applications can cause output stage instability. For normal

operation, output compensation circuitry is typically not

required. However, if the OPA561 is intended to be driven

into current limit, an R/C network (snubber) may be

required. A snubber circuit may also enhance stability

when driving large capacitive loads ( > 1000pF) or

inductive loads (motors, loads separated from the

amplifier by long cables). Typically, 3

to 10

in series

with 0.01

Ķ

F to 0.1

Ķ

F is adequate. Some variations in

circuit value may be required with certain loads.

OPA561

SBOS206A ≠ DECEMBER 2001 ≠ REVISED JUNE 2002

9

www.ti.com

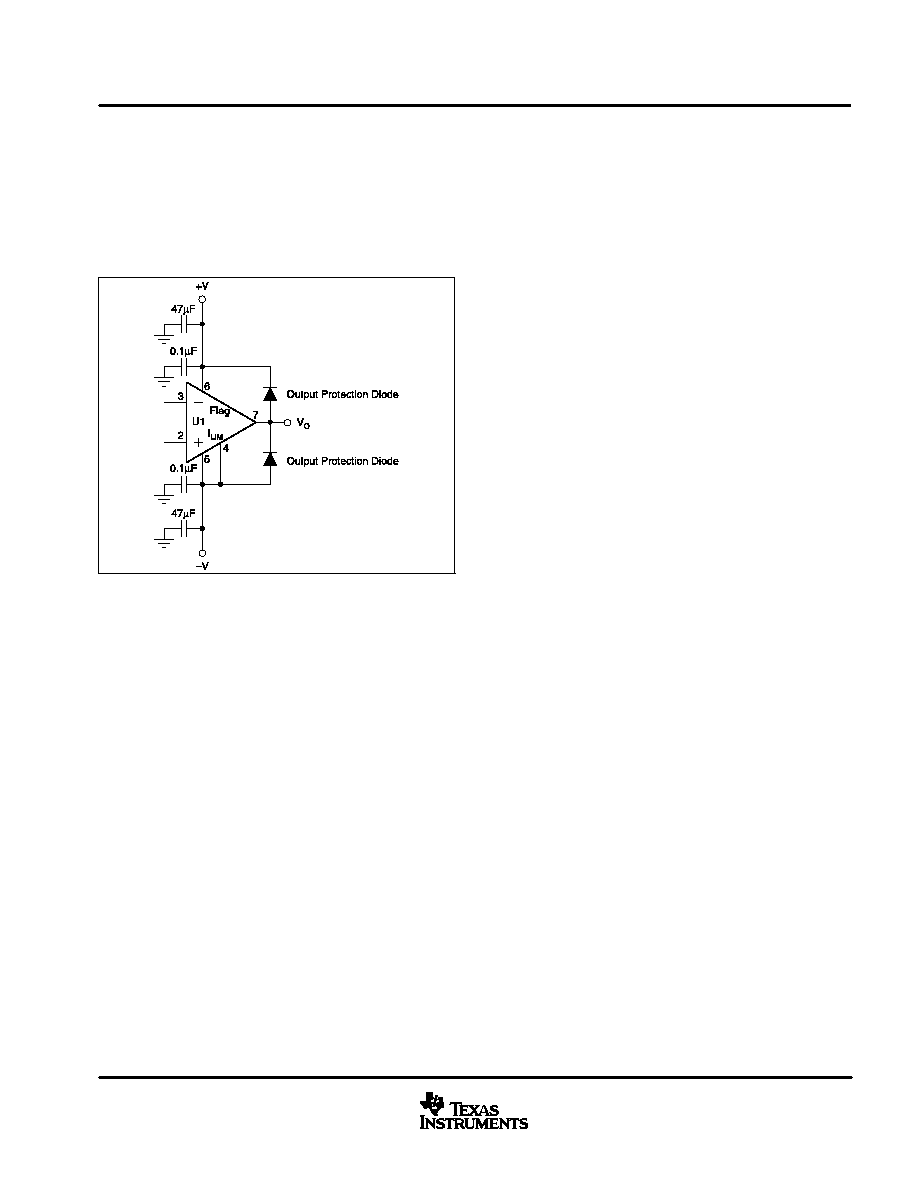

OUTPUT PROTECTION

Reactive and EMF≠generation loads can return load

current to the amplifier, causing the output voltage to

exceed the power≠supply voltage. This damaging

condition can be avoided with clamp diodes from the output

terminal to the power supplies, as shown in Figure 4.

Schottky rectifier diodes with a 3A or greater continuous

rating are recommended.

FIGURE 4. Output Protection Diode.

THERMAL PROTECTION

The OPA561 has thermal sensing circuitry that helps

protect the amplifier from exceeding temperature limits.

Power dissipated in the OPA561 will cause the junction

temperature to rise. Internal thermal shutdown circuitry

shuts down the output when the die temperature reaches

approximately 160

į

C, resetting when the die has cooled

to 140

į

C. Depending on load and signal conditions, the

thermal protection circuit may cycle on and off. This limits

the dissipation of the amplifier, but may have an

undesirable effect on the load. Any tendency to activate

the thermal protection circuit indicates excessive power

dissipation or an inadequate heatsink. For reliable,

long≠term, continuous operation, junction temperature

should be limited to 125

į

C, maximum. To estimate the

margin of safety in a complete design (including

heatsink), increase the ambient temperature until the

thermal protection is triggered. Use worst≠case loading

and signal conditions. For good, long≠term reliability,

thermal protection should trigger more than 35

į

C above

the maximum expected ambient condition of your

application. This produces a junction temperature of

125

į

C at the maximum expected ambient condition.

The internal protection circuitry of the OPA561 was

designed to protect against overload conditions; it was

not intended to replace proper heatsinking.

Continuously running the OPA561 into thermal

shutdown can degrade reliability. The E/S pin can be

monitored to determine if shutdown has occurred.

During normal operation the voltage on the E/S pin is

typically above (V≠) + 2V. During shutdown, the voltage

drops to less than (V≠) + 0.8V.

POWER DISSIPATION

Power dissipation depends on power supply, signal,

and load conditions. For DC signals, power dissipation

is equal to the product of output current times the

voltage across the conducting output transistor.

Dissipation with ac signals is lower. Application Bulletin

AB≠039 (SBOA022) explains how to calculate or

measure power dissipation with unusual signals and

loads and can be found at www.ti.com.

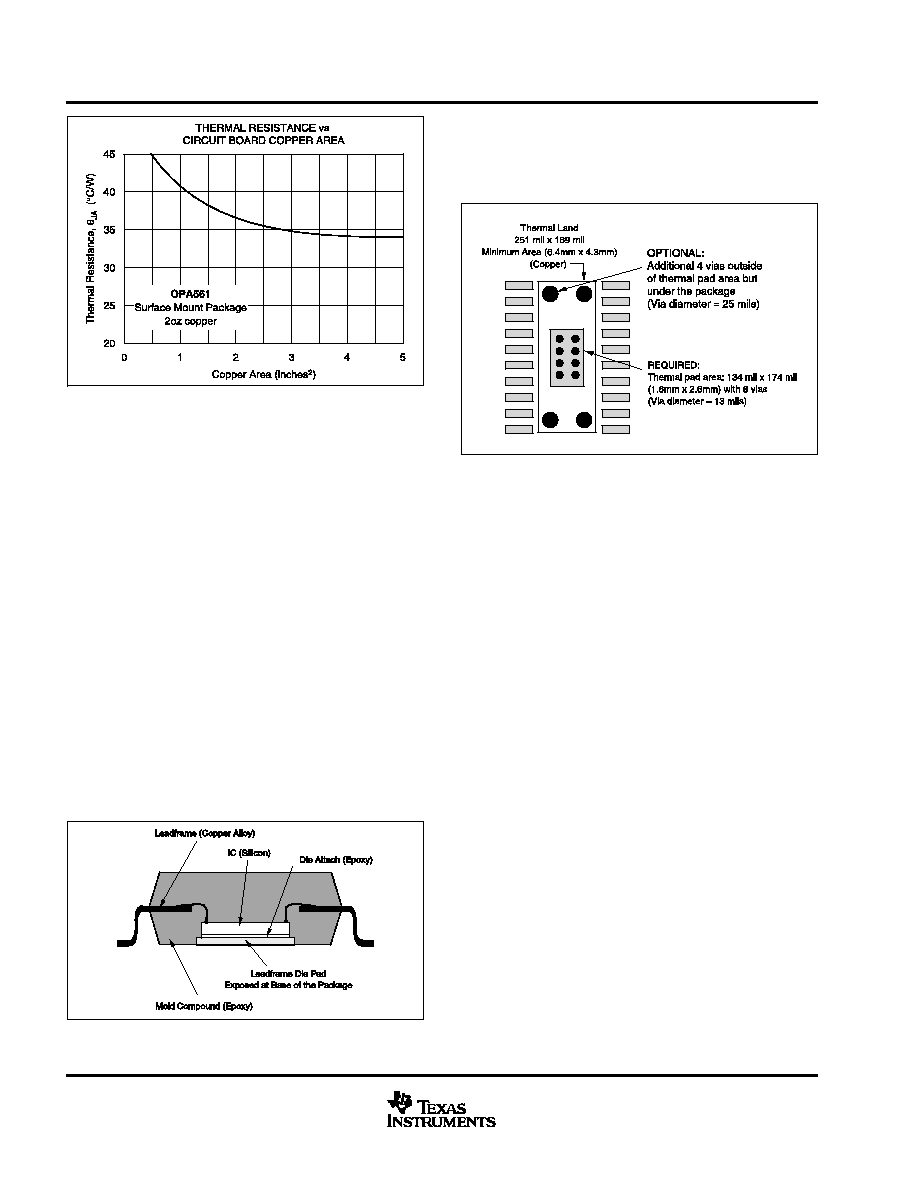

HEATSINK AREA

The relationship between thermal resistance and power

dissipation can be expressed as:

JA

=

T

J

≠

T

A

/

P

D

where T

J

= Junction Temperature (

į

C)

T

A

= Ambient Temperature (

į

C)

JA

= Junction to Ambient Thermal Resistance (

į

C/W)

P

D

= Power Dissipation (W)

To appropriately determine required heatsink area,

required power dissipation should be calculated and the

relationship between power dissipation and thermal

resistance should be considered to minimize shutdown

conditions and allow for proper long≠term operation

(junction temperature of 125

į

C). Once the heatsink

area has been selected, worst≠case load conditions

should be tested to ensure proper thermal protection.

For applications with limited board size, refer to Figure 5

for the approximate thermal resistance relative to

heatsink area. Increasing heatsink area beyond 2in

2

provides little improvement in thermal resistance. To

achieve the 32

į

C/W stated in the Electrical

Characteristics, a copper plane size of 9in

2

was used.

The HTSSOP≠20 PowerPAD package is well suited for

continuous power levels from 2W to 4W, depending on

ambient temperature and heatsink area. Higher power

levels may be achieved in applications with a low on/off

duty cycle, such as remote meter reading.

OPA561

SBOS206A ≠ DECEMBER 2001 ≠ REVISED JUNE 2002

10

www.ti.com

FIGURE 5. Thermal Resistance vs Circuit Board

Copper Area.

AMPLIFIER MOUNTING

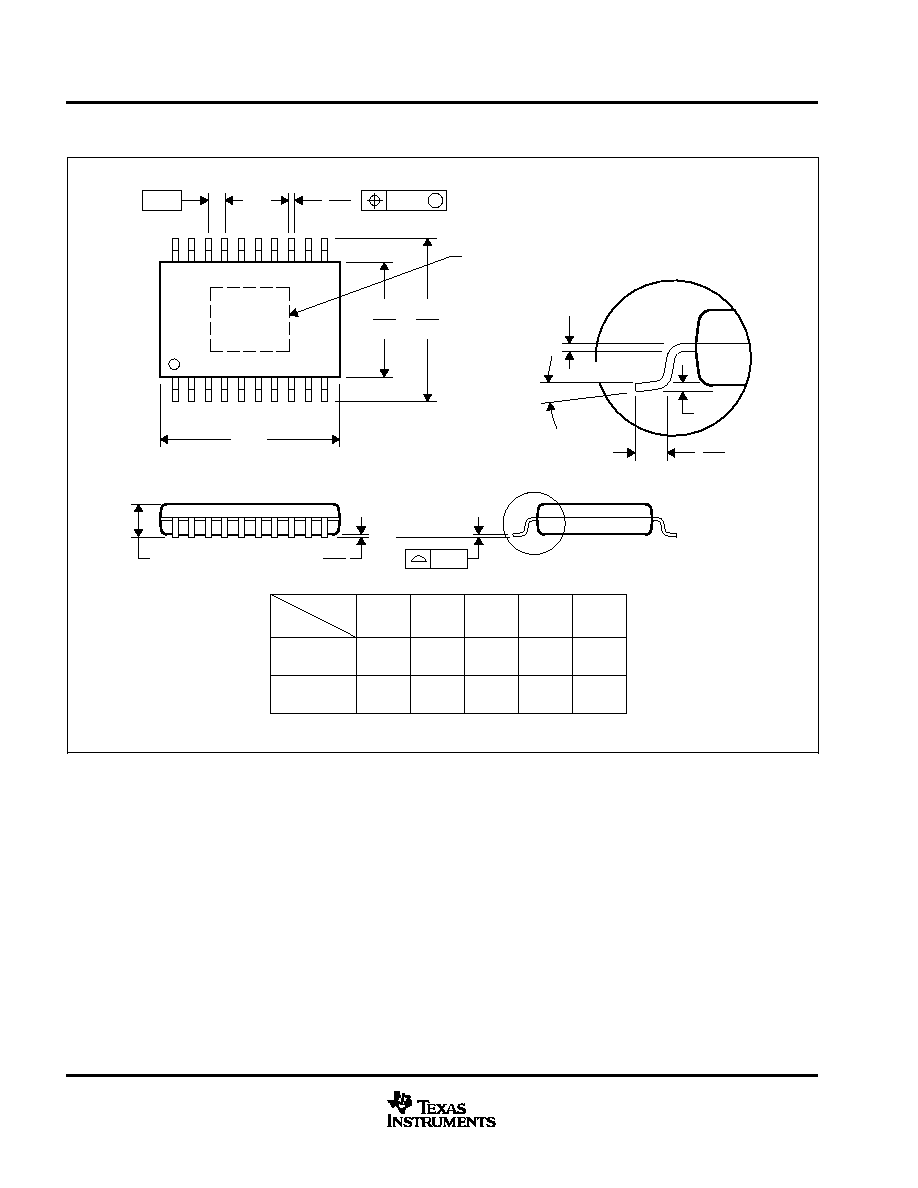

What is PowerPAD?

The OPA561 uses the HTSSOP≠20 PowerPAD

package, a thermally enhanced, standard size IC

package designed to eliminate the use of bulky heatsinks

and slugs traditionally used in thermal packages. This

package can be easily mounted using standard PCB

assembly techniques, and can be removed and replaced

using standard repair procedures.

The PowerPAD package is designed so that the

leadframe die pad (or thermal pad) is exposed on the

bottom of the IC, as shown in Figure 6. This provides an

extremely low thermal resistance (

JC

) path between

the die and the exterior of the package. The thermal pad

on the bottom of the IC can then be soldered directly to

the PCB, using the PCB as a heatsink. In addition,

through the use of thermal vias, the thermal pad can be

directly connected to a ground plane or special heatsink

structure designed into the PCB.

FIGURE 6. Section View of a PowerPAD Package.

PowerPAD Assembly Process

1. Prepare the PCB with a top side etch pattern, as

shown in Figure 7. There should be etch for the leads as

well as etch for the thermal land.

FIGURE 7. 20≠Pin PWP PowerPAD PCB Etch and Via

Pattern.

2. Place the recommended number of holes (or thermal

vias) in the area of the thermal pad. These holes should

be 13 mils in diameter. They are kept small so that solder

wicking through the holes is not a problem during reflow.

The recommended number of holes for the HTSSOP≠20

PowerPAD package is eight, as shown in Figure 7.

3. It is recommended, but not required, to place a small

number of the holes under the package and outside the

thermal pad area. These holes provide additional heat

path between the copper land and ground plane and are

25 mils in diameter. They may be larger because they are

not in the area to be soldered, so wicking is not a

problem. This is illustrated in Figure 7.

4. Connect all holes, including those within the thermal

pad area and outside the pad area, to the internal ground

plane or other internal copper plane.

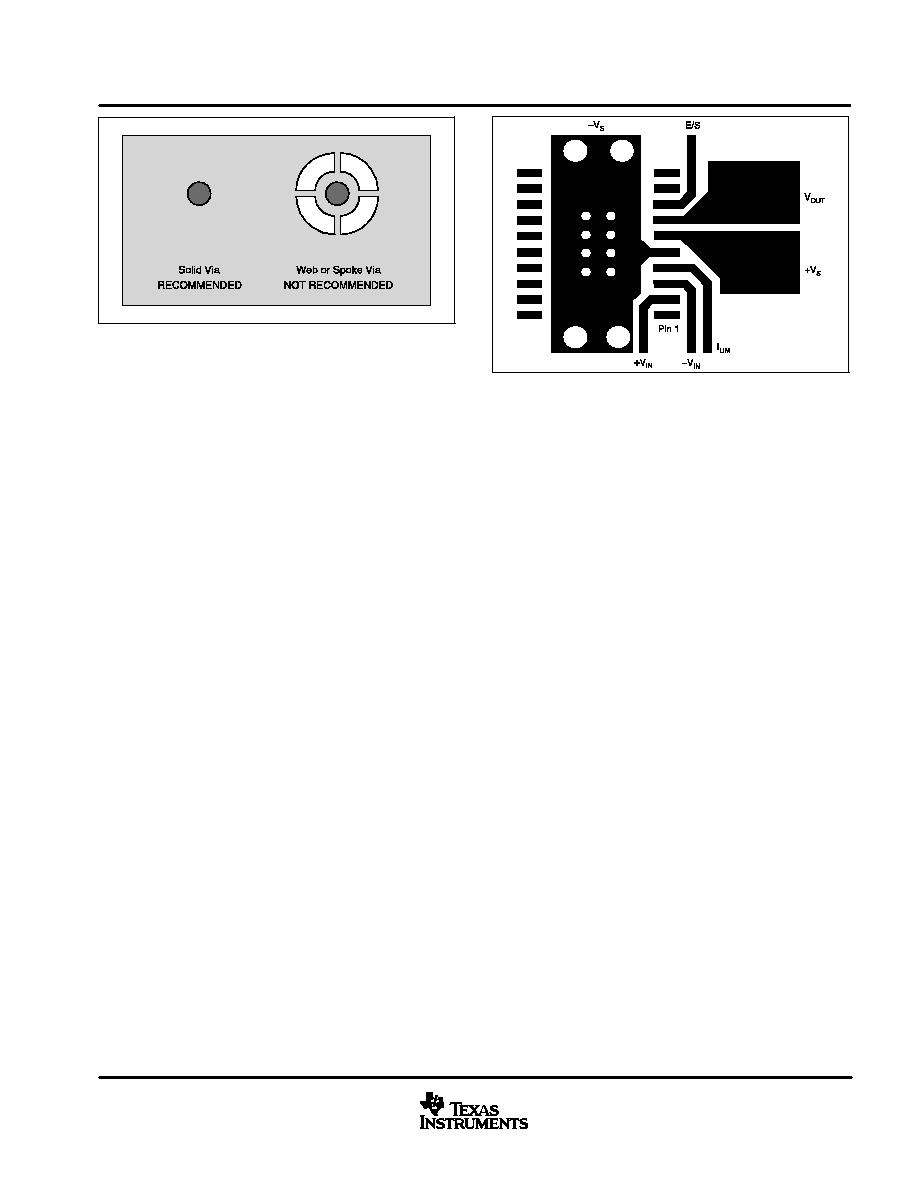

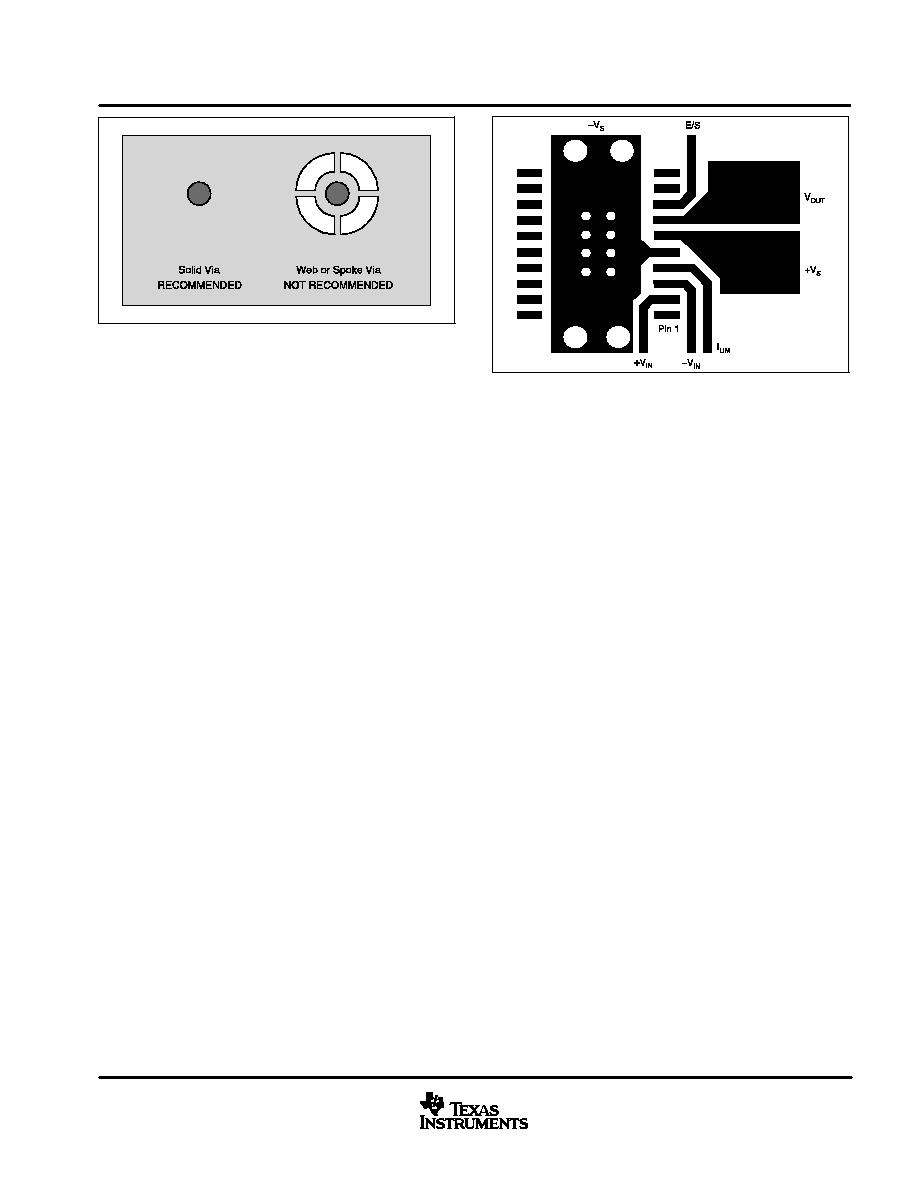

5. When connecting these holes to the ground plane, do

not use the typical web or spoke via connection

methodology, see Figure 8. Web connections have a

high thermal resistance connection that is useful for

slowing the heat transfer during soldering operations.

This makes the soldering of vias that have plane

connections easier. However, in this application, low

thermal resistance is desired for the most efficient heat

transfer. Therefore, the holes under the PowerPAD

package should make their connection to the internal

ground plane with a complete connection around the

entire circumference of the plated through hole.

OPA561

SBOS206A ≠ DECEMBER 2001 ≠ REVISED JUNE 2002

11

www.ti.com

FIGURE 8. Via Connection.

6. The top≠side solder mask should leave exposed the ter-

minals of the package and the thermal pad area. The ther-

mal pad area should leave the 13 mil holes exposed. The

larger 25 mil holes outside the thermal pad area should be

covered with solder mask.

7. Apply solder paste to the exposed thermal pad area and

all of the package terminals.

8. With these preparatory steps in place, the PowerPAD IC

is simply placed in position and run through the solder re-

flow operation as any standard surface≠mount component.

This results in a part that is properly installed.

For detailed information on the PowerPAD package includ-

ing thermal modeling considerations and repair proce-

dures, please see Technical Brief SLMA002, PowerPAD

Thermally Enhanced Package located at www.ti.com.

LAYOUT GUIDELINES

The OPA561 is a high≠speed power amplifier that

requires proper layout for best performance. Figure 9

shows an example of proper layout.

Keep power≠supply leads as short as possible. This will

keep inductance low and resistive losses at a minimum. A

minimum 18 gauge wire thickness is recommended for

power≠supply leads. The wire length should be < 8 inches.

FIGURE 9. OPA561 Example Layout.

Proper power≠supply bypassing with low ESR capacitors

is essential to achieve good performance. A parallel

combination of small ceramic (around 100nF) and bigger

(47

Ķ

F) non≠ceramic bypass capacitors will provide low

impedance over a wide frequency range. Bypass

capacitors should be placed as close as practical to the

power≠supply pins of the OPA561.

PCB traces conducting high currents, such as from

output to load or from the power≠supply connector to

the power≠supply pins of the OPA561 should be kept as

wide and as short as possible. This will keep inductance

low and also resistive losses to a minimum.

The eight holes in the landing pattern for the OPA561

are for the thermal vias that connect the PowerPad of

the OPA561 to the heatsink area on the printed circuit

board. The additional four larger vias further enhance

the heat conduction into the heatsink area. All traces

conducting high currents are very wide for lowest

inductance and minimal resistive losses. Note that the

negative supply (≠V

S

) pin on the OPA561 is connected

through the PowerPad. This allows for maximum trace

width for V

OUT

and the positive power supply (+V

S

).

OPA561

SBOS206A ≠ DECEMBER 2001 ≠ REVISED JUNE 2002

12

www.ti.com

APPLICATIONS CIRCUITS

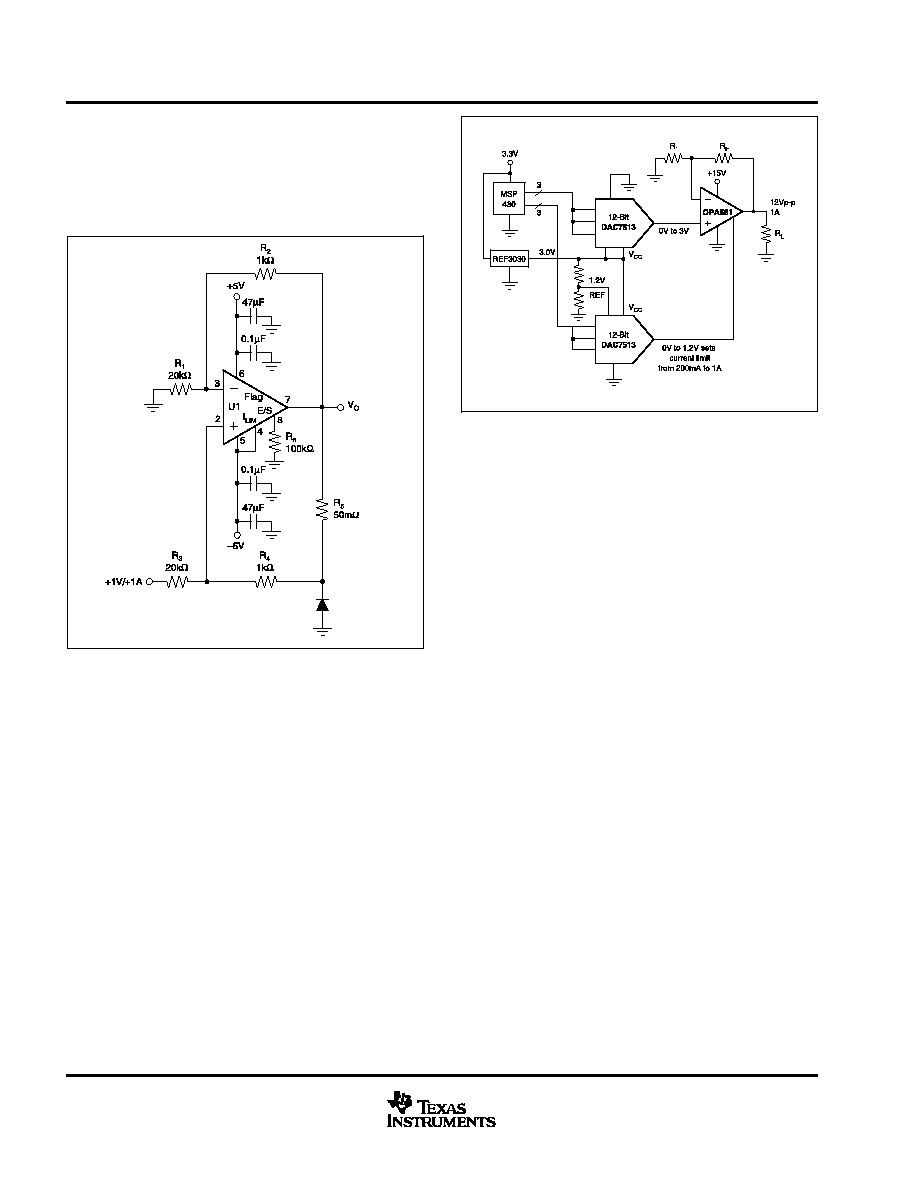

The high output current and low supply of the OPA561

makes it a good candidate for driving laser diodes and

thermo electric coolers. Figure 10 shows the OPA561

configured as a laser diode driver.

FIGURE 10. Laser Diode Driver.

PROGRAMMABLE POWER SUPPLY

Figure 11 shows the OPA561 configured with the

MSP430, REF3030, and DAC7513 as a space≠saving,

low≠cost, programmable power≠supply solution. This

solution features low≠voltage operation, small≠size

packages, (DAC7513 in SOT23≠8, REF3030 in

SOT23≠3) and low cost (under $10 for complete solution).

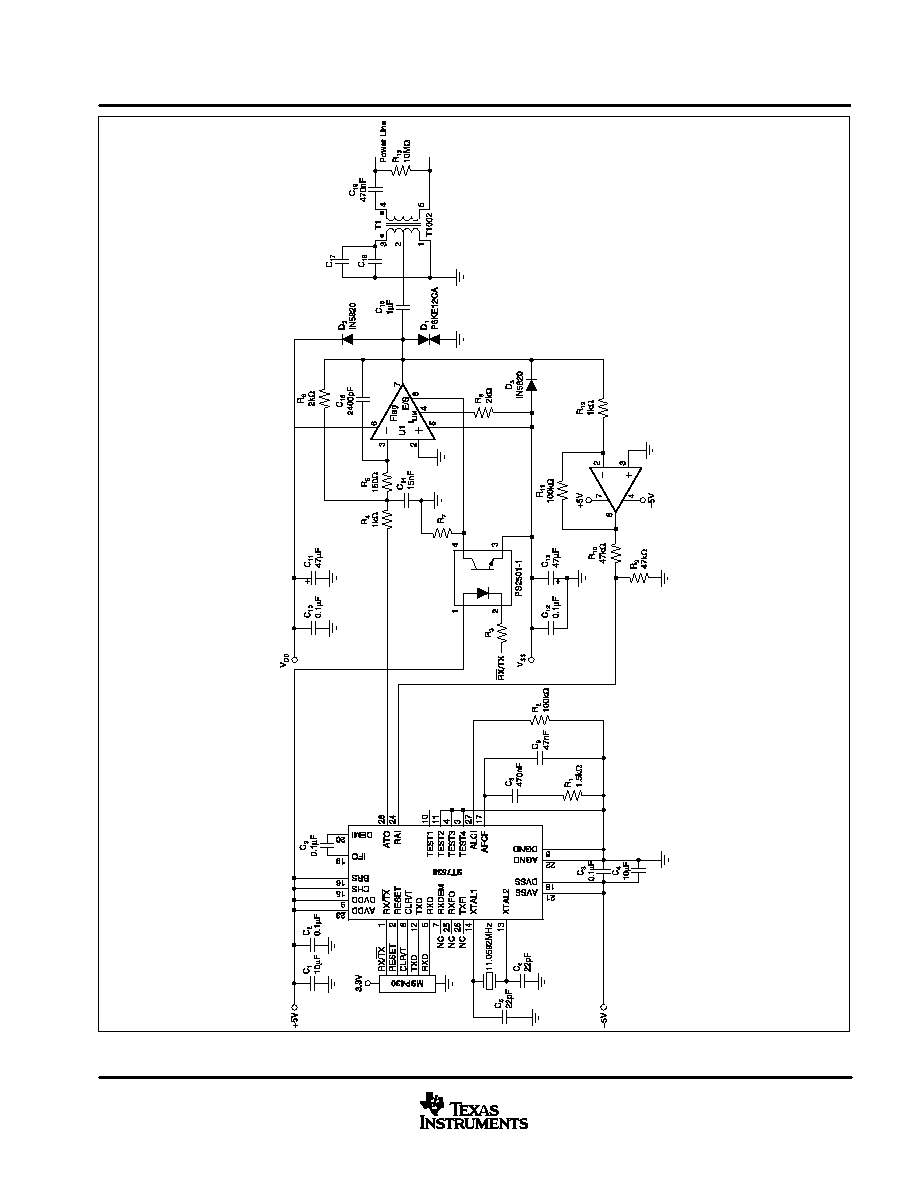

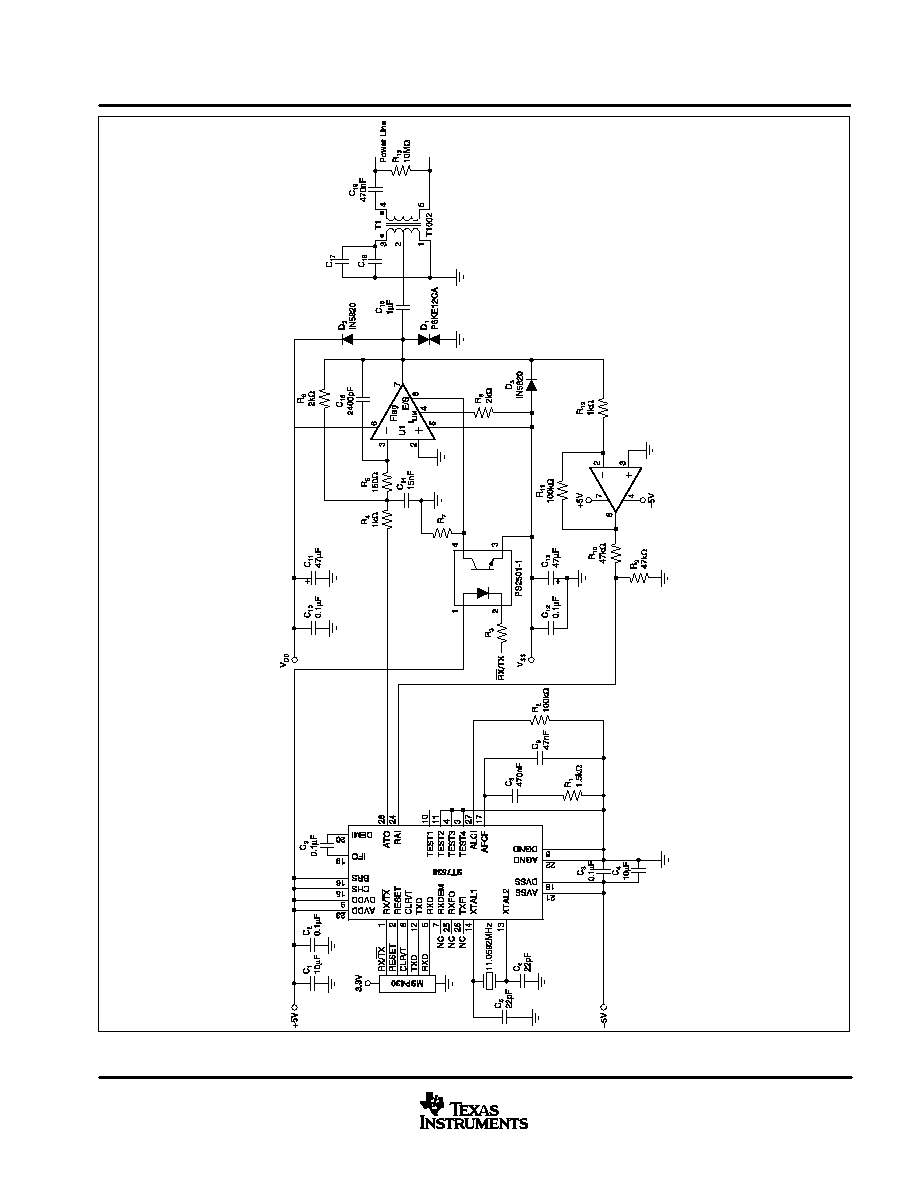

POWER≠LINE COMMUNICATION MODEM

The OPA561 is well suited to drive AC power lines for

low≠speed communications applications. It provides an

easily implemented, reliable solution that is superior to

discrete power transistor circuits. Advantages include:

S

Fully Integrated Solution

S

Integrated Shutdown Circuitry for Send≠and≠Receive Switching

S

Thermal Shutdown

FIGURE 11. Programmable Power Supply.

S

Adjustable Current Limit

S

Shutdown Flag

S

Power Savings

S

Small PowerPAD package

Typically such a system consists of a microcontroller, a

modem IC and the power line interface circuitry. See

Figure 12 for the half≠duplex power line communication

system.

It uses a, synchronous FSK≠modem, capable of 600

and 1200≠baud data rates and supports two different

FSK channels in the 60kHz to 80kHz range. A

microcontroller such as the MSP430 is used to control

the modem IC.

The OPA561 analog interface circuitry drives the FSK

modem signals on the AC power line. It filters the

transmit signal (ATO) from the ST7536 to suppress the

2nd≠harmonic distortion of the transmit signal. It also

amplifies the ATO signal and provides the very low

output impedance necessary to properly drive the line.

The impedance of a typical power line at 70kHz ranges

from 1

to 100

. The OPA561 is ideal for this type of

load. The transformer provides isolation and additional

filtering. C

9

prevents 50/60Hz current from flowing in the

transformer. This capacitor must be chosen carefully for

proper voltage rating and safety characteristics.

The receive input signal is amplified (G = 100) and

applied to the modem IC. The OPA561 is disabled in

receive mode to avoid loading the line.

OPA561

SBOS206A ≠ DECEMBER 2001 ≠ REVISED JUNE 2002

13

www.ti.com

FIGURE 13. Power Line Communication Driver.

OPA561

SBOS206A ≠ DECEMBER 2001 ≠ REVISED JUNE 2002

14

www.ti.com

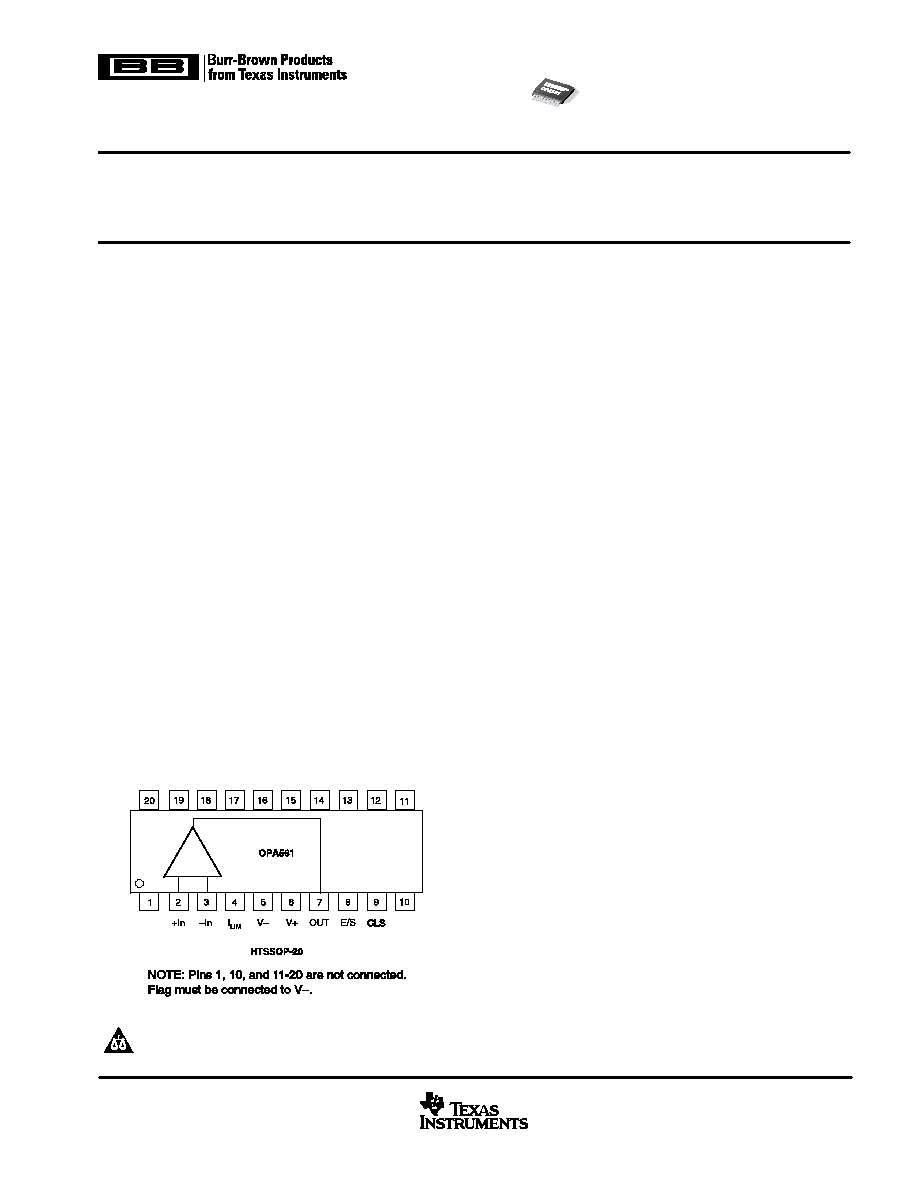

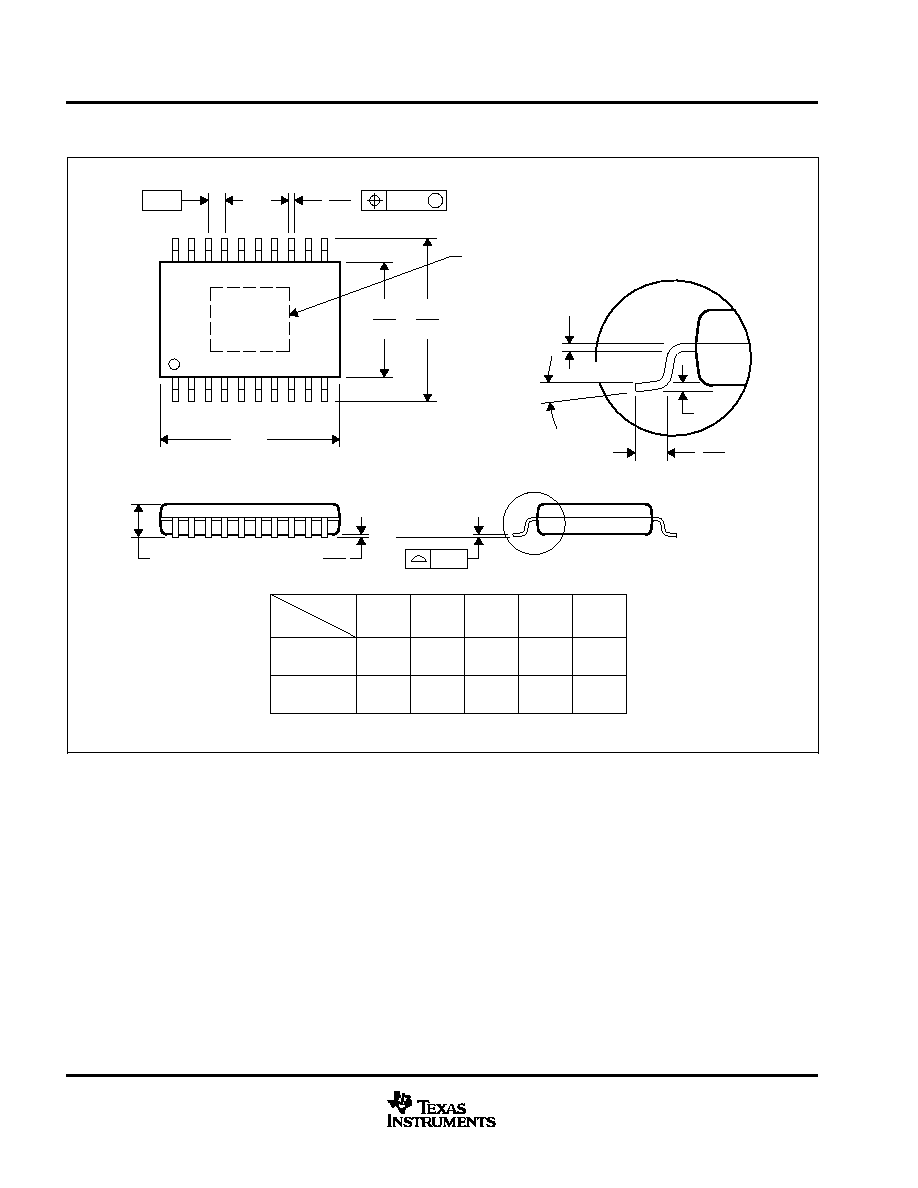

PWP (R-PDSO-G**)

PowerPAD

PLASTIC SMALL-OUTLINE

4073225/F 10/98

0,50

0,75

0,25

0,15 NOM

Thermal Pad

(See Note D)

Gage Plane

28

24

7,70

7,90

20

6,40

6,60

9,60

9,80

6,60

6,20

11

0,19

4,50

4,30

10

0,15

20

A

1

0,30

1,20 MAX

16

14

5,10

4,90

PINS **

4,90

5,10

DIM

A MIN

A MAX

0,05

Seating Plane

0,65

0,10

M

0,10

0

į

≠8

į

20 PINS SHOWN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusions.

D. The package thermal performance may be enhanced by bonding the thermal pad to an external thermal plane.

This pad is electrically and thermally connected to the backside of the die and possibly selected leads.

E. Falls within JEDEC MO-153

PowerPAD is a trademark of Texas Instruments Incorporated.

PACKAGING INFORMATION

ORDERABLE DEVICE

STATUS(1)

PACKAGE TYPE

PACKAGE DRAWING

PINS

PACKAGE QTY

OPA561PWP

ACTIVE

HTSSOP

PWP

20

78

OPA561PWP/2K

ACTIVE

HTSSOP

PWP

20

2000

(1) The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

PACKAGE OPTION ADDENDUM

www.ti.com

3-Oct-2003

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI's terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI's standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty. Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products

Applications

Amplifiers

amplifier.ti.com

Audio

www.ti.com/audio

Data Converters

dataconverter.ti.com

Automotive

www.ti.com/automotive

DSP

dsp.ti.com

Broadband

www.ti.com/broadband

Interface

interface.ti.com

Digital Control

www.ti.com/digitalcontrol

Logic

logic.ti.com

Military

www.ti.com/military

Power Mgmt

power.ti.com

Optical Networking

www.ti.com/opticalnetwork

Microcontrollers

microcontroller.ti.com

Security

www.ti.com/security

Telephony

www.ti.com/telephony

Video & Imaging

www.ti.com/video

Wireless

www.ti.com/wireless

Mailing Address:

Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright

2003, Texas Instruments Incorporated